Do-it-yourself wood antiseptic: components and nuances of preparing an effective impregnation

Wood is susceptible to mold, mildew, and woodworms.A tree that is not protected with a special product succumbs to rot much faster and is destroyed under the influence of weather factors.

To protect it and extend its service life, you should treat it with high-quality antibacterial drugs, which do not necessarily need to be purchased in a store. You can make wood antiseptic with your own hands using cheap and readily available components.

In this material we will look at how to prepare impregnations from inexpensive chemicals at home. Here are simple recipes for protective drugs that can be used in both small and large quantities.

The content of the article:

Why do you need to process wood?

Treating wood with antiseptics is necessary to protect against pests, bacteria, and mold. Putrefactive microorganisms can change the natural structure of wood fibers in a short time, and fungal spores leave dark stains that cannot be removed.

With constant exposure to moisture, mold appears on wooden objects, which leads to their destruction. Molds have a detrimental effect on human health, and when harmful ergot is first detected, it is necessary to take drastic measures.

Antiseptic agents have a general toxic effect on wood borers, putrefactive microflora and cause their death.

When exposed to an antiseptic, a protective anaerobic film is formed on the wood, which is unfavorable for the life of parasites, which also becomes a barrier to the penetration of moisture and oxygen. Therefore, a wooden product (armchair, bed, bath etc.), a building (house, bathhouse) or structure (gazebo, summer bathhouse) will last longer.

There are different types of antiseptic impregnations for wood processing:

- Oily ideal for impregnating wooden facades, outbuildings, garden gazebos, fences, benches and more. These funds do not provide moisture penetrates into the wood and is an excellent pest control. Oil solutions have a specific odor, are toxic, flammable and are not recommended for use in enclosed spaces.

- Wax. The direct purpose of wax-based protective mastic is to protect decorative wooden surfaces and products. The shelf life of the wax antiseptic reaches one year.

- Water based. Excellent for processing interior wooden building structures and facades. The advantage is the absence of toxicity, absolute safety, and the absence of a pungent odor. If the composition contains fire retardants, then this treatment gives the wood fire-resistant properties.

- Based on organic compounds. Organic non-oil products contain isotopes of sodium and phenol. When dry, they form a thin protective layer that protects the wood from the destructive effects of moisture and scorching sun.

Organic antiseptics can also be used outside buildings.After complete drying, it is necessary to open the surface with varnish or apply a layer of paint.

According to the type of protection, antiseptics are divided into from rot and mold, And fire bioprotection (with fire retardants).

Impregnations are classified according to the degree of toxicity for internal And external works.

Provide comprehensive wood protection combined antiseptics. These products protect it from inflammation and moisture, and from damage by putrefactive microorganisms.

They contain copper sulfate, which helps disinfect wood, but at the same time changes its natural color.

The best homemade impregnation recipes

A worthy alternative to store-bought impregnations is homemade antiseptics. Their effectiveness has been tested by time.

All home-made impregnations have a number of advantages:

- financial savings;

- efficiency, especially if bitumen or vegetable oils are used;

- significantly lower degree of toxicity of the finished product.

Necessary personal protective equipment when preparing homemade antiseptic: rubber gloves, shoes, respirator, robe, apron or special suit, glasses.

No. 1. Oil-based products

Oil-based protective products do not cause allergies when used. When processed internally, they add shine to wood surfaces.

For homemade impregnation, hemp or linseed oils, bitumen, and motor oil (used) are used.

A self-made antiseptic based on oils has proven itself excellent for both external and internal use. To make it, they mainly use technical varieties of linseed oil, which by its natural properties is a water-resistant polymer. To improve the quality and properties of the drug, extracts of burdock, elecampane or galangal are added.

The protective bitumen agent has several positive properties:

- availability of bitumen;

- Possibility of use in environments with high humidity levels;

- In addition to general biological protection, impregnation gives the wood hydrophobic properties.

Protective properties are maintained for a long period of time. The penetration depth of the impregnation is about 7 millimeters.

The bitumen agent is applied to the surface with a regular paint brush. After complete drying, it is necessary to open the wooden structure with oil paint. Under no circumstances should paint materials containing cellulose nitrate be opened.

Bitumen impregnation No. 1

A bitumen-based antiseptic helps preserve poorly dried wood. Glubokoye penetrates into the thickness of the wood material and at the same time allows it to “breathe”.

The technology for preparing the liquid mixture is simple.In a metal container, 1.5 - 2 kg of bitumen (depending on thickness) is heated to a temperature close to boiling.

Then the heating is stopped, removed from the heat and 1 liter of diesel fuel is added to the bitumen mass, mixed until a liquid consistency is obtained, which will remain fluid even after complete cooling.

Bitumen impregnation No. 2

If it is not possible to produce impregnation using this method, then diesel fuel can be replaced with active solvents - kerosene or high-octane gasoline. During production, the above proportions are observed: for 1.5-2 kg of bitumen, take 1 liter of gasoline/kerosene.

This method of creating a fast-drying, deep-penetration preparation based on bitumen does not require heating - just stir until it is completely dissolved.

