Installing a Topas septic tank: do-it-yourself installation + maintenance rules

When arranging an autonomous sewage system for a suburban area, many owners solve the issue of biochemical wastewater treatment by constructing systems based on stations, of which Topas belongs.

But how does this treatment plant work and how is the Topas septic tank installed? We will consider these issues in detail in our article, focusing on the step-by-step process of installing a septic tank.

We will also highlight the main advantages and disadvantages of this type of sewage disposal facility and the features of its maintenance, supplementing the article with step-by-step photos and useful video recommendations.

The content of the article:

Operating principle of the biotreatment system

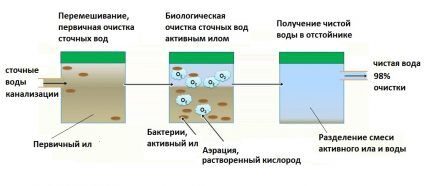

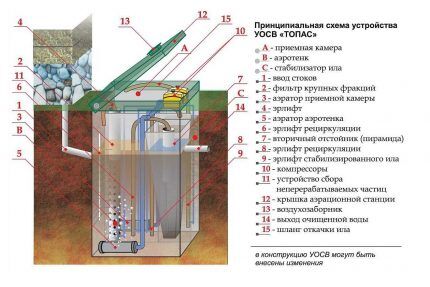

The Topas septic tank is a well-designed system of biochemical wastewater treatment, functioning due to the work of the main skeleton - anaerobic and aerobic bacteria. The chemical side of the process is the oxidation of the waste mass with bubble oxygen artificially pumped into the system.

The biochemical effect on sewage allows for maximum purification before discharge into the underlying soil, drains or filtration fields.

The organic component of the waste mass is destroyed by microorganisms, and the household component is destroyed by oxygen.As a result, wastewater becomes almost transparent and loses its tendency to decay and bacterial contamination.

The developed system complies with all generally accepted standards for wastewater treatment and is safe for the environment. Aerobes and anaerobes living inside the interconnected compartments purify and clarify wastewater by 98% by processing biological organic matter.

But installing a Topas septic tank is effective only when servicing cottages where people live all year round and operate the structure at least 3-4 days a week.

After all, one of the key conditions for the operation of a septic tank is the continuity of liquid flow. If the bacteria in a closed chamber do not receive food, they will die.

Each compartment performs one task assigned to it:

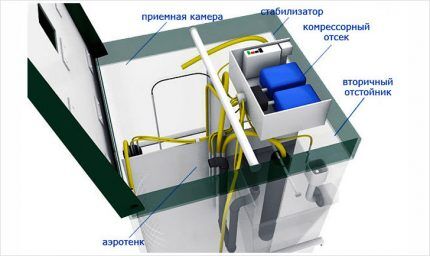

- First section. Accepts wastewater coming from the sewer pipe and allows it to settle so that large inclusions settle to the bottom. Here the mass is processed and oxidized by anaerobes. When the compartment is filled, the float switch is activated and gives a signal to the compressor to pump wastewater into the second chamber.

- Second section. It is called an aeration tank - a rectangular tank. It contains aerobic bacteria that eat and process organic matter. Oxygen is also supplied here, which is necessary for the final breakdown of organic matter and for the life of aerobes.

- Third section. Serves as a secondary settling tank. A “calming” pyramid is installed inside the compartment.Here, the active biomass that processes wastewater is separated from the water.

- Fourth section. It carries out the final separation of water and the result of the vital activity of aerobes - activated sludge. Water that has undergone multi-stage purification leaves the compartment through the outlet. Stabilized sludge settles to the bottom and accumulates there until it is removed. This moment should occur at least once a year.

At the first stage, the process of biological fermentation occurs, launched by microorganisms. The main work of decomposing pollutants is carried out inside the walls of the second compartment. At the entrance to the second chamber, a coarse filter is installed that catches clots and hair that have not settled at the bottom.

The movement of liquid from the third section to the fourth analogue can be carried out by gravity or stimulated by a pumping device. Depending on the natural or forced movement of wastewater, the station is equipped or not equipped with a drainage pump with a float alarm.

The operation of this seemingly complex device is based on the natural process of biological decomposition. The main thing is to ensure a continuous supply of oxygen and saturate the wastewater with a high dose of activated sludge, necessary for the intensive oxidation of organic substances.

In a separate bunker there are two compressor.

One of the main tasks of compressors is to activate the circulation of wastewater from one chamber to another and mix it with activated sludge. It acts as a natural filter that binds together solid particles and foreign bodies that have entered the septic tank.

There is another article on our website in which we examined in more detail the principle of operation and Topas septic tank device.

Advantages and disadvantages of the structure

The main advantage of the system is that each stage of cleaning occurs without polluting the environment.

