How to properly disassemble a light bulb: instructions for disassembling various types of lamps

To make something interesting with their own hands, DIY enthusiasts implement non-standard ideas using improvised means.A use was also found for the ordinary bulb of a burnt-out incandescent lamp. But fluorescent and LED ones are not suitable for these purposes; they are disassembled only for repairs.

In any case, it is important to know how to disassemble the light bulb, and then you can experiment with its further use.

We suggest you understand the intricacies of this process. The article describes in detail how to act correctly if there is a need to open and disassemble various types of lighting fixtures. In addition, we have prepared interesting homemade solutions from old incandescent light bulbs.

The content of the article:

About disassembling an incandescent lamp

Old lamps are used to create vases and containers for spices, miniature aquariums and many other crafts.

If you decide to master this process, then you should start with an ordinary incandescent light bulb. Inside it does not have a filling that is hazardous to health in the form of additives from harmful substances. Therefore, disassembling it is not only simple, but also completely harmless to health.

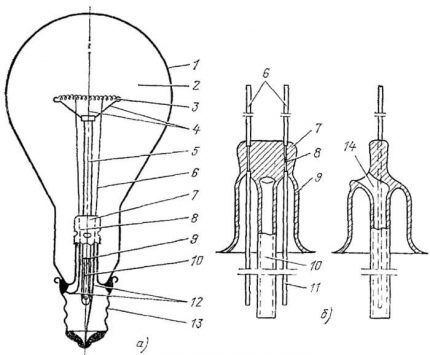

Briefly about the device

To begin dismantling the insides of the lamp, you need to become familiar with its structure in general terms. The main element is the filament body, the ends of which hold the electrodes.

Additional rigidity is created by holders mounted on a glass support - a bead. The rod is connected to a leg, which includes electrodes, a rod, and a plate.

All internal elements will have to be removed from the flask through its lower part.

How to disassemble

Here it is necessary to take into account some nuances, because You will have to work with glass. The material of the leg is very thin, while that of the base insulator is quite rough.

To prevent flying fragments and associated risks, you need to use a cardboard box as a workspace. Its bottom is covered with soft material.

Before starting the operation, you need to arm yourself with thin-nose pliers. With their help, it will be possible to dismantle the contact, firmly sealed at the neck of the flask.

The element is loosened and turned until the two wires going to the main part of the lamp - the filament body - break. Next, the released contact is removed.

The next task is to open the base insulation. This will require the same tool. Using thin-nose pliers, swing the light bulb leg and remove it complete with the plate, rod, electrodes, and filament body.

Having opened access to the internal cavity of the lamp, carefully clean it with a piece of textile. Without the insides of the light bulb, only the heat-resistant glass bulb remains.

How to use it depends on your imagination - it can become a container for spices, a tiny aquarium, a lampshade or a lamp.

For some crafts, a base will be superfluous.It is not difficult to remove since the connection is not very strong. You can simply keep it for a day in a mixture of hydrochloric acid with ammonium nitrate or in hydrofluoric acid. Which will dissolve the glue that attaches the base to the base of the flask.

With this option, it is important to thoroughly rinse the product in a soapy solution after the acid. And don’t forget to wear gloves to carry out all manipulations.

Another way is to unscrew the part at the point of contact with the glass, then remove the glue and remove the vessel. Sometimes it is enough to scratch the junction of the base and the bulb with a glass cutter to get rid of it.

Disassembling the lamp with socket

At replacing a light bulb All sorts of troubles happen. It also happens that it separates from the base. In this case, you cannot do without disassembling the cartridge. The work requires the use of protective equipment in the form of glasses and rubber gloves.

Turn off the electricity and make sure there is no voltage by using an indicator. Remove debris from the floor.

Next, they arm themselves with narrow-nose pliers and, rotating the base in the direction opposite to the clockwise movement, turn it out. For a more secure grip, the edges of the base are bent inward.

If the attempt fails, the connection must be loosened by rotating in different directions.When this action does not bring results, the tool is rested against the inner walls of the base and unscrewed in this way.

