How to crash into a gas pipeline: technical requirements and features of the work

Natural gas provides people with heat and hot food.However, to implement these functions it is necessary to connect it to the home - to install a pipeline connected to the central network, heating equipment and household appliances.

At the stage of designing the pipeline, it is necessary to figure out what permits need to be issued, how to properly cut into the gas pipeline and who to entrust such important work to. The answers to these questions are described in detail in the article.

In addition, we described different methods of connecting to the central line, and also outlined the features of connecting to a plastic and metal pipeline.

The content of the article:

What are the types of gas transmission lines?

A gas pipeline is a specialized pipeline whose purpose is to transport and store certain volumes of blue fuel. It may have different design features, differing depending on the tasks assigned to the highway.

For example, networks of international importance deliver huge volumes of gas over long distances, so they maintain constant pressure at a high level. That is why any experiments with gas supply systems are inappropriate and can be dangerous not only for you, but also for others.

This means that the best option for working with the system would be to call the appropriate services specializing in working with gas communications, which meets the requirements of the law.

Gas pipelines are designed like the circulatory system of the human body. Their role can be compared to the coronary vessels. And from the central pipes, regional pipes depart, distributing blue fuel among consumers.

They are smaller than the main ones, and therefore the pressure in them is much lower. However, even in such gas networks, its jumps are possible both in a decreasing and in an increasing direction.

Connection to gas communications occurs if the organization has a special permit. And you can try to do the wiring inside your home yourself. To do this, you just need to know a clear sequence of actions and adhere to the necessary safety measures.

Rules for calculating throughput

The main factor responsible for the continuous supply of blue fuel to consumers is the throughput capacity of the gas pipeline. This parameter is calculated using a special algorithm. Moreover, it is done regardless of the type of pipes used.

Maximum throughput gas pipe can be calculated using the following formula:

Q max. =196.386×D²×P/Z×T,

Where:

- R – operating pressure maintained in the gas pipeline, plus 0.1 MPa or absolute gas pressure;

- D – internal diameter of the pipe;

- T – temperature of the pumped blue fuel, measured on the Kelvin scale;

- Z – compressibility coefficient.

This formula establishes the following pattern: the higher the value of the T indicator, the greater the network throughput should be.

Otherwise, the gas transmission line will depressurize, which will inevitably lead to an explosion of this dangerous substance.

There is a more complicated formula. However, the algorithm given above is quite sufficient to perform the necessary calculations prior to inserting into the gas pipeline.

How to properly connect to a gas pipeline?

Tapping into the main network cannot be carried out with your own hands - only with the help of specialists from gas companies who have permits and permission to carry out such work. Regardless of the chosen company, there will be a large-scale preparation stage before connecting to communications.

Preparing for the tie-in

If you decide to entrust the process of connecting to the gas network to specialists from the relevant company, then you need to contact the permitting service. Here, in addition to submitting an application in the established form, you will need to provide a package of documents required by law.

When it comes to tapping into the gas pipeline of a newly constructed building, the owner should first of all provide a passport, identification code and approved gas supply system project.

In addition, you should prepare a set of documents:

- statement, certified personally by the head of the territorial gas sector department;

- connection permission to the gas transmission main, issued by the architectural planning department;

- photograph, made during the topographic survey of the area where the insertion will be carried out;

- technical passport for a private house, or a copy thereof certified by a notary.

The photograph must be certified by authorized gas service employees. It will depict the entire engineering infrastructure, including not only gas communications, but also water supply, heating network pipes, and sewerage.

If the house is under construction, then an appropriate architectural design, a permit for its construction and a floor plan should be provided.

And if its total area exceeds 300 sq. m., it is necessary to submit a thermal calculation of the building, a situational plan of the site on a scale of 1:5000, and consent of the neighbors to connect to the gas network, drawn up in writing.

The latter document will be needed in the case when it is planned to run part of the gas pipeline underground along areas that belong to them.

In most cases, permits of this kind are issued by the city gas department, since they are the rightful owners of gas transmission lines.

