Plastic wells for drainage: device, types, classification, installation instructions

The technology for constructing a drainage system involves the installation of wells that differ in purpose.They are needed to monitor the operation of the underground pipeline, regular maintenance and periodic cleaning. Previously, they were assembled from concrete rings, but now products made from polymer materials are used.

Lightweight and durable plastic drainage wells greatly facilitate the process of constructing the system. Polymer products are resistant to mechanical, chemical and biological influences. Product manufacturers have thought through all the details to ensure simplicity and high speed of installation.

We will tell you how to wisely choose polymer structures for a drainage system and how to install them. The article presented for review contains step-by-step instructions in detail. By following our advice, you can quickly install effective drainage in your suburban area.

The content of the article:

Classification of drainage system wells

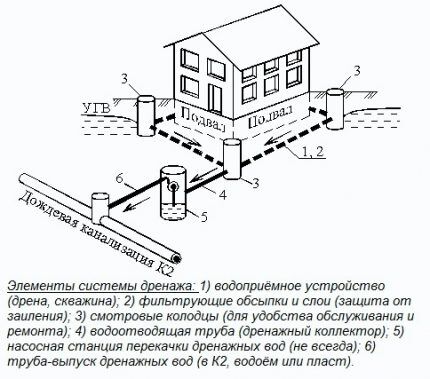

To rid the area of rain and melt water, it is not enough to install drainage pipes and trays on the site. The same applies to moisture in the soil; drainage pipes alone will not be enough, because... The liquid it collects must be discharged somewhere. For this purpose, a system of underground pipelines is created, an integral part of which are plastic wells.

There are several different types of such structures, each of which has its own purpose.They have different sizes and number of inputs, and can be with or without a sealed bottom. And all this variety of devices is now made of plastic.

Types of structures by functionality

Drainage systems use six types of plastic wells with different functional purposes:

- Collector. In suburban areas, one collector well is installed to receive waste from all types of sewer systems. If there is a need to stimulate the movement of wastewater, it is equipped with a pump. If it is planned to unload the system into the underlying layer, they are constructed without a bottom, similar to filtration systems.

- Observations. Arranged for system audit and periodic cleaning. They are located at turning points, forming nodes or connecting to central highways.

- Drops. They are installed at the junction of pipelines laid at different depths. They are also used when it is necessary to reduce the speed of gravity flow or when crossing any underground structures. They are practically not used in drainage systems.

Based on the type of access to system maintenance, wells are divided into serviced and inspection. The first type provides access to sections of the network running in the well for maintenance, the second provides for the performance of repair and other operations from the surface of the ground.

The functionality of the wells is different, but they are structurally similar. Generally speaking, it is a vertically oriented reservoir in the ground that has two or more outlets and inlets. Often one well combines a number of significant functions. But in most cases, each of them is mounted for one role.

Inspection well structures are designed for inspection and maintenance of the entire system. On the one side inspection wells They allow you to monitor the condition and capacity of pipes, controlling the level of their clogging, and on the other hand, it is from them that pipelines are cleaned.

The rotating type of inspection wells is used when it is necessary to turn the flow of water by 90º. Linear ones are installed on straight sections on average every 50 meters, but the permissible distance interval between them is 40 - 150 m.

If the system is supposed to be flushed manually with descent into the well, then it should have a diameter of one meter or more. In other cases, a structure with a diameter of 35–50 cm is sufficient. Exactly enough so that you can easily lower a hose inside for flushing or pumping.

Storage or collector options are large containers in which wastewater is accumulated for subsequent movement of drainage waste to discharge points. This could be a nearby body of water with standing or running water, or a storm drain.

Well, designed on the principle of a filter, allows water to drain into the underlying ground aquifers, diverting it away from the foundations of buildings.

However, it is permissible to install it only on sandy soils, gravel or pebble deposits with sand filler. Those. on soils with good filtration qualities equal to the ability to absorb water.

The entire system of pipelines and wells is built in such a way that the last structure in the chain is located at the lowest point of the drained territory. It is into the storage tank, filter or collector well that all water from the site must drain.

In this case, it is desirable that the water moves by gravity. If the installation of a gravity system is impossible due to technical conditions, the collector well is equipped with a pump to stimulate water movement.

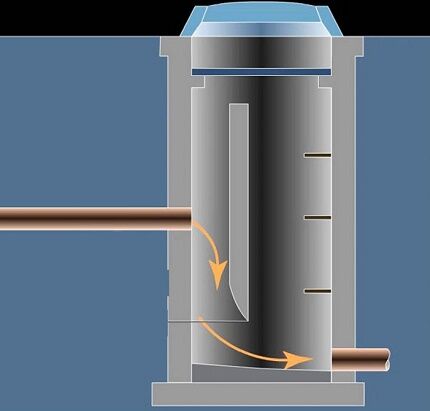

Differential wells differ in their internal structure as follows:

- chambers with one water extinguisher inside;

- collectors with a water trap system;

- high shafts with an inlet pipe at the top and an outlet pipe at the bottom;

- structures made of a pair of independent sections connected by an overflow channel at an angle.

