Do-it-yourself gas refrigerator: operating principle of a propane refrigerator + example of homemade assembly

The rather long history of the development of refrigeration technology is marked by the appearance of various types of household refrigerators.Among the existing designs you can find a household absorption apparatus - a gas refrigerator.

Models of gas refrigerators are made both stationary and mobile. Their relatively simple design does not exclude the possibility of creating a device with your own hands. To make a gas refrigerator, you need to study its structure and operating principle, don’t you agree?

The article describes in detail the design of a propane unit and the technical cooling cycle, and also provides step-by-step instructions for assembling and converting various modifications of gas refrigerators.

The content of the article:

Propane refrigerator device

The absorption principle of operation is the basis of refrigeration equipment that could run on propane.

Considering a gas refrigerator and the principle of its operation, it should be emphasized: in an absorption refrigerator, propane is assigned a modest function as a gas heater. The main components of the absorption process in the designs of household refrigerators are usually ammonia and water.

Ammonia acts as a refrigerant, and water acts as an absorbent substance.

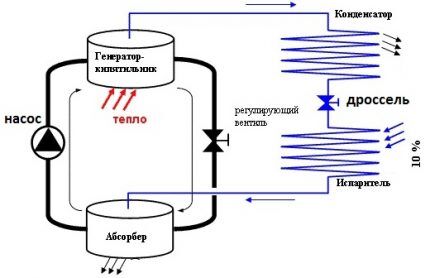

The simplified gas model contains the following technological modules:

- Gas heating module.

- Generator (more precisely, a boiler).

- Capacitor.

- Absorber (absorber).

- Evaporator.

A gas heater heats the contents of the generator. The generator module is designed to produce ammonia vapor and supply a weak ammonia solution to the absorber area.

The condenser module is used to cool the ammonia vapor to the condensation temperature. A module called “absorber” functions as an ammonia absorber. The evaporator of a gas refrigerator serves as a cold generator.

The principle of operation of a gas refrigerator

The technological cooling cycle begins with heating a concentrated ammonia-water solution with a gas burner. Due to the lower boiling point of ammonia, this substance boils faster than water. The process of formation of concentrated refrigerant vapor begins, which enters the condenser.

Here the ammonia vapor condenses, and the liquid ammonia rushes to the evaporator, where it boils due to the removal of heat from the products, forming a vapor-liquid mixture.

The absorption refrigerator circuit also provides for the operation of a device called a “reflux condenser.” This module is installed at the outlet of the boiler and is designed to obtain a weak ammonia-water solution in the process of partial condensation of saturated vapors.

This weak solution is collected in the absorber. The saturated vapor-liquid ammonia mixture from the evaporator is sent there, where it is absorbed. Then the cycle repeats.

Most absorption household refrigerators are equipped with electric heaters. For example, such models include refrigerators "Sadko", "Morozko" and others.

But it is quite acceptable to replace an electric heater with any other heat source, including a propane burner, a heating radiator, and even chimney smoke.

Therefore, it is theoretically quite possible to use the mentioned models of absorption technology to create a gas refrigerator with your own hands that operates in constant mode.

How to make a gas refrigerator

A relatively simple way to manufacture a gas refrigerator, as already noted, is to use an exhausted absorption apparatus as the basis. To bring the same “Sadko” or “Morozko” model to “mind”, it is enough to exclude the electric heaters installed in the system from the design.

Instead of dismantled heating elements, it will be necessary to introduce gas heating by installing a heat exchanger and a propane burner in the structure.

The model of the absorption refrigerator “Morozko” of the fourth edition of the ASh-30 series is well suited for creating a mobile device. The dimensions of the case of this design are 450*400*405 mm, weight no more than 15 kg.

The temperature of the freezer when the structure is operating at full capacity may well reach 10-12°C with a minus sign.It is not for nothing that the idea was born among skilled designers to remake the electric heating, replacing it with a propane heating pad.

However, the idea of a gas refrigerator is dubious, and there are a number of reasons to support this. Thus, the absorption process requires almost twice as much time to generate cold as a conventional compression refrigerator.

From an economic point of view, the design does not seem entirely rational, considering how much gas will be required to obtain 1°C sub-zero temperature for a home-made version. Nevertheless, design interest regarding the possibility of implementing the idea is quite high.

Step-by-step process for remaking “Sadko”

The electric heating elements of the Sadko refrigerator are located on the siphon tube. This structural element (siphon) is located at the bottom of the rear wall of the device. The siphon area is covered with a metal casing, under which there is a layer of heat insulator (mineral wool).

Initially, the amateur designer will need to perform the following steps:

- Place the refrigerator in a convenient place for work.

- Remove the protective cover on the rear wall.

- Remove thermal insulation material.

- Remove the heating elements from the siphon tube.

It should be borne in mind that do-it-yourself modifications here involve some risk. The absorption refrigerator system is filled with ammonia and hydrogen under pressure up to 2 atm.Careless dismantling of system parts and electric heaters can lead to depressurization of the system, which is hazardous to health. Caution must be exercised.

The next step for the amateur designer is to install a heating system that runs on propane. That is, it is necessary to mount a module in the area of the siphon tube that would carry out heating as a result of gas combustion. It is unacceptable to heat the tube with an open flame.

