Repair of the Topas septic tank: features of professional and independent service

When a breakdown of engineering systems occurs in a private home, it’s time to joke: the hour of reckoning has come for several years of convenience. The failure of a treatment plant seems to stop life in the house - now there is no way to do a full cleaning, or to wash or do laundry.

Calling a specialist is not always possible, so you have to carry out TOPAS septic tank repairs and maintenance yourself. Let's look at the structure of the septic tank and the most common breakdowns that can happen.

The content of the article:

Briefly about the principle of operation of the station

When starting to repair a wastewater treatment plant, it is necessary to have an understanding of the principle of its operation. The operation of the device is based on the purification of liquid household waste using bacteria.

And if energy-independent systems rely on the work of anaerobic bacteria, the life of which is possible in the absence of oxygen, then wastewater treatment plant "Topas" cleans waste thanks to anaerobic and aerobic organisms.

The difference in the living conditions of these microorganisms affects the completely different operating principles of wastewater treatment devices.

In conditions of complete absence of oxygen, fermentation of the waste mass is carried out by anaerobes. The process takes place in the first compartment of the treatment plant. Then the settled and fermented wastewater comes to the disposal of aerobes located in the next three compartments of the system.

Aerobic microorganisms break down and process suspended particles and impurities found in wastewater much faster, but they require a constant supply of oxygen. In addition, oxygen is necessary for the oxidation of mass. Aeration of the wastewater is provided by an electric pump, so operation of the device without power supply is impossible. Read more details about how aerobic and anaerobic bacteria work for septic tanks.

Septic tank design and cleaning technology

The septic tank capacity is divided into four independent tanks, and each one performs a special function.

The chambers are connected to each other in such a way that when there is an intensive flow of wastewater, the purification process is accelerated, and when there is a small flow, it becomes more effective due to the repeated distillation of waste.

Since the flow of wastewater in households is irregular, this feature is very important for the high-quality and uninterrupted operation of the station.

Operation in continuous fluid flow mode

In the case of continuous flow of wastewater, the technological process occurs as follows:

- Through the supply pipe (1) the waste flows into the first receiving chamber (A) (or, as it is also called, the equalization tank). There they mix with previously received waste, and large particles settle. As soon as the wastewater reaches a certain level, the sensor is triggered.

- The automation includes an airlift (3), which pumps wastewater through a filter that performs rough cleaning (2) and a hair catcher into the second chamber (B). The compressor (7), supplying air, also turns on.

- In the aeration tank (second chamber B), wastewater undergoes biological treatment with the help of biologically active sludge: large particles are broken down into smaller ones, and organic matter is processed by aerobes. The bubbles of oxygen injected here at the same time ensure the mixing of wastewater with activated sludge, and it acts as an adsorber, binding suspended particles.

- The seething mixture of sludge and wastewater enters the third compartment - the secondary settling tank (B), and is pumped by the recirculation airlift (4) through a container in the form of an inverted pyramid. Here, purified water is separated from activated sludge.

- The sludge separated from the liquid component enters the stabilization compartment (D), and the clarified water is discharged outside the station through the outlet pipe of the device (9).

The station, with the exception of routine inspections and cleaning, does not require user participation - all processes occur automatically. Purified water can be drained into the ground, absorption well, drainage ditch, and used for irrigation.

Reverse cycle phase

If there is not enough wastewater entering the system for its continuous operation, then the installation operates in recirculation mode. As soon as the level in the first compartment (A) reaches the set minimum value, the float switch (10) is activated.

The switch acts on the solenoid valve and the wastewater goes through the entire cleaning process again.

The recirculation mode occurs in the following sequence:

- The wastewater is aerated in the receiving tank (A).

- After the aeration tank (B), the wastewater is pumped into the activated sludge stabilization compartment (D). There the sediment is divided into fractions.

- Old and heavy sludge sinks to the bottom of the chamber (D), and light sludge, together with clarified waste, is sent back to the first chamber (A).

