Two-pole and three-pole switches: purpose, characteristics, installation features

The purpose of circuit breakers introduced into electrical network circuits concerns protective functions.If you use a hand-held device during network overload, the likelihood of significant equipment damage increases significantly.

Automatic two-pole and three-pole switches reduce such risks to a minimum, as they provide instant circuit breakage in case of an accident.

We will understand the features of electric machines, and provide tips on choosing, installing and operating such devices.

The content of the article:

Design of circuit breakers

In the practice of using such equipment, there is a frequent use of three types of devices: single-pole, two-pole, three-pole.

What is the difference between these three types of slot machines? Let's try to figure it out.

A single-pole device, in general, does not raise any special questions. If you implement switch single-phase circuit, then the device will work like a regular switch, only in automatic response mode - that is, without user intervention, it will break the circuit in case of violation of the specified operating conditions.

Brief characteristics of a two-terminal network

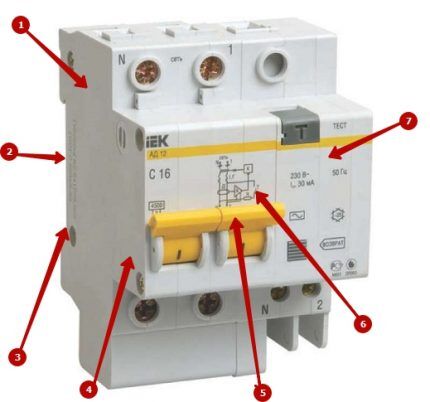

A similar device, but designed in the form of a two-pole circuit breaker, is slightly different in functionality.

The circuitry of the two-pole device is made taking into account the control and comparison of the operating conditions of two independent current lines.

Two-pole circuit breakers are used, as a rule, for implementation in electrical network construction projects, when it is necessary to control and compare the operating conditions of two sections of a single electrical network. Essentially, the two-pole device configuration is a tandem of a pair of single-pole devices.

However, the two-terminal circuit protection and blocking circuit works on the principle of comparing the parameters of each device separately, in real time. If in any of the two control sections the parameters go beyond the settings, both lines are immediately broken.

This important point shows: replacing a two-pole machine with a pair of conventional single-pole devices is impossible in principle. In case of overload of one of the circuits (or short circuit), only one circuit breaker will operate.

But given that the electrical network is unified, electricity will continue to flow through the second device powering another section. Such a situation leads to dire consequences.

Meanwhile, there are two subtypes of two-pole devices:

- with single pole protection and normal neutral switching;

- with protection of both poles and their simultaneous switching.

The former are usually used as input machines, thanks to which phase and neutral conductors are switched. Moreover, this connection scheme involves the use of an additional PE line - a grounding wire.

The latter are used in circuits of one network, where two sections operating under conditions of different current loads are powered.

Features of the three-terminal device

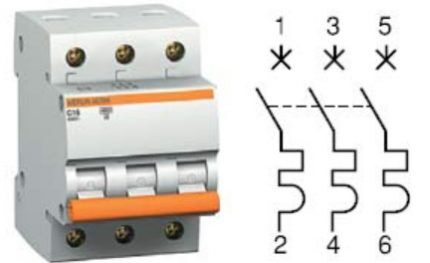

The main purpose of a three-pole circuit breaker is to use three-phase networks in circuits. The design features of this type of device include the presence of protective functions on each individual pole.

Triggering of the protection on any of the poles leads to the opening of all poles.

Despite the specific purpose of machines of this type, it is quite acceptable to use them on single-phase or two-phase lines.

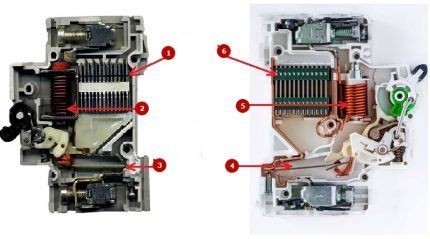

Structurally, a three-pole circuit breaker contains the following elements:

- control mechanism;

- contact system;

- arc extinguishing module;

- release device.

Free contacts are usually mounted inside the device cover. The contact system is connected to the traverse of the main contacts kinematically.

The functional components of the device are mounted inside the housing. The cover and body of the machine are made of materials that do not allow electric current to pass through (plastic, textolite, etc.).

The three-terminal protection mechanism ensures instantaneous shutdown, both in the “auto” mode and in the case of manual action. Moreover, if there is an overload in the electrical circuit, instantaneous shutdown occurs regardless of the force on the control handle.

That is, even if the user holds the handle in the on state, the machine will still open all poles in overload mode.

There are modifications of three-terminal networks, where one more pole is added for the neutral conductor. In fact, we are talking about a four-pole design in terms of structural details.

