For what purposes is a steam boiler needed: diagram and operation

The steam boiler is an old invention, but it is still used in industry.For example, at power plants, where the steam generating unit is one of the main elements of electricity production. Steam boilers are also installed in all boiler houses of plants and factories. They are rarely used in everyday life today, because they have been replaced by safer and energy-efficient water boilers.

The content of the article:

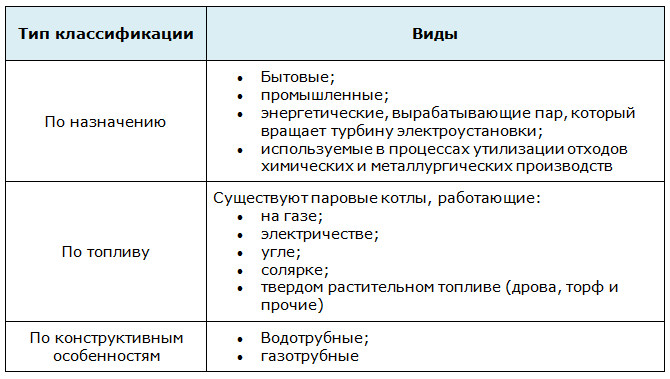

Classification of steam installations

There are several scales by which classification is carried out. The main ones are three scales.

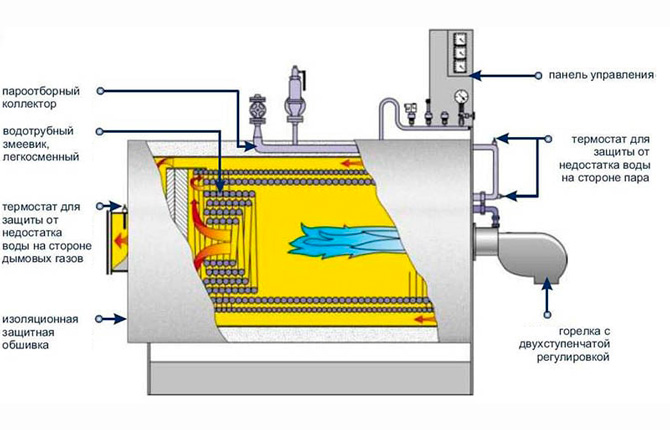

Water tube

They convert water into steam faster than gas pipes. They have a higher efficiency due to the design features of the unit. In essence, it is a housing with a large number of pipes located inside it. Water moves through the pipes, and fuel burns between the pipes.

At high temperatures, water turns into steam. And since there are many pipes, their heating area is correspondingly larger. And the more pipes in the boiler, the more intense the transition of the liquid into a vapor state occurs.

Water tube steam boilers are divided into two subgroups:

- straight-through;

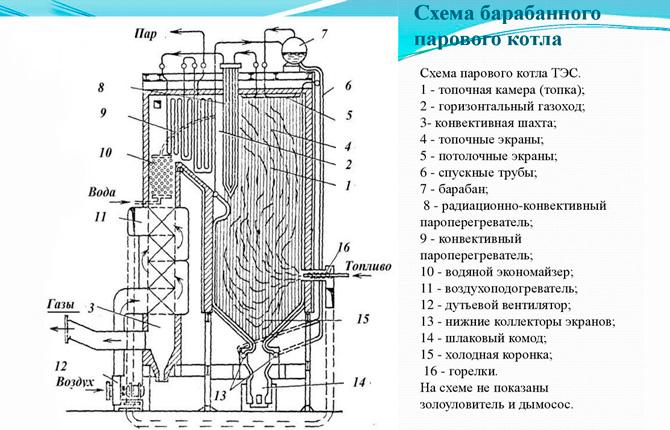

- drum type.

The first are pipe-type structures, which were mentioned above. The latter are presented on the market in two positions – horizontal and vertical. But the operating principle of this type of device is the same.

Its design includes a drum that not only collects steam, but also separates condensate from it. The latter is sent to the heating zone, that is, water losses are reduced.

To obtain high-temperature dry steam in industry, several drum-type boilers are installed in series. And such steam can be compressed to maximum pressure, which is necessary in many technological processes.