This means that a heat exchanger will need to be made. This could be, for example, a massive block of copper with a built-in gas-burner.

The manufacture of a gas heating system necessarily involves the organization of a complex of protection against overheating. The operating temperature range for heating the siphon of the Sadko refrigerator is 50 - 175°C. Based on these values, you should consider a scheme for turning on and off the gas supply during heating.

For circuits with electric heaters in absorption models, it is used refrigerator thermostat T-120 series. But this device regulates the operation of the heaters taking into account the temperature of the evaporator.

A gas burner together with an automatic control device is a slightly different system. If a propane refrigerator is made with long-term use in mind, full-fledged automation will have to be made.

That is, for example, to control not only the heating temperature of the heat exchanger, but also to control the flame and monitor the gas pressure. We must not forget about the fuse system.

Homemade assembly examples

It was not possible to find examples of home-made designs of gas-powered absorption refrigerators that would be noted for long-term operation. There are only experimental options, often started but not completed.

There are also examples of assembly where a gas refrigerator was assembled with your own hands using a simplified method.

For a simplified assembly option, I used propane tank, the outlet of which was connected by a hose directly to the direct-action burner. The burner was fixed to the chassis of the absorption refrigerator, and the working nozzle was directed directly to the siphon tube.

The burner was ignited manually. Also, without any automation, using a purely “touch test” method, the heating temperature of the siphon was controlled.

The results are disappointing. During operation of the manual heating gas installation for 12 hours inside the freezer, the maximum temperature of the lower threshold was obtained - not lower than +3°C.

Thus, tests of a propane absorption refrigerator, made by hand using a simplified scheme, showed the extremely low efficiency of the gas apparatus. Moreover, judging by the gas consumption, this option for obtaining cold (Sadko-G) is unreasonably expensive.

DIY design alternative

The meaning of assembling a gas structure is also lost because there are practically no old factory structures of this kind in domestic use. Gas refrigeration equipment with an absorber (Russian production) is basically an industrial installation, large-sized, heavy, equipped with complex gas equipment.

Therefore, an alternative for homemade gas refrigeration equipment is considered more attractive. These are modern mobile compact cooling systems from a series of thermal containers and similar developments. Any of these systems covers the need for cold that burdens lovers of outdoor trips.

The price of the devices is quite reasonable. Most likely, buying, say, a refrigerator brand Comfort, will cost several times less than the cost of modernizing the old absorption system.

At the same time, according to the technical characteristics, modern compact refrigeration equipment actually comparable to the same parameters "Sadko". And the temperature range looks more attractive (up to -18ºС).

Finally, there is an opportunity to buy an imported industrial refrigerator that actually runs on propane. A good example is a universal device from a German manufacturer, produced under the brand Waeco-Dometic Combicool.

The design of the mobile refrigerator ensures that cold is obtained when operating from one of three energy sources, including a gas cylinder.

Conclusions and useful video on the topic

Advantages and disadvantages of a mobile refrigerator that can run on both electricity and gas:

A short video review of a Dometik brand car refrigerator:

The conclusions from the whole story with the construction of refrigeration equipment that is “free” in all respects are clear. The only reason to assemble a gas refrigerator on your own is the desire to do something yourself.

Often the pleasure from one’s own success overshadows any innovation on a global scale. However, modern factory models are more reliable and safer.

Do you have experience creating a gas refrigerator? Or do you use a purchased absorption type unit? Please share your opinion and leave comments. The contact form is located in the lower block.

I have heard many times about this miracle of handicraft and am planning to make one similar to myself. But there are several questions that raise concerns:

1. It is clear that vaporous ammonia is different from ordinary ammonia. But still, in terms of health hazards, how are things going? I wouldn’t want to go to the hospital because of leaks caused by my unprofessionalism in the assembly.

2. More on everyday topics.Electricians cannot “complain” about such a device? We have an apartment building, and about once every six months the maintenance company comes and checks the apartments (wiring, meters, etc.).

You will wake up and run away from ammonia - in lower concentrations there is usually no harm, unless you are allergic to ammonia (and it can also happen from simple substances, when, indirectly reacting with proteins, the substance causes an immune response to its proteins or already deactivated foreign bodies).

Electricians don’t care if you don’t take anything past the meter, of course, if your girl doesn’t work there. According to the law on the protection of consumer rights, no one has the right to impose services on you, send them to Gazprom to sort things out if anything happens :-))

I decided to make such a refrigerator according to your design, I have time to assemble it, I have an old Morozko refrigerator. In offline mode, such refrigerators work for a long time, and given the fact that at our dacha the lights are often turned off, but we want to cool drinks and prevent food from spoiling, we would really like to have such practically free equipment, especially if we built it ourselves.

Alexey, maybe it would be better to invest efforts in purchasing an emergency generator? Then the issue of power outages will be removed in principle.

If you heat with network gas, the price gain is 7(!) times per kilowatt of thermal energy. True, you will never get permission for such a device - even if you are hung all over with leakage sensors, shut-off valves, etc.

But you can install the stove without any protection! RULERS MUST BE CHOOSE RIGHT! But that’s for later - but for now, no one has yet latched on to an absorption air conditioner based on solar tubes...