Looping of a gas pipeline: its functions and features of arrangement for a gas pipeline

All gas pipelines are built taking into account the consumption of blue fuel by all existing consumers.But during operation, the amount of gas used often increases and one day the available capacity for its transportation becomes insufficient.

As a result, pipeline owners have to look for a way out, and one of the options may be gas pipeline looping. Today, specialists and other interested parties are increasingly turning to it.

Let's figure out what this process is and how to implement it in practice.

The content of the article:

What is looping?

The name of the looping process comes from the English word “looping”, which means “loop”. And this is the exact name of the process of the same name. Since it represents the laying of a new section of the gas pipeline, parallel to the main line.

Such a branch is always part of an already existing system and its beginning is insert into the main branch. And where the design eliminates the need to separate gas flows, the loop is closed.

Looping of gas pipelines serves to solve two main tasks, including increasing the existing capacity of the main line or reducing pressure loss during gas transportation.

First of all, this applies to high-pressure lines, since it is in them that the most unstable conditions are created, leading to a decrease in efficiency. And, consequently, to financial losses.

But pressure stabilization is also possible in all other types of networks, that is, those transporting gas at medium or low pressure. Since a parallel pipe helps to reduce the pressure at the beginning of the journey and significantly increase it at the end.

With the help of looping, specialists are able to solve a number of other problems, including the following:

- Using an additional line while repairing the main one.

- The use of such an artery to change the configuration of the main one. For example, while gas flows along a parallel branch, the position of the pressure stations on the main one can be adjusted, which will contribute to more efficient operation of the system in the future.

An important advantage of this design is the ability to use it as the main pipeline for gas transportation. This helps to get the desired result in the shortest possible time, saving money on the construction of a new gas pipeline.

This method has been known for a long time, but its peak use is at this time. This happens because the gas system in the post-Soviet territory was formed a long time ago (1975-1990), and now it is being refined and improved to suit modern needs.

From the above we can conclude that today looping is actively used for several reasons, which include:

- staged construction - initially all gas pipelines are built taking into account existing needs, and then, as necessary, the throughput is increased;

- lack of own funds or investments for the construction of new networks - this is due to a decrease in demand for gas, and, accordingly, a decrease in interest in the industry of creditors, investors and even ordinary consumers.

This information indicates that looping may be a cheaper option than constructing a full-fledged new gas pipeline.

Subtleties of arrangement and application

The design of the parallel pipeline is almost identical to the main line. In view of this, looping can be used in the same conditions as the main gas pipeline, that is, in almost any.

When is this method used?

But you should be aware that the presented performance improvement option is only one of several competing methods.

Among them are the insertion of larger diameter pipes and increasing the capacity of stations with pumping equipment.

In addition, looping can be part of combined main line unloading methods. For example, this option is to use parallel lines in conjunction with increasing the capacity of pumping stations.

Guidance documents allow the use of multiple loopings on one site. The diameter of the pipes may vary, but if their maximum size is not enough to transport gas, then products of the same size are usually used in different branches, which ensures the same speed of fuel movement.

This cannot be achieved by using different pipes, and this leads to the fact that individual sections of the pipeline will wear out faster. Although this information is mostly relevant for main gas pipelines, where the pressure is always highest.

The exact diameter can only be determined using special calculations, according to which design is carried out, carried out on the basis of governing documents.

How the loop works

After the start of using a parallel gas pipeline, there is a reduction in the transported volumes of fuel along the main pipeline. As a result, the hydraulic resistance that must be overcome is reduced, which leads to a significant reduction in pressure losses.

Therefore, at the same gas pressure it is possible to transport large volumes of blue fuel.

Such an additional highway will be effective no matter its length. But the longer it is, the more noticeable the result will become.

When can looping be used?

As mentioned above, looping is one of the competing options for unloading a gas pipeline. Therefore, its installation requires technical justification and comparison with other methods.

That is, a parallel line can begin to be built after its effectiveness has been proven in comparison with inserting a larger pipe, increasing the capacity of pumping stations, or some combination.

You also need to know that looping is mainly used to unload gas pipelines transporting blue fuel somewhere for large consumers, which are cities, large enterprises, and others.

For households and other small consumers, this method is of little relevance, since in most cases gas is supplied in insufficient quantities not due to overloading of pipes, but in case of incorrect hydraulic calculations.

Even if the system is operating at its limit due to the fact that the number of consumers (gas stoves, water heaters) in the house has increased, then usually the best way out of the situation would be to install larger diameter pipes for the main line, rather than using looping.

The reasons for the irrelevance of this method for low-power pipelines are that:

- Any gas pipeline with looping will solve a problem that any of the parts of the structure can handle separately.

- Each parallel pipeline line can be put into operation after approval of the same project as in all other cases. That is, it will take the same amount of time to create as a regular one, and the costs will be similar, which also does not provide a competitive advantage.

- For the construction of the looping, the same materials are used as for the main line, which again does not make the task easier.

- The aesthetic appearance of a gas pipeline with looping may be worse than a regular one, since several lines and more massive supports are unlikely to decorate a personal plot.

In view of all that has been said, representatives of Gorgaz can easily reject the gas pipeline project with looping as unfounded.This may happen because it will be difficult for specialists to explain why a complex type of line is needed to supply small consumers.