As soon as the water level in the surge tank (A) reaches its maximum, the system switches to direct continuous cleaning mode.

How to avoid breakdowns?

An important detail in preventing breakdowns is the correct installation of Topas septic tank. In addition, like any device or mechanism, the wastewater treatment system requires regular technical inspection. It consists of a visual assessment of the work and pumping out the accumulated sediment.

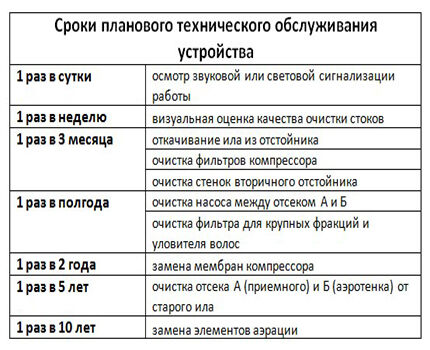

During the inspection, it may be necessary to remove blockages or carry out minor repairs to the TOPAS installation. The frequency of preventive measures is outlined in the table.

The design of the septic tank is made in such a way that all elements can be removed and washed, and the filter of large impurities can be cleaned of collected hair. The sludge from the stabilization chamber must be pumped out at least once a year. If the water in the water supply system is hard, the station must be cleaned more often.

Removing accumulated sludge from chambers

The longer the wastewater treatment plant operates, the greater the content of sludge and sewage, the more dirty the compressor filter is. Therefore, the equipment requires regular cleaning.

All work is performed in a certain sequence:

- Disconnect the device from the power supply. This will allow sediment to settle to the bottom and allow the compressor filters to be safely cleaned.

- Unscrew the screws from the compressor covers to gain access to the filters. The filter in the form of a foam rubber gasket is removed and shaken out. If it is very dirty, wash it under running water and dry it. The covers are returned to their place and tightened.

- Within 15 minutes the sludge settles and pumping can begin. To do this, lower the drainage pump to the very bottom of the sludge stabilizer chamber and pump out the sediment until the water level drops by 50 cm.

- Next, the aeration tank chamber is cleaned. Sludge is pumped out from the bottom, lowering the water surface by 15 cm.

There is no need to completely pump out activated sludge, because it is what helps clean sewage.

Cleaning everything on your device

The next step is to clean the airlift and the filter for large fractions:

- Before removing the hoses of the mamut pump and filter, mark one of the tubes and the pipe to which it is attached with electrical tape, so as not to confuse them in the future (they have different capacities).

- Disconnect the flexible tube from the pump pipe. If it is difficult to remove, warm up the joint.

- Take out the airlift tube and blow it out under pressure of water or air.

- Remove the coarse filter. It is washed from the outside, the collected debris is shaken out into a bucket, the holes are cleared of hair clogged in them, and the filter is washed from the inside.

- Then remove and clean the hair catcher.

The final stage is pressure washing of the walls and tubes of the station, collecting floating debris. Before starting work, cover the compressors with cellophane to protect them from water. Rinsing begins from the upper elements.

A high-pressure apparatus provides good water pressure, which can wash out old deposits.

Reassemble the system in reverse order. The hose markings can be left for future maintenance work. The next cleaning can be done after 6 months.

Evaluation of device performance based on water quality

A functioning purification plant produces practically pure water at the outlet, free of impurities and foreign odors. It can be used for watering lawns, flower beds, and gardens. If the water coming out of the device is cloudy, this indicates poor cleaning.

The culprit for this may be the short period of operation of the station (up to one month): the new equipment does not have a sufficient amount of biologically active sediment, which plays a major role in wastewater treatment. Biological equilibrium can be established more quickly by adding activated sludge from an already operating station.

This also happens due to changes in external conditions: a sharp decrease in temperature, indicating increased acidity of the pH of wastewater or the discharge of chemicals into it (for example, containing chlorine). Usually, when these causes are eliminated, the situation normalizes on its own.

