Adjusting the automatic control of a gas boiler: device, principle of operation, tips for setting up

Gas boilers are often used to heat houses - convenient and quite economical appliances that run on blue fuel.The correct functioning of these devices is ensured by a number of devices that monitor the operating mode.

Timely adjustment of the gas boiler automation allows you to increase the efficiency of the heating device, as well as ensure reliability and safety in operation. And this, you see, is a rather important point for all users.

But how to make the adjustment and is it possible to do it on your own? Let's try to figure out these issues together. For this purpose, let’s take a closer look at the design and operating principle of the automation using the example of one of the most popular models.

We will also pay attention to the issues of setting up the equipment and the main problems that the user may encounter in the process of setting up and further operating the gas boiler.

The content of the article:

Types and principle of operation of automation for boilers

This definition means a system of actuating and control devices aimed at maintaining specified modes, as well as promptly responding to emergency situations.

This ensures the safe use of boilers with minimal human involvement in the processes occurring in the device.

All automation used for the correct functioning of heating devices can be divided into two fundamental groups:

- autonomous, not dependent on external power supply;

- devices that require an external source of electrical current to operate.

Let's look at each group of devices in detail.

How do energy-dependent devices function?

Such systems are complex electronic units that require electricity to operate.

At the same time, these devices allow you to regulate the fuel supply and the degree of heating by turning off or opening the tap, which helps save heating costs.

Problems solved by automatic devices:

- opening/closing the gas supply system valve;

- starting the device in automatic mode;

- preset or emergency shutdown of the boiler;

- adjusting the burner flame level using the existing temperature sensor;

- displaying data on the screen for visual reading (air temperature, water heating level, etc.).

In addition, modern automatic devices can have a number of additional functions that greatly facilitate the operation of boilers.

These include:

- management of equipment operation and monitoring of its functioning;

- protection of the heating system from malfunctions three way valve;

- protection of equipment from freezing (if the temperature in the room suddenly drops, the device automatically starts the boiler into operation);

- self-diagnosis, which allows you to detect defects in components and parts, as well as identify malfunctions in the functioning of components. This option allows you to timely identify a malfunction that could lead to a serious breakdown requiring major repairs or a complete replacement of the boiler.

At the same time, reliable and stable operation of electronic automation devices for gas boilers can only be carried out under certain conditions.

Namely:

- no power surges;

- strict adherence to the recommended temperature regime;

- no problems associated with long service life.

If these rules are violated, high-tech devices can quickly fail.

There is a wide range of such automation on the market, which may involve programming or do without it. Such devices include the devices listed below.

Thermostat for measuring room temperature

The air temperature measurement sensor is located in the room, but is connected by cable to a boiler located in this or another room. The device not only monitors the heating level of the room, but also regulates the operation of the heating device.

As soon as the temperature drops below the designated level, the thermal device sends a signal to the boiler, upon receiving which the heating equipment automatically starts working.

When a comfortable level of air temperature in the device is reached, the valve closes, after which the operation of the boiler, and, consequently, the heating of the room stops, which helps to save fuel.

Our other article contains detailed information about the types and thermostat connection diagrams for heating boiler.

Daily programmer for 24 hours

Like a regular thermostat, the device regulates the operating mode of a gas boiler, but has expanded capabilities.

Using this device, you can set a program for the operation of heating equipment for 24 hours, providing different levels of heating during certain periods of the day (for example, lowering the temperature in rooms at night or when people are unoccupied).

Most devices provide automatic repetition of the cycle, and to change it, you need to change the program. Connecting such a device can occur either using a cable or through a special radio channel.

Long term weekly programmer

Unlike the device described above, the weekly device allows you to schedule the operation of the boiler in advance for seven days at once.

Devices of this type, as a rule, provide several different modes, and it is also possible to create your own programs for the operation of heating devices.

All data is transmitted to a backlit display, which allows you to comfortably track information. Since the range of the programmer is 30 meters or more, it can be placed in living rooms.

Operating principle of non-volatile automation

At the same time, individual boiler parts that perform the control function do not require the use of electricity.

They are adjusted manually, as well as under the influence of geometric changes that occur in mechanisms under the influence of heat.

Despite the large range of models with electronic equipment, options with mechanical control are also very popular.

This can be explained by several reasons:

- Democratic price. Prices for such devices are significantly lower than for fully automatic analogues.

