Safety rules when using a gas boiler: requirements for installation, connection, operation

Natural gas is one of the cheapest types of fuel for autonomous heating and hot water systems.But you must admit that any equipment using methane from a pipe or propane-butane from a cylinder is a potential danger. Therefore, everyone must always follow strict safety rules when using a gas boiler.

There are a huge number of models of such water heaters, but the basic operating standards are the same in all cases. Next, we will describe the requirements of SNiPs, GOSTs and safety regulations to make it easier for you to understand the nuances of safe installation and use of gas speakers, stoves and fireplaces in your home.

The content of the article:

Requirements from regulatory collections

All government regulations that relate to household gas equipment are aimed at its safe use and reducing the risks of emergency situations. Gas as a fuel for water heaters, heaters and cooking stoves is cheap and accessible. However, if the devices on it are used incorrectly, this is a very dangerous fuel.

The gas for the boiler is under pressure in the pipes and cylinders. At the slightest depressurization and/or extinguishing of the burner, methane or propane begins to enter the room, forming an explosive gas-air mixture inside.

Such an abnormal flow of “blue fuel” into a room can be determined by the specific smell in the air.Then you should immediately turn off the gas valve, ventilate the house and call gas specialists. And no use of matches or lighters, as well as turning on electrical switches, bells, telephones, etc. until completely ventilated.

All gas boilers, heaters and furnaces are divided into two categories - those that depend on electricity and those that do not. The former are more practical, safe and effective. But the latter will work even in the event of a power failure.

Plus, when connecting volatile models, in addition to the general rules, you should also take into account the PUE standards. Without RCD It is prohibited to connect them to the electrical network.

It is prohibited to hang a wall-mounted version of a gas boiler, a water heater, on a wall made of plasterboard or other soft material. Proper fastening reliability wall-mounted gas equipment in this situation it is impossible to ensure. And any sagging or falling of a gas device means a pipe rupture and an accident with an explosion.

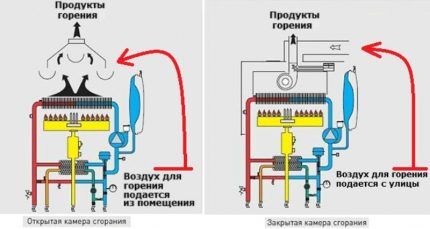

In individual and apartment buildings up to 5 floors high, it is allowed to install atmospheric gas boilers with an open combustion chamber. If the building has more floors, then gas equipment can be installed in it only if it is equipped with a closed, sealed combustion chamber.

Air exchange and room for the column

For a gas boiler to operate smoothly, it requires a constant supply of new air. Without oxygen, methane, propane and butane will not burn. Gas fuel alone is not enough for the proper and safe operation of the equipment in question.

Ventilation in the room for a gas heater must ensure sufficient air exchange. For a boiler with a power of up to 25 kW, natural air flow through windows, vents and doors is sufficient. But if the equipment is more powerful, then you will have to build an inlet for it ventilation system with compulsion.

Generation of 1 kW of thermal energy in a gas boiler requires about 0.12 m3 natural gas and about 1.2 m3 air. These figures should be used to calculate the required need for oxygen, as well as the fuel itself.

GOST standards for a boiler room or a room with a gas boiler stipulate the following rules for operating the equipment:

- Minimum 3 air changes/hour.

- An influx of about 10 cubic meters of air per cubic meter of burned gas for its complete combustion.

The more powerful the gas equipment, the more air it requires to operate efficiently and with high efficiency.

The room for a gas boiler must be:

- non-residential - boiler room, kitchen, utility room, basement, room in the basement;

- with ceiling heights from 2.2 m and volume from 8 m3 with a closed combustion chamber (height from 2.3 m and volume from 9 m3 with the chamber open);

- with a window that has an opening sash or window;

- with a natural ventilation system.

At the same time, it is allowed to install and use a gas boiler in the kitchen only if it has a power of less than 60 kW.

Removal of combustion products

The chimney from the boiler must not be routed through residential premises. Ideally, the pipe from the column should go through the external wall directly to the outside.But with a low power of the heating device and when using a cooking stove, it is permissible to organize ventilation through a regular common house ventilation duct.

