Light bulb socket: design principle, types and connection rules

Do you have to replace a light bulb socket with a new one, but you don’t know how to do it correctly so as not to damage important wires and components? For such a simple job, you don’t want to call an electrician, whose services will be quite expensive, right? Or do you need to upgrade your home electrical system by replacing individual elements?

We will help you understand the features of connecting various cartridges - the article discusses the main types and markings of factory-made electric cartridges.

Instructions for connecting a socket with threaded terminals are also provided and existing options for mounting it in lighting installations are considered. Visual photos with a step-by-step process of connection and installation, and videos demonstrating the replacement of the cartridge and the correct connection of wires to it have been selected.

The content of the article:

Purpose and features of the cartridge

An industrial or home electrical network consists not only of wires and lamps, but also of many electrical installations that serve to control or communicate individual parts of the circuit.

The socket connects the lamp base to the electrical cable and at the same time fixes it in a lamp, chandelier, or simply holds it suspended.

The problem of quickly replacing lamps arose as soon as electric lighting was invented, that is, at the end of the 19th century.The first lamps had bases, but the methods of connecting them to the wires were different and had no classification.

In 1881, Edison patented the first threaded type base and cartridge for it. Thus, the most popular types of bases and sockets have remained relevant for more than 130 years.

Of course, they were originally invented incandescent lamps. Then gas-discharge and LED ones appeared; their installation required both already familiar and structurally different types of cartridges.

For the manufacture of modern cartridges, various materials are used, among which you can find traditional metal and ceramics, as well as heat-resistant polymers and even silicone.

The latter option is most often used to create design compositions. Silicone products are equipped with a 1 m electrical cord and are painted in all the colors of the rainbow.

When purchasing a sconce, chandelier or other lamp, you need to pay close attention to the manufacturer’s recommendations: if you install lamps that are too powerful, the sockets may fail and the shades may become deformed.

Types of electric cartridges by type of base

As mentioned above, two large categories of cartridges remain in demand - for a threaded base and for pins. They are often universal, that is, suitable for different types of lamps.

For example, incandescent lamps and stylized lamps are equipped with threaded ones. LED devices.

But some products can only interact with one option. Let's take a closer look at their design features and technical characteristics that you need to rely on when choosing.

No. 1 - popular threaded options

Sockets with internal threads are designed for lamps with a threaded base. The sizes are usually designated the same: for example, for a lamp with an E14 socket, a corresponding E14 socket is required, although an adapter from E27 to E14 is possible.

The numbers 14 and 27 indicate the diameter, with 27 often considered the classic size and 14 called the minion.

There are only 8 standard sizes of socles, therefore, the same number of cartridges for them: E5, E10, E12, E14, E17, E26, E27, E40.

The most popular are plastic products. They have a limited service life and are subject to the requirements set out in GOST 2746.1-88. The method of mounting the cartridge may differ and can be suspended, with a straight or inclined flange.

The first is used for fastening to the ceiling or mounting fixtures, and flanged ones are used for installation on the surface.

Table of characteristics of the most common threaded sockets for connecting lamps to the electrical network, which differ in size. The larger the diameter of the cartridge, the higher the power and load current.

| Chuck size | Maximum power, W | Load current, A | Purpose |

| E14 | 440 | 2 | A cartridge with an internal thread ∅14 mm, which is also called a “minion”. Suitable for household incandescent lamps with low power |

| E27 | 880 | 4 | A chuck with a ∅27 mm internal thread, which is considered traditional, but is increasingly being replaced by ∅14 mm. Suitable for various types of medium power lamps |

| E40 | 3500 | 16 | Ceramic chuck with internal thread ∅40 mm. Serves to connect high power lamps required for street or industrial lighting |

The housing is made from various types of plastic, so before using the lamp you need to study the markings to find out the permissible power of the lighting device.

If you screw in a high-wattage light bulb, the plastic will melt or gradually deteriorate due to regular heating.

