Fecal pump for a cesspool: tips for choosing + review of the best brands

A cesspool is the simplest sewer storage tank that requires periodic emptying.In order to empty the container of sediment, vacuum cleaners are usually called.

However, a fecal pump for a cesspool will also help with this task, helping to empty the storage tank on its own. Let's admit it: not all of us know which unit should be chosen for this procedure.

We have reliable information that provides answers to a wide range of questions that arise among owners of autonomous sewer systems. Using the information we provide will greatly facilitate and speed up the selection of a technical device.

The article, brought to the attention of site visitors, describes in detail the design features and operating principle of fecal pumps. The differences between the units, depending on the upcoming operating conditions, are indicated. To help the buyer, ratings of popular models, photos and video reviews are provided.

The content of the article:

Features of the design of fecal pumps

The main purpose of the equipment is to pump out viscous and dirty liquid with a high concentration of fibrous and solid inclusions. The mechanisms can easily handle liquid processing, the linear size of inclusions of which can reach 50 mm.

Mud pumps are indispensable:

- at cleaning cesspools and sewer wells from silt deposits;

- when transporting wastewater with the possibility of its removal to distances regulated by sanitary standards;

- when draining storm ditches and basements of houses.

The need for such equipment may also arise when arranging forced pumping of sewerage. They are installed when it is necessary to compensate for a small angle of inclination of the pipeline in order to prevent clogging of the system.

The main structural elements of the unit are:

- engine – a device that converts the energy generated by the sources into mechanical work, which drives the pump;

- water pump – a moving part that pumps liquid into a special tank;

- input channel – ensures that liquid enters the pump;

- outlet valve – drains wastewater into a waste tank.

- chopper – a rotating element designed for grinding large inclusions.

A characteristic difference between fecal devices and other types of pumps is their increased reliability and larger channel diameter.

The chopper is a mandatory functional element of most models. It consists of rotating knives installed at the input of the unit.By grinding branches, debris and even small stones into small fractions, the rotating elements prevent clogging and failure of the unit.

Since mud pumps are designed to operate in aggressive environments, the product body is always made of heavy-duty materials. Most often, steel, stainless steel or cast iron are used to create it.

Differences between units according to operating conditions

Depending on the type of design and the possibility of positioning the unit relative to the sewerage system, slurry pumps are of the following types: submersible, semi-submersible and surface.

Regarding the ability to pump waste, all three versions of manufactured units have virtually no differences. But still, each type has its own characteristics.

Submersible models

Any submersible pump model is a monoblock, which is buried directly into the contents of a sump or cesspool. The unit is lowered and installed at the bottom of the tank.

This type of pump is famous for its high performance at an affordable price.Due to this, they are widely in demand both in domestic use and on an industrial scale.

A special feature of submersible models is a strong sealed housing that protects the “insides” from the penetration of aggressive environments characteristic of wastewater collection systems and sedimentation tanks. To ensure that devices can operate uninterruptedly in this arrangement, manufacturers equip them with powerful pumps.

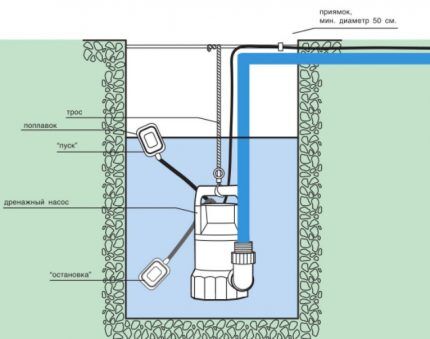

Submersible structures include a float. It is connected to a sensor that reacts to the degree of filling of the tank. If the wastewater level is too low, the device automatically turns off.

Pumps equipped with floats can be left in wells for a long time. They will empty the tanks in a timely manner, ensuring continuous operation of the system. The main thing is that the temperature of the liquid to be pumped is less than +40°C.

