Bathroom sealant: types, selection tips and instructions for use

Repairing and equipping a bathroom requires sealing cracks and treating seams between tiles and plumbing fixtures.An abundance of moisture is a prerequisite for the appearance of mold and mildew in the bathroom walls and damage to the finish.

To minimize the risk of problems, bathroom sealant is used as a joint filler - the waterproof composition prevents moisture from penetrating behind the plumbing. The task of any owner is to choose it wisely and learn how to apply it correctly to surfaces. This article is devoted to solving these issues.

The content of the article:

Main types of sealant

The sealant is a mixture of polymer, filler and hardener.

Depending on what polymer the product is based on, sealants come in several types: silicone, acrylic, polyurethane and a combination version.

Compositions of different types have their own advantages and disadvantages, and features of application.

Silicone acid and neutral

Silicone-based sealants are among the most popular. They go well with any type of material: ceramics and glass, wood and metal, concrete and polycarbonate.

The undeniable advantages of silicone sealants include:

- resistance to moisture;

- ability to easily tolerate high temperature amplitudes, the range of which can vary from -50° to +200°C;

- resistance to aggressive UV rays;

- long service life, which can reach about forty years.

The material has an elastic structure, due to which the fibers can elongate by 900% when stretched. It shrinks by no more than 2%.

Silicone-based compositions are divided into two groups:

- One-component - used for household purposes. They are characterized by the fact that hardening occurs at the moment of contact with air.

- Two-component - are used in the industrial sector. Hardening of compositions of this type occurs upon contact with a “catalyst”.

If when using two-component compositions there are no restrictions on the thickness of the putty, then in household one-component sealants hardening is achieved only if the layer of material does not exceed 2-15 mm.

Household one-component compositions, depending on the type of vulcanizing agent, are presented in two types:

- acidic – acid acts as a catalyst;

- neutral – alcohol or ketoxime acts as a vulcanizer.

Acidic ones are also called “acetic” due to their characteristic odor. They are used to work with ceramics, wood and plastic.Since acid compounds can oxidize alloys and metals during the vulcanization process, they are chosen for treating surfaces that are resistant to rust.

In other cases, preference is given to neutral analogues. They are able to withstand significant temperatures and have a high level of bacterial protection.

The main thing to consider when choosing such compositions is the color, which can be predominantly white or transparent. This will minimize dissonance when bathtub installation or installation of a shower stall with transparent walls.

The popularity of silicone sealants and their demand for arranging bathrooms is justified by an impressive list of positive qualities, these are:

Moisture-resistant and non-moisture-resistant acrylic

Acrylic polymer-based compounds adhere well to mineral surfaces such as plaster, brick or concrete.

The main advantages of acrylic compositions:

- have a light texture;

- resistant to UV radiation;

- able to withstand temperature fluctuations from -25° to +80°C;

The popularity of sealing compounds of this type lies in a good external effect with fairly high performance parameters against the backdrop of an affordable cost.

The only drawback of acrylic sealants is the low degree of elasticity. Therefore, it is better to use them for treating those areas of the bathroom whose surface is not subject to deformation.

In addition, if such a composition is handled incorrectly, sloppy streaks can easily form, which can be quite problematic to get rid of.

Acrylic sealants do not contain organic solvents. And therefore they are absolutely safe for human health. You can work with them even without any protective equipment. Acrylic sealants harden within 24 hours.

Silicone acrylic sealants

There are also combined options available on sale - silicone-acrylic sealants. They successfully combine the advantages of each of the types described above separately.

They are often used as glue when it is necessary to join surfaces.

Polyurethane - an improved chemical product

Compositions of this type are chosen for professional construction and major repair work. Polyurethane easily eliminates the defect in cases where previously sealed seams are no longer satisfactory.

Polyurethane sealants are famous for their high resistance to mechanical and chemical influences. This effect is achieved by adding rubber and various types of plasticizers to the raw material.Due to the aggressiveness of some components, it is necessary to work with polyurethane compounds only in protective equipment.