Boilers of this type are divided into two positions - non-volatile and circulation. They differ from each other in the absence or presence of a circulation pump, respectively. The presence of the latter increases the efficiency of the installation. The thing is that during one revolution of water in the boiler, 10% of its volume evaporates. That is, for the entire volume to evaporate, at least 10 revolutions will be required.

With gravity movement, this will take a lot of time, causing the efficiency to drop. The circulation pump moves the liquid quickly, more revolutions will be carried out in the same period of time. This means that the full volume of water will quickly turn into steam.

But in drum-type boilers, a condensate level regulator must be installed in the pump. Installation location: steam separator. Its task is to control the volume of condensate formed.

For example, if little of it is formed, the technical characteristics of the steam installation are reduced. If a lot of it is formed, this leads to a drop in pressure inside the unit. The consequences are rapid boiling and explosion.

The steam separator is a large cross-section pipe resembling a drum. Hence the name of the boiler. This pipe collects water saturated with steam. In fact, two processes (heating the liquid and vaporization) occur separately from each other. Hence the high safety of operation of this type of equipment.

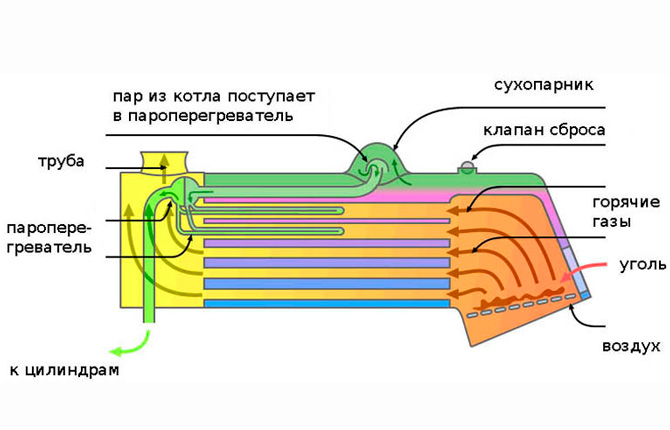

Gas pipe

Structurally, this is a boiler, inside of which large diameter pipes are located around the firebox.Hot gases move in them, and water flows between them. That is, this is the opposite of water tube analogues. Gas tube plants produce high-temperature steam, which is more often used in recycling processes.

A gas-tube steam boiler has one significant drawback - the high pressure of the final product. The latter is found in large quantities in the unit. This is what causes a decrease in the safety of the installation. Therefore, boilers are equipped with an expensive and complex security system. In addition, both the body and pipes are made of thick steel, which increases the cost of the equipment.

A striking representative of the gas-tube type is the locomotive boiler.

Both installations (water-tube and gas-tube) can produce different types of steam:

- saturated;

- overheated water.

The first is a medium that forms at a temperature of +100°C. It cools quickly with the formation of condensate, which re-enters the heating zone. Such installations are used for domestic heating. The pressure in a steam boiler of this type does not exceed 100 kPa.

The second is a medium obtained at a temperature of +500°C. Therefore, water suspensions and drops never form in it. With gradual heating, water can form, but for this purpose a separator is installed in the design of the installation.

Scientific and technological progress does not stand still. Today, manufacturers offer water-tube installations that are no different from gas-pipe installations in terms of efficiency and safety. Firstly, they are sheathed with thermal insulation material. Secondly, the inside is lined with infrared material, which acts as a reflector of thermal energy.

And since water-tube devices are several times cheaper than drum-type devices, plus their operation is simple, today their popularity and demand has grown sharply.

Efficiency also increases due to the latest steel alloys from which device parts are made. A new heating technology was also introduced, which uses two torches located opposite each other. The technology is called “oncoming torches”.

With their help, the heating temperature reaches 1800-1900°C. Usually it does not exceed 1200°C. Accordingly, the efficiency of such installations is at least 90%.

Domestic boilers

There is great interest in these units today. But also requirements to them considerable:

- compactness;

- light weight so as not to pour a foundation under it;

- high safety factor;

- possibility of servicing by unqualified personnel;

- minimum start-up and heating time.

