How to hide a gas boiler in the kitchen: the best design options and camouflage tips

If you are not an ardent supporter of the loft or techno style, then the appearance of the heating unit is unlikely to be enjoyable.After all, it is produced focusing on the mass consumer, and not on your personal taste. Naturally, you will think about how to hide a gas boiler in the kitchen so that it fits perfectly into the interior picture.

However, when it comes to camouflaging gas equipment, things are not so simple. In addition to finding the most suitable design option, you also need to take into account the standards. Compliance with the rules that ensure normal operation guarantees safety when using a gas hot water supplier.

We will tell you how best to hide the presence of a far from attractive object in the kitchen, taking into account the requirements of gas services and fire authorities. The article we presented describes in detail the standards for the location of gas equipment. Here you will find interesting and practical solutions for decorating kitchens with gas boilers.

The content of the article:

Standards for premises and equipment

Before you start developing a unique design for arranging a kitchen with a gas boiler or choosing a ready-made solution for its design, you should find out how the room should be equipped for the operation of gas equipment.

It is important to decide in advance on the type of boiler that can be used in a private or multi-storey building.You should find out what needs to be done to ensure complete security. Only then will it be possible to select a camouflage method that does not violate regulatory requirements.

Requirements for organizing gas supply

The regulations state that:

- Installation of a boiler that processes gas to prepare coolant or sanitary water is allowed only in buildings with up to five storeys inclusive.

- In the kitchen of a separate apartment in a high-rise building, boilers with a capacity of up to 35 kW are installed. These are mainly wall-mounted flow-through heat generators (columns) that supply sanitary hot water.

- In the kitchens of private houses, if it is impossible to arrange a separate boiler room, it is allowed to install a boiler with a capacity of over 35 kW, subject to all safety measures and measures regulated by regulations.

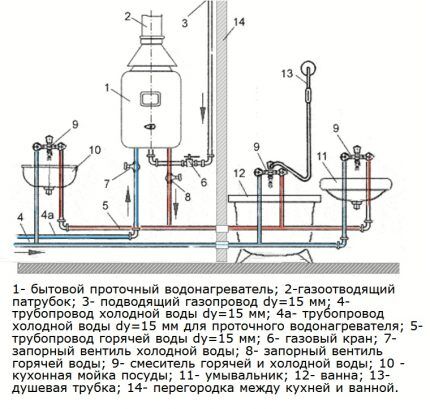

In private houses with autonomous communications, it is recommended to organize boiler rooms with a pair of boilers separate from the kitchen. It is best to prepare the coolant floor standing boiler. But it is advisable to entrust the heating of water for sanitary and hygienic purposes to geyser or a capacitive water heating unit (boiler).

It should be remembered that the total heating output of the two boilers involved, located in the same vat, should not exceed the technical limit of 100 kW. Please note that installation of gas boilers is allowed in corridors if they have transoms for ventilation. It is no longer possible to install any gas boilers in bathrooms.

Rules for arranging a kitchen space

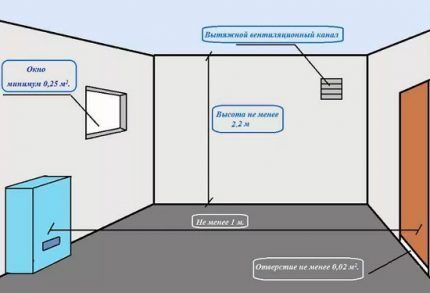

Installation and subsequent operation of gas water heating equipment is allowed in kitchens with a ceiling height of not lower than the limit of 2.0 m specified in building regulations.If the height of the room is reduced due to the installation of a suspended/stretch ceiling, it is dismantled or switched to the electric type of hot water preparation.

If, in addition to a gas boiler, there is also a gas stove in the kitchen, the minimum ceiling height should be 2.2 m. The distance from the floor plane to the ceiling in the boiler installation area should be the same if the ceiling in the kitchen is built with a slope.

Installation of a gas boiler can be carried out in the following premises:

- volume 7.5 m³, if only one unit is to be operated;

- volume of 13.5 m³, if two heat generators are used in preparing the coolant and heating the water.

The cubic capacity of kitchens equipped with both boilers and gas stoves is calculated as the sum of 6.3 m³ plus 8, 12 or 15 m³ depending on the number of burners (2, 3 or 4 pieces).

The room for the location of gas equipment of any type must have its own source of natural light, i.e. window. The window must have a freely opening window. It is necessary for ventilation with a natural impulse to move the air mass.

