How to properly assemble a stove with a stove: a detailed guide and recommendations for independent stove makers

Where there is access to solid fuel, the good old Russian stove will always be relevant.It will warm the house, you can cook food on it, and such a unit does not depend on the presence of a centralized gas pipeline or electrical network. However, among a number of advantages, there is also a disadvantage - the complexity of constructing the structure.

Do you want to make a stove, but don’t know how to properly fold the stove and arrange the chimney? We will help you realize your plans. The article describes in detail all the stages of constructing a wood-burning stove, provides practical recommendations for choosing materials and outlines the technological nuances of masonry work.

The content of the article:

Types of household stoves

Depending on the main function, there are three type of brick stoves:

- for heating;

- for cooking food;

- combined option.

The latter is intended both for heating the home and for preparing food. For organization of stove heating houses have an impressive chimney system with numerous channels. It must retain as much heat as possible from the combustion of fuel and smoke gases in order to warm the air inside the house.

If you need a stove for cooking, you can make do with a regular vertical chimney, but install a hob above the firebox. You can also make an oven underneath it. To create a combined version of such a stove, both a hob and a chimney that retains heat are used.

Depending on the type of device, choose its location. The heating stove should not be placed close to the outer wall, otherwise some of the thermal energy will simply evaporate outside.It is better to place it in the center of the room so that the air in different parts of the house warms up evenly.

It is better to think about this point when designing a house. A heating stove can become an object that divides a large room into several separate zones. Each of them will be warm.

The hob is treated completely differently. In a closed kitchen, it is best to place it close to two adjacent external walls. This will allow excess heat energy to be transferred outside so that the room does not overheat during cooking.

Cooking stoves are also installed separately, in the open air. This is a popular element of the recreation area. Nearby there may be a grill, barbecue, cauldron and other cooking utensils. On a cool evening, the warmth from such a stove will pleasantly warm your vacationing guests.

A combination stove, like a cooking stove, is placed near two walls, but it is better if they are internal. Then the heat will not go outside, but into the house, and the kitchen will be moderately warm. The chimney is made massive, as for heating, but it is shifted towards the living rooms. As a result, thermal energy is distributed fairly evenly throughout the house.

Preparation for work

For laying a stove with a stove, different types of brick are used. Usually they take solid red for the outer masonry and fireclay for the inner lining of the firebox, as well as the smoke well.

The foundation is poured with concrete mortar. To prepare it, you will need cement of at least M400, preferably M500.The sand can be river or from a quarry, but it must first be sifted to prevent the ingress of impurities. Clean water should also be used. For the solution, you should also take granite crushed stone about 30 mm.

The foundation is backfilled using rubble granite, a suitable fraction is approximately 300 mm. In addition, you will need to prepare a solution of red clay and sand.

Instead of clay, you can purchase clay powder; the instructions for using it are indicated on the package. All components must be of good quality; the integrity and service life of the future stove depends on this. To seal joints you need to prepare high temperature sealant.

The work is carried out using ordinary construction tools.

You may need:

- containers for mixing the solution;

- Master OK;

- Bulgarian;

- plumb line;

- level;

- roulette;

- rule;

- mallet;

- furnace hammer;

- other devices for processing and laying bricks.

To make a high-quality solution, it is better to use a hammer drill or drill with the appropriate characteristics, as well as an attachment designed for these purposes. A shovel and a sieve will come in handy.

Construction of a wood stove

Once the type of device has been selected, materials have been prepared and a suitable location has been selected, work can begin.

The process of creating a wood stove is divided into three stages:

- Construction of the foundation.

- Construction of the furnace itself.

- Creation of a chimney structure.

All work should be carried out strictly according to technology. During operation, such a device heats up and is subjected to high loads. Even a small mistake can lead to big problems in the future. If in doubt, it is better to consult an experienced stove maker.

Construction of a separate foundation

The base for the stove should not be connected to the strip or column foundation of the house. The device is heavy, it will upset the base more than the walls and roof. Therefore, even at the design stage, this point must be taken into account.

If the house has already been built, but you still need a stove, you will have to open the floor, get to the ground and fill a separate base. The exception is a monolithic foundation; its load-bearing capacity will withstand such additional load without noticeable deformation.