Among the undeniable advantages of the system it is also worth highlighting:

- High cleaning efficiency.

- Economical power consumption.

- No noise during operation.

- Easy to care for.

Thanks to its compact dimensions, the treatment plant can easily fit even in a limited area.

A significant disadvantage of the structure is its energy dependence, which is associated with the operation of the compressor. The lack of uninterrupted power supply at the site makes the operation of the biological treatment plant impossible. Therefore, it is recommended to supplement the standard equipment of the station with an autonomous generator in case of interruptions.

It is also recommended that during long-term power outages, reduce water consumption so as not to overfill the station with untreated wastewater, which can spontaneously be disposed of when the volume increases and contaminate the soil.

A significant disadvantage of such ready-made structures is their high cost. But when recalculating the savings in servicing with vacuum cleaners, it is immediately clear that the investment will pay off quickly.

And a pleasant bonus will be the absence of unpleasant odors and the ability to position the structure close to the house, which is so important when arranging a small area.

Subtleties of choosing a septic tank wisely

The commercially available models of this cleaning station differ in power. Thanks to the wide model range, you can choose a design whose parameters will fully meet the customer’s needs.

For furnishing private houses, models with a numerical index of 5.8 and 10 are most often chosen. The Topas-5 model has a capacity of 1 cubic meter and is designed for a salvo discharge within 0.22 cubic meters.

The productivity of Topas-8 is 1.5 cubic meters, it copes with a salvo release in the region of 0.44 cubic meters. The Topas-10 model successfully operates with a productivity of 2 cubic meters, and its salvo release volume is 0.76 cubic meters. meters.

Topas-5 is chosen for arranging an autonomous sewer system for small houses with no more than five residents. This does not take into account a large number of plumbing fixtures.

For large cottages, the number of households in which reaches 8 people, choose a septic tank with increased productivity - the Topas-8 model.

If you plan to connect several washing machines and install a jacuzzi in addition to a shower cabin, choose the model of the following modification Topas-10.

Each model has two modifications, differing in height:

- Standard – involves inserting a sewer pipe at a depth of 0.4-0.8 meters.

- Long – for deepening a sewer pipe up to 0.9-1.4 meters.

For areas where the geological section is represented by soils with low filtration properties, it is worth choosing models equipped with a pump. They provide a forced system for the removal of treated wastewater to the disposal site. Such modifications are marked “PR”.

Topas septic tank installation technology

The process of installing a Topas septic tank with your own hands includes a number of main stages.

Stage #1 - choosing a location and digging a pit

When installing a Topas septic tank with your own hands, it is important to clearly determine the location of the structure. According to SES standards, the treatment station must be installed at a distance of five meters from the foundation of a residential building.

If a large area of the site allows you to place a septic tank at a remote distance from a residential building, then when laying a sewer pipeline, an inspection well should be provided.

The location for the installation is also chosen so that when installing the pipeline, the number of turns is minimized. During operation of the system, solid inclusions will accumulate in them, complicating the flow of wastewater.

The size of the pit is determined based on the dimensions of the septic tank, adding 50-60 cm for width and length. For example, for the Topas-5 model, whose dimensions are 1000x1200x1400 mm, you will need to dig a hole measuring 1800x1800 mm at a depth of 2.4 meters.

Typically, such structures are relatively compact, so excavation work can be done manually.

The depth of the pit is made at least 10 cm greater than the height of the structure being installed. If the neck of the septic tank rises above the ground, then it is not the height that is taken into account, but the depth of immersion. If the groundwater level is low, it is enough to equip the bottom of the pit by filling and compacting sand.

If the groundwater level is high, it is advisable, but not necessary, to concrete the bottom.

If it is intended to lay a concrete foundation, the height of the pour should be taken into account when determining the depth of the hole.

The traditional installation scheme under normal geological and hydrogeological conditions suggests that the station cover should rise above the ground by 15 - 18 cm.

Stage #2 - arrangement of the bottom in areas with characteristic floods

If there is a possibility of flooding of the station, the bottom of the pit is constructed using a special method. It must first be carefully compacted and leveled, guided by the level. The prepared base is lined with a layer of sand, forming a “cushion” 15-20 mm thick.

The sand layer will raise the septic tank above the surface to a height of 15-20 cm. Thanks to this solution, you can prevent flooding of the treatment plant equipment during floods and melting snow. After all, the ingress of water can have a detrimental effect on the operation of not only the compressor, but also the entire system as a whole.

If groundwater comes close to the surface, it is advisable to reinforce the bottom of the pit with a sand-cement screed or concrete slab. To strengthen the loose walls of the pit, the pit is strengthened with formwork made of wooden boards or made of fine-mesh metal mesh.

