Gas burner design, features of starting and adjusting the flame + nuances of disassembly and storage

Every owner of an apartment or private house where gas equipment for the heating system is installed has encountered problems associated with its setup or interruptions in operation, right? To ensure proper operation of the heating system, you need to know the nuances of the operation of gas appliances and the features of their settings, and all this information is collected in this article.

This publication also contains comprehensive information about the types and design of a gas burner. In addition, you will find information about setting the flame in gas burners and the main reasons why your equipment malfunctions or does not work at all.

The content of the article:

Burner design and its types

All heating boilers differ from each other in the type of fuel they use. The most accessible, of course, is gas. This type of fuel is the most common and produces the least combustion waste. At the same time, the efficiency level is quite high.

A standard gas burner is the main element in the heating system, which supplies and ignites fuel in a gas boiler. We will talk in detail about the design and principle of operation of the burner further.

How does a gas burner work and work?

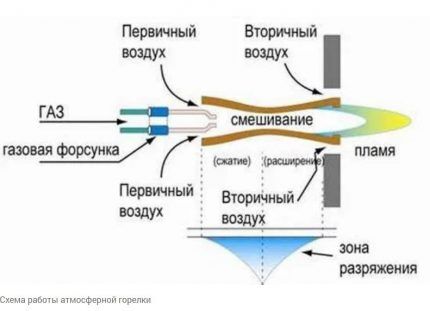

The gas burner is designed to supply a combustible mixture along with air, then these components are mixed in the combustion chamber.The further process is to maintain even combustion of the fuel.

The principle of operation is supposed to be divided into the following stages:

- Preparation;

- compound;

- combustion.

So, first, all the necessary components of the combustible mixture undergo a preparatory process. They gain a certain speed, temperature and the desired direction of particle movement. Next, the fuel is combined with air and enters the fuel combustion chamber. After this, it ignites.

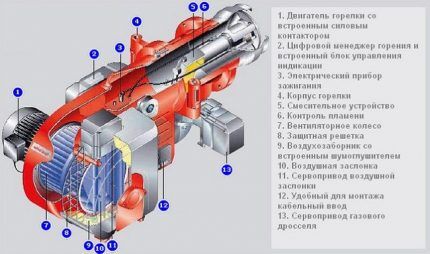

The main structural elements of a gas burner are discussed in the diagram below.

Regarding possible burner breakdowns and safety use of gas equipment At the same time, boiler manufacturers did not forget to take this point into account. Thus, all modern boilers have additional structural elements that ensure safer operation and automatic shutdown in the event of a burner breakdown or other emergency situations.

When some elements of the equipment fail, in the event of their breakdown, the device turns itself off.

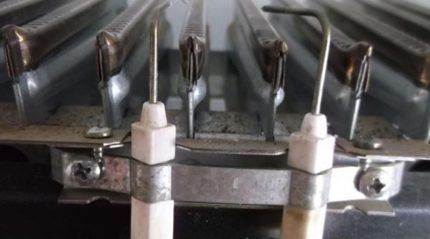

There are models in which ignition occurs by supplying a spark from an electric piezoelectric element. But such boilers also have components that can ensure the safety of using the equipment in case gas burner failure or other malfunctions.

To avoid problems when igniting the burner, it is important to carry out maintenance in a timely manner. Mandatory inspection and maintenance of the gas boiler must be performed before the heating season, but at least once a year.

Main types of burners for a gas boiler

For maximum efficiency of the heating system in a private house, a burner is installed in a gas boiler. Such equipment facilitates the regulation of combustion processes in the system. As a result, the fuel burns evenly.

Based on their operating principle, burners are divided into:

- injection;

- turbocharged;

- combined.

Injection (injection) type of gas burners - an integral part of a gas boiler. It works in such a way that air enters the work area by injection.To evenly maintain the combustion process, the oxidizer enters the tank under a certain pressure and mixes with gaseous fuel.

This type of appliance is designed exclusively for use with natural gas. For another type of gas, e.g. liquefied, additional elements must be installed.

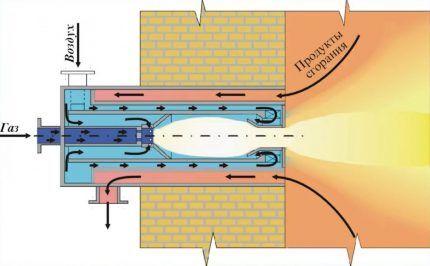

The second type of burners (turbocharged) works on a different principle. Here, air enters the work area and is mixed with combustible fuel using a fan. Thanks to the control system, it is possible to regulate the speed of rotation of the blades, thereby regulating the supply of oxidizer. Such a device allows high-quality increase boiler efficiency.