If turbidity of the effluent is observed constantly, then the most likely reasons are an increase in the amount of effluent and insufficient aeration. The latter sometimes happens due to damage to the distribution pipes and oxygen leakage.

The quality of water purification can be determined visually by taking a sample. To do this, a bubbling liquid is drawn from a working device in the aeration tank compartment into a glass container with a volume of about 1 liter. A properly operating unit will have a ratio of settled sludge to clear water of 2:8.

If there is less sludge, it means that the installation is not yet fully ready for operation or is not sufficiently loaded with wastewater.If more, this may mean that the system cannot cope with a large amount of liquid household waste or the float switch is set low in the compartment and does not switch to recirculation mode.

Breakdowns of the treatment plant and methods for correcting them

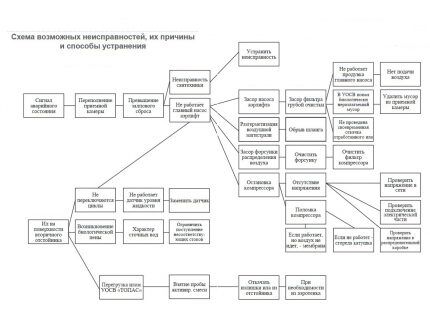

Almost all pumping station breakdowns are manifested by an increase in the level of wastewater in the receiving compartment. A rise in the level activates an emergency float, which triggers an alarm - a bell or a light signal. This alerts the user to the danger of flooding the system and releasing untreated wastewater outside the unit.

Flooding of sewage treatment plant

First of all, you need to check whether the drainage channel for purified waste from the device is clogged or frozen. If not, then you need to look for the cause of the station’s flooding based on the type of equipment. It can be with a gravity drainage system or with forced pumping.

In models of installations with forced pumping, the problem may be drainage pump failure or a stuck float switch. To check the operation of the pump, remove it and connect it to another outlet. If the pump is in order, but does not turn on after connecting to the station, then most likely the problem is with the float switch - it needs to be replaced.

The following problems may be common to gravity and forced models. Check whether liquid is pumped from the receiving compartment to the aeration tank. If not, then the culprit is a faulty airlift.

The reasons for the breakdown may be the following:

- the airlift tube is damaged;

- the airlift of the main pump is clogged;

- the float switch is faulty;

- The compressor membrane that supplies air to the airlift is damaged.

Breakdowns are eliminated by replacing damaged elements or cleaning clogged areas.

RCD tripping and problems with power supply

If, when starting the station, an RCD (residual current device) is triggered, the reason may lie in damage to the compressor or drain pump, float switch. It is also necessary to check the electrical wiring and sockets.

Disturbances in the operation of the installation can also be caused by a prolonged power outage, and then there is a possibility of overflowing of the tanks and the occurrence of an unpleasant odor due to the onset of the development of anaerobic microorganisms. If the voltage drops in the network are within 3% of the nominal value, it is necessary to install a stabilizer.

Changing the water level in an idle station

It is not advisable to leave the TOPAS cleaning system idle for a long time.

But if this does happen, and it is discovered that the water level in the tank is changing, then possible malfunctions may be the following:

- Failure of plumbing fixtures leading to water leakage. You need to find the source of the leaks and repair or replace them.

- The device casing is damaged. If the problems are minor, then you can try to solder the case; if not, you need to contact professionals for help, and they will replace the damaged area. And it’s good if you can get by with repairs, because replacing the entire body will not be cheap.

- Improper installation and, as a result, flooding with rain or flood water.

- The station tank must be installed so that the lid rises 15 cm above the ground surface.

A problem can also be a poorly organized exit of purified water from the system. The situation of poor outflow can be aggravated by poor soil throughput.

Tips for use

Violation of the operating rules deprives the consumer of the right to warranty service. They also say that maintenance and repair of the TOPAS WWTP can only be carried out by specialists from service companies or by persons who have studied the installation instructions and have undergone safety training.

There is also an article on our website about how to properly maintain a Topas septic tank in winter - read Further.