This is due to the design of submersible units, when the device’s engine is cooled by the same liquid that is to be pumped.

Submersible pumps, even those equipped with grinders, need regular cleaning of mechanical particles. To do this, they are removed to the surface every three months in order to perform prevention.

It is possible to fix some breakdowns of pumping equipment with your own hands; for more details, see this article.

For ease of use, some manufacturers equip submersible models with cables or skid lifts. They make it easier to remove the unit to the surface after completion of work, for maintenance or in case of breakdown.

Pumping out a cesspool with a submersible pump is carried out in the following order:

Semi-submersible units

Semi-submersible models are considered universal because they combine the advantages of submersible and external analogues. In semi-submersible models, only the pump is buried in the wastewater, and the device’s motor remains on the surface outside the cesspool.

Due to the fact that the engine of the unit is located outside the liquid medium, it is much easier to carry out preventive inspection and repair work.

For fecal pumps for domestic purposes, the supplied hoses may have a small diameter. This can significantly limit the throughput of the unit. In addition, most models are not equipped with cutting mechanisms.

This significantly limits their scope of application. In this regard, semi-submersible models are often chosen only as temporary ones.

Compared to submersible models, semi-submersible pumps are much cheaper. This is explained by the fact that the mechanisms of the devices and the materials used to manufacture the cases are slightly less resistant to the harmful effects of an aggressive environment.

Terrestrial surface models

External pumps do not have a very high throughput. In addition, they have limitations regarding the size of inclusions. The diameter of the fractions should be within 5 mm. The maximum permissible length of the connected hose in standard models does not exceed 7 m.

Surface models are chosen in situations where mobility is necessary.

When planning to use a ground pump permanently, you need to take care to protect the unit from adverse external factors. To do this, it can be placed in a caisson or pit constructed near the cesspool.

If there is an outbuilding next to the work area or a space in the utility room has been arranged, the unit can be safely placed there.

Sewage pump selection criteria

All pumping units are divided into household and industrial. Household units, in comparison with industrial analogues, have lower power and performance characteristics. And their cost is much cheaper.

Choosing a unit that is suitable for arrangement of a cesspool In the conditions of your site, you should focus on the following criteria:

- Device power – determines the speed of pumping liquid from the tank.

- Maximum pressure degree – indicates how high the unit is capable of lifting the pumped liquid.

- Environment Settings — temperature and chemical aggressiveness.

- Material case manufacturing.

- Additional functionality - presence of a chopper.

To correctly calculate the required power of the unit, take the volume of the cesspool as a basis. The larger the pumped volume, the higher the power should be.

To determine the required degree of pressure, focus on the height of the walls of the pit. If they exceed a height of three meters, it is better to purchase a household model with the maximum degree of pressure.

The markings on the body will help you understand the capabilities of the equipment:

- Digital code without any letters, this indicates that the model is intended for pumping wastewater whose fraction size does not exceed 5 mm.

- Letter "F" indicates that the unit is capable of transporting liquids whose inclusion size reaches 35 mm.

- Letter "N" indicates the device’s ability to operate in an aggressive environment.

If you plan to use the pump only to drain the toilet, you can choose a model that has a maximum permissible pumping temperature of 40°C. If the drains of the same dishwasher or washing machine are connected to the system, you will need a unit designed to lift hot drains.

The most expensive ones are steel models. They are famous for their large working resources. The average price range is occupied by cast iron products. It is durable in use. But the fairly large weight imposes severe restrictions on the scope of their application.

Budget models are made of plastic. The material used to make the internal mechanism depends on the type of unit and its purpose.

To pump out single-chamber cesspools, units equipped with rotating knives are used. If the cleaning system consists of several wells, then after the first settling tank, only silt is present in the liquid from large inclusions. There is no point in overpaying for a more expensive model in order to grind sludge.

In addition to performing immediate duties, the fecal pump can be loaded with one-time work, for which it is not necessary to purchase specialized equipment.