Despite the noise that comes from the fan, such devices are quite effective, and unwanted sounds can be eliminated by installing additional noise-reducing devices. They are more productive. But, as you know, turbines often fail if operating rules are not followed.

But there are also burners combined type. They are also designed for boilers and operate not only on gas, but also on other types of fuel. Such heating systems do not require additional structural elements, since they are installed initially. These types of equipment are much more expensive.

Burners are also divided into industrial And household. There is practically no difference between their operating principles.

But, despite the differences in the design of gas burners, they are all designed for high-quality fuel combustion.

Setting the gas burner flame

In order to properly configure the burner of a gas boiler, you must first follow the operating instructions for the gas appliance. Next, we’ll talk about how to properly start and set up a gas burner, and in what cases flame adjustment is necessary. But first things first.

Features of boiler burner settings

It is recommended to adjust the burner flame using a gas analyzer. It shows information about amount of airthat mixes with the gas, namely the level of oxygen involved in the process and the amount of CO.

Typically, CO should be no more than 50 ppm, oxygen concentration should be approximately 3 to 5%. If it is less, then most likely the gas will not have time to burn, as a result of which a lot of soot will accumulate, the CO level2 will be higher than normal, and the efficiency of the equipment will decrease.

If the air is more than normal, then the temperature of the household burner of the gas boiler will be too high, and this can lead to tragic consequences, including an explosion of the equipment.

The flame in the gas burner should be blue. If you find that the color has an orange tint, then try reducing the amount of gas. Reduce until the color turns blue (blue). This color is a sign of optimal operation of the gas appliance. The main thing is not to reduce the fuel supply to the point where the flame becomes almost colorless. In this case, it will go out very quickly.

Setting the starting gas supply is only necessary during ignition and does not affect the performance of the device. But if necessary, it is possible to adjust it too. To begin with, you should reduce the starting fuel supply. Reduce until the burner stops turning on. After this, you can turn the regulator until ignition resumes. You can watch the video at the end of this article for more details on setting the flame of a household gas burner.

We also recommend that you familiarize yourself with the intricacies gas boiler adjustments.

When is flame adjustment necessary?

An atmospheric gas burner, which operates without a built-in fan, very often fails; a turbocharged one breaks down much less often. During prolonged use of the device, its components may break or stop working at full capacity.

For example, a gas boiler may experience reduced efficiency or a decrease in flame.

And this can happen for the following reasons:

- High burner power installed for equipment that is designed for less powerful burners. In this case, there is not enough space for proper combustion of fuel, the fuel burns unevenly, which leads to soot quickly accumulating on equipment parts.

- A lot of soot in the chimney can have a bad effect on the draft of a gas boiler. Because of this, the subsequent removal of combustion products is very weak, little air enters, and the flame becomes yellow.

- The presence of burner defects is one of the reasons for reduced boiler efficiency, but in this case, adjusting the flame will not help fix the problem.

- Pressure drops when supplying gas can also contribute to the formation of soot and carbon deposits, and this will significantly reduce the productivity of the equipment.

All these reasons can affect the flame temperature in the gas burner, in which case repairs will be required.

Recommendations for storage and disassembly

All gas appliances require careful handling and compliance safety rules. Therefore, it is not recommended to repair malfunctions without permission or disassemble the burner and the gas boiler itself.

In order to avoid emergency situations, as well as to ensure the correct and efficient operation of the device, it is best to contact the gas company with which you have contract signed on TO.Calling a specialist will be the most reasonable decision, because the price of your life and the lives of the people around you is much higher than calling a specialist.

As for storing household gas burners, everything is simple. They must be stored in a dry and ventilated area to avoid corrosion of metal parts.

To store the boiler itself, you need to make sure that there are no plugs at the outlets for connecting the heating pipes.

You also need to make sure that there is no water inside. If you do not drain the water, the tank will rust and the boiler will be unusable.

Conclusions and useful video on the topic

We recommend watching a thematic video on setting the flame in a gas burner. This video talks about the main problems of a gas burner when adjusting the flame is required.

Watch the following video, which details the main reasons why your gas burner is not working properly, or has stopped lighting altogether. The most common reason is the accumulation of large amounts of soot, which is formed from incomplete combustion of gas:

Try to use your own equipment correctly; if the gas boiler burner starts up with some interruptions, then you need to urgently carry out diagnostics and find out the cause of the interruptions, otherwise the device may harm your property or life.

It is also worth remembering about the storage and transportation of gas burners. To do this, you need to study the operating rules that are written in the documentation. Such documents must be included when purchasing equipment. In any case, if you find out any malfunctions, immediately contact the gas service or reliable specialists who will help you solve the current situation.

Would you like to supplement the above information with useful information on the topic of the article? Or would you like to share your own experience of setting up a household gas burner with other users? Write your comments, share your experience, participate in the discussion - the feedback form is located below.