Separately, it is worth highlighting sanitary sealants, which contain an antiseptic agent. Due to this, in addition to the main function - a protective barrier, silicone sealants prevent the appearance and spread of colonies mold in the bathroom.

Composition and properties of sanitary sealant

For installation and repair work in the bathroom, sanitary sealant is most often used. It is a dense viscous mass.

The main components of silicone sealant for the bathroom are:

- the basis, the role of which is played by silicone rubber;

- amplifier – determines the level of strength and viscosity of the material;

- adhesion primer – determines the reliability of adhesion of the composition to the surface being treated;

- plasticizer – increases the elasticity of the material;

- vulcanizer - a substance that converts the primary form of sealant in the form of a paste into a structure resembling plastic rubber.

In addition to the main components, to improve performance, the sealant may contain various types of fillers, for example, quartz flour, glass dust or chalk, as well as extenders and dyes.

The scope of application of sanitary sealant is quite wide:

- sealing joints;

- gluing surfaces;

- insulation of new and renewal of old seams;

- sealing of communications pipe outlets;

- sealing parts that will be exposed to high temperatures.

In an effort to expand the scope of application of the material, manufacturers add fungicides to the composition. These components are capable of destroying mold spores and preventing the appearance of fungus, which is especially important when it is necessary to seal joints in rooms characterized by high humidity.

Criteria for choosing wisely

Regardless of the type of polymer on which the composition is made, a high-quality sealant must have three constant characteristics - water resistance, safety and durability. The density of the composition must be at least 0.8 g/cm.

To enhance strength, sealants contain various types of plasticizers. But some manufacturers, in order to reduce the cost of finished products, increase the percentage of additives.

To protect yourself from low-quality material, when purchasing a product it is important to pay attention to the amount of impurities. It should not exceed 10-12% of the total mass.

For work in bathrooms, it is better to choose compounds labeled “sanitary”. A quality product should always have warranty and accompanying documentation.

When choosing products, you should also take into account that not all compositions can be painted after application. This is especially true when it is necessary to install plumbing fixtures that have a certain shade. Bathroom design should not suffer from mismatched shades.

Among the budget options, these have proven themselves well:

- "Sanitary silicone" famous manufacturer Tytan Euro Line;

- "Titanium" Polish company "Selena";

- "Moment" - a group of silicone sealants, the manufacturers of which can be listed as Russia, the Czech Republic, Belgium and Germany.

If we consider the line of professional products, then for bathrooms you can safely choose "Sanitary" trademark Tytan Professional. Has proven itself from the best side and Ceresit German giant "Henkel".

The only thing is that this antimicrobial composition is not suitable for sealing aquariums and gluing food surfaces.

The following selection of photos will introduce you to the bestsellers, whose popularity is confirmed by successful practice:

Instructions for use

It is better to carry out work on preparing the surface and applying sealant in one day. When applying the composition in several stages with a short break, there is a high probability of uneven drying, which may delay the start-up of the bathroom.

Carrying out preparatory work

Sealants for household purposes are available in the form of tubes with elongated spouts. Some craftsmen, in order to create more accurate seams during application, additionally purchase special attachments for tubes.

In addition to the sealant itself, before carrying out work, it is necessary to prepare in advance a set of materials and tools:

- masking tape 20-30 mm wide;

- white spirit, acetone or any other fat-soluble liquid;

- spatula, the width of the blade is selected depending on the thickness of the seam;

- cotton napkins or clean rags to eliminate mistakes in work.

When working with sealants that contain aggressive components, you should additionally take care of purchasing personal protective equipment: a respirator, goggles and gloves.

Before applying the sealant, the surface must be prepared: cleaned of dirt, eliminated all irregularities.At this stage, you need to carefully inspect the walls for the presence of mold. If one is detected, you need to eliminate the problem by treating the area disinfectant.

