DIY copper pipe installation: copper pipeline installation technology

A household water supply network assembled from rolled copper pipe elements is considered one of the most reliable. Of course, the development of such a highway is not a cheap pleasure.However, the high cost of the water supply system is compensated by its durability and other significant advantages.

In order to somehow save the budget of the water supply organization, you can install copper pipes yourself, having first studied the technology of the work. Do you doubt your own capabilities?

We will tell you what tools you need to prepare, we will describe step-by-step processes for assembling a copper pipeline by soldering, as well as using compression fittings. The following photo instructions and practical tips will help you avoid mistakes and set up a reliable utility network.

The content of the article:

Copper as a material for making pipes

Copper is the optimal material that ensures the performance of systems at high pressures and temperatures. Therefore, copper pipe is used not only for the installation of hot water supply pipes or heating system lines, but also for other purposes.

For comparison you can take polypropylene pipes and copper. The former are able to withstand temperatures only up to + 95ºС at pressures of no more than 25 ATI. The latter are capable of operating at T=250ºС and pressures up to 300 MPa.

Copper is the main material from which the French, British, Australians, and Swedes prefer to install water supply and heating systems. High mechanical strength, ease of machining - these properties have made seamless copper pipes popular in the construction of various types of communications.

Modern production of such products involves applying a protective polymer layer to the surface of the pipes, which eliminates the appearance of stray currents in magnetic field zones.

Nuances of installing copper lines

Plumbers, who have a set of tools and experience working with copper, perform a number of actions during the installation of copper pipelines:

- cleaning, calibrating, cutting;

- giving the desired shape;

- crimping, soldering, connection.

Each owner of an apartment or private house can perform the same actions with their own hands.

The main thing is to learn the nuances of technology and the secrets of producing such work. Each action requires an appropriate tool.

As a rule, a mechanic's tool kit includes:

- copper pipe cutter or hacksaw;

- files, sandpaper, rags;

- locksmith wrenches;

- gas key No. 1;

- manual calibrator, pipe bender;

- gas stove, flux, solder, fum tape.

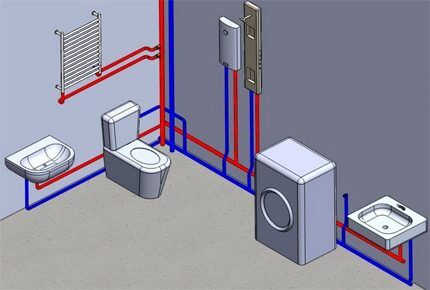

The start of installation work is always preceded by activities aimed at calculating and drawing up water supply wiring diagrams or heating systems.

Based on their diagram, the required number of copper pipes, their length, diameter, and the number of additional installation parts are calculated.

Methods for connecting copper pipes

In practice, one of two methods is used to assemble copper pipelines - by soldering or mechanical crimping.

Secrets of soldering with a gas torch

When choosing a soldering method for installing the system, you must consider the following: all connections made in this way are permanent. Soldering provides a high percentage of density guarantee, but imposes some restrictions on maintenance. It is often impossible to upgrade a system without adding complexity.

So, if it is necessary to change some part of the water supply (heating system), for example, due to the introduction of new equipment, difficulties may arise. You will have to use a gas torch and soldering technique again just to be able to introduce a coupling, tee or other part into the system.

Therefore, solder joints are used in hidden plumbing projects embedded in walls or under floors.

The soldering process is inextricably linked with the operation of the gas burner (open fire and combustion products).Therefore, this technique is not always suitable for installation, especially in rooms where a fine finish was previously carried out.

Step-by-step soldering installation process:

- Two pipes are cut to size. The end area is cleared of burrs.

- The end part of one of the pipes is expanded with a calibrator - a socket is made.

- Use a wire brush and sandpaper to clean the soldering areas until they shine.

- Cleaned surfaces are treated with a flux solution.

- The processed parts are inserted one into the other.

- The joint is heated with a burner to the melting temperature of the solder (350-500ºC).

- The end of the solder rod touches the lower edge of the socket.

Under the influence of high temperature, the solder melts and rushes into the gap area between the walls of the pipe and the socket due to the capillary effect created by flux evaporation. This results in a neat and high-quality solder connection. This is just one example of pipe-in-pipe soldering.

Soldering with fittings and other elements is carried out in the same way.

Step-by-step instructions for soldering copper pipes, as well as technical nuances of the work are given in this article.

Connection with compression fittings

It is much simpler and easier to install copper pipes with your own hands if you use another widespread technology - mechanical crimping. In this case, special fittings are used to create a connection between copper pipes.