Therefore, even if such an idea has arisen, then in the early stages of creating the desired project, you should contact the responsible persons of your city gas company for approval.

Some installation features

Since any parallel line is an ordinary gas pipeline, all rules and regulations for such structures apply to it. As a result, after the creation and approval of the project, the usual insertion of a new pipe into the main line occurs.

The only important feature is the need to shut off the existing gas pipeline on both sides. For which special shut-off valves, pressure relief fittings and other equipment can be cut into.

Gas pipeline construction standards

Loopings are subject to the usual rules for all gas pipelines. Therefore, work can begin only after the approval of the relevant project. They can be carried out by licensed specialists.

All equipment and materials that will be used for construction must be checked for appropriate certificates, damage and other defects.

When carrying out the arrangement, steel pipes are used, or more precisely, certain types of them that have undergone special anti-corrosion treatment, as well as their polyethylene analogues.

The necessary work is carried out in stages, that is, such an operation begins with preparing the looping for assembly. For this purpose, trenches are dug, supports are installed, then shut-off valves are installed on both sides, receivers are installed, to which pipes of a parallel line are welded at the next stage.

During construction, responsible persons are required to control a number of important parameters, which include the fit to the bottom of the trench, the distance between various communications - both third-party and related to the design of the gas pipeline itself. Welded joints and anti-corrosion coating are subject to special control.

After completing the installation of the parallel line, appropriate tests must be performed. Before carrying out such operations, it is necessary to carry out preparatory work.

For example, the trench in which the looping is mounted should be covered with a layer of soil. But it is unnecessary to completely fill it up, since such a procedure is performed only after successfully passing the test for suitability for use.

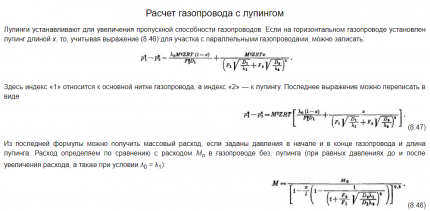

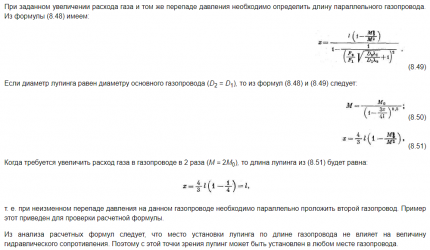

Performing gas pipeline calculations

Guiding documents allow looping to be calculated only using special formulas. Some of them will be attached below, but we can say in advance that only specialists will be able to make calculations.

Since its implementation uses a large number of different variables, which makes the task complex.

That is, a person or organization interested in developing a project and building a looping will not be able to save even on preliminary calculations.

Because, unlike a number of other similar procedures, for example, hydraulic calculations, a simple and accessible computer method is not used. As a result, the designer must have a sufficient supply of specialized knowledge.

After completing the calculation, it is recommended to contact Gorgaz for approval. If this is not done and the project is not fully developed, this can lead to significant financial losses. Since any of the many requirements of gas workers may not be met.

We also recommend reading our article on designing a gas supply system. More details - go to link.

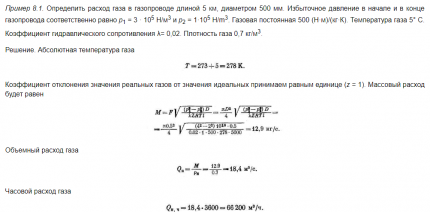

Example of gas pipeline line calculation

To calculate a parallel gas pipeline line, you need to know a number of initial data, including volumetric, hourly gas flow, gas resistance coefficient, fuel temperature and a number of other data. All the necessary information is taken from a pre-compiled diagram.

The complexity of the example calculations additionally indicates that this work must be done by specialists or errors cannot be avoided. Which will lead to loss of time and money.

For more information on how to calculate a gas pipeline system, read this material.

Another example of looping

One of the most famous gas pipelines with looping, put into operation in recent years, is the parallel line of the Pelyatka-Severo-Soleninskoye main line. Its length is 30 km, but for construction it was necessary to develop a considerable 160 km of road.

In addition, it was necessary to lay almost 90 km of cable. The work was carried out by more than five thousand qualified specialists over six months.

The arrangement consisted of the following stages:

- installation of piles, preceded by drilling;

- installation followed by welding of supporting structures;

- laying and welding of the looping pipes themselves;

- quality control of welded joints;

- cleaning looping;

- testing followed by launch in test mode;

- anti-corrosion treatment of all metal elements.

The steps are listed in the correct order. As a result, this looping makes it possible to transport gas to consumers at the lowest cost, and uninterruptedly.

As experts pointed out, the economic effect from using this 30-kilometer pipe will amount to an impressive 6.5 billion rubles, and this is only in 2 years from the moment the line was put into operation.

Conclusions and useful video on the topic

This short video allows you to better understand what a gas pipeline with looping is:

Any looping is capable of unloading the main line, thereby increasing the amount of fuel transported to consumers. Moreover, without any increase in costs. At the same time, a parallel gas pipeline line is not a panacea for all possible cases.

Therefore, before developing a project, it is necessary to ensure the feasibility of using this network offload option.

Still have questions about the topic of the article? Have you found any bugs or have valuable information that you can share with visitors to our site? Please leave your comments in the block below the article.