We make nests for laying hens with our own hands: drawings, diagrams, photos

The health and productivity of the bird, as well as the safety of the eggs, depend on how well the nests for laying hens are made.Outwardly, everything is simple, a nest for laying hens is more like a box with or without bedding. But it is its construction that takes the most time and attention in the process of building a chicken coop.

The content of the article:

Requirements for nests for chickens

It is very important that birds are not afraid and do not ignore the nest-cells made for them. Sometimes chicken coop owners are outraged by the behavior of laying hens who do not like the new plastic or wooden trays at all. Eggs are found everywhere, but not in nests built for them.

There may be several reasons for this behavior of chickens, but most often either the nests are poorly located in the chicken coop, or the laying hens do not feel safe. For example, the smell or the wrong size of the nest may deter.

In order for laying hens to get used to and use the nests for their intended purpose, it is necessary that the arrangement of the trays meet the minimum requirements:

- The size of the box did not restrict the bird’s movement; it could stand up to its full height or, if necessary, turn around inside it.

- Normal air temperature, stable air flow. A hen that has experienced stress, heat, or extreme cold coming from the wall of the coop will never choose that nest again.

- The bottom of the tray can be designed in different ways; most often it is made perforated or mesh to avoid the litter from becoming damp.

- Laying areas should not be exposed to direct light.

Sunlight from windows or red lamp radiation should not fall on the nests. This always leads to overheating of the bird. The hen can simply leave and lay an egg in a completely inappropriate place.

Therefore, you need to check the nests in the chicken coop with your own hands more often, pick up the eggs if possible, or use trays with an additional tray to collect them.

In addition, the design should provide easy entry and placement of the hen inside the box, without exorbitant high jumps or transitions along the perches at the cells.

And the well-being and productivity of laying hens largely depend on such little things as the quality of the litter. Hay (dried grass) lined with fresh straw usually works best. The hay is soft, well ventilated, and prevents the egg from rolling around the nest.

The straw is hard, holds the shape of the nest well, and prevents the hen from tearing and throwing the litter out of the box. Chickens often perform similar procedures when they are not happy with something or are bothered by parasites.

Where is the correct place to place nests?

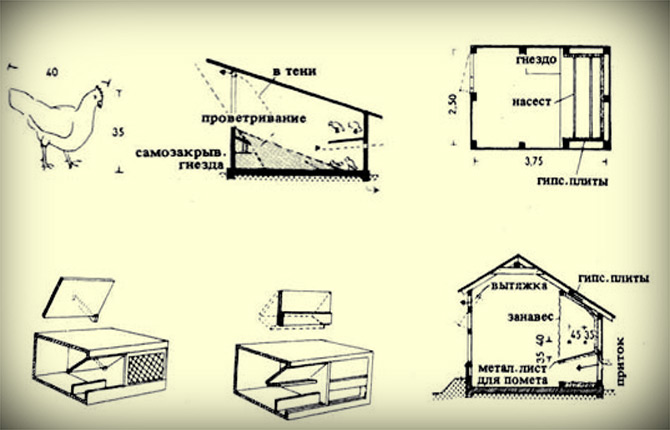

In small chicken coops, places for laying hens are hidden in separate niches or boxes cut into the wall at a height of 40-50 cm above floor level. The niche is equipped with a hatch on the outside of the wall, which makes it possible to take eggs from the nest without scaring other laying hens.

As a rule, the chicken coop is installed so that the niche is protected from wind and sunlight, the walls around the nest are insulated with mineral wool.This protects the birds from temperature changes and noise.

Where to put nests in a large chicken coop

The choice of location is determined by the size of the house and its orientation relative to the wind rose. Inside a large chicken coop, boxes with nests are placed on walls with window openings, possibly closer to the exit or to the supply air vent.

In summer chicken coops, nests are most often moved closer to the front door, sometimes even placed on the floor to improve ventilation of the nest. It is clear that if the floor is adobe, then the boxes are installed on boards or gratings made from slats. This is necessary to ensure air flow to the nest from below, but to avoid dampness.

