DIY roof gutters: instructions for making your own drainage system

Roof drains are part of a complete drainage engineering structure of buildings.The system is designed to ensure the collection and removal of precipitation products (rain, melt water), thereby performing the function of protecting the facade, foundation and adjacent elements.

Typically, the installation of such systems is the prerogative of professional builders. However, it is also quite possible to make roof gutters with your own hands. Let's figure out how to do this.

The content of the article:

Drainage system of residential buildings

To have an idea of how to make gutters for the roof of a house or shed with your own hands, at a minimum, you need basic information about the system as a whole.

The structure, designed to protect the foundation of the building, prevent soil erosion and flooding of basements, consists of the following prefabricated parts:

- drainage gutters;

- gutter mounting brackets;

- drainpipes;

- connecting elements of straight pipes (couplings);

- fastening clamps for drainpipes;

- tees, contours, drains, plugs;

- funnels and gratings of water collectors.

Drainage gutters are installation elements assembled from separate trays, including corner ones.

The gutters are placed directly under the bottom edge of the roofing and secured with brackets.

Thanks to drainage gutters, water is collected over the entire roof area and the collected liquid is redirected to the locations of the drain pipe funnels.

About pipes and fittings

An integral element of the system is drainpipes (metal or plastic, round or rectangular), designed to discharge water from the level of the uppermost floor of the building to the ground level.

Drainpipes are assembled from several separate pipes, connected to each other by connecting elements.The fully assembled pipe is fixed vertically using fastening clamps.

Additional elements of the drainage system are plugs for gutters, contours, tees, funnels, protective nets, and gratings.

Gutter plugs are installed at the ends of the gutter lines and have a variety of configurations and shapes (right-handed, left-handed, universal). Due to the contours, accurate installation of pipes is carried out in complex architectural areas. Tees provide technical drains, and funnels, meshes and grates facilitate efficient water removal.

We also recommend reading our material on how to independently calculate the amount of materials needed for arrangement of drainage system.

Do-it-yourself drainage system: instructions

Having basic knowledge, it is already easier to solve the problem of how to make gutters from the roof of a private two-story house. But for a complete picture of possible projects, it is advisable to also become familiar with the methods that are used to construct such systems.

There are two ways (except for the so-called unorganized system):

- Installation of internal drainage.

- Installation of external drainage.

The first method is widely used on buildings with several floors (more than two). The peculiarity of the scheme is obvious - drainpipes are mounted inside the building and are placed in close proximity to the load-bearing walls.

The second method of external installation of drainpipes is almost always used for private low-rise housing construction. It differs from the first method by placing gutters outside the building.

Quick Photo Guide

The stages of assembly and installation of the drainage system are carried out in a standard manner. Let's look at the construction option produced after the roofing is installed. If you want to make a drain, the master will have to complete the following steps:

To collect and drain rainwater, you need to attach a drainage funnel and a riser to the gutter, through which the water will flow either into a container for collecting it or into a storm drain:

Installation of a drainage system

As a rule, work on the installation of a drainage system begins before the start of work on laying the roofing or at the final stage of laying the lower roofing sheets.

However, if the roof structure allows the gutters to be attached to the eaves (front) board, the drainage can be done after laying the roofing carpet. But work on the façade of the building must be finally completed in any case.

The sequence of actions is as follows:

- Installation of gutter brackets.

- Assembly, installation, fastening of drainpipes.

- Drainage system design.

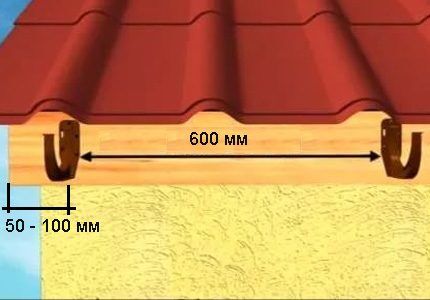

The brackets that will hold the gutters in a horizontal position are fixed to the bottom board of the sheathing, preferably at the point where it rests on the rafter beam. Or they attach the brackets to the cornice front board. In any case, the frequency of mounting the brackets relative to each other is no more than 600 mm.

The brackets should be mounted in such a way that after installing the gutters, their front edge is 20-30 mm below the roof plane line.

Technique for controlling slope and offsets

When creating a gallery from brackets, it is necessary to take into account the slope towards the drainpipe collection funnel. To do this, taking into account the given slope, install the initial and final gutter holders and pull the control cord between them.

The permissible slope of the gutter is 2-3 mm per meter of length. The indentations from the extreme end lines of the roof to the first and last brackets are made at a distance of 50-100 mm. The same standards apply to the distance from the bracket to the inlet funnel of the drainpipe.

Using the control cord (the second thread stretched between the brackets), the “run-out” of the leading edge of the fastenings relative to the conventional edge of the roofing is also controlled. Here, the distance from the conventional edge of the covering to the front edge of the gutter bracket should be equal to the maximum radius of the semicircle of the fastening bracket, minimum 1/3 of the radius.

At the end of the installation, the gutters are laid, followed by their fixation with special protrusions of the brackets, and the installation of end caps and inlet funnels.

Making a receiving funnel

To connect the gutter with the drainpipe, it is necessary to install a receiving funnel. It is not difficult to install this part in the system with your own hands.

The process is as follows:

- Take a structural part - a receiving funnel.