- Ease of use. The simplicity of the non-volatile automation device used in mechanical models allows even a person who is not related to technology to quickly understand the settings.

- Reliability. Mechanical devices do not depend on power surges or complete power outages, so they can function without a stabilizer, which is desirable when working with volatile equipment.

The disadvantages of such models include lower accuracy of adjustments, as well as the need to monitor the operation of the boiler.

As for the settings, it is done manually.Each mechanical device is equipped with a temperature scale, the numbers of which indicate the maximum values (from min to max). The operating temperature is set by selecting the required mark on the gradation bar.

After starting the unit, the thermostat is responsible for its operation. The operating element of this device is a rod, which, contracting when cooled, opens the gas supply valve, and then increases in size due to the increase in temperature and shuts off the flow of blue fuel.

Using a similar process, you can also reduce or increase the heat level.

Elements of safety and comfortable operation

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure safe operation, and devices that facilitate comfortable operation of the boiler.

The following parts are responsible for safe operation:

- thermostat;

- draft and flame control sensors;

- safety valve.

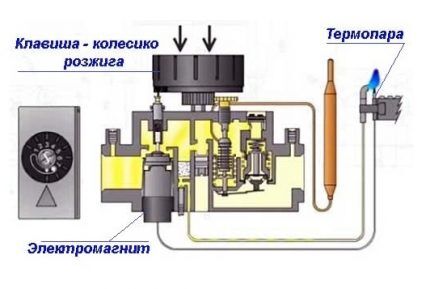

Flame sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

Flame temperature regulator (thermostat) maintains the required temperature of the coolant, and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical point (maximum or minimum).

Traction control module stops the gas supply to the burner as soon as the location of the bimetallic plate changes due to increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

We examined temperature, draft, pressure and flame sensors in more detail in this article.

In the heating system safety valve – an integral component of pipeline fittings, which is important in monitoring the volume of coolant involved in the circuit.

The hole in the valve through which gaseous fuel moves is called the seat. To turn off the device, you need to close it with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as modeling:

- Single-stage devices have only two operating positions: on/off.

- The two-stage device is equipped with one input and two outputs, and the valve opens when it is turned to an intermediate position, due to which the switching occurs more smoothly.

- A three-stage device is equipped with boilers that have two power levels.

- Modulating valves are used to smoothly change the power rating of devices.

Automation, used for convenience, includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

Automation responsible for safety

According to the rules set out in the regulatory documentation (SNiP 2.04.08-87, SNiP 42-01-2002, SP 41-104-2000), gas boilers must have a safety system. The purpose of this block is to urgently shut off the fuel supply in the event of any breakdown.

The principle of safe operation of the gas boiler automation system is based on monitoring instrument readings.

The control unit monitors the following factors:

- Gas pressure. When it drops to a critical level, the supply of flammable substances is immediately stopped. The process occurs automatically using a valve mechanism pre-set to a certain value.

- Gas supply. Responsibility for this property in volatile devices lies with the maximum or minimum relay. The mechanism of operation is to bend the membrane with the rod as the number of atmospheres increases, which leads to the opening of the contacts of the heating device.

- No flame in the burner. When the fire dies out, the thermocouple cools down, causing current production to stop, and the gas supply stops due to the gas valve being closed by the electromagnetic damper.

- Availability of traction. As this factor decreases, the bimetallic plate heats up, which causes a change in its shape. The modified element presses on the valve, which closes, stopping the flow of flammable gas.

- Coolant temperature. Using a thermostat, it is possible to maintain this factor at a given value, which helps prevent overheating of the boiler.

The possible malfunctions mentioned above can cause the main burner to go out, resulting in the possibility of gas entering the room, leading to fatal consequences.

To avoid this, all boiler models must be equipped with automatic devices. This is especially true for outdated models, where such devices have not yet been provided by manufacturers.

Features of the autoblock device

As a rule, manufacturers use special control units, which include the devices listed above. Despite their external differences, they all act on the basis of the same principles. To get acquainted with the best models and manufacturers of automation, go to this link.

The most widely used products are the Italian brand EuroSIT. The most popular model is Eurosit 630, which is characterized by easy functionality, compatibility with designs from various manufacturers, reliability and durability.