In addition, you will need to provide technical passports or other documents attached to the gas appliances that are planned to be installed in the building - permission to use the equipment at your place of residence, certificates of conformity, as well as service contracts.

You will also need an inspection report for smoke ventilation ducts and other documents required by law. Only having all the permits and acts in hand can you begin to carry out tie-in work, i.e. exclusively on a legal basis.

It must be remembered that unauthorized connection to the main gas pipeline, without completing the necessary documents in accordance with the procedure established by law and coordination with the relevant services, is fraught with administrative measures. And if at the same time there was damage to the gas pipeline, then there will be criminal penalties.

Features of the tapping process

The process of tapping into a gas pipeline is the connection of a new pipe through which the substance will be transported from the central pipeline to the consumer. As a rule, connections of this kind are made without cutting off the gas supply in the main network.

There are certain points to consider. One of them is high pressure in the main pipeline, so tapping work is carried out using a special device. And this is done after completing the installation and checking the functionality of the installed pipeline for the new consumer.

If the construction of an individual branch can be carried out by employees of private companies, and some processes can even be carried out by the owner himself, with the appropriate skills and tools, then the connection to the central highway can only be carried out by a specially trained employee, following the developed instructions.

His actions will necessarily be supervised by a gas service specialist.

Rules for performing work

The set of rules that must be followed when tapping into a gas pipeline is not difficult to remember. However, during connection work it should be strictly adhered to.

These are the following points:

- When the network is characterized by low pressure, it is recommended to insert into its communications at values from 20 to 80 mm of water. Art.

- Work on a pipeline under medium or high pressure is permitted only after its level has been reduced to acceptable levels.

- If it is not technically possible to reduce the pressure, you will have to resort to the help of specialized equipment that is designed to carry out work in non-standard conditions.

- It is important to involve employees of relevant organizations who have special permission to carry out this type of work.

- If you are going to use welding and gas cutting, you should control the pressure in the area, which during installation should be maintained in the range of 40-150 kg/cm.

Compliance with a set of these simple rules will allow you to avoid emergency situations during the process of tapping into a gas pipeline and guarantee the safety of others.

Possible connection methods

Connecting the new blue fuel supply network to the existing one is carried out using tapping or welding.

In the first case, the operation of the main pipeline does not undergo fundamental changes, since the process of cold tapping into a gas pipe is carried out without the use of welding. The volume of the pumped substance and its pressure do not change and are still kept within the operating range of the network.

This method is used to connect new consumers. To perform work related to the central network, you must have permission and permission to carry out gas hazardous activities.

Without special training, it is absolutely forbidden to interfere with the functioning of the main pipeline. Violation can result in tragic consequences, resulting in death or imprisonment.

The second connection option is more familiar to most ordinary people. It is reliable and has stood the test of time. However, a specialist who carries out insertion in this way must have a high level of professional qualifications and also have a special permit.

The methods of joining themselves are:

- insertion into a gas pipeline under low pressure;

- under medium and high pressure gas, when special devices are used;

- with the gas turned off and the pipes completely freed from it.

The choice of connection method to the gas pipeline depends on a number of factors.Therefore, the decision must be made by the people making the connection on a case-by-case basis.

As for the contractor, there may be 2 options: representatives of the gas service or employees of a private company who have the legal right to carry out actions, as well as the necessary equipment and permission to carry out gas-hazardous work.

Moreover, in the second case, the office can undertake obligations to prepare and execute a package of documents for legal connection to the main gas network. However, all additional services will affect the final cost of connection.

Features of inserting into a metal gas pipeline

The insertion into the central branch of metal pipes is carried out after drawing up a sketch of future work and preparing all the materials that will be useful in the process based on the chosen connection method.

The first thing to do is clean the work surface. At the same time, absolutely everything unnecessary is removed from the place chosen for connection to the gas pipeline: debris, paint, rust. Next, mark the insertion site, making marks. Make the necessary holes.

After this, the wells are well treated. When cutting the surface of the pipe, the cracks are carefully coated with clay. This is required to minimize the risk of igniting escaping gas while making the cut.

The holes made are sealed as soon as possible with an asbestos-clay plug, and the area being treated is quickly cooled.