Today, manufacturers offer two types of household installations - coil, also known as classic, vortex jacket.

The first is one pipe, coiled into a spiral. Water moves along it, turning into steam. The steam capacity of the equipment is small. But in this case, this does not play the most important role, because a domestic boiler must produce low-potential steam.

The operating efficiency is also low, but this can be corrected by frequent arrangement of spirals. But such a boiler holds a record for heating time - 3 minutes after turning on the torch.

The second is a completely unique steam boiler design. A body of two shells, between which water is passed. There is a firebox inside, and when burning, the torch twists in a spiral, increasing heat transfer. No pipes.

Other benefits:

- vertical arrangement, hence increased compactness;

- efficiency, like drums;

- heating time – 5 minutes.

Three minuses:

- the equipment is expensive;

- the design is complex;

- complete dependence on energy - the blower, without which the unit does not work, requires an electricity supply.

Technological application of boiler steam plants

There are several industries where steam boilers are constantly used:

- The first industry is thermal power engineering. Steam is used to heat large workshops, for example in the automotive industry. The steam heats the water to the required temperature, which is then driven by pumps along heating mains to multi-storey buildings and other objects.

- The second industry is energy. Here, steam is used to spin a turbine, which produces electric current.

- The third industry is the production of building materials. For example, concrete products are dried with steam.

In many industries, steam boilers are an integral part of the technology. This includes disinfection, drying of food products, culinary processing, preservation, etc.

Disposal of gaseous waste also involves the use of steam plants. In this process they act as coolers. Such a boiler takes thermal energy from gases coming out, for example, from high-temperature furnaces.

Operating principles and design

Their main purpose is to change the physical state of water, that is, to transfer it from liquid to gaseous with the required parameters. The process goes like this:

- the boiler is filled with water by gravity or using a pump;

- the heating system turns on;

- steam formation begins;

- the liquid level gradually decreases, reaching the minimum level;

- the level sensor reacts and turns on the pump;

- water fills the pipes.

We can say that steam boilers operate on a cyclic principle.

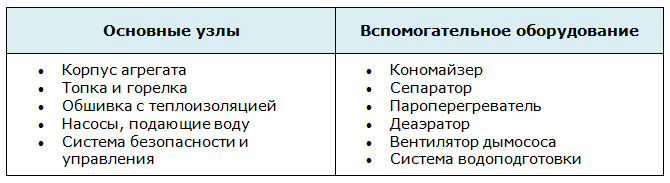

Structure

Steam boilers consist of main and auxiliary units and parts, plus automation.

The main requirement for steel products is to be made of heat-resistant alloys. This is the only way to achieve the maximum level of safe operation of boiler equipment.

The security system plays an important role. These are not only temperature and pressure sensors. The system includes mechanical safety. It includes check valves, electric valves, and other shut-off valves. This double protection ensures maximum safety, especially in cases where the electronics fail. At this time, the mechanics take over all functions.

There are special requirements for the water treatment system. Water must meet certain standards. These standards are different for direct-flow and drum units. In the latter, the liquid must be perfectly clean, almost distilled. After all, in such devices it does not disappear anywhere. That is, fill the boiler once, and it will work for many years.

If the water is hard with impurities, then everything pipes after a while they will become clogged with deposits and rust. Their diameter decreases, thermal conductivity decreases, which leads to a decrease in efficiency. The steam will not be the same as needed (temperature, humidity).

Despite their complex design and low safety, steam boilers are still in demand. Especially on ships, in power plant technology, factories where high coolant temperatures are required. Therefore, manufacturers are doing everything to increase operational safety, reduce the cost of equipment and the complexity of maintenance.

If you have questions, ask them in the comments.If you liked the article, share it on social networks so that others can become familiar with the topic. Save the link to your bookmarks.

We also recommend watching selected videos on our topic.

How does a steam boiler work?

Steam boiler - design and maintenance, detailed overview.

Information sources:

- https://pechiexpert.ru/parovoj-kotel

- https://clubpechnikov.ru/parovoj-kotel

- https://kotle.ru/parovye-kotly/ustrojstvo-parovyh-kotlov