Which gutter is better - plastic or metal? Comparative review

The drainage system is an integral part of the roof of any building. According to its design, it can be internal or external.Structurally, it includes pipes, gutters, funnels, bends, elbows and other components.

Different materials are used to make these elements. Is it difficult to choose the appropriate type of drainage system among the offered assortment, but you don’t want to overpay? Let's figure out together which drain is better - plastic or metal, for which we will carefully compare, within the framework of this article, all the characteristics of the systems offered on the market.

We will also provide recommendations to potential buyers on choosing the optimal drainage system, providing the material with video tips and photo illustrations.

The content of the article:

Which is better: plastic vs metal?

By definition, it is impossible to get rid of rain and melt water. Residential and non-residential buildings must be somehow protected from their influence, otherwise the walls, roof and foundation will not last long.

If there is no drainage system on the roof, then not only the exterior decoration, but also its supporting structures will quickly begin to collapse. It's better to spend money and make an effective drainrather than having to overhaul the entire building.

All drainage elements can be divided into two groups based on the material they are made of:

- metal;

- plastic.

The first group includes products made from steel, copper, zinc and aluminum, and the second - from PVC, polypropylene and polyethylene. And each of these materials has its own advantages.

In short, galvanized or polymer-coated steel, unlike plastic, does not change its geometry in the sun and does not burst from ice freezing inside. Copper and zinc gutter elements will last the longest, but they are also the most expensive. Plastic gutters are available in a variety of colors and are inexpensive.

However, the choice of material for a roof drainage system greatly depends on the configuration of the roof, the amount of precipitation and the average annual temperature in the region where the building is built.

Before you go to the store to purchase a drain, you need to study all the nuances of the options offered. In some cases, you can get by with inexpensive plastic, while in others it is better to take something made of metal.

Features of metal systems

Previously, gutters were made of zinc and copper. However, the first metal turned out to be too susceptible to corrosion and short-lived, and the second was very expensive. If zinc is used now, it is only in the form of an alloy with titanium. More often it is used simply for galvanizing steel.

It is galvanized steel gutters and pipes that are mostly offered by sellers when a buyer asks to see a metal drain.

Material #1: Galvanized

Steel products are the most affordable option for metal drains. They are made from cold-rolled steel, which is coated with a layer of zinc.

Such oriental systems are characterized by a long service life (if the zinc coating is not damaged), resistance to UV and temperature changes. They can easily withstand large volumes of snow without breaking in the winter.

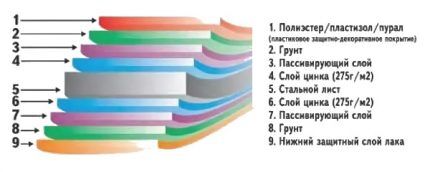

To give the drainage structure a more presentable appearance and increase its service life, galvanization is coated with polymers:

- pural (PUR);

- plastisol (PVC, PVC);

- polyester (PE or MPE).

Pural coating is resistant to mechanical damage and ultraviolet radiation and belongs to the middle price segment. A steel gutter with it will last 30–35 years without replacement.

Plastisol (polyvinyl chloride) is distinguished by a wide range of colors and low cost. However, under the influence of UV rays it softens and becomes deformed. Its service life is up to half a century, but not in southern regions with high insolation.

Ordinary polyester (PE) is cheap, can easily withstand exposure to ultraviolet radiation, but is easily scratched even by ice. This coating will last 10–15 years. Then the protection will disappear and moisture will begin to destroy the steel base. It has a more durable analogue with the addition of Teflon - MPE. However, unlike PE, this color option is limited to shades of gray.

If the roof is metal-tiled, then the elements of the eastern system are best chosen from a similar material with an identical multi-layer structure. This way, they will have a common service life before repair; replacement of the roof and gutters can be done later together at the same time.

Material #2: Aluminum zinc (galvaluum)

Galvalume is steel coated with an alloy of aluminum and zinc (Al+Zn) with the addition of silicon. This material is many times superior to conventional galvanizing in terms of heat resistance, coating strength and corrosion resistance. It is not afraid of acid rain and ultraviolet radiation.

And for a scratch to appear on it, you have to try hard. Snow and ice are unable to harm him.

Zinc has a higher electrochemical potential compared to iron. As a result, it gradually “dissolves,” leveling out oxides that are just beginning to form on the steel. Corrosion simply cannot reach the base metal through such a protective layer.

Material #3: Titanium-zinc

This alloy also has high corrosion resistance and strength. It consists of titanium, copper and zinc. The first metal is responsible for reducing the susceptibility to corrosion, the second for ductility, and the third serves as a base.

These metal gutters can be installed on roofs of any shape and bend easily without breaking.

Titanium-zinc is not afraid of water; it is an ideal alloy for constructing gutters. Its main problem is its susceptibility to electrocorrosion. When it comes into contact with copper or iron, it inevitably begins to deteriorate. And practically nothing can be done about it. All that remains is to exclude such contact. If the roof is covered with copper sheets, then it is better to take the gutter from another metal.

Material #4: Aluminum

Compared to steel, aluminum gutters are lighter and less susceptible to corrosion. The lightness of the metal allows the walls of pipes and gutters to be made thicker. At the same time, such a drainage system does not unduly load the fasteners, but is able to withstand significant loads from snow, ice and water.

Aluminum easily tolerates frost, sun and mechanical shock. It is durable, but noisy and relatively expensive. If the cottage has poor sound insulation, then every drop of rain falling into such a drainage system will be perfectly audible inside.

