How to fix a toilet to the floor: a review of technical details and the best installation methods

Equipping a modern home with a toilet room is a traditional touch of any project.In turn, installing a toilet in a toilet is also a long-established procedure. Installation is usually performed by default during residential construction.

We will tell you how to fix the toilet to the floor. Together with you, we will analyze which method of fixing plumbing fixtures is best to use if you suddenly have to change the device during operation. Taking into account our advice, you can quickly and easily complete the work without involving a plumber.

The content of the article:

Technical nuances of plumbing installation

A toilet of any configuration, like a plumbing fixture in general, is installed in accordance with the installation instructions. The initial installation of these plumbing fixtures (during the housing construction stage) is usually carried out by professional contractors.

But in the future, already established property owners often reconstruct the toilet, in particular, change the toilet. And they do it themselves in order to save on installation services.

Users often change equipment to suit personal preferences. Some of them do not know all the nuances of installation and fastening methods.

Self-reinstallation is not prohibited and is encouraged. However, such intentions of the owner must at least be accompanied by knowledge of methods for attaching the toilet to the floor.It would seem like a trivial detail of the installation procedure, but when they want to see a high-quality, reliable installation as a result, even the smallest details are important.

The nuances of installing toilets are directly related to the choice for installation type of plumbing fixtures. In everyday life, floor-mounted toilets are most often used. At the same time, most of the mounted devices have a compact product configuration.

How to fix a compact and any other toilet to the floor of the toilet room, doing the installation yourself?

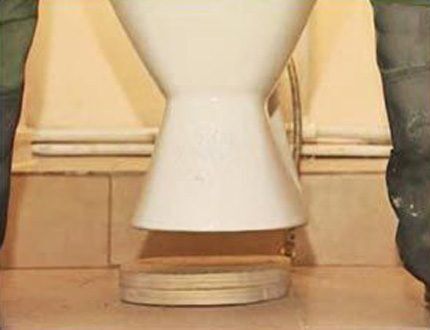

Self-taught craftsmen should strive for approximately this result.

Analysis of fastening methods

Construction practice indicates at least three methods of attaching toilets to the floor surface:

- standard installation kit;

- by using special adhesives;

- by installation on cement mortar.

The standard installation kit (dowel-screw) is usually recommended for use as long as it is installed on an extremely flat floor surface.

The method, from the point of view of reliability and stability of the structure, is considered acceptable, but does not completely satisfy in all cases. We usually apply the “standard” to compact models that have light weight and modest dimensions.

Another method of attaching the toilet to the floor is glue mounting, which provides a high level of joint strength. But in this case, quick dismantling of the product if necessary is excluded.Therefore, the adhesive installation method is used where installation involves long-term use of plumbing fixtures without the prospect of replacing them.

Epoxy resin is often used as an adhesive. This glue is distinguished by high characteristics in terms of reliability and strength of fastening.

Cement mortar is often considered as an alternative to the standard and adhesive methods. In fact, this method is not much different from “planting with glue”, since cement contains an adhesive component. Meanwhile, connecting the toilet to the floor with cement mortar shows a lower degree of strength compared to special-purpose adhesives.

The choice of fastening method largely depends on the type of base on which the installation is being made. About how to put toilet on wood floor, learn from the article, which covers this issue in detail.

Technology for attaching the toilet to the floor

When turning to one or another method of attaching a home appliance to the floor, the master will need a certain set of tools.

Usually, work is carried out without much difficulty when you have at hand:

- construction hammer drill (plus a set of drills of different diameters);

- hand drill (plus drills of different diameters for ceramics);

- manual mechanical press (pistol-push);

- screwdrivers, bench wrenches, pliers, hammer;

- tape measure, pencil, core, rubber spatulas (wide, narrow);

- sandpaper (coarse, fine).

Possible materials for plumbing installation:

- plastic dowels (d=8-12 mm, 2-4 pcs.);

- metal screws (d=6-8 mm, 2-4 pcs.);

- gaskets for the screw head (2-4 pcs.);

- glue (liquid nails, silicone, epoxy);

- cement, quarry sand (at a ratio of 1:2);

- wooden board (thickness 20-25 mm);

- sheet rubber (thickness 10-15 mm).

Installing a toilet and attaching this type of plumbing to the floor with standard fasteners involves drilling holes for dowels. If the configuration of the plumbing fixture is made for fastening with two screws (screws), you need to drill two holes. In another case, respectively, four.

Some difficulties accompany the drilling process when put the toilet on the tiles. Careless action, lack of experience, ignorance of the technology for drilling holes in ceramic tiles are the main reasons for installation failures. You need to drill ceramics with a special drill, observing the rule of gentle pressure and low drill speed.

Installation followed by fastening with cement mortar also has its own characteristics. Here, an important factor determining the quality of the connection is the composition of the solution. Therefore, it is recommended to adhere as closely as possible to the established ratio of 1:2 (M200), where the first number is the amount of cement, the second is the amount of quarry sand.

With this ratio, the grade of cement mortar obtained is M200, which is optimal for use in domestic conditions.

Fastening with cement mortar is rarely practiced in modern construction conditions.

Step-by-step screw fastening process

If you choose the first option for attaching the toilet to the floor of the toilet room (standard with screws), the following steps are performed:

- The exact location on the floor of the sole of the plumbing fixture is determined.

- Marks are made of the centers of the mounting holes on the surface of the coating.

- Using a drill for ceramic tiles, holes are drilled at the marked centers with a depth equal to the thickness of the tile.

- Using a concrete drill, holes are drilled to the required depth (usually 60-70 mm).

- Dowels from the fastening kit are inserted into the resulting holes.