No. 2 - variety of pin varieties

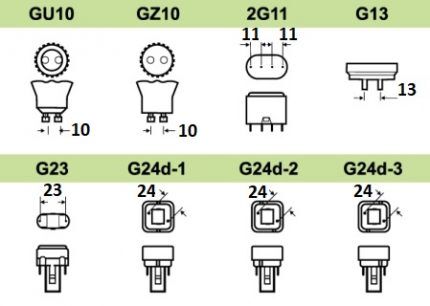

Requirements and standards regarding pin cartridges are located in GOST R 60400-99. They operate from a 220 V network.The letter G indicates the type of cartridge (pin), and the next number is the distance between the two holes for the pins.

If there are not 2, but 4 contacts, then the diagonal distance between opposite holes (grooves) is indicated. Special types are marked with additional Latin letters or numbers.

Cartridges for pins are used for domestic and industrial premises, as well as for lamps that are installed on the street - along park paths, roadways, for lighting areas or local areas.

| Chuck size | Maximum power, W | Load current, A | Purpose |

| G4-G10 | 60 | 5 | Varieties from G4 to G10 inclusive are suitable for mounting low-power halogen lamps. The number after “G” is the distance in millimeters between the pins |

| G9 | 60 | 5 | Lamps for G9 sockets have a loop-shaped flat base that is inserted into special grooves |

| GU10 | 50 | 5 | Analogue of the cartridge for G10 socket. Lamps have nubs at the ends of the pins that are inserted into the holes and then secured with a twisting motion. |

| G13 | 80 | 4 | Cartridge for linear lamps for various purposes. Features – paired use and rotary connection mechanism |

| GX53 | 50 | 5 | Similar to G10, but with an increased distance between pins - 53 mm. Designed for installation in suspended structures, therefore it has a minimum thickness. |

To install U-shaped and cylindrical lamps, use sockets GX23, G24, 2G7. They differ in the number of contacts - 2 or 4, have a load current of 2 A. The recommended lamp power is up to 75 W (for 2G7 - 50 W).

Thus, pin sockets can differ in the following characteristics:

- body material;

- inner liner material;

- type of fastening of the cartridge to the base and wires;

- number of contacts;

- distance between contacts.

All of the above parameters can be indicated when labeling the product.

Linearly elongated gas discharge lamps have a slightly different type of fastening. In addition to the fact that the sockets are paired (the lamp is inserted on both sides), they are designed to operate from a 220 V and 380 V network, with a rated current of 1 A or 2 A.

By design, the sockets are end-mounted, pendant and rack-mounted - this also depends on the type of lamps used. The number of contacts may be different: for example, if there is a conductive strip - three instead of the usual two.

In order for the cartridge to fulfill the warranty period, it is necessary to follow the installation rules, select the product according to the technical characteristics of the lamp, and select the desired degree of protection (moisture- or dust-proof).

In addition to cartridges for pin and threaded sockets, there are products for other types: focusing, pin, with recessed contact, soffit.

They are used for installation and connection of LED and gas-discharge lighting devices.

Additional information on types of base is presented in the articles:

- LED lamp sockets: types, markings, technical parameters + how to choose the right one

- Types of lamp bases for lighting lamps: standard markings and types of bases for light bulbs

Labeling of factory products

Professional electricians are not content with one size and a quick visual inspection of the product; they carefully read the markings printed in indelible ink or embossed on the visible part of the socket.

The most responsible manufacturers apply the markings and attach short manuals to the products listing important characteristics.

The list of parameters that can be found on the cartridge is not always complete.

Usually any of the following characteristics are reflected:

- type, for example, threaded, pin;

- size;

- temperature;

- load current;

- power;

- voltage;

- manufacturer's trademark;

- level of protection;

- presence of contact for grounding.

Before purchasing cartridges, study the manufacturer’s website, where detailed technical information and a diagram with dimensions are usually posted.

When choosing, it is also worth considering that ceramics are stronger than plastic and can withstand higher temperatures. If the cost of a product is questionably low, there is a chance that it is a fake.