Approximately the same elements are used when working with polypropylene pipes. But for copper they make a slightly different design of the crimp ring - one-piece, without a cut.

Compression fittings are made of brass. Judging by the degree of ductility of materials, these values for copper and brass are almost the same. An important feature of the brass-copper pair bond is the almost complete absence of galvanic connection between the materials.

This factor guarantees the cleanliness of the connection during operation - the absence of oxides, corrosion, etc.

The situation is completely different with aluminum. This metal, unlike brass, is galvanically bonded to copper. Under conditions where tap water is saturated with salts, that is, it is an active electrolyte, a favorable environment for the occurrence of an electrochemical reaction is formed.

Under the influence of this reaction, aluminum is destroyed. Therefore, direct connection of copper pipes and aluminum radiators (or other aluminum devices) is undesirable. For example, steel transitions should be used.

Installation of crimp fitting:

- The end area of the pipe is cleared of burrs.

- A nut, ferrule, and fitting are put on the end of the pipe.

- Using a wrench of the required size, the fitting is held in one position.

- Use the second wrench to screw the nut onto the thread of the fitting.

The tightness of the connection is achieved by uniformly pressing the crimp ring along the diameter of the copper pipe. It is not recommended to use extreme force when tightening the nut. From the initial stop, it is enough to tighten the nut 1-2 turns.

Advantages application of press connectors – they can be disassembled and reassembled if necessary. But at the same time, the quality of the seal of such connections is influenced by changes in the temperature of the external and internal environment.

Often, due to temperature changes, crimp connections leak. This defect can be eliminated simply and quickly by tightening the union nut.

However, for hidden installation of a water supply system, the method of crimping push-in connections of copper pipes is clearly not suitable.

Tools for mounting elements

It is not always possible to cut a pipe without damaging the wall structure. The wall thickness of copper pipes up to a diameter of 28 mm is only 1 mm. Even the use of disk pipe cutter for copper pipes does not provide full guarantees of evenness of the cut. If wall disturbances are observed, a calibrator is used. This tool is used to calibrate (align) the pipe and socket.

Pipe cutters are available in manual, electric, pneumatic, and hydraulic types. Structurally, the pipe cutter is a mechanical clamp, where two rollers act as supporting elements. One of the rollers has a cutting edge.

The cutting process is carried out by sequentially pressing and rotating the pipe cutter around the pipe axis. The smoother and more often the pressing is performed, the better the quality of the pipe cut.

Installation work is often accompanied by bending of copper pipes. A high-quality, even bend of any radius helps create a tool called a pipe bender. There are two types of copper pipe benders - spring and mechanical.

The first tool has a simple but effective design. Designed for bending small diameter pipes. The second type includes several design varieties.

A spring pipe bender is made in the form of a long casing that fits onto a copper pipe. One end of such a casing is slightly widened for greater ease of use. The copper pipe placed in such a springy shell is bent by hand without the risk of jamming at the bend.

Disadvantages - the bending radius has to be checked by eye; for a specific pipe diameter you need your own spring pipe bender.

Mechanical pipe benders (lever, segment, crossbow, hydraulic) allow you to bend pipes of different diameters (from 10 to 125 mm). Copper pipes of large diameters are usually bent in segments and hydraulic pipe bender. The bending angle when working with such devices can be 180°.

Characteristics of copper water supply

Durability copper water pipes to some extent due to the fact that the chlorine contained in the water, in reaction with copper, contributes to the formation of a thin oxide film on the inner surface.This film additionally protects the pipe wall from the negative influence of the pumped medium.

Copper is also considered the optimal material according to the results of sanitary and bacteriological studies. This metal has a bacteriological effect, for example, against the staphylococcus virus.

Copper has a high thermal conductivity coefficient. This point forces us to take measures aimed at isolating pipes from the external environment.

An uninsulated cold water supply system in the summer can create a serious problem with the collection and disposal of condensate. Uninsulated hot water pipes experience significant heat loss. When installing copper pipe networks with your own hands, you should take these points into account.

Conclusions and useful video on the topic

You can learn how to install a copper water supply in the following video:

Quality, reliability, durability – plumbing and heating systems endowed with these properties often delight apartment and house owners if copper is used for installation work.

Indeed, when there is confidence that there are no leaks and are not expected in the future, that there are no gusts even in severe winter, this means that a system of copper pipes is installed in the house.

Do you have anything to add or have questions about the technology for installing copper pipes? Please leave comments and participate in discussions about the post. The contact form is located in the lower block.