Amount of air for combustion of natural gas: formulas and examples of calculations

The efficiency of all kinds of gas equipment depends on the quality of the combustion process.What is directly affected by the amount of air for burning natural gas, which is not difficult to calculate. Why not take care of fuel efficiency and increase equipment efficiency by performing the necessary calculations yourself, right?

But how to do this correctly and where to get the data for calculations? To understand this topic, let's look at the theory of air flow for gas combustion in our article and get acquainted with the simplest formulas for calculating the required volume of air. We’ll also talk about the practical benefits of these calculations.

The content of the article:

Theory of air consumption for gas combustion

The procedure for obtaining thermal energy directly affects the duration of operation, the frequency of work on maintenance of gas-using equipment. It should be understood that the optimal gas-air mixture is the key to safety. Let's talk in more detail about the air consumption for gas combustion.

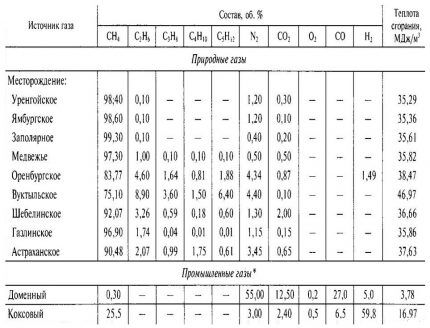

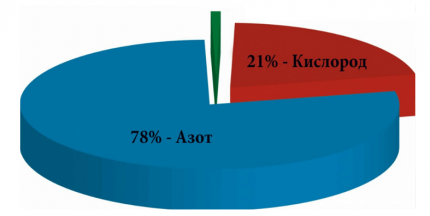

To burn one molecule of methane, which is the main component of natural gas, exactly 2 molecules of oxygen are required. If translated into understandable volumes, then in order to oxidize a cubic meter of the specified fuel, you will have to use 2 times more oxygen.

But in real conditions everything is more complicated.Since air is used as an oxidizing agent to carry out the chemical-physical combustion process, the composition of which is only a fifth of oxygen, necessary to maintain combustion. And, to be precise, then 20.93% - this is the percentage that is usually used for all kinds of technical calculations. That is, 9.52 times more air will be needed.

You can find out the specified number by performing 2 steps:

- Division 100/21. This operation makes it possible to find out that there is 4.76 times more air in any volume than oxygen.

- Multiplying 4.76 by 2, which equals 9.52 — exactly how many times more air will be needed to burn any volume of natural gas.

But there is one important caveat: the calculated amount of air required for efficient gas combustion is a theoretical flow rate. But in practice it will be needed. The reason is that the calculation was carried out for ideal conditions, but in reality there are almost always a number of factors that make significant adjustments.

These include:

- composition and quality of reagents (air, gas);

- type of equipment used to supply energy;

- equipment condition;

- method of supplying gas, air, as well as a number of other points.

If special accuracy is needed, then the features listed above can sometimes be taken into account. For example, you can find out the exact composition of the gas at the nearest gas service office. But, when special accuracy is not needed, the resulting value of 9.52 is simply multiplied by the so-called excess air ratio. The value of which usually lies in the range of 1.1 - 1.4.

When the calculation must be as accurate as possible, then the amount of air actually used should be divided by its theoretical flow rate. But in most cases it is easier to use the average value excess air ratio. The value of which should be multiplied by 9.52 and as a result you will find out the exact amount of consumed air needed to ensure the gas combustion procedure.

So if it is equal to:

- 1,1 — air mass will be needed 10.472 times more;

- 1,4 — air will need to be used 13.328 times more.

That is, to burn each cubic meter of energy, up to 13.328 m³ of air will be needed.

Formulas and examples of calculations

The required value in each specific case can be obtained using a special formula or average indicators. Let's talk about these methods in more detail.

Method #1 - calculation using formula

Which states that the hourly volume of air (Vh ), required for combustion, will be equal to:

Vh = 1.1 x Kizb.v x VT x Vg/h x (273 + t)/273,

Where:

- TOizb.v — excess air coefficient;

- VT - theoretically required amount of air;

- Vg/h — hourly gas consumption by equipment;

- t — temperature values in the room where the gas equipment is located.

The hourly gas consumption required for calculations is indicated in the passport of any gas appliance.

That is, if such a value is 10, and:

- room temperature, for example, 18 ° C;

- excess air coefficient - 1.1.

Then we perform the above mathematical operations, namely:

1.1 x 1.1 x 9.52 x 10 x (273 + 18) / 273 = 122.1

As a result, it turns out that in this particular case, to burn gas, 122.1 m³ of air will be needed every hour.

Method #2 - calculation using averaged data

If you do not want to perform a similar calculation of air for combustion of the required amount of gas, then you can listen to the recommendations of many manufacturers and specialists.

Which say that the process will be effective if at least 1.6 m³ of air is supplied hourly for each kilowatt of power.