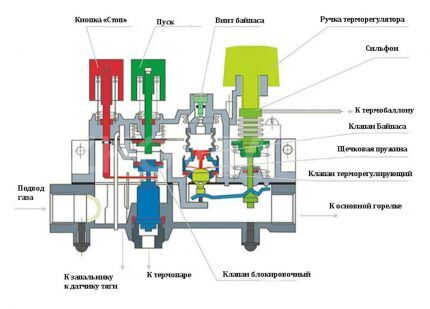

Using Eurosit 630 as an example, we will consider in detail the design of the automatic block.

The device is a casing containing all structural components (spring valve, pressure regulator module, shut-off valve), which makes its installation much easier.

A pipe is connected to the body through which gas is supplied, as well as cables from sensors and other devices.

There are some difficulties when installing and setting up this device, but once you get used to it, you can practically not worry about the operation of the gas boiler.

How to set up the automatic heating device?

The adjustment involves setting up the EUROSIT 630 controller, which maintains the temperature regime of the liquid in the circuit, and in a critical situation blocks the gas supply.

Before setting up the automation of various models of gas boilers, you should install the equipment, strictly following the drawing. In this case, it is important to check the complete set of device parts, which must match those stated in the instructions.

The adjustment is carried out using a knob that allows you to control the transfer of the boiler to three positions:

- shutdown;

- ignition;

- setting the temperature mode (from 1 to 7).

To turn on the ignition device, the lever must be moved to the second position, placing it opposite the icon with the image of a spark.

When pressed, the piezo ignition button will be activated, causing the pilot burner to light. In this case, the lever must be held in this position for 10-30 seconds. After releasing the button, the igniter should stop working.

When the lever is pressed, the solenoid valve opens and gas is supplied to the igniter (it should be left open even after the handle is released).

In this case, the thermocouple must provide protection against the return of fire. The sensors, which are elements of the circuit, are closed in the working position. After receiving the signal, they open, which causes the unit to shut down.

Problems when turning on the ignition device

If you have difficulty turning on the device, you can use the following instructions. First of all, you need to stock up on the necessary equipment, namely open-end wrenches, a screwdriver, a multimeter, pliers, and alcohol for cleaning parts.

Carefully remove the terminals of the device: they are shorted together, then tightened with pliers. To determine the cause of the malfunction, you need to turn on the igniter.

If ignition occurs normally, most likely there is a breakdown in the draft sensor. In this case, it is necessary to unscrew this element (to prevent overheating, it is surrounded by paronite gaskets).

After this, using a tester you need to measure the resistance, the value of which should be 1-2 ohms. If a malfunction is detected, this part must be replaced. If the element functions normally, it is enough to wipe it with alcohol, after which the device is reinstalled.

To identify problems in the thermocouple traction breaker, the terminals are removed, after which the resistance is checked, the value of which should be equal to 3.

If the obtained value does not correspond to the optimal value, you need to use wrench No. 9 to unscrew the nut that secures the thermocouple to the traction breaker, after which use wrench No. 12 to unscrew the latter half a turn.

After this, you need to remove the plastic insert with contacts, then the part is completely unscrewed. The thermocouple is checked: it should be connected to the solenoid valve and secured with key No. 9. If after this ignition is still not possible, the problem lies in this part.

To resolve the issue, the nut securing the thermocouple to the igniter is unscrewed with a No. 10 wrench, after which the element is installed in the desired position.

To evaluate the result of the work, you need to measure the EMF (it should be equal to 18 mV), then clean the thermocouple contact and the elements of the traction breaker with alcohol. The final stage is assembling the device.

Troubleshooting other problems with automation

A common reason for lack of ignition is contamination of the insulator along which the wire leading into the combustion chamber is laid. Such a malfunction can be easily eliminated by wiping this part with a soft cloth. If it is heavily soiled, it can be moistened with solvent and then wiped dry.

Soot deposits that form inside the combustion chamber can also prevent the pilot from turning on. This defect can be easily eliminated by tapping the tube supplying gas to the burner.

After a break in operation, it is recommended to check the condition of the pipes. If not used, spiders may build nests in them or other insects may get in, which may impede gas flow.

Poor water heating may indicate too large deposits on the walls of the heat exchanger. To solve the problem, it is advisable to rinse the circuit with hot water with the addition of a mineral solvent.

If this does not help, it is better to contact a specialist, as the cause may be damage to the electronics or the flow sensor.