In the case of raising broilers, it is better to abandon wall nests or make special ladders from boards. Laying hens of this breed are easily injured when they jump unsuccessfully or fall from a small height.

Types of structures and their implementation

Each summer resident tries to make his own version of nests for laying hens. If there are a lot of chickens on the farm, it is possible to make several models of different types and sizes. But you shouldn’t get carried away with construction. The optimal rate is three birds per nest.Even if you make more nests, the hens will still choose a few of the most convenient ones, while the rest of the trays will stand idle.

There are quite a lot of possible nest options:

- open drawers;

- cells with mesh floor;

- mesh with industrial-type trays;

- all kinds of plastic containers converted into boxes with bedding;

- blocks with semi-automatic accumulation of eggs.

The most common options include buckets, containers for liquid products, and plastic boxes attached to the wall in any way.

You can buy a ready-made box for a nest for a laying hen. As a rule, they are made of polyvinyl chloride plastic and, judging by reviews, are not very comfortable for chickens.

Many laying hens simply ignore them because of the smell and the very inconvenient slippery lid on the egg receptacle. In addition, the plastic resonates strongly even with little noise in the coop, which always frightens the laying hens.

Box-shaped

More recently, when there were not so many plastic containers in use, nests for village chicken coops were made in the form of wooden boxes or woven from wicker.

Wicker seats made from wicker were considered the best option due to their lightweight and durable construction. Laying hens willingly used baskets filled with sawdust and straw. The litter did not fall out, it can be replaced in a matter of seconds.But the price of hand-woven baskets has increased sharply, so wicker has almost ceased to be used in chicken coops.

Boxes are always a summer option, nests made of plywood and boards were installed for laying hens at the entrance to the hen house, sometimes even under a canopy if it is too hot inside the house.

Portable (adjustable) include relatively new designs of boxes with a mesh bottom and a tray for collecting eggs. A stainless steel tray is used together with the nest box. The mesh provides good ventilation and easy cleaning of the nest from droppings.

For example, in the winter, when chickens lay eggs much worse and the need for laying boxes is reduced several times. Instead, in early spring, boxes are installed for newly hatched chicks. And after a couple of months, the boxes are reinstalled under a canopy or inside the chicken coop.

Cellular structures

They are used only for raising birds for eggs or hatching chickens. Laying hens can be kept several at a time inside a cage, but most often it is one or at most two hens. There is no nest as such; it is replaced by a rather thick bedding of sawdust and straw.

Home cages allow you to control laying hens, select eggs, and leave some part for hatching chicks without injuring the hens. Such designs are fundamentally different from cage nets for chickens (without walking).

This is semi-industrial equipment for home farms for the purpose of producing eggs in commercial quantities. There are no nests inside the cages, the chickens are not raised, but purchased from incubators.

It is believed that cage housing ensures high bird productivity, at least twice as much as when laying hens use traditional nests.

But the cellular scheme has two significant drawbacks. Firstly, the quality of the eggs is much lower than when the hen lays them on the litter. Secondly, chickens require serious support with vitamins and medications, but they still get sick much more, and the productive life of the bird is reduced by 30-40%.

Block options

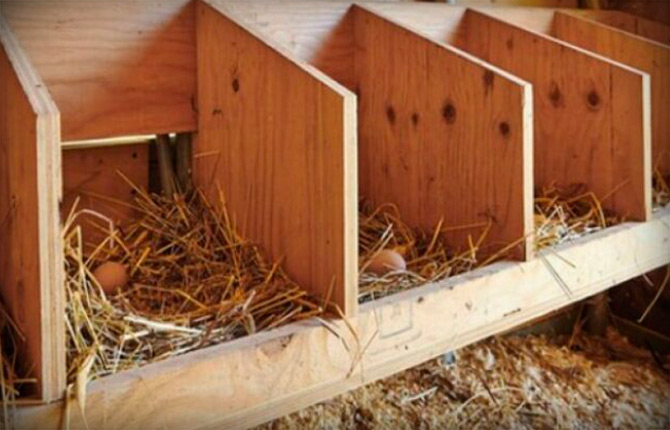

The most common scheme for arranging nests. The main difference from boxes and cages is that each laying hen is allocated a separate tray or niche with walls and a roof. Inside the block there can be from 5 to 10 compartments for birds.