That is, the calculation can be completed in just one action. For this purpose, the power value of the gas appliance taken from the passport should be multiplied by the indicated 1.6. The result will be the amount of air required for efficient combustion.

For example, if the power of a gas boiler is 40 kW, then this value should be multiplied by 1.6:

40 x 1.6 = 64

This will result in 64 m³ of air, which will need to be supplied to the gas appliance every hour.

Practical meaning of air flow calculation

Skills in performing such calculations may be needed to increasing efficiency gas equipment, as well as eliminating the causes of its malfunction.

Prevention of breakdowns and reduction in equipment efficiency

For example, knowledge of the optimal amount of oxidizer will be needed when the surfaces of chimneys (internal), structural elements of equipment (heat exchangers, burners, etc.) quickly become covered with layers of soot, other combustion products.

If the removal of contaminants does not give the desired effect, like any other measures (adjustment, replacement of parts, assemblies). Which indicates the presence of the so-called underburning of the energy carrier, which occurs due to insufficient air.

And also knowledge of the required air flow will be required in the following situations:

- Excessive gas consumption detected, which cannot be eliminated with the help of adjustments or other manipulations. Since the cause may be mechanical underburning. That is, a process in which too much air is supplied, which also leads to incomplete combustion of the gas.

- Frequent changes in the color of “blue” fuel during combustion have been noticed - for example, orange, white, red, yellow.These are more complex cases than the previous ones, since the cause may be either excess or insufficient air.

- Unstable gas combustion process. For example, if not all working openings of the burner, gas boiler burners, etc. are used. And cleaning the listed structural elements did not lead to improvement, since in such situations it will definitely be necessary to supply an order of magnitude more air.

Despite the presence of various reasons, the calculation is performed in the same way, according to the methodology outlined above.

The benefits of calculations when installing a boiler room

Calculation of the amount of air required for effective gas oxidation is necessary in cases of arranging a furnace, installation, replacement of gas equipment and other similar ones.

And the calculations are carried out, but the situation in each indicated case is complicated by the fact that in order to obtain all the necessary data it is necessary to perform a number of calculations.

Which calculations include:

- total air flow - it is necessary to supply air to the room with gas equipment not only for the combustion process, but also for its ventilation (in SNiP II-35-76 it is clearly stated that in rooms used as furnaces, 3 volumes of air must be changed every hour);

- sections of the exhaust duct;

- cross-section(s) of the opening(s) of the input channels;

- natural draft in the provided exhaust duct;

- actual air mass velocities in sections of future air ducts;

- pressure losses due to various local resistances;

- the size of the window placed in the room with gas equipment.

In addition to the correct arrangement boiler room ventilation, it may be necessary to perform a number of other procedures, for example, performing an aerodynamic calculation.

After which all the information received should become the basis of the project replacements, installation of equipment, redevelopment, which is submitted to the local gas service for approval. Where, if errors are identified, the document can be sent back to the originator.

That is, the set of procedures for calculating all the necessary values is quite complex. Therefore, in the case of installation, replacement, or transfer of equipment, only a few will cope with the task. Most property owners will find it easier to turn to specialists for help. Which will not only perform the necessary mathematical operations, but also adapt the calculations to the legal requirements for the arrangement of furnaces, ventilation systems, smoke removal, and all others. Which are set out in SNiP II-35-76, as well as in SNiP 2.04.08-87 and a number of other less popular specialized documents.

If in any particular case there is no need to draw up a project, then the calculations performed by a specialist will eliminate the threat to the life and health of the owner of the gas equipment, his loved ones and people living nearby.

In addition, they will avoid actions interpreted by law as unauthorized connection to any gas pipelines. For which Art. 7.19 Code of Administrative Offenses of the Russian Federation provides for sanctions in the form of a fine, the amount of which is 10-15 thousand rubles.For example, this can happen if the owner of the premises, after performing the calculations, makes changes to the design of the heating system.

After the calculations, you should not make a rash decision to replace gas equipment, especially with different power. If this happens, then it is worth notifying representatives of the gas service about the actions taken. This will help you avoid fines.

And also, there is no need to implement the theoretical calculations made at the cost of violating the rules and norms set out in SNiP II-35-76, which regulates the scope of arrangement of premises intended for the use of gas equipment. Since according to Art. 9.23 of the Administrative Code, even for the smallest violations you will have to pay 1-2 thousand rubles.

Conclusions and useful video on the topic

The video material attached below will allow you to identify the lack of air during gas combustion without any calculations, that is, visually.

You can calculate the amount of air required for efficient combustion of any volume of gas in a matter of minutes. And owners of real estate equipped with gas equipment should remember this.Since at a critical moment, when a boiler or any other device is not working correctly, the ability to calculate the amount of air needed for effective combustion will help identify and fix the problem. Which will also increase safety.

Would you like to supplement the above material with useful information and recommendations? Or do you still have questions about the calculation? Ask them in the comments block, write your comments, take part in the discussion.

I would like to understand the percentage of under-combustion of natural gas elements and what is considered the norm.

Thank you.