In some cases, the energy of the flow is extinguished at the bottom, while in others this happens thanks to special fenders. The choice of a specific option depends on the level of difference between the sewer pipes, as well as the topography of the site and the characteristics of the soil layers on it.

Polymers used in production

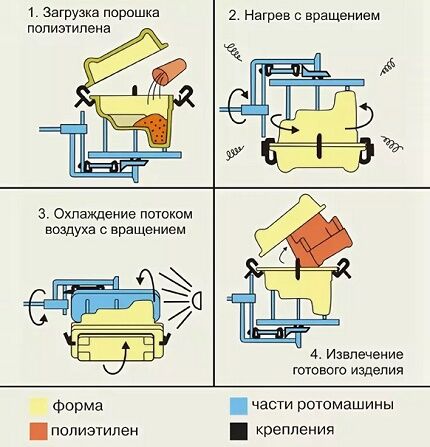

During production plastic wells For drainage, polymers of different structures and different technologies are used. The cheapest products are produced on rotary forming machines.They are the ones that can most often be found in domestic stores.

Wells are produced using the following polymers:

- PVC (PVC) – polyvinyl chloride.

- PP (PP) – polypropylene.

- PE (PE) – ordinary and high-density polyethylene.

Most often, one of them is used with some kind of filler, but various combinations are also common. Various components can be added to the resulting plastic: from dyes to sand.

Polyvinyl chloride products are the most resistant to aggressive chemicals that get inside along with wastewater.

They are even used in the construction of sewer systems at industrial enterprises. Polypropylene cases are characterized by high wear resistance and ductility, but become quite fragile when the temperature drops significantly.

Polyethylene drainage wells are frost-resistant. They may freeze, but after thawing this element of engineering communications quickly restores its shape without losing its tightness. This is the best option for moving soils.

Advantages of plastic products

Among the advantages of plastic wells for drainage are:

- Light weight, which allows you to do without a crane during loading/unloading and installation.

- Housing material resistant to aggressive environments, mechanical damage and low temperatures.

- Service life is 50–70 years without major repairs.

- Availability of all necessary factory-made inputs and outputs in the housing.

- Minimum volumes of excavation work due to thin walls and reduced diameter of the well structure.

- Extremely simple installation - the plastic product can be easily cut to the required size.

- The strength of the structure, which can withstand tens of tons of load from above and heaving of the soil in winter from the sides.

The lightness of the plastic elements of the well body allows all installation work to be carried out by a couple of people. But in this lightness lies the main drawback of plastic wells - during floods and heaving, they can simply be squeezed out of the ground.

Another relative disadvantage is the high price of a plastic drainage well. However, here it is worth considering not only the cost of the product itself, but also the costs of its installation. In the case of a plastic structure, you will not have to order special lifting equipment; a couple of installers and ropes will be enough to lower the assembled elements into the pit.

Taking into account the long service life of several decades without major repairs, the price no longer seems so high. The initial cost of a plastic well pays off with interest.

In addition, it is much easier to connect pipes to it than to a concrete or brick analogue. No specialized skills are required for its installation; there is no need to invite highly qualified specialists.

Construction of a plastic well

Structurally, the well structure made of plastic includes:

- conical neck;

- a circular working chamber (shaft);

- sand collection tray and bottom.

Instead of a sealed bottom, a drainage cushion of gravel can be installed, because leakage of drainage water during the period of system repair does not pose a danger to the underlying soils and the environment.

From above, the entire structure is closed with a hatch or a regular lid. They are made of plastic, cast iron or polymer sand. In this case, the neck of the well container may be missing, in which case the hatch is placed directly on the shaft.

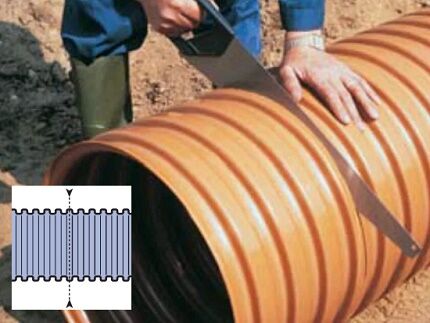

The shaft is made corrugated, so its strength characteristics increase. When compressed by soil, it will not collapse, remaining intact and sealed.

The bottom and the tray with pipes make up the kinet part of the well, where the pipe distribution is arranged. Also, all the garbage and silt that gets inside with the drains settles in it. Often they come with a special form for pouring a concrete support base (“anchor”).

When installing a sealed well structure for the drainage system, it is permissible not to use a tray. Instead, you can install a simple flat bottom. This design is cheaper, but this option is more susceptible to clogging with large debris. You will have to look into the well shaft more often for the purpose of inspection, and at the slightest clutter, clean it immediately.

A hanging ladder can be built inside the well or steps can be made in the form of inserts into the body. The pipelines are connected to special holes cut at the factory. Also, such an insert can be made at almost any point on the body.

The classification of plastic wells, their design features and scope of application is described in detail In this article.