Crafts from incandescent lamps

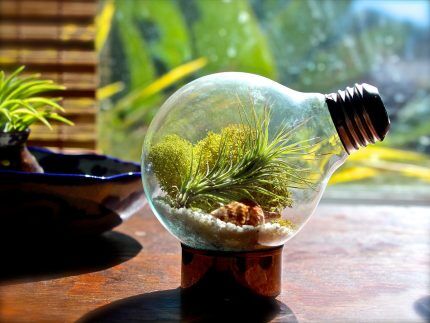

Let's look at examples of using an incandescent lamp. Many decorators use an old lamp to make a mini-terrarium. Some DIYers have learned to convert a standard lamp into an economical LED lighting device.

Original mini-terrarium made from a light bulb

First, the light bulb is prepared. Having taken out the contact, split the black insulation and pull it out. Using a flathead screwdriver, peel off the inner structure and then remove it. An empty flask with a base and a smooth, neat hole remains in your hands.

Next, you can take a beautiful stone or make a twisted stand from wire. In the first case, hot melt adhesive is applied to one of the faces at four points and a light bulb is glued. Now you can start decorating.

Ordinary forest moss is used as a filler for the terrarium. To this you need to add some soil and tree bark. To ensure that all this is inside, a cone is made from paper and inserted into the hole. A drainage of small pebbles is poured onto the bottom of the lamp, and a layer of sand is placed on it.

Carefully level everything with a stick and add soil. Then they take tweezers and use them to lay the plants. Water is drawn into a syringe with a needle and “watered” the planted area. Now the hole needs to be closed. To do this, you can use an acorn cap or a cork cut from a branch.

Its own microflora is formed inside. Plants continue to grow and develop.

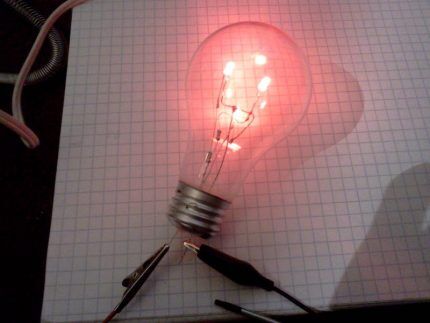

Making an LED lamp

Some home craftsmen make their own LED lighting devices based on incandescent lamps.

To do this, heat the soldering iron and remove the solder at the lowest point of the base. Next, the insulation is cracked, the internal filling is removed and the hole is expanded to the maximum.

Three LEDs are connected in parallel. A resistor is soldered to the “plus” of each of them. Since the resistance value depends on the power source, its value may be different. Two wires are connected to the circuit to supply voltage.

The structure is inserted into the hole and carefully straightened to prevent the wires from connecting to each other. The wires are brought out through the hole in the base. Connect the lamp to a constant voltage to check its functionality. Then the base is soldered.

Safe work with fluorescent lamps

CFLs can be disassembled, but not for the purpose of further use for crafts, but only if you need to repair the launcher. flask fluorescent lamp It’s better not to touch it at all, since you need to stay away from toxic mercury fumes.

This lamp consists of five parts:

- U-shaped or spiral flask;

- the upper component of the body with the bulb attached to it;

- an electronic board with a ballast mounted on it;

- the lower element of the housing with the electronics housed in it ballast;

- plinth - together with the bottom of the case, this is an integral structure.

To disassemble and access the launch controller, use a flat-head screwdriver with a wide tip. With its help, the housing latches are disconnected one by one. To perform the operation, you need to insert the tool into the groove and turn it.

This is not so easy to do. After prolonged use, accompanied by constant heating, the plastic loses volatile substances and becomes hard. The latches themselves often break during the disconnection process.

If the constipations do break, they are simply cut off with a sharp tool or sawed off. To do this, you need to arm yourself with a small disk cutter. You can buy it or make it yourself.

First, measure the circumference of the body with a caliper. Then a pin with a cutter is inserted into the chuck of the drilling machine. This is done in such a way that the latter is above the frame at a height equal to ½ the diameter of the lamp body.