There must certainly be a door limiting the kitchen space. However, it should not interfere with air flow.

Therefore, it is necessary to provide a ventilation grille at the bottom of the door leaf or leave a gap between the door leaf and the floor. The total area of the ventilation gap is at least 0.2 m².

In kitchens with a gas water heating unit, especially those equipped with atmospheric gas burners, there can only be natural ventilation. Forced options with mechanical stimulation and the addition of heated air are permissible only in the northern regions.

Features of boiler selection

Individual heat generators - factory-made water heating units - are suitable for installation in the kitchen. Both flow-through wall-mounted models and floor-mounted ones paired with boilers are applicable.

You should purchase automated equipment that can function without constant maintenance by the operator/owner.

The following water heating units can be used in the arrangement of apartment buildings:

- turbocharged, i.e. equipped with a sealed (closed) chamber for processing blue fuel;

- capable of heating the treated environment to 95º;

- operating under a pressure of 1 MPa;

- equipped automatic security.

Safety automation is needed to interrupt the gas supply to the burner in the event of a threatening situation. Threats include malfunction of protection circuits, a drop in pressure of heated water or coolant, flame extinction, and malfunctions in the smoke removal system.

In the same way, the automatic device will stop the operation of the boiler if the heated medium reaches the temperature set by the owner or the maximum permissible temperature.

In the kitchens of apartment buildings in our country, heat generators with an atmospheric (open) combustion chamber are traditionally installed. They heat water for owners of apartments in old housing stock, in which centralized hot water supply was not previously provided.

Fire prevention standards

Before deciding how and what is the best way to close a gas boiler installed in the kitchen, we will look at the rules for preventing accidental fire of adjacent or adjacent surfaces and structures.

To prevent and prevent danger, you need to:

- Provide a space of 2 cm from the walls of the flow-through wall-mounted boiler to all adjacent surfaces around the perimeter.

- Create a distance of 10 cm from the floor-standing boiler and cylinder water heater to the surfaces.

- Protect the walls of a building made of flammable material with plaster or cladding of non-combustible/hard-to-combustible finishing types. In this case, there must be at least 3 cm between the boiler and the wall.

When using tiles in wall decoration, it is allowed to reduce the distance from the walls when placing floor equipment. The geyser can be hung flush against a tiled wall.

The function of insulating flammable walls can be successfully performed by roofing tin on an asbestos sheet with a thickness of at least 3 mm. A similar tandem of tin and asbestos is laid on the floor before installing the floor model. The protective finish must be at least 10 cm larger than the outline of the insulated equipment.

All of the listed types of gaps and indentations are necessary for continuous cooling of water heating equipment.

Specifics of the location of the gas unit

Gas heating equipment is installed according to the design, which takes into account the type of wiring, the position of the expansion tank and circulation pump. If a wall-mounted device, for example, only prepares hot water for hygienic use, then place it as close as possible to the water collection point.

According to regulatory requirements:

- The distance between the column and the kitchen sink can be at least 30 cm.

- The distance between the wall-mounted water heater and the gas hob can be at least 10 cm.

- The distance between the floor heat generator and the refrigerator is specified by the boiler manufacturer. Usually, at least 30 cm is indicated. The same size is acceptable for other household electrical appliances.

- The distance from the top edge of the parapet boiler to the ceiling is at least 80 cm.

- The distance to the outlet required for powering volatile gas boiler systems must be at least 100 cm.

The most important rule that should be followed when installing any type of boiler is to ensure unobstructed access both directly to the unit itself and to the most important components that require regular inspection and maintenance.

It is strictly forbidden to lay the pipes through which blue fuel is transported to the devices in grooves or to cover it with non-dismountable boxes. Allowed to use camouflage structures with hinged or sliding doors, roller shutters, blinds.

Design achievements in the field of camouflage

In all cases and camouflage options, it is necessary to observe technological indentations and ensure full ventilation of the boiler. This means that those who want to hide heating equipment need to consider options for forming convective flows that cool the body.

Standard cabinet furniture for installation in the kitchen is usually not designed to hide a floor-standing or wall-mounted boiler model in one of its cabinets. True, there are headsets with a module designed just for this task. However, we are interested in other cases.

Let’s see if it’s possible to ideally hide a gas boiler in a homemade kitchen cabinet, and consider the best options that suggest how to do this work better and more correctly.

How to hide a wall-mounted boiler?