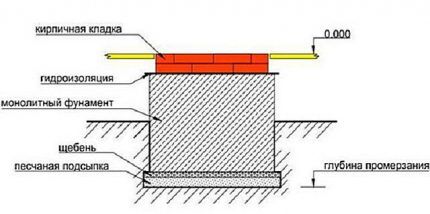

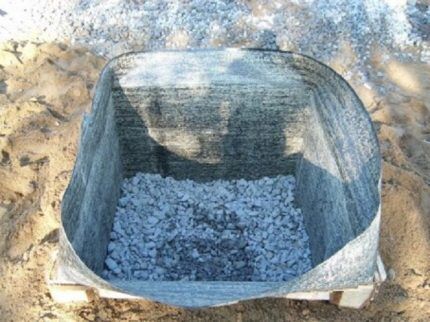

First, dig a pit of the same shape as the base of the furnace, but slightly larger, about 20 cm for each side, and about half a meter deep.

After this, perform the following operations:

- The soil at the bottom is carefully leveled and compacted.

- A layer of sand is poured to the bottom, it is also compacted and moistened; the recommended thickness of the sand cushion is about 90 mm.

- Sheets of roofing material are laid on the walls, this is a waterproofing layer.

- If necessary, roofing felt is reinforced with boards and bricks, which act as formwork.

- A layer of crushed stone is poured onto the sand and compacted.

- A reinforcing mesh is made from a metal rod, and wire is used for knitting.

- A solution consisting of cement with the addition of sand and crushed stone in a ratio of 2:1:2 is poured onto a third of the remaining height.

- Pour the next cement-sand layer (3:1), leaving about five centimeters to the top of the pit.

- After this, add another layer of the same mixture to the very top.

- The screed is leveled according to the rule.

Now you need to wait about four weeks for the fresh foundation to harden well.

It is recommended to moisten the surface of the base with water daily and cover it with a layer of film so that the process proceeds evenly.

After this, the formwork is removed, and the upper part of the base is covered with two or three layers of roofing felt, which are glued with bitumen mastic. Waterproofing will protect the stove body from contact with moisture from the ground. The bottom layer of the foundation, if desired, can be made of cement and gravel; the recommended proportion is one to three.

If you don’t have roofing felt at hand, ordinary boards can serve as formwork, but they need to be covered with plastic film to protect them from water. It is best to build the foundation for the stove to the level of the floor covering or even a little higher. This makes finishing work easier.

The part that rises above the floor is usually made a little larger; for this, the formwork is expanded.It would also not hurt to perform separate reinforcement of the top layer - a mesh with a pitch of about 75 mm will do.

The procedure for laying the furnace

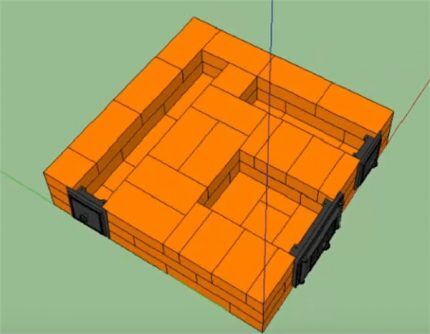

To understand how to correctly assemble a simple stove with a stove, first perform the so-called dry masonry, i.e. lay out the bricks in rows, according to the planned pattern, but without mortar. Instead, use pieces of plywood, slats or boards of suitable size. The space between the individual rows should be the same.

If the brick is laid correctly, the dry masonry is dismantled, after which the masonry mortar is prepared and work is done with it. The easiest way is to use clay powder from the store. You just need to dilute it correctly according to the instructions and add sand.

With clay it's a little more complicated. First, you need to soak it in water for about a day. After this, add sand in small portions to the resulting mixture of water and clay and knead the composition with your hands until smooth. The amount of sand depends on how thick the clay is used.