Additional information on choosing fecal pumps:

- Types of fecal pumps: how to choose a good unit for your needs

- How to choose a fecal pump for a summer residence: an overview of types

- Fecal pump with grinder: types, device, how to choose (+ review of the best brands)

Review of leading manufacturers

Leading manufacturers specializing in the production of pumping equipment are constantly improving their products in an effort to improve the performance of units. Each brand can reveal its unique design features.

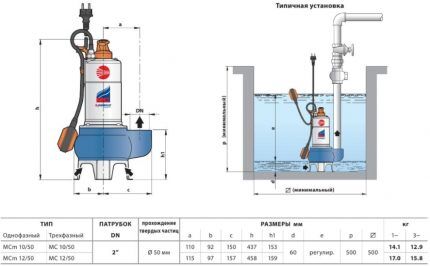

Products from the Italian brand Pedrollo

Pedrollo – the best Italian manufacturer, whose products are represented in more than 160 countries around the world. The equipment produced under this brand meets international quality standards UNI EN ISO 9001.

A special feature of Pedrollo products is that both external and submersible models are equipped with impellers, which at the same time serve as shredders. This solution is convenient because it eliminates the need to purchase additional equipment.

The second feature of the units of this brand is the two-channel design of the impeller. This solution allows us to minimize the risk of clogging the mechanism with fibrous inclusions, which often happens with conventional models when rotating elements become entangled.

Grundfos pumping equipment

The products of the Danish company, whose literal translation means “spring” as a synonym for purity, are very popular among customers, and are distinguished by the use of advanced water treatment technologies.

The impeller regulating system, in addition to the installed thermal relay, increases the operating life of the unit and increases its safety during operation. Equipment of this brand is capable of servicing fecal sewage systems, the short-term temperature increases of which reach about +35°C.

The model found many fans "Grundfos seg", which copes well with stagnant drains containing large amounts of garbage. The price of the product is 50 thousand rubles.

Professional units Calpeda

The Italian company is another largest manufacturer on the world stage. It boasts a wide range of models and a huge product line.

The series of fecal pumps of this brand is represented by four lines: "GMG" - with shredders, "GMV" — with a vortex impeller, "GMC" - with a single-channel wheel, "GMN" - with multichannel.

Gilex is a domestic product

The leader in the domestic professional equipment market is the brand Gilex. The company's production was built on the experience of global holdings using innovative technologies.

Pumps from a domestic manufacturer can be used for pumping and transporting contaminated water, which contains a high content of silt and sandy inclusions. The maximum fraction size is 35 mm.

The household model deserves special attention "Fekalnik 150/6", the price of which is on average 3 thousand rubles. The unit is not intended for professional purposes, but can easily cope with pumping out sewerage in a private home.

Conclusions and useful video on the topic

Before choosing a fecal pump model, it would be a good idea to see how it works and listen to the recommendations of experts.

A clear example of how a device with a chopper works:

Popular models of fecal pumps:

By choosing a sewer pump wisely, you can remove contaminants from the cesspool with a minimum of effort. Without saving on purchasing a high-quality unit, you can be sure that it will serve you well for many years.

Are you looking for an effective sewage pump? Or do you have experience using such installations? Please leave comments on the article and share your impressions of the operation of pumping units.

A couple of years ago, we bought a submersible pump with a shredder; I wouldn’t say it was cheap, but it has already paid for itself, since calling a sewer truck a couple of times a month is not very cheap. Yes, and it’s a little problematic for us, since we need a long pipe to bring it to the pit. The only negative: our model needs to be removed in the cold season, but if necessary, we immerse it again; nothing bad will happen in an hour or an hour and a half.

Sergey, tell me what model your pump has?

Where is all this going? Not to the neighbors? It’s clear with the car...into it, but where to?

It swings back... Where did it come from))))))))

Edik! You made my day with your comment! ))))