What if you need to match a kitchen cabinet that is not designed to conceal a boiler? The simplest answer involves disassembling it and cutting out holes at the bottom for connecting communications, and at the top for the chimney outlet. However, these measures are usually not enough.

Before upgrading a kitchen module, you should decide whether it is generally suitable for housing a gas heating or water heating unit inside it. To do this, you should study and actually measure the overall dimensions.

Between all the walls of the kitchen cabinet planned for remodeling and wall gas appliance should be at least 2 cm. If the unit will be hung on hooks close to a tiled or plastered wall, you will need to remove the back panel of the cabinet.

The best solution would be a frame made specifically for the gas apparatus, taking into account the necessary technological clearances and dimensions of the equipment. It is better to make this base welded metal, although it is easier and more accessible for the home craftsman to work with lumber.

It is enough to attach the doors from the kitchen cabinet to the frame. But it is better to make or order shutters with grilles or slats installed like blinds. As a result, the case will always be blown by air currents, cooled, and the device will function without interruption.

How to hide floor equipment?

Improving kitchen furniture to disguise a floor-standing unit is often not possible. The dimensions of the furniture module are usually too far from the ideal required to accommodate the heat generator with a full set of necessary gaps and indentations. In the home version, you will have to build a frame.

The indicated supporting structure must take into account that along the perimeter in plan, a distance of 10 cm should be taken from the body of the floor-standing boiler. There should be at least 30 cm between the top panel of the body and the upper edge of the frame. It is advisable to attach only the doors to the frame.

It is strictly forbidden to cover a floor-standing boiler with airtight panels. For normal operation of the burner there must be a continuous flow of air. Therefore, doors made of solid wood or chipboards must be equipped with ventilation holes.

Ideally, the doors for a camouflage cabinet should be lattice or made in the shape of blinds with wooden slats installed at an angle. The top panel installed on the frame must also have ventilation holes. They are needed for the exit of convective air currents.

If flammable materials are used in the manufacture of a camouflage box for a boiler, measures must be taken to eliminate the slightest threat. It is recommended to cover the side walls of the structure with asbestos and roofing tin. Unprotected areas must be treated with fire retardants.

In addition to the options listed, which admittedly are not the easiest to implement, there are methods available to most. This is pasting and painting the boiler body in compliance with the color scheme of the kitchen interior. It is possible to use decoupage techniques in the design.

What to do with communications and chimney?

Don’t forget about water, gas, chimney pipes and electrical wiring. The listed communications required for the operation of equipment for heating water or coolant look quite unattractive. Especially if they were built by an inexperienced and careless performer.

For the most part, communications for the operation of gas equipment cannot be masked due to the need for regular inspection and maintenance. The simplest method is to paint it with a suitable color paint or turn it into an original art object.

If the kitchen is being set up in a new building from scratch, you can think about the location of the boiler and furnishings in advance. In this case, you can make a partial change in the communication route. And the electrical wiring line in any case will have to be laid separately.

In a kitchen that has served its purpose, the water and gas supply pipes are decorated in a different way.Only boxes that provide unobstructed access directly to the pipes are applicable here. Access to the shut-off valves should not cause any difficulties. The best choice for this is a blind frame.

A coaxial chimney for a boiler with a closed burner can be hidden behind a stationary duct. An example of assembling a two-tier box will be demonstrated in the following photo gallery:

Do not forget that even such a reliable system as coaxial type smoke duct access must be guaranteed in case of replacement or repair. That is, it is necessary to leave the opportunity to disassemble the camouflage structure if necessary. It is advisable to use materials in the finishing that you won’t mind parting with before a complete replacement.

Conclusions and useful video on the topic

A visual demonstration of the process of masking a double-circuit boiler and pipes will help you understand the essence of the work:

The following video will introduce you to an elegant and stylish decoration option:

Using a furniture façade to hide a gas boiler is an excellent tip for those who would like to “fit” the equipment into a cabinet cabinet:

You can disguise a boiler located in the kitchen using any of the following methods. The main thing is not to forget about the ventilation gaps and the regular supply of air for the atmospheric burner. And it is important to create conditions for safe operation of the gas apparatus for others.

It is possible that you have a more interesting or simpler method of masking gas equipment in your arsenal. Share useful information in the block below. Leave comments there, ask questions, post photos related to the topic of the article.

The cabinet with lattice doors looks very nice. The main thing is that the gas workers don’t get to the bottom of it.