Main gas pipeline: nuances of design and construction

Transportation of gas through a pipeline is one of the most economical and efficient ways to deliver blue fuel.Its only significant drawback is the large capital investments in design and construction.

At first, it may seem that the main gas pipeline costs a pretty penny. However, over time, the expenses pay off, and small maintenance costs allow the owner to save considerable amounts. You will learn everything about the design and construction of a gas supply pipeline system from our article.

The content of the article:

General characteristics of central gas pipelines

A gas pipeline is a system of pipes and structures used to transport fuel from production or manufacturing sites to customers. It includes main and additional pipes. The diameter of the latter is determined by the characteristics of the transportation object, however, it cannot exceed 1420 mm.

Pipelines are divided into three classes depending on from pressure, under which the substance is transported. This indicator must be taken into account, since if the norm is exceeded, the likelihood of an accident increases.

Main gas pipelines are divided into aboveground, underground and underwater. The former, due to their slight rise, do not interfere with the movement of vehicles. This delivery option is used to overcome water obstacles, ravines and other obstacles.

Underground networks are laid in special trenches.The depth of the latter depends on the level of soil freezing. Therefore, when organizing the transportation of wet gas, it is important to take into account the climatic features of the area, soil structure, pipe diameter, etc.

And for pipes with dried gas, a trench 0.8 m deep is suitable. Its bottom is covered with a layer of compacted sand, the laid pipes are covered with several layers of bitumen-polymer mastic or polymer shell, then filled with soil.

Underwater systems are created for the purpose of transporting products from marine areas, along the bottom of rivers or large lakes.

The standard pipeline is equipped with a main and intermediate compressor stations. Each of them distributes the flow of fuel among branches with designed diameter and reduces his blood pressure.

For example, before reaching the final consumer, gas passes through the main and then an intermediate distribution point. As a result, the pressure decreases to the value provided by the local pipelines.

And to ensure balanced functioning of the system, special storage facilities are created directly in the consumption area. For example, in the summer, gas can accumulate, which is used in the cold season.

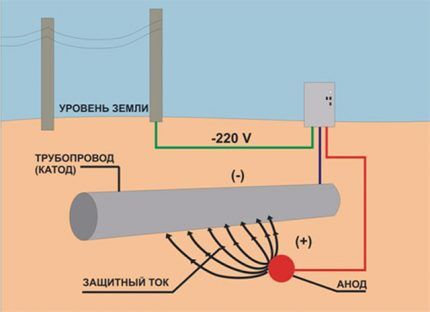

The destruction of pipes as a result of their contact with soil, water or air must not be allowed. This problem is solved through external anti-corrosion insulation.

It is important to ensure the reliability of the gas network. It is guaranteed through pumping equipment at compressor stations, the use of high-quality steel pipes, and the creation of additional parallel lines that are combined with the main one thanks to jumpers.

Key points in network operation

First, performance.It is calculated taking into account the fuel and energy balance of the areas where transportation will take place. Maximum loads are predicted. You also need to take into account that a particular region may develop in the future, so the volume of delivered gas will increase.

Used to improve performance gas pipeline looping. If the pipeline operates at medium power, then centrifugal blowers do not particularly affect efficiency. But their role increases with increasing load.

Secondly, automatic adjustment. When designing a network, the features of managing gas mains are analyzed. To do this, determine the stability of the system and detect processes that are not sufficient for balanced functioning.

Modern technical means allow you to change productivity automatically. If the necessary equipment is not available, then the speed and efficiency of transportation drops to literally zero.

On the one hand, the movement of matter occurs under the influence of inertia. But on the other hand, the system slows down the movement both due to the rounding of the pipes and directly due to internal resistance. Given the complexity of the equipment, both factors require an individual approach.

The third key point is notation. Special characters perform informational and warning functions. Placing signs is a mandatory rule for the use of main gas pipelines.

Designations allow you to identify objects, zone and depth of the pipeline.In fact, these are columns with two information blocks. The vertical area indicates the area of special danger, location and other important features.

And the horizontal one, with information about the location of the dangerous area, is installed at an angle of up to 30 degrees relative to the surface of the earth. It shows the distance in kilometers along the entire route.

How is a gas pipeline designed and built?

From proper design, hydraulic calculation of a gas pipeline and compliance with technological requirements in the construction depends on safety. Therefore, the work must be done consistently and responsibly.

Basics of drafting a project

The first and key stage. Provides for the formation of a document system where technical information is displayed. The diameter and operating pressure of the pipes are noted here. The number of stations that will be responsible for pumping is indicated.

The project contains a diagram of the proposed location of the main gas pipeline and a classification of networks depending on pressure. The document notes the location of the central and other regulatory installations.

The project must guarantee:

- constant transportation;

- possibility of preventive work;

- maximum comfort and safety for consumers.

In addition to technical and economic documents, it is also necessary to take into account the nuances of the external environment. The corresponding section describes environmental factors, soil structure, features of geographical location, etc.

All documentation undergoes strict examination by the responsible government agencies. This measure is aimed at preventing possible negative consequences due to errors in the main gas pipeline design.Specialists may allow, require adjustments, or not allow construction.

A properly formed project is a guarantee of comfort and safety of transportation, minimizing threats to human life and health, and preventing negative impacts on the environment.