- The plumbing fixtures are placed at the installation site, and the installation holes of the device are aligned with the holes made in the floor.

- The outlet pipe of the toilet bowl is connected to the sewage system with a corrugated hose.

- The device is secured to the floor using screws from the mounting kit.

After completing this work, the connection points are additionally sealed corrugated pipe to the toilet and to the sewerage system. For these purposes, sealant or similar products are used. Cosmetic sealing of cracks along the axis of connection between the sole of the device and the floor plane, if any, is also performed.

Installing the toilet and attaching it to the floor using the second method is considered to be as simplified as possible. Here, the “do-it-yourself” master does not even need skills or knowledge regarding drilling various types of building materials.

All that may be required is instructions for working with a manual mechanical press (push gun). And when epoxy resin is used as glue, installers can do without a “gun.”

The process of installing and securing a toilet using screws includes a number of traditional steps:

Having successfully completed the preparatory work, we proceed directly to the installation and fastening of an important household appliance:

Gluing the toilet to the floor

The work of securing the sole of the device to the floor with special glue is carried out in the following sequence:

- Accurate marking of the toilet seat.

- Preparing the base of the device (cleaning, leveling, degreasing).

- Applying adhesive mass to the surface of the sole.

- Installation of the device exactly according to the previously designated boundaries.

Under the weight of the plumbing, excess glue will inevitably appear along the outer edges of the sole. This excess is removed with a rubber spatula, after which the area where the glue residue comes out is additionally wiped with a rag soaked in soapy water.

Having completed the procedure, leave the plumbing for a day until it is completely fixed due to the drying of the adhesive mass.

Work is carried out using approximately the same algorithm when the method of fastening to cement mortar is chosen:

- Prepare a small amount of cement mortar.

- Markings are made for installation on the floor of the toilet room.

- The installation site is thoroughly cleaned of debris and dust.

- An even layer of mortar is laid out at the installation site.

- The sole of the toilet bowl is moistened with water, then the device is placed on cement.

- Excess cement mortar is removed with a spatula.

For this option, it is also recommended to wait at least 24 hours for complete fixation. Then you can perform additional actions - connecting the drain to the sewer, installation and fixation of the tank, installation of a toilet seat.

Scheme selection connecting the toilet to the sewer determined by the type of release of the device. Connection options are described in detail in our recommended article.

Other mounting methods

There is another way to fix toilets on the floor of toilet rooms. The technology is called “taffeta mounting”.

Due to its antiquity, this technique is quickly losing its relevance, but sometimes it is still used, but, as a rule, on wooden floors.The principle is to attach a plumbing fixture to a wooden board - taffeta, cut to the shape of the sole.

A shallow recess (up to 50-70 mm deep) is made on the floor of the room, where the plumbing fixtures are installed. This recess is filled with cement mortar. They take taffeta and randomly pierce it over the entire area with nails. On the side (bottom) where the nails came out, the taffeta is laid on a cement pad.

On the outside of the taffeta, the toilet is installed and secured. Of course, this is done after the cement mortar has completely set. Fastening is carried out according to the standard - with screws.

A kind of counterbalance to the outdated “taffeta” fastening technology is, perhaps, the most modern technique - fixing plumbing fixtures to support frame - installation.

True, the “installation” is a metal structure and provides for a slightly different form of installation – suspended. That is, the plumbing fixtures are not installed with emphasis on the floor of the toilet room, but remain suspended after installation.

Note to installers: useful tips

Plumbing fixtures are made from strong but fragile materials. Therefore, when securing a porcelain or earthenware appliance with screws (bolts), it is not recommended to use maximum force to tighten it.Be sure to use soft gaskets (silicone, rubber, plastic), placing them under the screw heads.

If glue is used for fastening, the quality of cleaning and degreasing of the bonded surfaces is of great importance in achieving joint strength.

When using epoxy resin, it is necessary to strictly observe the ratio of resin and solvent during the preparation of the adhesive mass. The glue must be applied evenly to the surface, preventing the formation of air cushions.

When installing the device “on taffeta”, it is advisable to choose strong wood as the material. You can use multi-layer plywood, but in any case you should provide high-quality waterproofing for the taffeta. A humid environment dramatically reduces the durability of any wood.

Conclusions and useful video on the topic

One of the options for attaching a plumbing fixture to the floor is discussed in the following video:

Which method of installing toilets is the best is up to the owner of the property to decide where the plumbing is to be installed and secured.

However, when choosing a technique, it is recommended to take into account the possible loads on the toilet, the material of the device (faience, porcelain), as well as the design features of the toilet room. A careful approach to business will definitely help you achieve the desired result.

Would you like to tell us how you installed the toilet yourself? Do you have useful information and photographs on the topic of the article? Please write comments, share your impressions and ask questions in the block below.

In order not to spend a significant amount of money on the services of craftsmen, I carried out most of the renovation work in the bathroom myself. I can say from personal experience that you can easily change the toilet yourself. I know about fastening with glue, but I prefer to use dowels. This method is more practical. The only obligatory condition is a flat base, otherwise the water will not be flushed correctly, and the toilet itself will “walk”.

I have always handled the installation of plumbing myself, so it turns out I already have a lot of experience. I didn’t even know that it was called “taffeta”, my mother-in-law used this way to fasten the toilet, she had some kind of wooden panels on the floor in her toilet. At our house it was fastened in a standard way, with dowels. Then, after the repair, I installed the installation, but I had to struggle with it, it’s difficult to align everything alone, a friend helped.

I'll tell you a cooler story. I bought an apartment and decided to attach a wobbly toilet to dowels. When they drilled the first hole, I realized that there was floor heating in the bathroom.

So measure it seven times. Good luck to you.