Which is better: prefabricated vs monolithic?

A prefabricated drainage well is assembled from various plastic parts, like a construction set. The monolithic product is already ready for installation; it just needs to be lowered into the hole dug for this.

Monolithic options are cheaper and stronger than their prefabricated counterparts. However, they are produced in a rather narrow range of standard sizes. They are installed only to the depth specified in the instructions.

Individual elements of a prefabricated structure are easier to transport and load into a car than a large monoblock product. But in terms of compressive strength, even when assembled, they are inferior to an initially solid well. A solid body, by definition, is capable of withstanding large hydrodynamic and mechanical loads.

Assembling plastic parts of a well for drainage involves the need to seal their joints. And each such joint is a potential hole and leak.

Plus, to tighten the elements you will need bolts and nuts. They should come together. If they are not available, then you should only buy galvanized fasteners, which are less susceptible to corrosion.

Technology for installing a plastic drainage well

If a prefabricated structure is chosen, it must first be assembled.You can do this in a pit, but then you will have to dig it larger.

The depth of the hole under the plastic drainage well is dug so that the pipes enter it below the freezing point of the soil and above the upper aquifer in it. It is worth remembering that under the structure you will still need to pour a crushed stone cushion of 10–15 cm and lay a concrete anchor slab of similar thickness.

If a plastic well is used to drain moisture into the ground, then the layer of crushed stone below should be at least 30–40 cm. In this case, you will have to dig a larger hole.

The width of the pit is made 30–50 cm larger than the outer diameter of the mounted tank. This is quite enough to lower the plastic product inside, and you won’t have to dig up any extra soil.

The height of the well structure is selected so that it cannot rise more than 20 cm above the ground.The only exception is the drainage option with a grate on top instead of a lid.

The hatches of all other types of drainage system wells should be located 10–20 cm above the turf level. Otherwise, during rain, water streams will begin to flow into them, carrying with them leaves and other debris.

If groundwater regularly rises to the surface in the spring, then a concrete foundation under a plastic well must be made. They are connected to each other with a nylon cable, which definitely will not rot in the ground. A concrete anchor is not needed only in areas with dense rocky soils.

To cut additional holes, you will need a cutter of the appropriate size. After making a hole, a rubber seal is inserted into it, inside which the adapter coupling is placed. The latter should fit tightly into the rubber gasket without gaps.

To do this, they must have the same size. For sealing purposes, the joints are coated with silicone grease, which makes it easier to press in the coupling and at the same time forms an airtight connection.

Then perforated pipes are connected to the well installed in the pit. drainage pipes and sealed sewer pipes necessary to carry away the water collected by the drainage.

To ensure free movement of water collected by drainage, they laid with a slope. So, under the influence of its own weight, the water will spontaneously flow towards the storage tank, collector or filter well.

And then all that remains is to fill the hole back up with soil or a sand-cement mixture. This is done evenly and layer by layer, so as not to sharply squeeze the plastic body and destroy it. The hatch is placed on top, installation is completed.

Insulation of a well structure

Drinking and sewer wells must be covered with thermal insulation material. They are used year-round, and the water in them should not freeze.

But with designs site drainage system the situation is somewhat different. They are not used in winter. Plastic wells are not afraid of frosts in spring and autumn. There is absolutely no need to insulate them.

However, if there is a desire to perform thermal insulation, then the ideal option here is foam sheets. This material is not afraid of moisture and cold.

Conclusions and useful video on the topic

Video #1. Technology for inserting into a plastic pipeline body using a coupling:

Video #2. Review of drainage wells from different manufacturers:

Video #3. Step-by-step installation of a plastic well structure:

A plastic well, intended for use in a drainage system, is a practical, durable and easy-to-install product. You don't have to use construction equipment to install it.

The variety of prefabricated and standard sizes of monoblock structures makes it possible to install drainage systems of any complexity. You just need to choose the right model in accordance with the functional purpose.

Please write comments in the block below. Here you can ask a question or talk about your own experience in installing plastic wells. Share interesting facts and photographs related to the topic of the article.

I choose a one-piece version of plastic wells. On my site there are solid clay soils. The layers lie in a thick layer close to the surface; in some places the loam is exposed at a depth of 0.5 m.During freezing, such rocks “shake” and can damage any joints. Wells are needed by the site for inspection and as storage tanks for removing water during heavy rains and melting snow. Without drainage, it was difficult to walk around the area even in rubber boots.

I plan to do drainage and will most likely install prefabricated plastic wells. I couldn’t find a monolithic one that was the right size for me. What is the best silicone grease to use for sealing joints? Do I mean from a specific brand or does it matter?

Hello. In your case, it also depends on the size of the well, as well as the types of joint geometry. Of the proven options, I can recommend polymer welding - this is the best option, better than any sealants.

This way you can achieve complete tightness of the well, even in the most inaccessible places. Factory seals can be used to connect pipes inside the well. How big of a well are you planning? I know the plastic versions come in different sizes. Or will you have a non-standard geometry?