By design, block options can be equipped with a roof or not. In the first case, the nests are located quite low above the floor level of the chicken coop.

Full-size blocks of several sections in a row are traditionally assembled in the form of a cabinet or mounted on the wall of a chicken coop in several tiers.

One common pole must be installed in front of each row, and a ladder is even installed so that the hens can climb to the place without jumping.

Most block circuits are made from OSB or boards, less often from more expensive plywood. In terms of their structure, they are almost identical, differing only in the design and size of the cells.

In simple blocks, the nests are made according to the classical design: from hay, sawdust and straw. The eggs remain on the litter. Every time you have to check whether the laying hen has broken an egg, this happens quite often. It is not recommended to leave eggs in the nest, as the next laying hen may simply peck or break it.

Improved nests for laying hens

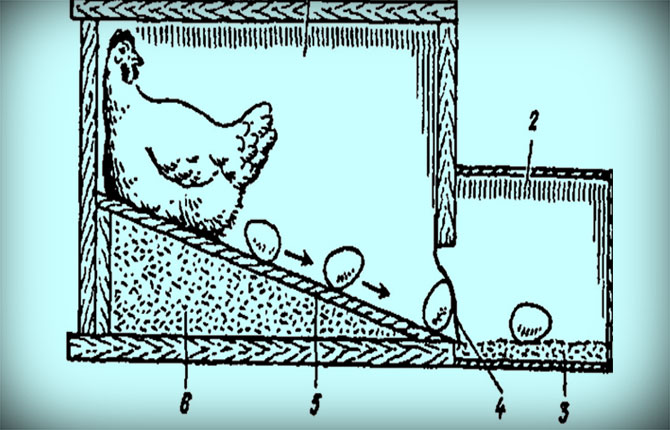

Many chicken coop owners prefer blocks with semi-automatic egg harvesting. The essence of the scheme is that the floor inside the section is inclined. The slope is usually made in the direction of the entrance to the nest.

There is not enough space inside the nest for an adult laying hen. But this is the main trick of the design. The calculation is made on the fact that while the hen turns around in a tight box, the egg will have time to roll down the slope into the net. You can’t get it here; the mesh is closed on top with a hinged lid.

A lining of soft material is placed directly in front of the mesh; it slows down the egg so that it does not break when it hits the metal mesh side.

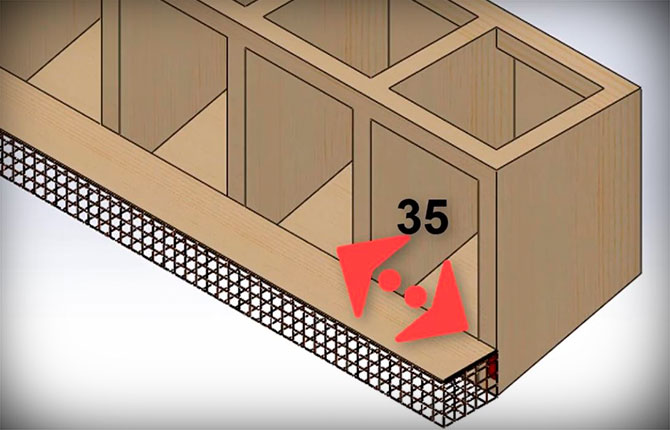

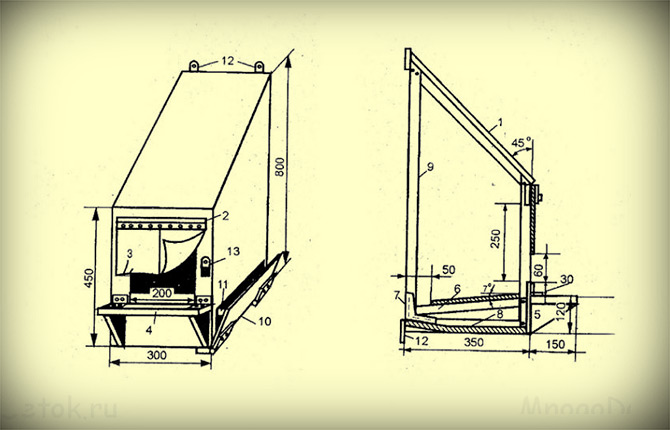

The block into several sections is assembled using a frame method. First, they knock down a frame of four longitudinal beams with a cross-section of 50x50 mm and 15 pieces of crossbars from a 50x20 mm lath.Moreover, the front (front) slats must be 40 mm longer than the rear ones, so that the floor inside the nest is sloping.

