Converting the boiler to liquefied gas: how to correctly convert the unit and configure the automation

The gas boilers offered for sale are oriented and configured to process main gas.But what should owners of private houses do in this case, which are not connected to a natural gas supply system? After all, we need to live in normal civilized conditions with a functioning heating system now.

Everything is extremely simple - switching the boiler to liquefied gas will allow you to heat the house and heat sanitary water using a group of cylinders or a gas holder. To achieve this goal, your unit will have to be slightly altered and reconfigured to other fuel pressure parameters. We will tell you in detail how this work is done.

The content of the article:

Reasons and principles of boiler conversion

From the first lines, we would like to warn you that work on re-equipping the boiler to switch to a different type of fuel must be carried out by the foreman of the organization with which an agreement has been concluded for the supply of gas and maintenance of equipment.

However, any owner should know the essence and stages of the process for basic control of the actions of invited performers. And doubts about their competence sometimes justifiably creep in. Therefore, it is better to monitor the implementation of the procedure, on which, by the way, the safety of the home and household depends.

It also happens that a gas service representative cannot get to a remote location. In this situation, the home master, of course, will try to do everything with his own hands. But for the result of the efforts of an inexperienced craftsman in the gas sector, he himself will bear responsibility, and the manufacturer’s guarantees will be void.

When purchasing a gas boiler for domestic use, we receive a device configured to process main-line fuel. A centralized gas pipeline supplies us with a mixture of combustible gases, in which methane predominates. The main gas enters the devices with a natural density and pressure of 21 mbar.

Liquefied gas is an exaggerated name for a mixture of propane and butane, in which either the first or the second component can predominate. It can contain predominantly butane with a slight admixture of propane, or vice versa, propane predominates by 99%.

The density of the liquefied mixture increases 600 times. The pressure does not increase as much, but it is still higher than that of natural fuel, 30-31 mbar.

The types of gases that boilers operate on are standardized. They are assigned codes that the manufacturer indicates in the technical documentation. Thus, the boiler’s consumption of main gas is marked with code G20. The ability to operate the boiler from a liquefied mixture with a predominance of butane is designated G30, and from a mixture with a predominance of propane - G31.

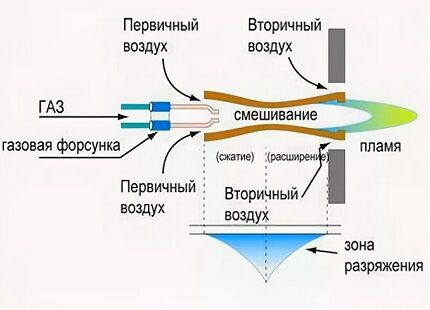

In order for blue fuel to fulfill its significant duties, gas enters the combustion chamber through nozzles. There, gas is mixed with air using a burner in proportions that are optimal for a particular type of fuel. This means that gas must be supplied to the burner in the volume necessary for normal combustion.

Normal mixture formation is possible if the diameter of the nozzles is suitable for its implementation. The size of the supply holes determines how much gas under a certain pressure will enter the combustion chamber with a specific volume of air. That is why nozzles with different cross-sections are installed for liquefied mixtures and for main gas.

Note that the cross-section of the nozzles is determined not only by the type of gas, but also by the power of the boiler itself. For your information, to operate a 10 kW unit operating at maximum operating mode, main gas requires 1.2 m³/h, liquefied mixture of any type 0.86 kg/h.

The more powerful the equipment, the more fuel is required to operate it. The larger should be the size of the nozzles that pass blue fuel into the combustion chamber. Their cross-section is clearly calculated and strictly regulated by the manufacturer, who produces burners with nozzles of a given diameter for a series of boilers of a given power.

So how can you switch to liquefied gas if you didn’t think to buy it in the first place? liquefied gas boiler? That's right, replace either the entire manifold with the entire set of injectors, or just the injectors, leaving the manifold in place. The second option is not possible in all boilers.

In addition to replacing devices for supplying liquefied gas, you will also need to reconfigure the burner of a gas boiler with an electronic control type. This is necessary for the complete delivery of air in the volume required for the uninterrupted combustion process. The new settings will also ensure that the gas supply is interrupted if a risky situation arises.

You will also need to install a reducer designed to regulate the pressure of gaseous fuel. TO gas reducer you can connect one or a group of cylinders. The gas valve may need to be replaced if necessary.

In any situation, before ordering a contractor to translate a wall or floor-standing gas boiler For liquefied fuel, you should consult the gas service that supervises your equipment and gas supply to your facility.

They will tell you which devices you should purchase for translation. They will calculate how much the modernization will cost you along with the specialist’s payment.

Baxi boiler conversion stages

In order to get a complete and meaningful idea of how to convert a boiler to operate on cylinder gas, let’s look at an example of converting a wall-mounted double-circuit unit from the Baxi brand.

Injector replacement procedure

In most boilers with the Baxi logo, there is no need to completely change the burner, just rearrange the nozzles. To do this, they need to be purchased in advance, focusing on the power of the device and the type of gas. In the example under consideration, to switch to G31 fuel you will need injectors with a diameter of 0.77 mm.

