High-temperature sealant for furnaces: application features + five best offers

The absence of cracks and crevices in the heating unit system is one of the mandatory requirements for its safe use.For these purposes, a high-temperature furnace sealant is used that is capable of maintaining insulating properties under extreme operating conditions.

Let's figure out how to choose the right composition, what to look for when purchasing, and what rules should be followed when applying sealed paste. To simplify the task of choosing, we will designate the five best offers from different manufacturers.

The content of the article:

Purpose of oven sealants

During active use of fireplaces and stoves, brickwork may crack. The risk of cracks increasing if the brickwork is not tiled, protected with a layer of plaster and covered heat-resistant paint.

Repair work cannot be postponed - using such a fireplace or stove becomes unsafe.

Possible problems caused by the appearance of through gaps:

- fuel consumption increases due to the fact that additional air leaks into the combustion chamber;

- soot appears outward from the cracks - a corresponding coating appears on the ceiling and walls; in such a situation even chimney cleaning does not solve problems;

- combustion products hazardous to health enter the room - there is a risk of poisoning;

- periodic extinguishing of the pilot flame - probably due to depressurization of the chimney;

- fuel burns at low temperatures, which causes more soot to settle on the walls of chimney pipes.

Depressurization of the heating system and an abundance of soot is a fire hazardous combination. Incoming oxygen provokes fire inside the chimney.

Timely sealing of cracks and gaps will help to avoid serious problems. It is clear that only heat-resistant compounds are suitable for such extreme operating conditions.

Classification of high-temperature compounds

The characteristics of sealants depend on the base of the thermal insulating paste. For the treatment of fireplaces and stoves, compositions based on silicate and silicone are suitable. The first group is heat-resistant sealants that can withstand direct contact with flame, the second group is heat-resistant pastes. Their operating temperature is significantly lower than refractory compounds.

Each type of sealant has its own characteristics and priority areas of use.

Silicate – heat-resistant mixtures

Sealing paste based on sodium silicate. Externally, the material looks like a viscous black mixture. After hardening, an inelastic layer is formed on the surface.

If this requirement is neglected, there is a risk of cracking of the insulating seam.

Technical characteristics of silicate compositions:

- permissible temperature indicators: short-term – 1400-1500°C, long-term – up to 1300°C;

- hardening time – 15 minutes;

- maximum seam thickness – 15 mm;

- release form: plastic tubes;

- linear deformation without destruction of the frozen mass – 7%;

- application conditions – temperature within 1-40°C, the exact value depends on the manufacturer.

Silicate compounds have good adhesive properties. To increase the reliability of the coupling, it is advisable to pre-treat a metal, concrete or brick base with an abrasive.

Heat-resistant paste is most effective when sealing joints of fixed elements with a similar expansion coefficient.

When is it advisable to use silicate sealant:

- sealing cracks in combustion chambers and other surfaces in contact with fire, as well as high-temperature gases;

- sealing cracks formed between steel and cast iron elements of stove appliances and brickwork;

- sealing chimneys, removing high-temperature gases, for example: solid fuel boilers and sauna stoves;

- processing of casting installation areas;

- eliminating leaks in heating boilers.

Heat-resistant pastes are used for sandwich chimney assembly – sealant is used to treat the joining surfaces.

Silicone – heat-resistant seals

Silicone-based insulating paste has a brownish-reddish color. The shade is due to the addition of iron oxide to the product.Heat-resistant silicone sealants with different operating temperatures are available for sale, the range of values being 170-300°C.

Silicone sealants retain elasticity after drying - the seams are not afraid of deformation loads and shrinkage of ovens. An additional plus is excellent water resistance, which allows the composition to be used to seal cracks in areas where the roof and chimney come into contact. Silicone paste cannot be painted.

Technical characteristics of heat-resistant seals:

- operating temperature range – within +300°С;

- packaging – tubes, packed in 310 ml;

- Drying period – about 20 minutes;

- application on a cold base at above-zero air temperature, but not more than +40°C;

- resistance to UV rays;

- sealing cracks with a depth of 6 mm.

The cost of silicone thermosealant is often lower than its silicate counterpart. However, due to the insufficient temperature threshold, its use is limited to the treatment of not too hot surfaces.

Scope of use:

- sealing brick chimneys in street areas;

- sealing the joints of the exhaust duct and roofing material;

- treatment of smoke exhaust ducts made of metal, brick and sandwich panels, provided that boilers with an efficiency of over 90% are used - the temperature of the exhaust gases does not exceed +150°C;

- treatment of blind cracks on brick external surfaces of stoves and fireplaces.

The high-temperature composition is also suitable for sealing threaded connections when installing heating circuits.