The result is a structure reminiscent of a mezzanine shelf, but more massive. The floor and partitions are sewn inside the block. This is a prerequisite for all designs.

Next, 20 cm pieces of timber are stuffed onto the front vertical posts in the lower part. It turns out to be a kind of cornice onto which the egg receptacle mesh is pulled and fixed. An additional strip must be placed along the upper edge of the cornice. It is needed so that the hen can safely enter the place inside.

Reverse floor nest

Most sloping floor schemes have one drawback. The eggs that roll out move in the same direction as the hen leaving the nest. That is, if the bird is not large, then it can have time to turn around and step on the egg before it rolls into the net.

Therefore, for young chickens it is better to make structures with a reverse slope of the floor, not forward, but back, towards the rear wall of the box.

With egg receptacle and double bottom

Many chicken coop owners make improved nest blocks for laying hens with automatic egg collection and a removable bottom. In fact, all block structures have one serious flaw. With nests constructed this way, it is quite difficult to remove droppings and debris from them, although laying hens rarely ignore block nests.

The tray itself for receiving eggs is lined from the inside with soft fabric, and a film “curtain” cut into petals is installed at the entrance. All this allows you to smoothly reduce the speed of egg rolling.

The nest itself is much larger, depth - 52 cm, width of the box - 62 cm. There is much more space, so the hens are more comfortable than in traditional tray nests.

The peculiarity of this scheme is its double bottom. The main (top) is made of nickel-plated steel mesh, the bottom is usually made of wood, lined with plastic. If necessary, the upper bottom can be removed and the droppings and debris can be thoroughly cleaned from the lower one.

The only disadvantage of such a nest - these are its dimensions. It can only be used for large chicken coops with at least two dozen laying hens.

Main plus — a fairly high level of comfort for laying hens. The less stress birds experience while laying eggs, the less sick they are and the better they gain weight.

With egg container

Another nest option with quick removal of the egg into a special container. Today this is one of the best projects of all known designs.

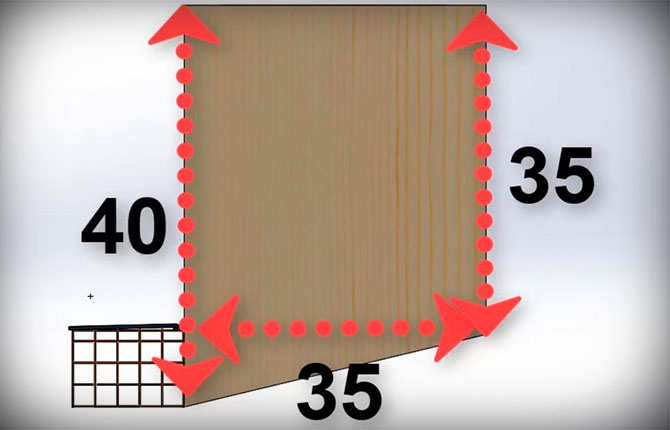

Two side walls are cut out in a rectangular shape, measuring 40x50 cm.Using self-tapping screws and a screwdriver, assemble the drawer and bedside table, but without the bottom. The bottom will have to be done separately.

The box is assembled end-to-end, without any additional frame made of slats.

Each of the four triangles will be installed with a slope towards the center (towards the egg collector).

The bottom is attached inside the nest using ordinary carpentry screws. Before fastening, the bottom will need to be carefully leveled so that it is horizontal relative to the walls.