In boilers that are too powerful, a “clocking” effect may occur, which manifests itself in too frequent switching on caused by intense heating of the gas. To correct the situation, it is recommended to reduce the fuel consumption supplied to the burners.

In mechanical devices, this can be achieved by rotating the adjustment lever on the gas valve, and in electronic models it is enough to use the control panel, where the corresponding operating parameter is set.

To extend the life of the equipment and gas boiler, it is recommended to carry out regular inspection and maintenance. We discussed how to perform maintenance correctly in next article.

Conclusions and useful video on the topic

On the presented video you will find brief instructions for installing a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design that provides many useful functions. The automation of most models greatly facilitates their operation, takes over control of the mechanisms and control over their operation.

This significantly increases the level of safety during the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to tackle this problem yourself and want to clarify some points? Feel free to ask your questions under this article, and our experts will try to help you.

Or have you successfully adjusted the automation and want to share your experience with other users? Write your tips, add photos depicting the main points - your recommendations will be very useful to other owners of the same boiler.

I bought an apartment with a double-circuit gas boiler Electrolux-24. I had never used a boiler before, and at first it took me a long time to get used to it. The heating of the water temperature is set to 36-38 degrees, and when I swim, the water heats up very hot, on the display up to 60 degrees, then it suddenly becomes icy. Not swimming, but complete torture. Tell me, what is the reason and how to eliminate it?

Irina, most likely your DHW circuit sensor is faulty. On boilers of this type two sensors are installed. One of them monitors the water temperature in the heating system and it very rarely fails. But basically the hot water circuit sensor fails, since your water most likely is hard. And he doesn't like it. Shouldn't cost too much. I bought one for my Baxi boiler a couple of years ago.

The process of adjusting from scratch for each model is described in the instructions or is available step by step on the Internet. My problem is this: the gas boiler is more powerful than necessary, precise tuning is important, because an untuned boiler “tacts,” which affects longevity. And the quality of heating suffers.Therefore, it is necessary to rebuild regularly and very important - I turn on the minimum water pressure (double-circuit) to adjust the burner. Well, in general, it’s better to let the specialists set it up first, and then do it yourself, otherwise it will cost more.

Good afternoon, please tell me. The Hubert boiler (Scotland) is at rest and then the pressure rises sharply for 20-15 seconds, the water gurgles and returns - what could this be? Thank you.

Hello. Is this the only problem that is observed with this boiler? The brand was indicated, but it would be even better if you wrote a model to guide you through the boiler diagram. And it’s not even clear whether the boiler is wall-mounted or floor-standing?

Let's look at the example of a wall-mounted Hubert AGB 20L boiler with a bithermic heat exchanger:

— check the serviceability of the water pressure sensor;

— check the expansion tank;

— check the heat exchanger.

I am attaching a photo of all the elements; the heat exchanger is located between the combustion chamber and the expansion tank.

But I recommend starting with the make-up tap, check whether it is working properly, it is often this that causes problems with sudden and short-term changes in pressure.

After cooling and then turning on the heating, when the automation is just getting ready to turn on the burner, a (small) ignition is observed in the nozzle.

Hello, Natalia. I understand that you are worried about the boiler making noises when you turn it on, judging by the symptoms described. The problem is quite common, but its solution is not difficult.

I will give a detailed description of how to fix the problem, as an example I will give photo instructions for repairing an Electrolux gas wall-mounted boiler. You need to get to the burner, remove it, remove the ignition electrode and clean it well. For preventive purposes, I also recommend cleaning the burner itself. Pay attention to the condition of the heat exchanger; it is from it that debris can get onto the burner. If you remove all deposits, the problem should go away.

Should the flame (height) of the main burner be adjusted when turning the thermostat in positions 1-7 on the EVROSIT 630??? And if the maximum pressure adjustment screw on the pressure regulator scrolls “endlessly” in both directions without changing the flame in any position of the thermostat 1-7

When you turn it off at 60 degrees, it heats up to 70, and when you turn it on at 50, it cools down to 40

How to adjust euro630

Is it possible to somehow connect eurosit630 with an electronic control unit?

Hello. There was a noise as if the boiler was running at full power. Although it costs 3 out of 7. And the smell of carbon monoxide appeared. I opened it and watched. I noticed that when it automatically turns on, flames shoot straight out of the round window. What is the reason? Boiler KMP "VEGA"

Good afternoon. You should contact a gas boiler specialist.