Ventilation of an inspection pit in a garage: specifics of arranging an air exchange system

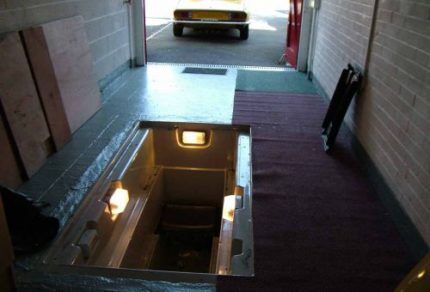

In domestic and outbuildings, as in a house, microclimatic balance is required.One of its components is a high-quality ventilation system. In addition to the vehicle storage area, ventilation of the inspection pit in the garage is necessary, because... and it participates in the general air exchange of the garage space.

We will talk about how to organize a stable change of air mass in a box buried in the ground. We will suggest which type of system is preferable and explain the reasons. Our recommendations will be useful to independent home craftsmen who want to keep both buildings and equipment in order.

The content of the article:

Advantages of a ventilated inspection pit

Despite the small dimensions of the inspection compartment, its constant drying and ventilation is very important. Moisture from the car often gets into it, therefore, condensation accumulates, destroying the walls. Because of this, the pit gradually reaches a state that is unsuitable for repair work.

Proper organization of ventilation will give positive results:

- Will bring the temperature back to normal.

- Normalizes the humidity level, which will have a good effect on the condition of the car, tools, and metal surfaces of the garage. In addition, dampness can create the preconditions for a short circuit in the electrical wiring of the pit lighting line.

- It will eliminate conditions favorable for the appearance of fungus, which can destroy even concrete and brick elements of both the room in general and the inspection pit in particular.

- It will prevent the accumulation of harmful fumes from fuel, paints and varnishes, machine oil, and technical fluids. This is important because Having reached a certain concentration, they can cause fire and poisoning.

From a pit in which ventilation is not provided, air saturated with moisture and various fumes will enter the room. This will have a negative impact on the health of the motorist.

Since the car enthusiast sometimes spends a lot of time in the inspection department, the air in it must be regularly updated.

Types of ventilation for inspection pit

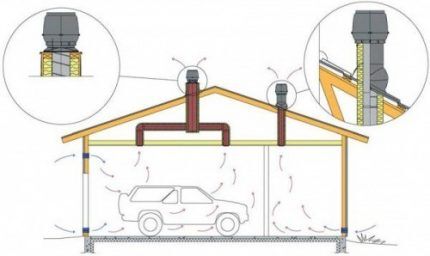

When installing ventilation in the inspection pit, as in other cases, they proceed from the laws of aerodynamics. Therefore, there are three options - natural, forced ventilation, and combined. The first method, due to the successful match between price and quality, is preferred by many car enthusiasts.

Air masses circulate due to the difference in pressure of air flows with different temperatures. At the same time, fresh air jets squeeze out the warm exhaust air. The circulation becomes more intense if the pressure drop, and therefore the thrust, increases.

During warm periods, natural ventilation does not work well. This is explained by a slight discrepancy between the air temperatures outside and inside. This circumstance makes us think about installing forced ventilation, although natural ventilation is often sufficient to dry such a small compartment.

Considering that for a garage the requirements for air exchange are increased, it is necessary to provide for the possibility of increasing the amount of supply air. Maximum efficiency can be achieved using a forced two-channel ventilation system.

In this way, both the optimal influx of fresh air masses through mechanical devices and the timely removal of contaminated ones will be ensured.

Organization of ventilation of the inspection pit

The ventilation system for the above-ground part of the garage is extremely simple, but the hood in the inspection pit of the garage is more difficult to arrange, since it has its own characteristics.

It can be implemented in two ways:

- By installing ventilation, which is part of the ventilation system of the entire building.

- A separate inspection compartment system, separate from the general ventilation.

The most effective solution is autonomous supply and exhaust ventilation system as an addition to the air exchange of the main building.

Before you start arranging ventilation in the inspection pit, you should develop a general diagram for the entire garage building. It marks holes in the wall, foundation, and plinth for subsequent placement of air ducts.

The project takes into account such aspects as the volume of the room, the number of cars, underground or above-ground options for placing pipes. They also consider the optimal route for the movement of air masses.

If the groundwater is not deep enough, in addition to the ventilation system, it is necessary to provide good waterproofing of the inspection pit. Then dampness will not accumulate through the floor and walls, and ventilation will do its job better.

Guided by building codes, it should be taken into account that with natural air exchange there should be about 1.5 cm of air duct diameter for each square meter of garage space. So, if you take a garage with an area of 10 m², then to install the ventilation system you will need pipes with a diameter of 15 cm.