The price of a set of nozzles for these boilers is approximately 2.5 thousand rubles. The set, produced for several similar boiler models, contains 17 of them and a spring. 15 injectors will need to be changed, 2 spare ones will be useful in case of unsuccessful actions.

And we will act like this:

- We disconnect the volatile devices of the boiler from the power supply. Turn off the unit and turn off the taps on the pipes supplying gas and water directly to the unit.

- We remove the front panel from the boiler, then separate the screen of the closed combustion chamber located behind it.

- We unscrew the screws holding the lid of the closed combustion chamber. It's located right behind the screen.

- We disconnect the wires of two electrodes: one from the flame control, the second from the ignition system.

- Remove the burner. In order to remove it, unscrew the two screws with Phillips heads that hold the device. They stand on the right and left, fixing the burner on the ramp.

- We unscrew the injectors using a wrench without dismantling or removing the ramp. You should not use pliers in this matter. They can deform the injectors without much effort. The nozzles of the injectors are thin and extremely precise in design, there is no point in spoiling them - they may still come in handy.

- Instead of unscrewed injectors, we install new devices designed to supply liquefied gas, and connect electrodes for the lighter and flame control system.

- We return the burner to its normal place. Its position will be “prompted” by the guides.

With the installation of the burner, all alteration procedures are completed. All that remains is to assemble the previously separated parts of the unit and fix the lid, the screen with the outer panel in the reverse order to the one in which they were disassembled.

But that's not all, the most serious and delicate work lies ahead - tuning.

The process of adjusting pressure using “folk remedies”

This stage is often available only to representatives of the gas service. After all, not every home craftsman has a pressure gauge that can recognize pressure readings in the range from 3 to 40 millibars. Buying a meter for a one-time job is not very reasonable; it is easier to use the services of a specialist who has this device in his arsenal.

But domestic inventors have found a way to measure gas pressure data in the system. We also managed to select a device capable of correctly displaying atmospheric pressure. Believe it or not, this is an ordinary tonometer, which the older generation in your family probably has.

It doesn’t matter whether you have a dial or electronic blood pressure meter at your disposal. Both options are quite suitable. Most of them respond well to deviations of 3 mbar (i.e. millibars).

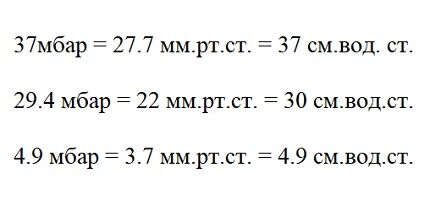

The only drawback is that not all devices are equipped with a corresponding scale with mbar divisions. But there is a scale with divisions in mm of mercury, and on the Internet there are a sufficient number of programs that convert all comparable physical units of measurement.

For our own convenience, we will make a sign with the conversion of units of measurement, then we will confidently begin to reconfigure the boiler automation to operate on a liquefied mixture of gases.

In the example proposed for consideration, the pressure at the inlet to the unit should be 37 mbar.We set the pressure limits for burner operation to 4.9 mbar at minimum, 29.4 mbar at maximum.

We need to first readjust the pressure before entering wall-mounted gas boiler. In our case, everything was designed for the use of main gas supplied at a pressure of 27-28 mbar. Now we set the reducer of the gas tank or group of cylinders to the required 37 mbar.

We configure the settings in the following order:

- We remove the lower fitting of the gas valve, essentially freeing the gas entry point into the system to adjust the dynamic pressure.

- We connect the tonometer. We simply disconnect the electronic meter from the tonometer reading system, after which we connect it with a narrow hose to the gas injection point, and immediately connect the pointer meter with a pear hose.

- We adjust the pressure to the parameters we require, taking into account that the device will show us mmHg. This means that we need to set it to 27.7 mm.

Note that the dial version of the tonometer is much more convenient in this matter. The super precision that the electronic system is trying to demonstrate is completely unnecessary here. In addition, it is easier to capture tenths with a pointer device that works without unnecessary “fuss.”

Next, we proceed to reconfigure the gas pressure entering the burner directly:

- We unscrew the upper fitting from the gas valve. We connect the tonometer to the freed hole.

- We start the boiler so that it works with maximum settings for the characteristics of hot water and coolant.

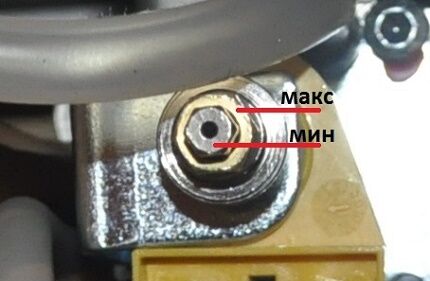

- We adjust the upper and lower limits for heating the coolant and sanitary water by turning the adjustment nut left and right.

We carefully turn the adjustment nut around its own axis. Turn it clockwise to increase, counterclockwise to decrease. We use a wrench with a head. We continue this way until the values coincide with the translated values in mm of mercury: 22 mm for the upper limit, 3.7 mm for the lower limit.