Accounting and compliance with restrictions

At design of gas supply systems at any level, the limitations of legislation, relevant standards and technical recommendations must be taken into account.

In particular, the construction of pipelines in any populated areas, in areas where agricultural work is carried out, in the immediate vicinity of airports and railways is strictly prohibited. There are also restrictions regarding ports and marinas.

It is also prohibited to combine pipelines, each of which is designed to transport substances with different characteristics. As already mentioned, the main line can branch - additional pipes are connected with jumpers to make it convenient to carry out repair work.

The depth of underground pipes is determined by the type of transported substance and the level of soil freezing in a particular region. The latter is especially important for pumping wet gas.

In most cases, we are talking about a dried substance, so the depth of the gas pipeline branches is from 0.8 to 1 meter. But this also has its own characteristics. If this area is drained, then the figure should be more than 1.1 meters. This is due to future ground settlement.

Features of pipe transportation

To transport rolled pipes, specialized vehicles are used, equipped with spreader trailers, turnstile gates and fastening equipment. The trailer has a reinforced connection to the vehicle body. And the cabin has a special shield that guarantees the driver’s safety.

Immediately before construction, external pipe quality control is carried out. If the latter have mechanical flaws or are damaged by corrosion, then they are not used. Fittings and materials used are also inspected.

Steel pipes are used for above-ground and underground pipelines. For the latter, polyethylene ones are also relevant. Although steel ones are universal, in some characteristics they are inferior to other options.

For example, polyethylene analogues have a longer service life, increased resistance to destruction and do not require the use of additional materials against corrosion. When arranging internal gas pipeline networks, more expensive copper products are often used along with steel pipes.

Will familiarize you with the guidelines for choosing pipes for the construction of gas supply system lines next article, which we highly recommend reading.

Subtleties of gas network installation

First, the inside of the pipes is cleaned. Further, the latter are installed by experienced specialists. It is necessary not only to prevent the loss of the substance, but also to take into account the speed of transportation and the level of pressure.

For installation of the system the following are used:

- pipe sections;

- half bends;

- transitions;

- bends;

- plugs;

- units for wells.

The use of the listed elements allows for the rapid construction of main, as well as less significant, gas pipelines and the creation of a hermetically sealed structure. Subsequently, the pipeline is welded: preparatory work, formation of close joints, welding in sections and in threads.

In this case, gas and electric arc, butt welding, soldering, etc. are used. Taking into account the responsibility, only professionals with a certificate in accordance with RD 03-495 are involved.

Welders of the 4th and 5th categories work with internal gas pipelines. Welding can be performed either directly in the trench (typical of an underground gas pipeline) or close to it.

Ballasting and object control

Ballasting and securing ensure that the pipeline is positioned correctly. For example, for the underground type, the following methods are used: concreting, pouring soil, hanging reinforced concrete weights and containers. To secure the pipeline, anchor devices are used.

Before putting the gas pipeline network into use, the internal surface of the pipes must be cleaned. The latter are inspected and mechanically affected in accordance with the measures provided for in SNiP 42-01.

The results of gas and electric arc welding must comply with GOST 16037. Representatives of the customer also have the right to control.

If the pipeline has passed all necessary tests and complies with the requirements of legislation, standards and recommendations, then it is put into operation by the customer.First you need to release the air, and then begin to transport the corresponding substance.

Main pipeline protection

The central gas network is far from a toy. Therefore, strict rules regarding its use are established. Activities of business entities near areas where the gas pipeline passes and is carried out connection to the gas supply system, limited. You must obtain appropriate permission from local authorities.

The owner enterprise must inform the population of adjacent territories at least once a quarter regarding the location of the pipeline. Print media, local television or radio are used.

The pipeline is considered a high-risk facility. This is determined both directly by the characteristics of transportation and by the serious properties of oil, gas and other substances.

Therefore, in the event of destruction of the integrity of the pipe, the following are possible:

- explosion;

- destruction and pollution of the adjacent territory;

- formation of a smoke cloud;

- fire;

- other negative consequences.

It is mandatory to place information signs in the immediate vicinity of the pipeline at a height of 1.5-2 meters from ground level. They must be readable and visible, located at intervals of 500 meters and at each turn of the route.

The intersection of a highway and a pipeline is undesirable, but in some cases it cannot be avoided. Signs prohibiting cars from parking are posted in such areas.

The basic rules and nuances of connecting a private house to the main gas supply system are given in the article, the contents of which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

Video #1.Details about the nuances of pipeline design of paramount importance:

Video #2. Construction of a central gas network:

Video #3. Anti-corrosion protection of pipelines:

The main pipeline is an object of increased danger. During construction, it is necessary to take into account the requirements of regulations and involve exclusively specialists who have the appropriate certificates.

In the future, it is necessary to strictly comply with the requirements for the operation of the facility. Then it will be a stable source of income for the owner and will provide end consumers with gas, oil and other transportation products.

Please leave comments in the block below. Share useful information on the topic of the article that will be useful to site visitors. Ask questions on controversial issues, post interesting photographs.

Information about the rules by which the main gas pipeline is laid will also be useful to ordinary people who plan to cut into it and receive gas. But often gas workers themselves spit on their own rules and lay them out at random.