All that remains is to degrease the prepared surface by wiping it with a cloth soaked in acetone or alcohol, and dry it by blotting it clean with a piece of cloth. Metal parts are degreased using a solvent.

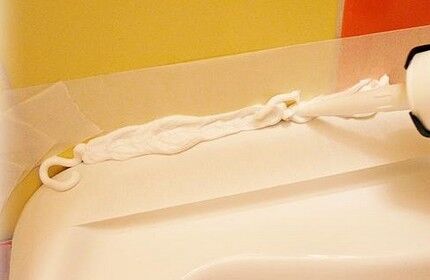

To protect the treatment area from sloppy blots, which can happen even with an experienced craftsman, masking tape is glued along the intended seam.

Features of applying the composition

Before applying the composition, cut off the tip of the spout from the tube. To increase ease of application, the cut is made at an angle of 45°. The bottle is installed in the mounting gun. In order to protect the mass from premature drying, the included cap is temporarily placed on the nozzle.

The raw material is applied evenly throughout the entire seam, trying not to make any interruptions, so as not to create gaps into the cavities of which dirt and moisture will get in during operation.

Important point! When working with sealant, it is important to avoid direct contact of the material with the skin and mucous membranes. If the substance accidentally gets on the mucous membrane, you should immediately rinse the area with plenty of cold water.

Particular care should be taken when working with acidic compounds.To protect the respiratory system from acid vapors released during the vulcanization process, work must be carried out wearing goggles and a protective mask, and the room itself must be regularly ventilated.

Ways to eliminate minor flaws

There is nothing difficult about adjusting a finished seam. To do this, use a narrow spatula to press the material, drawing it along the marked line. Such manipulations will allow you to better press the sealant onto the surface and make the joint smoother.

To remove sealant residues that “knock out” beyond the seam, the surface only needs to be wiped with a cloth moistened with water. If this does not help, you can use white spirit, an organic solvent "Antisilicon" or a specially developed remover "Foam-840".

After completion of the work, the masking tape is peeled off. If work was carried out without gloves, wash your hands thoroughly with soapy water.

After making sure that the applied composition is distributed evenly and neatly, all that remains is to wait for it to dry completely. This will take at least a day. But it will be covered with a thin film and the composition will no longer be sticky after half an hour. If an acid version is used, then the room must be thoroughly ventilated before using the bath.

Conclusions and useful video on the topic

Some useful tips on choosing, using and removing sealant.

Composition selection criteria:

Seam sealing technology using silicone:

Ready-made sealant remover:

If you take full responsibility for sealing joints and seams in the bathroom, you will protect yourself in the future from many troubles in the form of black spots of mold and mildew and make taking water procedures as comfortable and safe as possible.

Looking for plumbing sealant for your bathroom? Or do you have experience using a certain composition? Please share information with our readers - leave comments on the article, ask questions and participate in discussions. The contact form is located below.

I usually use silicone sealant. I found an option that suits me (probably I shouldn’t name the brand) and I always take it. In my opinion, this is the optimal balance between the properties and qualities of the material and its price. Just yesterday I went to change the sealant in a client’s bathroom. I thought it would be difficult to remove the old layer (it had already turned black and mold had appeared), so I bought a special remover. But it was of no use, everything was easily removed and so on. Probably, a high-quality sealant was used, since it did not lose elasticity over time. I always recommend that clients do not skimp on this consumable.

Nothing lasts forever anyway. So we took sanitary sealant, the most popular, as the seller said. The main thing for us was that mold did not grow at the joints.

The sealant is normal, water does not leak into the cracks, there are no complaints about that. But after a couple of months, a gray fungus began to appear on it. And what's the point of the fact that it was written on the packaging that it was antibacterial?

We read what it consists of – acetic acid. Still, it’s a humid environment, so you need to add some special substances.Now I have to dig it out and buy something new, this one didn’t justify itself.