We determine tenths on a scale literally “by eye.” To set 3.7 mm, we find approximately the middle between 3 and 4, then slightly shift the readings to 4. Well, we can say that we have set it.

Now we tighten the fitting and assemble the boiler, after which we start it up and check its operation. The error of the adjustment in the example did not exceed 1%, which is really remarkable for home performance.

Likewise, all retrofitting and reconfiguration work is carried out on many double-circuit wall-mounted units. Such devices include products from Airfel, for example, the Digifel and Digifel DUO models.

Rework steps with changing the burner

The design of a number of boilers is designed in such a way that there is no point in turning out the nozzles separately. For them, manufacturers produce modules designed for liquefied gas. You can easily change the burner module, for example, in the Navien Deluxe boiler.

The whole job consists of replacing the manifold with injectors with exactly the same device, but with holes of a different size. The fact that it will be factory-made is a definite plus, guaranteeing the tightness of the gas pipelines. There is no need to doubt its further safe operation.

Re-equipment and reconfiguration work in this case is carried out as follows:

- Disconnect the unit from the power supply and turn off the tap on the gas supply pipe.

- Remove the front panel from the boiler body.

- Disconnect the electrodes connected to the ignition system.

- We dismantle the gas supply pipe located within the boiler, having first unscrewed the 4 screws holding it.

- Remove the cover installed on the closed combustion chamber. To do this, unscrew 11 screws.

- We dismantle the overheat protection sensor along with the bracket intended for it.

- We remove the manifold along with the injectors attached to it. To remove it, unscrew the two screws located on the right and left of the device.

- We install a sealing ring on the new manifold to be installed, sealing the inlet of the gas pipe. We mount the new manifold in its original place and secure it with screws.

- The microswitch, fifth from the bottom, is moved to the right. So we reconfigure the device to operate on liquefied gas.

After these simple manipulations, we assemble the boiler, observing the reverse sequence. In the same way, most floor-standing gas boilers are remade and reconfigured, especially if they are of the condensing type. This version of boilers is most often even designed for transferability.

The following photo selection will help you visually familiarize yourself with the procedure for replacing a manifold with gas injectors and setting up the boiler:

Now all that remains is to change the manifold and configure the gas unit to operate from cylinders or a gas tank:

However, you should know that both of the above-described conversion methods are not generally implemented with all models of units. There are boilers that you shouldn’t even try to convert to liquefied gas, especially units that were produced a long time ago.

In any case, before planning a rework and translation, you need to ask representatives of the company that carried out the first launch whether it is possible to implement a similar project. It is also worth studying the passport of the gas processing equipment and the manufacturer’s recommendations. Usually the possibility is specified there.

Safety Recommendations

Converting the boiler and reconfiguring it to consume liquefied gas dictates the need to “reconfigure” your attitude towards the device for supplying and storing blue fuel.

You must remember that:

- Cylinders or gas tanks, which are gas storage tanks that supply fuel to household appliances as needed, need to be refilled periodically.

- To fill a group of cylinders or a gas holder with gas, you need to contact certified organizations that have equipment to record the weight of the gas in the cylinder and its actual volume in the gas holder.

- Filling closed gas tanks is carried out to 85% of the useful volume of the vessel. This reserve is necessary in case of thermal expansion of the fuel to avoid an explosion.

A non-hazardous situation that requires special attention when replenishing liquefied blue fuel reserves is the filling of liquid with a density different from the density of the previous liquid. Because of this difference, the remaining liquefied gas may not mix with the newly filled portion.

In the tank, due to the difference in density, a kind of two non-connecting sectors are formed, in each of which liquefied gas circulates. However, convective heat exchange will occur at the sector boundary after a short period. After the temperatures are equalized, the densities will be equal and the liquids will be able to mix.

Usually this process, meaning direct mixing, is accompanied by intense evaporation of liquefied gas. To avoid associated losses, mixing devices should be used during the filling process. But it is better to choose a method that eliminates the above-described phenomenon.

Replenishing cylinders and gas tanks with blue fuel in general is a process that requires increased attention, otherwise problems can be very serious and even catastrophic. The rapid spread and evaporation of the liquefied gas mixture is recognized as a significant problem.

If not violated safety rules gas-consuming equipment, main methane rarely explodes. This only happens with significant leaks, if the technical state of the gas in the surrounding space changes dramatically. For example, in a kitchen with obvious signs of a leak, instead of mandatory ventilation, they turn on the light.

When liquefied gas expands in a closed container due to external heating, it will necessarily explode if there is not enough space left in the container for its expansion. Blue fuel burns extremely intensely. Since the gas is quickly absorbed by the atmosphere, the combustion zone expands at high speed.

Conclusions and useful video on the topic

The following video will introduce you to the organization of heating using liquefied gas and the procedure for converting the boiler to its consumption:

The technical and technological essence of converting a boiler to consume a gas mixture in a liquefied state should be known to both independent home craftsmen and customers of gas service workers.

It should be remembered that the second option is preferable, since the gas is explosive, toxic and flammable. In addition, if third-party intervention occurs, the equipment warranty will be invalidated.