It’s better to play it safe and buy a more expensive, but high-quality electric cartridge from a reputable brand.

How to connect the cartridge correctly?

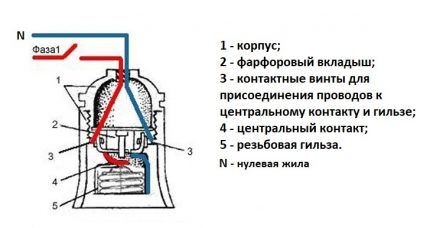

Among household products, the most difficult to connect wires to is the old type of cartridge - “Soviet”, since it must first be disassembled.

These devices are easily recognized by their black polymer housing. To get to the terminals, the carbolite housing must be unscrewed.

To secure the wires, they need to be stripped and shaped into “loops” to make it easier to secure to the contacts. The phase is fixed to the central screw contact, zero - to the second terminal.

When tightening a threaded connection, it is necessary to apply force and remember that it simultaneously transmits tension to the contact. When the wires are connected, all that remains is to connect the two parts of the housing.

Mounting methods in lighting fixtures

Difficulties in installing the socket may be caused by the design of the chandelier or lamp. In order to quickly cope with the replacement of a broken product, we recommend that you become familiar with its structure and position in advance, before the initial installation of the lighting device.

Lamp manufacturers most often choose the following methods of mounting sockets:

- for the electrical wire;

- on a metal tube;

- using a bushing;

- latches.

Option #1. When attaching to an electric drive, it is necessary to additionally strengthen the wire; for this, use a sleeve with a fastening screw, which is screwed into the bottom of the cartridge.

Option No. 2. The metal tube is used more often, as it allows the installation of heavy chandeliers with a large number of decorative elements.

Option #3. Cartridges with bushings are heated, as a result of which the elements are deformed. Therefore, it is recommended to replace plastic bushings with metal ones.

Option No. 4. The latter mounting method is suitable for devices with screwless terminals. The cartridge is installed in parts. First, the bottom is secured, then the wires are inserted, and only then the remaining part of the cartridge is mounted using latches.

Connection option with screw terminals

Cartridges of a more modern type do not need to be disassembled - the terminals are located on the outside. The wires are fixed with screw clamps, the connection process takes only a few minutes.

The only disadvantage of such a cartridge is the impossibility of repair. If the terminals are burnt or the product is deformed, you will have to replace it completely.

The connection option with clamps is relevant for luminaires designed for E14 and E27 lamps.When installing a new cartridge and replacing it, be sure to check it for integrity and compliance with standards.

Let's assume that the number of turns must be at least three, and there must be no cracks or chips on the body.

Conclusions and useful video on the topic

Installation of different lighting devices may differ, so we present several video instructions for connection.

Connecting ceramic and carbolite cartridge:

Option for connecting wires to a plastic socket:

Replacing the G4 chuck:

The cartridges are designed quite simply, so you can disassemble, replace or repair home electrical installations yourself.

The most important thing is to turn off the mains voltage if you are working with a lighting device, and strictly follow the recommendations of experienced electricians. When installing a new model, you must follow the manufacturer's instructions.

Do you have anything to add or have questions about choosing and replacing a light bulb socket? You can leave comments on the publication, participate in discussions and share your own experience. The contact form is located in the lower block.

By the way, about cartridges marked “G”. When they were doing the repairs, I came across this and wondered what kind of marking it was. I read a lot of articles. All these markings and features. It was useful to clarify this issue just before installing spotlights. Still, you need to know what you are dealing with, and this information may be useful later in everyday life. I also looked at the diagrams.

I do a lot of things at home with my own hands, but the knowledge is often lacking. That's why I educate myself on the Internet.Now I wanted to make lighting in a new house myself, the material and video recommendations for working with sockets came in handy; it is clear that the markings on the light bulb base and the socket must match. Connecting the cartridge correctly was also easy.