The drilling equipment is turned on, the lamp body is pressed against the cutting tool and the outer part of the body is carefully cut. Similar cuts are made at intervals of 1.5 cm along the entire contour.

A screwdriver with a thin rod is inserted into the slots and the cuttings are lifted. Then take a screwdriver one size larger and open the housing of the lighting fixture.

Next, check the lamp bulb for serviceability. Why take a multimeter and check the conclusions in pairs. Resistance within 15 ohms is considered normal. If everything is normal, they conclude that there is a malfunction ballast module.

If the filament breaks, the ballast may still be operational. In this case, the flask is disposed of, and the working device is used as a spare part.

If there is a fuse in the control circuit, it may blow. The issue is resolved by installing a resistor with a resistance of several ohms in its place.

If only one filament has burned out, it can be shunted with a resistance, but this will result in an overload of the ballast. Such a restored lamp will not be able to work for a long time - a year maximum.

Once the repair is complete, the two halves of the lamp are simply glued together. To simplify the reconstruction process, the product is sometimes heated using a hair dryer.

If the lamp cannot be repaired, it must be disposed of. Read about where to dispose of used fluorescent lamps in this article.

How to disassemble an LED lamp

First of all, it is necessary to check the voltage supply to the cartridge contacts. To do this, screw in a working lamp; if the light comes on, the previous device is faulty.

The reasons for the failure of an LED lamp can be very different - the diode is burned out or the board is not in order.

They often stop working due to condensation that has accumulated inside the housing. In any case you need LED lamp repair with preliminary disassembly of the structure.

The components of an LED lamp are:

- shell;

- base;

- matrix with a package of LEDs;

- diffuser;

- driver.

The lamp bulb is not airtight because there are no gases in it.The shell can be made of either plastic or glass. The plastic light diffuser is located at the top.

Applicable LED lamp sockets varied. The components of the package are groups of LEDs soldered onto PCB or aluminum boards.

Drivers in the form of individual blocks or built into the housing serve to transform the input voltage to a value most suitable for LEDs assembled in groups. The most popular power supply schemes are transformer type.

To make the inside accessible, you need to open the fastening clips that hold the diffuser dome. If it is attached to the housing with screws, they must be unscrewed.

There is another disassembly method used for devices made using sealant sizing. For implementation you will need a syringe with a needle, an awl, and a solvent. To detach the diffuser, you will need to remove the sealant that secures it to the retaining ring.

An awl is passed along the edge and the solvent with which the syringe is filled is injected into the groove. After 30 seconds, the diffuser is removed by twisting. The radiator is removed using a screwdriver, and the LED matrix is unsoldered.

A burnt-out LED can be easily identified visually. It reveals itself by having a black dot. As an option, to make the lamp work again, a jumper is placed at the edges of the unusable LED, but it is better to replace it with a new one.

Conclusions and useful video on the topic

Video of the disassembly process, where everything is clear without unnecessary explanation:

The process of disassembling and repairing an LED lamp:

Disassembling the incandescent light bulb is easy. You can make a lot of interesting things out of it, but you can’t reuse it for its intended purpose. Fluorescent and LED light bulbs can be disassembled to a certain point and repaired.

Do you have experience disassembling lamps? Or maybe you have made interesting objects from old lamps? Please share your skills with readers - leave comments and attach photos of your homemade products. The feedback form is located below.

Repairing LED lamps is not a bad idea. I order a bunch of LEDs from Chinese stores and solder them into burnt-out lamps. You can save a lot of money on this. But, again, this is an activity for those who like to make things with their own hands. The biggest problem is removing the protective glass from the diode light bulb. You have to remove it so that it doesn't burst. Otherwise, the light bulb will lose its aesthetic appearance.

I got excited about the idea of decorating the interior of the workshop. I dismantled many different old lamps and installed lighting around the entire perimeter. And hanging from above are light bulbs with a terrarium inside. I’ll continue to look for inspiration, maybe I’ll find something else interesting on similar sites. And one more question: after what time does it take to change the terrarium (clean the light bulb), etc.?

What solvent?