Functionally, a four-pole machine resembles a two-pole system. The task of the device is the same, only in relation to a three-phase network.

Generalized technical characteristics of machines

Information about the main parameters of the circuit breakers is indicated on its body. To understand alphanumeric notations, you must be able to “read” device markings.

Widely used in everyday life and industry are devices that meet the following basic technical characteristics, depending on their design:

| Machine configuration | 1-pole | 2-pole | 3-pole |

| DC voltage, V | 240 | 440 | 600 |

| AC voltage, V | 380 | 380 | 660 |

| Rated current, A | 0,6 — 100 | 0,6 — 100 | 0,6 — 100 |

| Independent release voltage, V | 24 — 440 | 24 — 440 | 24 — 440 |

| Standard ambient temperature, ºС | -25 / +60 | -25 / +60 | -25 / +60 |

Devices are selected according to certain criteria, including voltage, rated current, temperature indicators.

Read more about choosing circuit breakers in the following articles:

- Selecting a circuit breaker: types and characteristics of electrical circuit breakers

- Selecting a machine based on load power, cable cross-section and current: principles and formulas for calculations

Installation details of switches

For all electrical devices of this design, the order of implementation into the electrical circuit is determined.

The established procedure, in particular, requires the following actions by installers before two-pole and three-pole switches are installed:

- the device must correspond to the design for the current circuit;

- the machine body is free from deformation and damage;

- The on/off lever works clearly in manual activation mode.

The base on which the device is supposed to be installed must be checked for evenness of the surface. Installation on bases where, due to the uneven surface after mounting, the machine body is subject to bending stresses is not allowed.

Connection to network conductors

Connecting copper conductors with a cross section of 16 - 25 mm2, performed through cable lugs (GOST 9688-82). If it is necessary to make a connection with copper conductors with a cross-section of 4 - 16 mm2, cable lugs of a different type are used (GOST 7386-80).

In relation to connections of aluminum wires, end elements similar to TAM-7 are used, corresponding to the parameters GOST 9581-80.

The network conductors supplying voltage from the power source are connected to the upper group of fixed contacts of the circuit breakers. It is necessary to supply and connect conductors so that they do not create forces on the terminals of the machine.

The tips should be tightened tightly with contact clamps, but without extreme force that could lead to thread failure. The termination of conductors in cable lugs should be given great care. Be sure to use insulating tubes and tape as a protective sheath.

Nuances of placement and fastening

When installing several pieces of equipment, it is necessary to follow the rules for arranging the devices relative to each other. Thus, the distance between closely located devices should be maintained at least 5 mm.

Minimum distances from metal parts of switchgears: from above 30 - 50 mm, from the side 5 - 10 mm, depending on the magnitude of the supplied voltage.

If the installation uses devices that are structurally made in an additional shell, all installation manipulations with them are carried out with the shell cover removed. The installation of the cover is carried out taking into account the correct insertion of the drive mechanism. The cover is fastened with screws evenly.

Upon completion of installation, the machines must be checked for clarity of the moment of switching on/off.

Wiring diagrams and rules for connecting the switch are described in detail in this article.

Maintenance during operation

Normal operating conditions of two-pole and three-pole circuit breakers make it possible to allocate time for technical inspection of devices no more than once during three years of operation. This fact once again confirms the high quality of execution of almost any machines.

Meanwhile, according to the instructions, a technical inspection must be performed if the circuit breaker has tripped due to a short circuit current.

For any reason, be it a device triggered in an emergency or scheduled maintenance, technical inspection of devices includes:

- diagnosing the on/off mechanism in manual mode without load;

- checking the tightening of the screws of the main and free contacts;

- reliability of fastening the device to the base;

- cleaning from dirt and foreign objects;

- simulating shutdown by mechanical impact on the sensitive element;

- performance check in operating mode.

The practice of using electrical networks marks the handling of devices from different manufacturers, including domestic and foreign.

The majority of all automatic protection devices in use are characterized by impeccable performance in terms of quality.

Conclusions and useful video on the topic

What are slot machines and how they differ can be found in the following video:

About the selection criteria for protective devices:

The reliability of automatic locking devices is often determined not by the brand, but by the correct selection taking into account the workload. Also, the precise calculation of the cross-section of the conductors supplying the load from the machine and the calculation of the cross-section of the input cable have a significant impact on the operation of the devices.

When all the installation nuances are taken into account, even Chinese devices, which are several times cheaper than branded ones, work for a fairly long period of time without any particular complaints.

Share with readers your experience in connecting two-pole and three-pole switches. Please leave comments, ask questions about the topic of the article and participate in discussions - the feedback form is located below.