No. 2. Water-based impregnations

The most popular water antiseptics made at home are using sodium fluoride and copper sulfate.

Recipe #1 - antiseptic with sodium fluoride

One of the safest for humans and domestic mammals is a low-toxic antiseptic based on sodium fluoride. The required concentration of the finished solution is from 0.5 to 4%.

The entire manufacturing process of this protective impregnation consists of stirring until the substance is completely dissolved in hot water.

When making impregnation, the following proportion must be observed:

- sodium fluoride - 50–400 grams;

- hot water - 10 liters.

To work indoors, the concentration of the solution should be less saturated, and outside it should be much stronger.To be sure of the accuracy of the concentration, you can use potassium permanganate as a marker, which will act as a litmus test and give a textured, visually visible coloring of the wood, which disappears after the surface dries.

An aqueous solution of sodium fluoride is mainly used to treat exterior wood surfaces that do not touch the ground. The effect will last longer if you open them with varnish. This will prevent protective substances from being washed away by rain, melt water and snow.

To treat monumental wooden structures made of wood that are in direct contact with the ground, you can use an aqueous solution based on copper sulfate.

Recipe #2 - impregnation with copper sulfate

It is safer to prepare impregnation for wood based on copper sulfate in a closed container, as harmful fumes are released.

Required components:

- copper sulfate - 200 milligrams;

- potassium permanganate - 20 grams;

- water - 20 liters.

To prepare this solution, you must thoroughly mix these ingredients. For greater convenience and to obtain a homogeneous consistency, it is better to mix in a plastic canister.

Recipe #3 - antiseptic from vitriol and sodium bichromate

Ingredients:

- copper sulfate powder - 0.5 kg;

- sodium bichromate - 0.5 kg;

- warm water - 9 liters;

- vinegar 9% - 50 grams.

Mix all the ingredients and fill with water heated to 50 °C. Mix everything thoroughly and the solution is ready for use.

No. 3. Wax-based antiseptic

Wax not only protects the surface from moisture penetration into the wood and from possible mechanical damage, but also emphasizes the texture and gives it a lasting, pleasant aroma.

Components:

- wax - 100 grams;

- crushed rosin - 25 grams;

- turpentine - 50 milliliters.

The wax is heated in a water bath, then 25 grams of crushed rosin and 50 grams of turpentine are added there. The resulting mass should be brought to a boil, removed from heat and wait until it cools completely.

Dry mint or propolis are good shock absorbers that will give the mastic a pleasant aroma. Rub the product in with a lint-free cloth until a shine appears on the wood.

Tips for applying impregnation

Before starting work, it is advisable to more thoroughly prepare the surface on which the composition will be applied. Clean from dust and other contaminants and sand. Pre-treat existing cracks with white spirit and prime with alkyd primer.

Long-handled synthetic brushes or felt rollers are ideal for applying oil liquid. Excess must be removed with a soft, lint-free cloth. Repeat the manipulation in 1-2 steps.

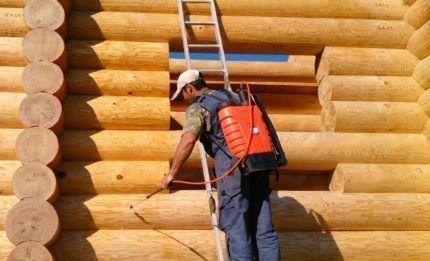

Thick antiseptics are applied with a regular paint brush, sponge or soft rag, or a lint-free roller, while liquid ones are best applied with a spray gun.

Designate a special area for work. Prepare in advance all the tools, personal protective equipment and buy the missing items.

Internal wood impregnation work is permissible in well-ventilated areas.

If desired, you can also use the old method to protect wood, which practically eliminates costs - burning or digestion in saline solution.

You can also impregnate wood using traditional methods - birch tar, flax oil, pine resin mixed with crushed coal and salt.

Conclusions and useful video on the topic

Recipe for preparing wood impregnation:

Detailed instructions for making impregnation for fire-bioprotection at home are in the following video:

Wood has always been in demand and people have invented various ways to protect it from pests and minimize the harmful effects of precipitation, high and low temperatures. You can use both purchased products and make your own using natural ingredients, most of which are available on the farm.

What antiseptic do you use? Share your recipe for the perfect impregnation, which is easy to prepare yourself - the comment form is located below. If you have questions about wood preservatives or application nuances, ask our experts and other site visitors.

The simplest time-tested antiseptic is a mixture of liquid glass and water... Proportions 1/1 to 1/2... Even damp boards if you paint them with this composition... They will lie in a damp basement and will be fresh... Try it... You can apply it with a brush or spray... You should not make such a mixture thick... Because with a large concentration, a shine may appear on the caresses... This is an old, half-forgotten method of antiseptic wood..

liquid glass will only last for 3-4 years

Please re-read your recipes. The cheapest, I think, is 200 milligrams of copper sulfate per 20 liters of water.

Cheap, though.

Most likely 200 grams of copper sulfate (1% solution, but 3% solution is better), but not a milligram.