According to the rules of use and fire safety requirements, a gas boiler in a residential building is allowed to be used only if it is factory-made. Homemade products cannot be connected to a gas pipeline or LPG cylinder.

The chimney from the gas water heater is made:

- from non-flammable materials that are not subject to active corrosion;

- without constrictions along its entire length;

- with a maximum of three turns;

- with a cleaning hatch and a tap at the bottom for draining condensate;

- with an outlet above the roof ridge to organize traction.

For powerful boilers, supply ventilation with additional air injection is usually equipped. But if the device is designed to work with a coaxial smoke exhaust pipe, then it is permissible to refuse forced inflow. A two-pipe chimney is already designed for sufficient air exchange in both directions - both into and out of the firebox.

Cylinders, fittings and pipelines

Before you start using a newly installed gas boiler, you should check the tightness of all gas pipeline joints. To do this, just moisten the joints with soapy water, and then slightly open the gas. If it leaks into the room, the soap will begin to bubble.

It is important to ensure that gas hoses were not compressed or overstretched. Unused cylinders (empty and filled) are required by safety standards to be kept outside the room with a gas appliance. And the one used should be placed so that direct sunlight does not fall on it.

The rules allow placing LPG cylinders with a capacity of up to 50 liters inside a private house. If a gas tank is installed, it must be at least 10 m away from the cottage. All pipes from it must be in plain sight; covering them with decor or laying them hidden in the selected walls, grooves for finishing, is prohibited.

Also, the boiler itself cannot be installed in niches or hard-to-reach places. It is possible to cover it with non-flammable decorative structures, but access to the device, gas valves, meters and elements of the control system must be unobstructed.

Any work near the column, cylinder, gas pipeline or chimney should be carried out after shutting off the gas. And then turning on the equipment again for heating is allowed only after it has been thoroughly checked.

Safe operation of a gas boiler

Methane is lighter than air, and propane (LPG), on the contrary, is heavier. When there is a leak, the first one rises to the ceiling, and the second one goes down to the floor. To eliminate dangerous concentrations of gas and avoid an explosion, it is necessary to provide natural ventilation in the first case with an exhaust vent at the top, and in the second with a vent at the bottom of the wall.

When cleaning to clean and wash the outside of the column, only non-aggressive detergents should be used.Also, do not use abrasive powders or rough brushes.

To avoid problems when operating a gas boiler, you should:

- Purchase the device and fittings for it only from a trusted company.

- All equipment must be installed exclusively at the factory.

- The initial installation and connection of the column should be entrusted to specialists from the gas service servicing the house or village.

- Regularly inspect the boiler for corrosion and destruction, and carry out a full technical inspection at least once a year.

- Make sure there is sufficient air exchange (if there is a small air flow or poor ventilation, the burner in the combustion chamber may go out).

- Avoid placing various foreign objects on the gas appliance.

- To avoid overheating of the unit, constantly monitor the level of coolant and water in the boiler.

- For a volatile boiler, provide an uninterruptible power supply with a capacity of at least 12 hours and a separate line with an RCD.

- It is mandatory to connect any gas equipment to a grounding loop.

Also, in addition to the built-in automation, it is recommended to install various security systems that shut off the gas supply when certain problems are detected.

The law does not require the installation of methane (propane) leakage sensors in rooms with a boiler. But their installation is highly recommended by all safety rules.

Conclusions and useful video on the topic

Rules for using gas at home:

Requirements for the operation of gas appliances:

About the safety of using gas equipment:

Even to the slightest extent, it is impossible to neglect building codes, operating rules and fire safety requirements when using a gas boiler.

To avoid emergency situations, you must constantly monitor both the technical condition of the column, the tightness of the gas pipeline connections and the absence of blockages in the chimney. Only if all the recommendations described above are followed will it be possible to talk about the safe operation of the gas heating system.

Please write comments, ask questions, post photos on the topic of the article in the block form below. Tell us how you comply with the requirements for safe and trouble-free operation of a gas boiler. Share useful information.