To connect sewer networks, a ditch is dug, which will ensure that the pipeline passes below the freezing point of the soil.

The bottom of the trench is leveled and compacted, ensuring an inclination angle of 3%. This is necessary to create conditions for the unhindered discharge of wastewater towards the septic tank. The compacted bottom of the trench is lined with sand or crushed stone.

In parallel with this, a ditch is being prepared for laying a pipe that will drain the treated wastewater into filtration well, pond or any other receiving container. When compacting the bottom of the outlet ditch, the slope for forced evacuation of liquid may not be observed.

Stage #3 - installation of a treatment plant

To dive models with a numerical index of 5 and 6, you can get by with three or four people. The larger Topas-8 model will have to be loaded using small-scale mechanization.

Before immersing the station in the pit, it is necessary to connect the drainage main line and cable passed through a corrugated PVC channel or HDPE pipe to the connection points.

The body of the structure is tied with ropes and lowered into the pit. During transportation, the cables are threaded through special eyes.

A tank installed on the bottom must be aligned horizontally with the vertical, guided by the building level, since tilting of the septic tank is unacceptable. Correction of the position is carried out by pouring sand under it.

If a concrete slab is provided at the base of the pit, the tank is secured with cables immediately after installation.

Topas septic tanks are supplied without pipes and openings for the inlet of the sewer line. To supply sewerage from the house they use PVC pipes D110 mm or D160 mm. The hole for its entry is cut after the fact, but so that there is at least 1.5 m between the bottom of the septic tank and the pipe.

The hole should be cut carefully, because it should repeat the profile of the incoming highway as accurately as possible. After inserting the pipe into the hole, the joints are welded using a welding rod.

To prevent freezing of the pipe section lying above the freezing level, it must be insulated with rolled foil material or with the help of shells. Only after the communication inputs have been entered and arranged, the pit is finally backfilled with sand.

Stage #4 - connecting electricity and normalizing pressure

At this stage, the septic tank is connected to the power cable. To power the structure, a PVA electrical cable with a cross-section of 3x1.5 sq. mm is used. To protect it from mechanical damage, a corrugated pipe is used.

The electrical cable can be placed in the same trench along with the sewer pipe. The main thing is to ensure its tightness.

Filling the voids between the walls of the structure and the foundation pit is carried out in parallel with filling the container with water. In this way, the process of equalizing the pressure of the partially hollow station and the surrounding soil is carried out.

The water level in the tank should be 15-20 cm higher than the height of the backfill. The work is carried out until it is completely backfilled.

To fill the pit with a septic tank, use clean sand without clay inclusions and construction waste. As the voids are filled, the mixture should be compacted manually every 20-30 cm. The remaining 30 cm of space between the walls of the pit and the septic tank is filled with fertile soil.

Ditches with outlet and inlet pipes laid in them are also covered with sand and previously removed soil.

Key points for structural maintenance

The service life of the Topas system is more than ten years. But the key to the smooth operation of a structure is its proper maintenance. The operating requirements for any type of treatment plant are the same.

When operating such a treatment system, it is allowed if the wastewater contains residues of gentle detergents and phosphate-free washing powders. The presence of toilet paper residues in wastewater will not cause any particular harm.

When servicing a Topas septic tank, it should be taken into account that it is strictly forbidden to dump into it:

- Spoiled vegetables and fruits.

- Remains of building materials, including sand.

- Detergents with a high content of chlorine.

- Automotive consumables.

- Residues of medicinal preparations.

- Rubber, film and other synthetic compounds that are not biodegradable.

It is also not recommended to discharge water that has been purified using an oxidizer into a septic tank. If the operating rules are repeatedly violated, breakdowns are possible and then it will be necessary to septic tank repair Topas.

To avoid troubles, in addition to proper operation, it is necessary to regularly perform maintenance activities on the treatment plant. So, once a month it is necessary to clean the coarse filter. Once a quarter, remove waste sludge from the stabilizer. Replace the membrane annually.

Comprehensive preventive cleaning of the bottom and walls of the structure from silt sediment should be carried out every three to four years.

A complete general cleaning of the septic tank, including checking the float mechanism and replacing the aerator, is performed once every ten years.

Maintenance activities for the Topas septic tank in winter have their own characteristics. We looked at them in detail In this article.

Conclusions and useful video on the topic

The principle of operation of the structure:

Septic tank installation guide:

By correctly installing and launching the structure, as well as observing the above rules during its operation, you will be able to use the amenities of a treatment plant that can serve uninterruptedly for decades.

Have you installed a Topas septic tank on your property yourself? Share your impressions of its operation, tell us, are you satisfied with this treatment facility? Leave your comments under our article, add a photo of your septic tank.

Or maybe you are just planning a purchase and have questions? Ask them in the comments block - our expert will definitely help you.