Types of thermosealants by release form

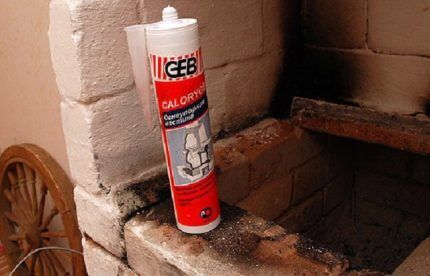

Most manufacturers sell insulating compounds for furnaces in tubes. Before use, the cylindrical container is placed in a construction gun.

There are products in soft small tubes. It is advisable to use them for processing small areas. No additional equipment is needed to apply the composition.

High-temperature sealants are produced in the form of one- or two-component compositions. The first category is most actively used in everyday life.

The one-component composition is ready for use and does not require any preparation. This sealant takes longer to dry, leaving time to correct possible errors.

This option is more often used in industrial settings, when it is necessary to process large areas. Two-component mixtures have not taken root in everyday life due to the technological complexity of use.

Algorithm for choosing a suitable tool

Knowing the properties and recommended scope of application of various compositions of high-temperature sealants, it will not be difficult to make the right choice.

So, attention should be paid to the following parameters:

- operating temperature;

- environmental friendliness;

- brand name.

Temperature endurance. The indicator depends on the base of the sealant - silicone or silicate. When choosing, it is necessary to compare the upcoming operating conditions of the paste with the values of the maximum permissible temperature.

If you save money and purchase a cheaper analogue, the components will simply burn out over time - the mineral filler will delaminate and you will have to repair the heating device again.

Environmental friendliness. The composition should not contain substances that release toxic volatile compounds when heated. Regular inhalation of such vapors has a negative impact on human health.

To protect yourself, it is better to refrain from purchasing goods from unknown manufacturers at a suspiciously low price. You need to carefully examine the packaging - counterfeits often contain spelling errors, and the text itself may be printed illegibly.

Manufacturer company. Among the wide range of products, domestic and foreign companies have won the trust of buyers: "Moment", MasterTeks, Penosil, Kraftool, Alteco, Tytan, Soudal, Macroflex and etc.

Rules for using thermosealants

The tactics for using silicone and silicate mixtures are similar. However, there are also features that should be kept in mind when sealing furnace equipment.

Working with silicone compound

In addition to the construction tools for work, you need to prepare: a rubber spatula, latex gloves, and a brush.

The surface to be treated needs preparation:

- clean and degrease the base;

- It is advisable to treat metal elements with sandpaper to improve adhesion;

- wait for the surface to dry completely if water was used during cleaning.

The next stage is filling the cylinder into the construction gun. Cut off the sealed cap at an angle.

For uniform hardening, the silicone composition must be provided with air access. Therefore, the thickness of the sealant recommended by the manufacturer cannot be exceeded.

The time for complete polymerization depends on the conditions. The packaging indicates the rate of hardening at optimal parameters: humidity - 50%, temperature - 23°C. In practice, the values vary significantly. The lower the room temperature, the longer it will take for the sealant to “set.”

Technology for applying heat-resistant sealant

To process with a refractory compound, in addition to the tools and materials described above, you will need masking tape and a construction knife.

The surfaces are prepared in the same way as before applying the silicone composition: cleaned, degreased, and the metal is “sanded” with an abrasive.

Technological nuances of using silicate sealant:

- the porous base must be dusted and slightly moistened;

- work is carried out only at above-zero temperatures, optimally above +20°C;

- when applying the mixture, adhere to the insulation thickness recommended by the manufacturer;

- excess sealant must be removed immediately, without waiting for the mixture to dry;

- The masking tape is removed after applying the composition.

Some oven sealants require many hours of drying at different temperatures. This information must be clarified in the product instructions.

Top 5 best offers

The demand for high-temperature silicone and silicate sealants is very high, so such products are present in the product lines of many manufacturers. In order not to get confused in the variety of offers, we present a list of the most worthy and popular formulations from foreign and domestic companies.

1st place – Penosil+1500°C Sealant

The first place was given to the silicate composition from the Estonian manufacturer Penosil. Despite the stated high technical characteristics, the sealant is relatively inexpensive.

Penosil is suitable for external and internal use, for example contact with stone, brick, concrete, metal.

Specifications:

- temperature resistance – 1500°C;

- mobility – 0%;

- color – dark gray;

- application temperature – 5-40°C;

- hardening time - about 24 hours;

- volume – 310 ml.

Among the main advantages of fireproof sealant are: low cost, excellent quality, ease of use, versatility. User reviews are mostly positive; Penosil copes with the task. The downside is the hardening time; the oven can be turned on a day after treatment.

2nd place – Makroflex TA145

The Belgian company specializes in the production of insulation and sealants. The range includes a heat-resistant silicone mixture. Scope of application – places exposed to temperatures not exceeding +260°C.

It is not advisable to use the composition for processing metal elements prone to corrosion (lead, copper).During the curing process, the sealant releases acetic acid fumes.