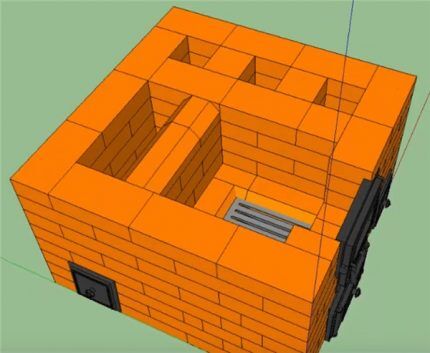

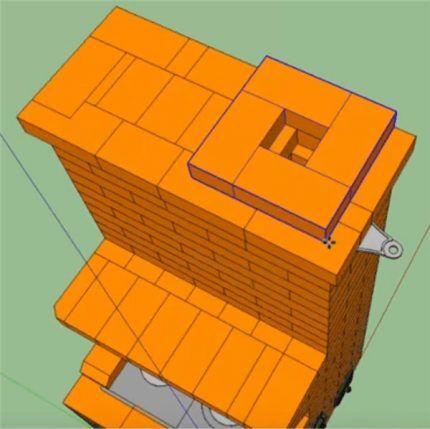

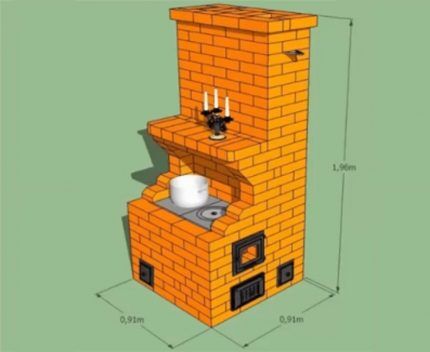

As a result, the resulting mixture will become thick enough so that it does not flow from the shovel, but slides off it. In addition, the composition should not stick to metal tools. If the resulting mixture meets these characteristics, you can begin laying. Here is an example of a circuit for a small combination oven.

First, markings are applied to roofing material glued to the base.

The first two rows are made continuous, while the vertical joints between whole bricks in adjacent rows should not coincide.

The next two rows are made with gaps for the blower and holes for cleaning the chimney. The openings are closed with metal doors.

The doors should be prepared before installation: drill holes in the corners, insert pieces of wire into them and wrap the frame with asbestos cord. Pieces of wire are placed in the mortar between the bricks

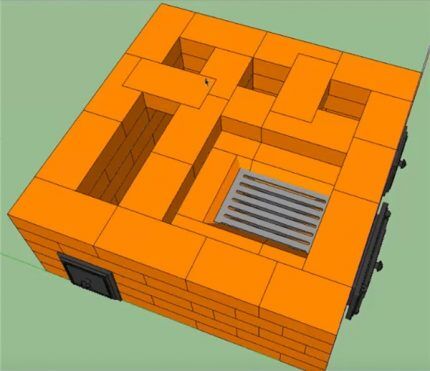

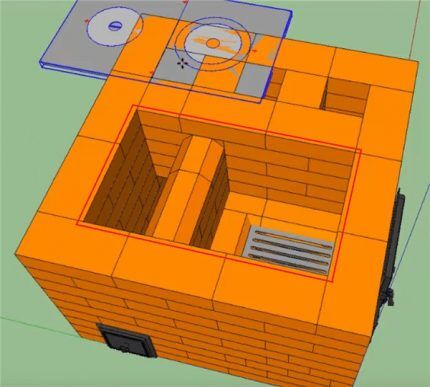

The fourth row is made of fireclay bricks, since the firebox already begins here. Part of the height of the brick is selected, and a grate is placed above the opening.

The fifth row is performed in the same way as the fourth. From the sixth to the eighth, the masonry continues to be repeated, but a gap is left for the combustion chamber door.

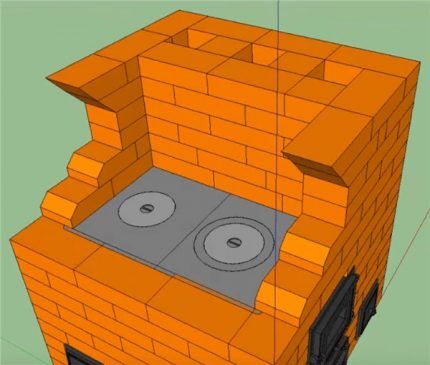

The row above the firebox door will become the base for the stove. Part of the brick around the perimeter is removed, lined with asbestos cord and a cast-iron hob is placed on top.

If done correctly, the slab and the top of the ninth row of bricks will be level.

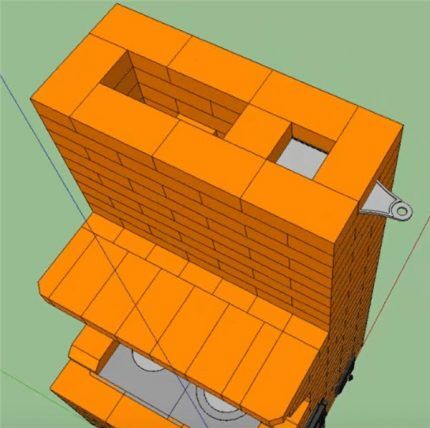

Next, they continue to lay out the side walls and the chimney duct. This will take about six or seven more rows. The next row should also include a canopy hanging over the stove. To strengthen it, use a steel corner.