The next stage of work will be the installation of a disconnecting device. After the metal has cooled, remove the plug in order to be able to remove a section of the cut pipe from the gas pipeline.

Now, a disconnecting device is installed in the resulting gap. It consists of a set of rubber and wooden disks and bags filled with clay of a viscous consistency.

Next, install the pipe. Having closed the hole with a disconnecting device, they begin to make the main hole intended for connecting a new pipe. First of all, it is necessary to check the diameter, since sometimes the markings have to be adjusted.

Next, make a hole and install the pipe. Its butt joints are welded on both sides and the valve on it is closed. Afterwards the holes are sealed.

Having completed the installation of the pipe, begin welding the new pipe. Before this, the metal slag formed after making the main hole is removed. Having cleaned the surface of the pipeline, install a new pipe in the holes and, covering it with clay, make welding seams.

Next, take an aqueous solution of soap and carefully coat the new seams with it, making sure that they are tight and that there is no leakage of blue fuel.

If no gas leak is observed, proceed to the final stage of work, that is, backfill the trench. However, this is not such a simple operation as it seems at first glance.

Backfilling of the trench must also be carried out in accordance with the standards given below:

- around the circumference of the insertion point of the ball valve and the connecting pipe, it is necessary to backfill soft soil with a layer more than 20 cm thick and compact it;

- It is strictly forbidden to use a bulldozer or other heavy construction equipment to completely fill the trench with soil.

The collision of the mentioned equipment with the layer of soil covering the insertion point and the pipes coming from it, as well as with the ball valve protruding above the soil surface, is strictly prohibited.

Insertion into a plastic pipeline

Connecting to gas pipelines made of plastic pipes is not as financially expensive as compared to steel gas transmission lines. And in the case of plastic pipes, this is much easier to do than with metal ones. It is important to follow a clear sequence of actions.

Plastic products are now used quite often when installing engineering structures.

Their advantages include:

- no expensive insulating materials required;

- affordable price with a high level of technology in installation and construction work due to the use of automatic welding machines, low demand for heavy equipment and expensive employees;

- service life – at least 50 years;

- minimal costs during operation and repair.

On the eve of the insertion, it is necessary to purchase high-quality fittings (connecting elements) manufactured at the factory in accordance with GOST requirements. And also to make the seams more reliable, you will need to use specialized glue and a bell joint.

In addition, it is necessary to carefully ensure that the junction of the pipes is as tight as possible and has the best density.On the eve of installation, the insert must be treated with an anti-corrosion agent.

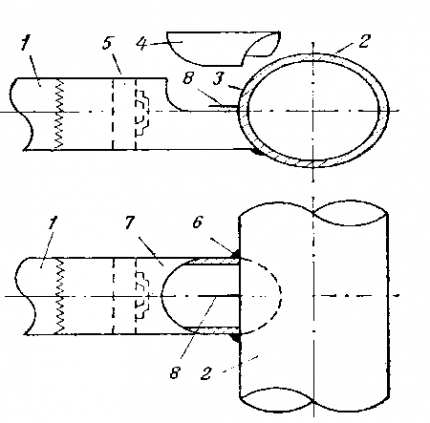

As for the process of tapping into a gas pipeline consisting of plastic pipes, it is carried out as follows. The pipes are connected with special steel or polyethylene inserts. They are located perpendicular to the existing gas transportation system. Their length can range from 80 to 100 cm.

The extension process itself is carried out using plastic pipes with a socket-contact connection at the base. The technology for inserting into a gas pipeline is carried out as follows: by heating the steel insert to a temperature of 60°C, a plastic structure is quickly and with physical effort put on it.

A fairly popular technology is connection through the use of a ball valve. The maximum diameter of a gas pipeline made of polyethylene products into which an insert can be made is 500 mm for models with SDR 11 and 800 mm for models with SDR 17.6.

In this case pressure in the gas pipeline should not be more than 1 MPa (10 bar). The technology itself for inserting polyethylene pipes into gas pipelines is carried out in a certain sequence.