Manufacturers often coat aluminum gutters with polymer paint.This increases anti-corrosion protection and allows the product to be painted in a color from the RAL catalog. For the roof of the house, you can choose aluminum elements of the drainage system in either a noble silver shade or in any other color. In this regard, aluminum outperforms many metal competitors.

Material #5: Copper

Copper gutter is a fusion of luxury and aesthetics in the exterior of a private home. It will cost a hefty sum, but with proper installation it will last as long as the building itself. Copper is wear-resistant, durable and does not deform in heat or cold. Scratches and natural patina give it only elegance. And it is completely indifferent to ultraviolet radiation.

A metal drainage system made of copper reflects the refined taste of the owner of the cottage, as well as his financial viability. Such a drain costs a lot of money. It is not for nothing that all products made from this metal are classified as elite class. But the copper drainage system on the roof will certainly last for more than a hundred years.

Have you decided to buy metal gutters for the roof of your home? In this case, we recommend that you detailed instructions for their installation with your own hands.

Specifics of plastic structures

Modern plastic products are resistant to damage and moisture, do not discolor for a long time in the sun and are extremely easy to install on the roof. Plastic drainage systems are cheaper than metal ones. But in terms of wear resistance and service life of 10–15 years, the former are much inferior to the latter.

In stores you can find plastic gutters made from:

- polyvinyl chloride (PVC);

- polypropylene;

- polyethylene.

The most popular option is PVC. It can easily tolerate air temperatures ranging from -15...+60 °C. In the southern regions, this is a completely worthy competitor to this or that metal. But for the roofs of buildings in the North it is better not to use polyvinyl chloride drainage. The other two polymers become brittle when frozen and crack from minimal external influence.

Russian climatic conditions do not shine with moderation and temperature warmth. Low frost resistance for plastic gutters is a huge disadvantage. According to reviews, even PVC drainpipes in the middle zone are often broken from the inside by ice in winter. In this regard, plastic cannot keep up with metal.

Plastic gutters often break under the weight of snow and ice in the spring. And in the summer heat, they sag due to the fact that the PVC softens and “floats”.

To avoid these problems, it is necessary to install fasteners with small increments and lay heating cable. These are additional costs, but in the case of a plastic drain there is no other way.

However, plastic drainage systems have many positive aspects:

- Good noise absorption.

- Easy to install.

- Possibility of installation with any type of roofing.

- Excellent anti-corrosion properties of the material.

- Low cost - 2-3 times cheaper than a galvanized metal competitor.

- Smooth surface that does not trap leaves or other debris.

- Extensive range of colors.

In terms of all its characteristics, a plastic drain is slightly inferior to a metal one. But if you need an inexpensive design for DIY assembly, then PVC pipes, gutters and funnels are best suited. But we must remember that if a plastic element of the drainage system breaks down, it will have to be completely replaced; it is impossible to repair it.

How should you choose gutters?

The choice between plastic and metal is determined by many factors. The drainage system is not something independent. It must match the roofing material and the shape of the roof.

When choosing a drainage system, you need to focus on:

- roof slope area;

- financial opportunities;

- climatic conditions (amount of rain and snow, air temperature throughout the year);

- building facade design;

- laid roofing material.

If there is a possibility of ice formation, then it is best to opt for a metal drain. This also applies to situations with heavy rainfall and severe frosts. In this case, the plastic should be immediately put aside.

If the house is covered with metal tiles or corrugated sheets, then the best choice would be a metal drain made of galvanized steel with a polymer coating to match the color of the roofing material.

And for a roof made of flexible tiles or other soft roofing, a plastic option is more suitable. It is also worth taking a plastic structure under the slate.

Much when choosing a drain depends on your financial capabilities. First you need to calculate the required number of standard elements for assembling gutters. We discussed how to do this correctly in next article.

If, due to a lack of funds, cheap materials were chosen to cover the roof, then there is little point in spending money on copper drainage. This is impractical and will look ridiculous.

In such a situation, it is better to install plastic pipes and gutters, and next year fully invest in a new roof and gutters.

Conclusions and useful video on the topic

The video materials below will definitely help you understand the issue of how to competently select elements of a roof water drainage system. There are many nuances in this topic; it is better to eliminate mistakes in advance.

Comparison of gutters made of metal and plastic:

An example of drainage systems - the choice between plastic and metal construction:

An example of making homemade gutters in the following video:

Without a drainage system, a house is doomed to destruction. Uncontrolled flows of water from the roof will ruin the facade and then destroy the foundation.

When choosing a metal or plastic drain, you should carefully look at what plastic or metal it is made of. In both groups there are many options with different characteristics. In some cases, galvanization or aluminum will be optimal, while in others it will be better to purchase PVC.

Do you have practical experience in selecting and installing a drainage system and want to share it with other users? Maybe you do not agree with the theoretical information provided in the article? Or do you have a different opinion on this matter? Describe your view on this issue - leave your comments under our article, add a photo of your drain.

They wanted to save money, so they installed a plastic drain around the house in the village. After a winter at a temperature of -25 degrees, it was already cracked and by spring it was leaking. It began to fade in the sun. I had to throw it away and convert it to metal with a polymer coating. More expensive, but fewer problems. Even if it bends, you can straighten it. And if you have the money, then install aluminum, it looks very cool.

The roof of the house we bought was equipped with plastic gutters, but I didn’t pay much attention to this when we bought it. In the second year they cracked; our winters are cold. In the end I ordered aluminum ones. It is not afraid of frost, can withstand all loads, and there were no problems during installation. It’s true that it is written that you can hear noise from the rain, but there was no such problem with plastic ones.Of course, copper ones are the most beautiful and look rich, but it was a pity to spend so much money.