For long-term and successful use of the station, it is necessary to conscientiously follow the recommendations, namely:

- it is prohibited to make design changes to the station structure;

- it is unacceptable to drain various chemicals, products containing chlorine (in large quantities), water obtained from the regeneration of drinking water treatment systems;

- It is prohibited to discharge construction waste, non-biodegradable compounds, food residues and cleanings of forest mushrooms, and pet hair into the sewer system.

Despite numerous prohibitions, the manufacturer fully allows for the reasonable use of modern detergents and hygiene products:

- It is allowed to dump toilet paper into the sewer system;

- You can drain drains from washing machines and dishwashers that do not contain chlorine;

- it is allowed to drain a small amount of cleaning products for plumbing, kitchen equipment, and sanitaryware no more than once a week;

- It is permitted to discharge kitchen waste without restrictions.

In addition, during a power outage, it is necessary to reduce water consumption as much as possible to prevent the chambers from overflowing and contaminated water from spilling.

Conclusions and useful video on the topic

The planned cleaning of the TOPAS station is clearly described in the video:

Video about the repair of the station after the flood:

It is quite possible to clean and repair LOS TOPAS yourself. But in order to be able to take advantage of warranty service, it is better to ask the manufacturer or seller what kind of work the users themselves are allowed to carry out. Otherwise, tampering with the system may deprive you of your legal rights to free services from service providers.

After reading the material, do you have any questions? Or you have already encountered a septic tank breakdown and you have something to advise our readers, please leave comments, share your experience, ask questions, and we will try to answer them promptly.

Please tell us how to properly use a septic tank in the “summer resident” mode. Those. is it open only in summer or only on weekends? What about the power supply? Should I turn it off or not? Thank you.

Hello. In case of frost below -20 or in case of prolonged absence, it is recommended to preserve Topas. For this:

1. Turn off the power.

2. Disconnect the air compressors from the working chamber of the septic tank.

3. Remove the purified water discharge pump (if you have such a function).

4. Leave at least 3/4 of the total maximum volume of water in the septic tank.

About the “summer resident” mode or, as it is also called, the weekend mode. If there is a power outage, the operation of the station will not be complete, since the absence of oxygen for aerobic bacteria for more than 6 hours is destructive. Anaerobic ones will survive, but your station will be an ordinary cesspool without wastewater treatment, with a capacity of up to 200 liters.

If this happens rarely, let’s say you live in the country, you just sometimes leave for a long time - the operation of the station will resume, aerobic bacteria will appear when the station begins to operate normally. But upon arrival only on weekends - this is irrelevant.

Topas is like a Lada, you always need to fix something, sometimes you just carry out maintenance and after a week the pump no longer pumps, in general there is always something to do, it’s better to treat the septic tank as a hobby))

I have Topas-8 Pr, it has been working for 10 years. I mostly serve myself. This year I encountered the following problem. Apparently, after my oversight and the entry of chlorine-containing toilet bowl cleaner, an odor appeared, in chamber B the film and the drain turned brown. I carried out a complete pumping out of all chambers with jet washing, filled them and started them up again. For the first 2 weeks everything was fine, but now the smell has returned. The drain is almost transparent, there is a light coating on the drainage. What is confusing is that a film appears again in chamber B, and in sump D the water is blacker than usual. What can you recommend? Could this be due to excess waste?

Hello. Tell me, is it possible to somehow replace the “umbrella” for air intake on the Topas 8 cover with a lower version? Should I cut it off and replace it with fine mesh? We want to make a drive-in for the car (tiles or asphalt) in the place where the septic tank is located, but we don’t know if it’s possible to make some alternatives with a lid so that this umbrella doesn’t get in the way... Thanks for the answer!

Good afternoon Is it possible to use SYNERGETIC to remove blockages from a Topas 5 septic tank? It is biodegradable, but still contains alkali.

Good afternoon. Water accumulates in the pipe to the connected compressor, why does this happen and how to fix it. Thanks for the answer.