First of all, the faucet is welded. On the eve of equipment installation, fittings and embedded heaters (coupling and overhead maintenance) are installed in the existing network, and an overhead ball valve is installed in accordance with SP 42-103-2003.

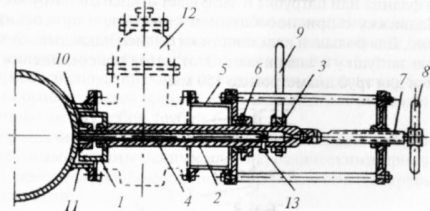

Next, the equipment is assembled and installed.The drill rod, at the end of which a milling cutter is mounted, and the insertion unit are fixed on the free branch pipe of the ball valve. To do this, it is tightened with bolts of the half-ring of the clamping device. These actions allow you to obtain a completely tight connection.

The next step will be crimping the insertion unit through a fitting with a tap. In this case, the pressure should be 0.1 MPa higher than in the existing gas transmission main.

Afterwards the connection is made into the pipeline. The drill rod rotates using a ratchet lever, feeding the cutter forward, which, in turn, cuts through the wall of the gas pipeline.

Then the rod with the cutter is moved back, and the ball valve is closed. The moment the cutter enters the operating gas pipeline is determined as the force with which the drill rod rotates decreases, as well as by changing the length of its stroke.

After the hole is made, the drill rod with the cutter is retracted by rotating the handles of the cutting device counterclockwise. As soon as the cutter is moved outside the ball valve, it must be closed.

After this, the pressure in the gas pipeline tapping unit should be relieved, and the equipment should be dismantled. Having closed the valve, the gas is released from the tapping unit through a gas outlet hose and a valve with a fitting. At the same time, the equipment is removed from the free connection of the ball valve. The cutter can now be removed from the drill rod.

At the next stage, it is necessary to remove the cut pipe fragment from the cutter and remove the resulting chips.

Then the gas pipeline branch is connected.It is welded using a coupling to the free pipe of the ball valve. After the blue fuel is launched, the welded joint must be pressurized under operating pressure, having previously treated the joints with an aqueous solution of soap to ensure that there is no gas leakage.

Having successfully completed the tie-in into the main gas pipeline, it is necessary to complete the documentary part of the work by concluding an agreement on supplies, technical and emergency dispatch services with the regional representative of the gas company in the region.

Work on the acceptance of a new gas facility after completion of the tapping process and sealing of devices that monitor the volume of consumed blue fuel are carried out by a representative of the above-mentioned company.

On our website there is a block of articles devoted to connecting gas to a private home, we recommend that you read:

- How much does it cost to connect gas to a private home: the cost of organizing gas supply

- How to connect gas to a private house: input device + installation of the system

- Technical conditions for gas connection: procedure for obtaining the necessary documentation

Conclusions and useful video on the topic

The video demonstrates tapping under pressure in real time without shutting off the gas:

Video about cutting into an existing high-pressure gas pipeline:

An example of tapping into a gas pipeline under pressure in the video:

Having a general understanding of the technical requirements and the procedure for carrying out work on connecting to the gas network, it will be easier to navigate all the nuances, and it will also become easier to control the work of the company with which the connection agreement has been concluded.

In addition, the absurd desire to cut into a gas pipeline yourself will disappear, inviting a handyman in order to save money.

Share with readers your experience in coordinating documents and connecting to the central gas pipeline. Please leave comments on the article and ask questions that interest you. The feedback form is located below.

The information is certainly useful, but I would not recommend going there to a person who has never done it. Still, gas is no joke. It is imperative to obtain permission in advance so as not to incur a fine. We did just that, waited about a week until specialists came to us and connected to the gas main. But, in my opinion, they didn’t check for leaks, or I didn’t see it.

The fines for such insertions are now large. Although the idea of making inserts is now in many people’s heads. They extract it here, in Russia, and set the price for gas as for European consumers. The entire family budget is spent on utilities in winter. A welder I know tried to crash into it, but he was immediately caught. If you are going to open some kind of business using gas, then you cannot do it without making acquaintances in the administration.

You are obviously unfamiliar with European gas prices for the population. Prices there are several times, or even tens of times higher. Google it for fun.