Specifications:

- stable heat resistance - 60-260°C, short-term exposure is acceptable - up to 315°C;

- width of the applied layer – 6-30 mm, depth – from 2 mm;

- hardening time - about 2 days;

- application conditions – temperature within 5-40°C.

During polymerization, it is necessary to ensure good ventilation in the room - inhalation of acid vapors can lead to poisoning. Once dry, the sealant is safe.

3rd place – Soudal

Sealing paste based on sodium silicate. There is no asbestos in the composition, so after hardening the insulating layer does not crack or crumble. Temperature resistance Soudal – 1500°С.

Suitable for concrete, metal, brick bases.

Specifications:

- mastic color – black;

- maximum heat resistance – 1500°C;

- operating temperatures – 1-30°С;

- deformation during movement – no more than 7%;

- film formation time – 15 minutes at +20°C and humidity 65%;

- cartridge volume – 300 ml.

Despite the higher cost than the silicate analogue from Penosil, Soudal sealant is in demand. The composition is suitable for sealing cracks whose depth does not exceed 5 mm. If the gap is larger, you can cover the main part with another material and treat the top with a heat-resistant sealant.

4th place – Kraftool Kraftflex FR150

Heat-resistant composition based on silicate. The sealant is inert to chemical influences and perfectly resists atmospheric factors.

Special restrictions on use Kraftflex FR150 No. It is suitable for sealing elements exposed to direct flame, fixing fire bricks and air ducts.

Specifications:

- paste color – black;

- maximum permissible heating temperature – 1500°C;

- film formation time – 15 minutes;

- hardening speed – 2 mm/24 hours;

- operating temperature – 5-40°C;

- packaging – 300 ml.

The sealant is indispensable for objects operated in extreme conditions. The composition can withstand temperatures down to -40°C. Cons of Kraftflex FR150: drying time, relatively high price.

5th place – Moment Germent

Waterproof, high temperature sealant based on silicone. The mixture is inert to chemicals and retains its insulating properties in conditions up to +216°C.

Use on mirror and stone surfaces is not recommended.

On practice Germent showed reliable adhesion to various materials. The silicone insulator is petrol and oil resistant and is not afraid of UV radiation.

Specifications:

- remains stable at -65°С…+260°С, short-term temperature jumps up to +315°С are acceptable;

- film formation time – 10 minutes;

- polymerization rate – 1.5 mm/day;

- color – brick red;

- elongation at break – 115%;

- bottle volume – 300 ml.

The fifth place in the ranking is due to the high cost of the product. In practice, Germent has proven itself well - it is easy to apply, dries quickly enough, and forms a reliable adhesion to materials.

Conclusions and useful video on the topic

Review of oven sealants, recommendations for choosing the optimal composition:

Rules for applying a sealing composition using the example of Penosil heat-resistant paste:

The quality of repair and subsequent operation of the furnace depends on a number of factors. An important role will be played by: the correct choice of sealant composition, adherence to the technology of its application and drying. It is necessary to compare the characteristics of the insulating paste with the conditions of its use and study the manufacturer’s instructions before performing repair work.

Looking for a quality high-temperature furnace sealant? Or do you have experience using an insulating compound to seal cracks or crevices in a heating unit? Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.

Are there such heat-resistant sealants that would withstand external weather factors well - rain, snow, etc.?

As for sealants for stoves and chimneys, after the polymerization (hardening) process, they perfectly withstand weather conditions such as rain and snow. Only you need to apply the sealant to the surface of the chimney in suitable conditions:

- no snow or rain;

— ambient temperature not lower than +5 ºС;

— humidity within 50%.

It will take about 1-2 days for the sealant to harden, after which it is not afraid of any weather conditions.

From personal experience, I can recommend using Penosil sealant, which can withstand temperatures up to +1500 ºС. I myself can personally confirm the figure of +780 ºС. The sealant can withstand this temperature without problems; it was not possible to test it higher. Rain and snow do not in any way affect the quality characteristics of this sealant.

BecauseWe install a lot of stoves and fireplaces, both civil and industrial, and began to use such sealant as “OGNETITAN-1500”. The sealant is of high quality and the price is very good. Holds temperature and open flame perfectly (up to 1500 degrees). No cracks or peeling appear over time. This company also buys silicone fire-resistant sealant OGNETITAN SN, but we buy it for sealing air ducts and trays, because... it is very elastic.

Good afternoon,

Please tell me what sealant you recommend using to repair the stove where the brick connects to the cast iron firebox door? i.e. brick on metal. Thank you.

What is the temperature of the metal pipe at the roof crossing? A small gap has appeared between the pipe and the rubber seal. What is the best way to seal?

Hello, tell me, if there is a leak in the water tank in a sauna stove, what sealant can I use?

Why didn’t they tell you about Ognez stove sealant? it's generally 1600 and quite popular