- Place it on the wall of the gutter from below and outline the outline of the hole.

- Drill a hole in the gutter wall along the marked line.

- Clean the edges of the hole with sandpaper and coat with glue.

- “Fasten” the part to the gutter with locks, aligning the holes.

There are several options for installing a receiving funnel on a chute. For example, instead of drilling a hole with a crown mounted on a drill, you can make a through hole with two counter cuts using a regular hacksaw.

You should also take into account that in some installation cases the introduction of compensating (temperature expansion-sensitive) receiving funnels is required. Such parts are placed between two cornice trays and secured in the standard way with special locks without the use of glue.

How to make roof drainage pipes?

The number of drainpipes is calculated based on the number of inlet funnels of the gutters and depending on the height of the building. According to standards, one receiving funnel is sufficient for 10 meters of gutter length.

The length of pipes for industrial drains is usually 3-4 m. When assembling, it is recommended to focus on the minimum number of pipe connections. That is, the optimal installation option is to use pipes 4 m long.

Together with straight pipes, two standard bypasses (angle 112º) and one drain for each unit of drainpipe (subject to a traditional residential private house design) will be required.

From the outlet of the receiving funnel, due to the connection of two contours, the outlet for the water pipe is brought closer to the wall of the building. If necessary (depending on the width of the cornice), the contours are supplemented with a pipe section.

Further actions:

- The lower contour is supplemented with a connecting element (coupling).

- The first straight pipe is inserted from the bottom of the coupling.

- Under the coupling, a clamp is placed on the pipe and secured to the wall.

- Before the next inter-pipe connection, fastening clamps are installed every 1.8-2 meters in length.

- The next coupling is installed and the process is repeated.

This is how the drain is assembled to its lower edge at a distance of 30-35 mm from the wall of the building. According to standards, the horizon of the lower edge of the drain is set at 250-400 mm above ground level.

You can read detailed instructions for installing roof gutters Here.

Connections with contours and couplings are usually sealed with rubber rings included in the set of shaped parts. But instead of O-rings, it is also possible to use glue (for plastic). A drain is installed on the lower edge of the drainpipe if there is no surface drainage system around the perimeter of the building.

To collect rainwater in a container, install a selector:

Some features of polymer systems

Compared to metal drainage structures, polymer systems are attractive due to their cost-effective installation and simplified assembly.

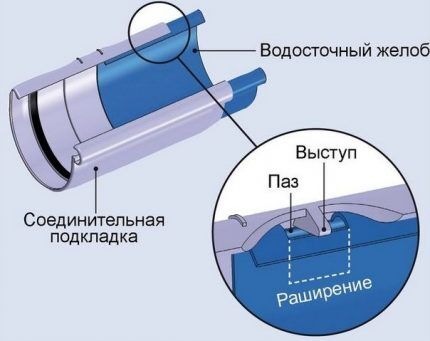

Meanwhile, plastic has the properties of changing structure under conditions of fluctuations in ambient temperature. Therefore, for anyone who decides to make a drain for the roof of a private house with their own hands, these properties of the material should be kept in mind and an installation technique that compensates for thermal expansion should be used.

Compensation for thermal expansion/contraction is achieved, for example, by incomplete insertion of the smooth ends of the pipes into the socket parts. Also, loose tightening of the rim of the fastening clamps releases the axial displacement of the parts as a result of thermal expansion.

It is advisable to limit the use of glue when installing drainpipes; use it only on one part of the connections. Installation of socket connections should be carried out in the socket position with the “up” direction.

Almost all manufacturers of modern drainage systems have taken into account the properties of plastic and produce shaped parts (expansion elements) adapted to temperature changes.The body of such parts indicates the temperature scale according to which they are mounted in the system.

The influence of temperature may cause deformation of the plastic. Therefore, it is necessary to comply with installation standards and the distance between fasteners. Compliance with the rules is a guarantee of installing a high-quality roof drainage system.

IN this material You can get acquainted with all the advantages and disadvantages of plastic and metal gutters.

Conclusions and useful video on the topic

You can learn how to properly design a drainage system from the following video:

Assembling a drainage system with your own hands is a solvable task. It is clear that independence primarily pursues the goal of saving. Meanwhile, when planning to install a drain with your own hands, it is advisable to carry out calculations based on such parameters as the total roof area and the average statistical intensity of precipitation in the area.

The calculation results will contribute to additional savings, since they can be used to accurately determine the need for materials and parts for installation.

Do you have any questions about how to install a roof drain yourself? Ask them in the comments section, and we will try to answer them promptly. There you can share your experience or give valuable advice on arranging a drainage system to visitors to our site.

Last year I helped a friend build a summer house. The bulk of the work was carried out by a team of builders, and the rest on their own. We did the drainage ourselves. There is nothing complicated about it. The main thing is to follow the technology, calculate the required amount of materials and install everything correctly.The house is one-story with a regular gable roof, so we made an external drainage system. We installed brackets, assembled and secured pipes, gutters, and brought out the drain. Everything worked out as it should.

We made the same system for an additional extension, we just thought that it was too expensive to buy a drainage system, so we made it and assembled it from scrap materials. In general, everything turned out to be much easier than I thought, you just need to imagine how it works, and, of course, have straight hands. It was cheap in terms of money, the main thing is that water now does not fall from the roof onto the ground and does not erode the soil.