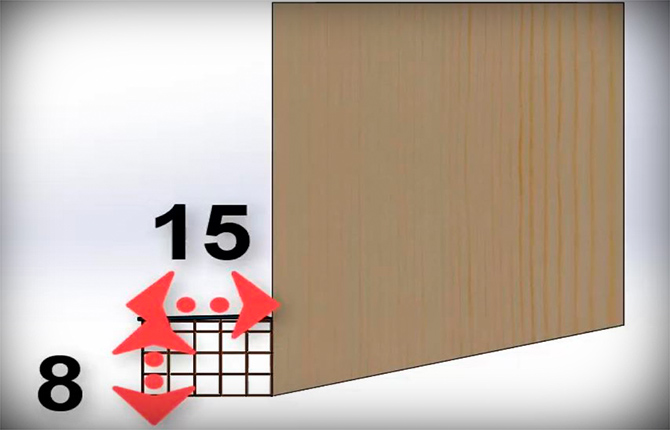

You can use a drawer from an old bedside table as a container, or make a box yourself. Inside you need to glue a soft material - padding polyester or foam rubber. Eggs fall from a height of 8-10 cm, so the surface should be soft and absorb the fall as much as possible.

All that remains is to glue the cup into the hole, install the container and carry out the tests. According to statistics, only in one case out of 200 the egg receives minor damage.

Advantages of the socket of this circuit:

- simple design;

- large internal space, the hen has a lot of free space, so the bird is not in danger of overheating;

- huge entrance, the laying hen can jump into place directly from the floor of the chicken coop;

- compact sizes.

In addition, in this project the eggs are securely protected and hidden in a container. If in previous options they remained in the net and could be damaged, then container storage reliably protects them even from known pests, which often climb into the chicken coop at night.

The small weight and dimensions allow you to store the nests in the utility room; you can leave a couple of nests inside the chicken coop, clean the rest and preserve them in the barn for the winter. With the start of the season in early spring, the nests are moved and installed in the chicken coop, and with the arrival of summer, boxes for laying hens can be placed under a canopy in a cool place, protected from light.

Swivel bottom design

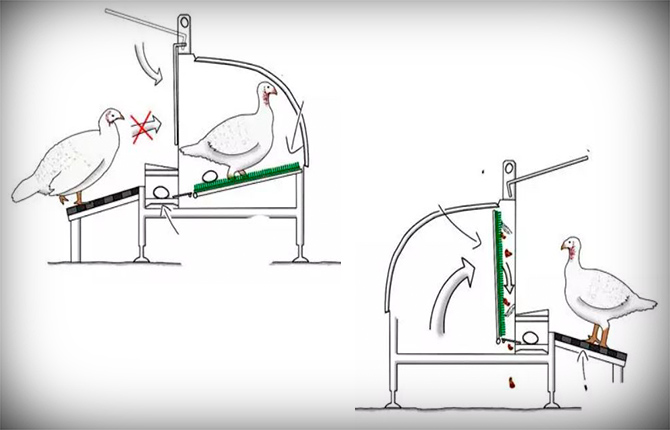

One of the desires of chicken coop owners is to automate the process of cleaning the box. Therefore, all kinds of projects are being developed in which droppings are removed due to the movement and weight of the hen.

One such nest design is shown in the diagram below.

According to the authors, as soon as the hen goes inside, the floor will lower and stand on a stand. After the bird leaves the room, the bottom should rise, the egg will roll into the egg receptacle, and debris and droppings will automatically fall into the hopper for cleaning.

Results

Making comfortable nests for laying hens with your own hands is not that difficult, even for a novice amateur carpenter. There are drawings, the material can also be purchased, all that is required is to correctly cut and assemble the design parts.

Tell us about your experience building places for laying hens.Which of them, in your opinion, turned out to be the most successful? Also share the article on social networks and bookmark it.

In my village I saw one summer resident’s nests piled in the entryway of his dacha. Chickens live and feed in a chicken coop, and lay eggs indoors. The neighbor says it took two weeks to get used to it, but now nothing has gotten better, they’ll carry on until late autumn.

All these automatic things only scare the bird. This is good in theory, but nonsense in practice. My chickens lay eggs only on open boxes, with bedding and on the floor.