All that remains is to lay out the chimney; its height is nine bricks. In this example, on the sixth row out of nine, they stopped laying out the partition between the left and middle channels. Thus, a gap was created for the free movement of smoke.

Now we need solid masonry over the left and center channels.

In the right smoke channel, before the last row of bricks, a gate is inserted and a gap is left for the chimney pipe.

All that remains is to arrange the chimney and carry out facing work, if necessary.

Important nuances and tips

Experienced stove makers sometimes ignore the dry masonry stage, but for novice craftsmen it is mandatory. This will help you understand the internal structure of the stove, all its channels and cavities, in order to prevent possible errors.

In almost every row, some bricks are adjusted to size. Experienced stove makers advise that when dismantling dry masonry, separately fold the elements of each row. You can also take a marker and put the row number and the number of the element’s place in the masonry on each brick.

Instead of mortar for dry masonry, it is most convenient to use wooden slats of the same thickness. They will also be useful in the future to control the amount of mortar between the bricks.

The work is carried out as follows:

- During “wet” masonry, each row is first laid out dry to once again check the position of all elements.

- On the bottom row, narrow slats that were used previously are placed on the sides.

- A layer of solution approximately 10-12 mm thick is applied on top.

- Lay the brick and hammer it with a rubber hammer until it settles on the mortar to the level of the slats.

- The laying continues in the same way.

- After removing the slats, the resulting cavities are filled with solution.

- The resulting fresh seam must be immediately embroidered to give the masonry an aesthetic appearance.

The slats are removed only when the row is third or fourth from the top. Now they can be reused. To carry out the work you will need about four sets of such slats.

Each row that is laid on the mortar must be checked by level and plumb for its position relative to the horizontal and vertical.

Crushed bricks cannot be used in laying parts of the furnace that are subject to constant temperature loads. In general, it is undesirable to use elements with cracks and chips in the construction of solid wood and chimneys. Crushed bricks may only be used to fill the base for the foundation of the stove.

Old brick obtained from dismantling destroyed structures is suitable for laying a foundation if it is not severely damaged.

The quality of the masonry largely depends on the adhesion strength of the brick and mortar.

To improve this point, experienced professionals recommend:

- Before laying, red brick is soaked for 7-10 minutes. Fireclay only needs to be dipped in water and shake off the drops.

- Place the brick in place in one clear motion, without moving or tapping it.

- Apply only the required amount of mortar to the masonry site. The seams in the solid wood should not be more than 5 mm, in the firebox - no more than 3 mm.

- During the laying process you need to “mop”, i.e. use a stiff brush to rub the inside surface of the smoke ducts and oven chambers to create the smoothest possible surface along the flow path of the flue gases.

If it was not possible to immediately put the brick in place, you should completely clear the mortar from both the element itself and the place where it is installed, and lay the brickwork on a fresh layer of mortar.

When laying pipes, it is allowed to use only red solid bricks, which are well resistant to acid deposits and temperature changes. The smoother the internal surface of the chimney, the better the draft and the less blockages. You can treat the insides of the pipe with liquid glass.

On our website there are articles with a detailed description of the technologies for constructing different types of brick kilns, we recommend that you read:

- DIY mini Russian stove: specifics and procedures for building a compact stove

- Do-it-yourself Russian stoves with a stove bench: construction manuals with diagrams and procedures

Useful video on the topic

Scheme for creating a small heating and cooking stove:

Construction of a furnace equipped with a drying chamber according to Proskurin’s drawings:

Laying a stove does not tolerate fuss and haste. It is necessary to think through and carefully carry out each stage of work in order to obtain the desired result. It's better to start with a small design, as described above. Having gained experience, you can move on to building more complex ovens: with an oven, drying chamber, arched openings, etc.

Do you have experience building a stove with a stove? Please tell readers about the technical nuances of arranging the foundation and laying the solid fuel unit. Comment on the post, participate in discussions and add photos of your homemade products. The feedback block is located below.

It is imperative to wet the brick. Firstly, water will wash away dust and improve adhesion to the solution. And secondly, damp brick will not take water from the mortar. It will dry more slowly and become stronger. But not just any clay will do. Previously, stove makers were not lazy to travel several tens of kilometers to get what they needed. Unfortunately, it is impossible to determine the quality of clay by eye. You need either experience or advice from a specialist.

Excellent description and advice, thank you very much. Unfortunately, I cannot understand the principle of the structure of “wells” or how they are laid.