If the area of the room is 2 times larger, then the diameter of the pipe increases 2 times. If there are several holes, the calculated diameter is divided by their number.

There is another formula for determining the parameters of the ventilation holes. Their total size should correspond to 0.3% of the room area. This method is usually used when calculating a mechanical single-channel system.

Natural ventilation installation technology

In the process of searching for a solution to the problem, how to make a hood This type of inspection pit and garage should be guided by the following principles:

- It is necessary to leave a gap of about 150 mm wide along the edges of the pit.

- Boards for covering the pit should be placed with a 100 mm gap.

- A gap is required on the side opposite from the hood.

In this case, two boards are removed from the boardwalk to allow air flow. To create conditions for exhaust hood, one board is removed.Supply and exhaust ventilation ducts are placed in opposite corners of the inspection section. The end of the inflow pipe is left at an average distance of 25 cm from the floor level.

At the next stage, retreating about 10 cm from the ground surface, place the top of the supply pipe. The exhaust air duct is located as close as possible to the inspection pit cover. The opposite end of the exhaust pipe, which goes out, is raised above the highest point of the garage roof by at least 0.5 m. During installation, the horizontalness of the pipes is controlled.

The inlet opening must be regularly cleared of snow in winter. It’s easier to increase the hood height, and at the same time the draft will increase. To improve circulation, pipes are equipped with deflectors. The supply air duct is equipped with a grille to prevent insects and rodents from getting into it.

In cold winter conditions, pipes must be insulated, otherwise they may freeze. In an unheated garage, natural ventilation may not function well not only in summer, but also in winter.

When the car engine is running, it becomes a source of heat, but two hours after it is turned off, the temperature in the room differs little from the outside temperature. The effectiveness of natural ventilation decreases.

The solution is simple: to maintain air exchange and prevent condensate from freezing in the exhaust duct, use an ordinary 40 W incandescent lamp. The cartridge is suspended under the channel opening and turned on.The lamp generates heat, which is enough for the air to move at a speed of 0.2 to 0.4 m/s.

It is important to insulate the channel and prevent moisture from entering it. It should be noted that an incandescent lamp produces little heat, and it is unlikely to be enough for the entire length of the ventilation duct.

It is not worth replacing an incandescent lamp with an LED or fluorescent analogue. They generate significantly less thermal energy. It is better to use a low-power infrared device.

Forced ventilation system

A ventilation system with forced impulse in the inspection pit is not installed very often. In this case, mechanized means of motivation are used. Sometimes they also provide air heating using a duct heater.

The supply of air masses is carried out using duct fan. In this case, it is irrational to use monoblock air handling units. And a fan for inflow is not always used, only if there is such a need.

To implement a forced ventilation scheme, electrical power is required. Additionally, the system is sometimes equipped with timers so that it turns on and off automatically. In some cases, the ventilation control is connected to the light switch.

Compared to natural ventilation, the forced system has many advantages:

- The possibility of increasing efficiency, as a result of which an increased volume of fresh street air quickly displaces waste materials mixed with harmful substances.

- Elimination of dependence of air supply on external factors due to the presence of fans in the system. Air masses can be supplied to the desired zone, in a certain volume, at the desired speed.

- The car will always be in a favorable temperature regime.

Unless there are compelling reasons, it is not advisable to equip the inspection compartment with mechanical ventilation. This option is better suited for a cellar.

Combined pit ventilation system

The combined type system is the most popular. It provides for both the presence of mechanics in the hood of a garage or pit, and the flow of air carried out according to a natural pattern.

A fairly rapid flow of fresh air into the garage is possible due to the presence of a rarefied pressure zone. It is created by a fan when exhausting dirty air. At the same time, it is necessary to maintain the possibility of natural ventilation in case the power goes out and the fan does not function.

To be on the safe side, lay two parallel lines, or make a hole at the fan installation site of a slightly larger diameter. The advantages of the combined system are that it is not dependent on the outside temperature. This method of normalizing air exchange is quite cheap.

As a minus, it can be noted that the air ducts quickly become dirty, so they need to be cleaned periodically. In addition, the air flow is not heated.

Conclusions and useful video on the topic

Video about how to install a hood in the garage and in the inspection pit in particular:

Experience in creating ventilation in the garage and basement with your own hands:

To obtain the expected effect, ventilation in the inspection compartment of the garage must comply with installation rules and feasibility from an economic point of view. The choice of system should be made based on the specifics of the building and size. Only by using these factors will it be possible not only to create optimal conditions for car maintenance, but also to spend money rationally.

Would you like to share your own experience in installing air exchange in a garage inspection pit? Do you have valuable information on the topic of the article that will be useful to site visitors? Please leave comments in the form below, ask questions and post photos on the topic of the article.