Waterproofing the floor in an apartment: features of the choice of insulating materials + work procedure

Breakdowns often occur in the water supply and heating systems, so there is always a risk of water leakage.Agree, this can cause a lot of trouble, such as, for example, flooding someone else's apartment or destroying your own floor coverings. Also, do not forget that excess moisture can lead to the appearance of mold and mildew, which can negatively affect your health.

Therefore, it is necessary to take care of protection from moisture in advance, namely at the very beginning of the repair. To do this, the floor is waterproofed, which will serve as a reliable barrier from the effects of water.

Next, we will tell you how to independently carry out waterproofing work in an apartment, and also help you choose suitable materials.

The content of the article:

The main advantages of floor waterproofing

Waterproofing is the protection of the concrete base, screed and front floor covering. Experts advise carrying out waterproofing immediately before screeding, since concrete can absorb moisture through micropores and subsequently collapse.

This is especially true for owners of first-floor apartments, since the screed is exposed to cold (from the basement) and warm (from the apartment) air currents.

However, the most reasonable option would be to do waterproofing the floor throughout the apartment, because:

- the solution used for floor screed contains water, so there is a risk of leakage to neighboring apartments located below;

- the heating system may fail, which will also lead to flooding of the lower floors;

- waterproofing will increase the strength and durability of the floor, protect against microcracks;

- When installing a heated floor system, waterproofing is required.

It is worth noting that waterproofing in areas located close to plumbing equipment must be especially carefully arranged.

Selection of insulating materials

The building materials market offers a wide range of waterproofing for floor coverings, which differ depending on the method of application and area of use.

Let's take a closer look at the main types of waterproofing materials.

Rolled waterproofing materials

The basis of roll waterproofing is fiberglass or a mixture of polyester resins.

Such coatings include hydroisol, isoplast, roofing material and the like.

Depending on the method of fastening, there are the following types of roll insulation:

- Adhesive. Attached using bitumen mastic or synthetic resin based adhesive. There are also self-adhesive options. The base must be well prepared. It is considered a simple option, as it does not require special skills.

- Welded. The base is polyester or fiberglass. Using a gas burner or a heat gun, the bottom layer of insulation (bitumen) is melted and then installed. This method is not advisable to use in enclosed spaces, as bitumen vapors are toxic.

- Mechanically installed. The basis for this type is sand with a fine fraction or roofing felt. Fixed with self-tapping screws. This option is labor-intensive and not reliable enough.

The main reason for choosing roll-type waterproofing materials is the relatively low cost. Another advantage of roll coatings is the ability to immediately carry out further repair work.

Disadvantages include difficulty in installation in a small area, for example, In bathroom.

It is also worth noting that during the installation of rolled waterproofing, seams are formed, which in the future may compromise the tightness of the protective coating.

Coating materials for waterproofing

Today, coating materials are the most popular materials for waterproofing, and in terms of their effectiveness they are replacing even rolled materials.

After applying the mastic, a film is formed, which will serve as a protective barrier against unwanted moisture. Mastic materials for floor waterproofing are made on the basis of bitumen, acrylic and synthetic resins.

Depending on the constituent components and operational characteristics, there are several types of coating materials:

- Polymer cement mastics. They contain cement, fine quartz sand and polymer additives. The material has high adhesion and durability. The disadvantage is the drying time of the finished surface.

- Bituminous. Depending on the method of application, there are hot and cold application mastics.The latter option is better suited for waterproofing the floor in an apartment, since bitumen does not require heating to 160-180 °C, unlike hot-applied mastic.

- Polymerbitumen. Basically, compositions are produced based on the modification of bitumen with latex, polyurethane or acrylic. The materials have great strength along with high adhesion. They have a higher cost than previous types of mastics.

- Acrylic. Compared to bitumen materials, they are much more environmentally friendly and odorless. Suitable for underfloor heating systems. Their main disadvantage is their high cost.

Ready-made mastics and dry mixtures are available on the market. It is enough to dilute the latter with water according to the manufacturer’s instructions.

When choosing a suitable mastic, it is necessary to take into account not only the price of the material, but also the indicated consumption per 1 m2. Often, inexpensive mastics are more viscous, which increases the material consumption declared by the manufacturer.

Penetrating compositions

The action of penetrating mixtures, so-called “impregnations,” is based on penetration into the structure of the concrete base and the ability to react with it.

Before applying impregnation, the concrete surface must be moistened. In addition, before using impregnation, preliminary application of a primer is not required, which will significantly reduce the cost of materials.

It should be noted that impregnation is not used on surfaces made of foam concrete, aerated concrete and brick, since the desired chemical reaction will not occur. The main disadvantage of the application is the high cost of materials.

The procedure for carrying out waterproofing work

Almost all waterproofing methods include preparing the base, priming the surface and installing waterproofing materials. Let us consider the features of possible methods in more detail.

Method of roll floor waterproofing

First of all, it is necessary to prepare the surface, namely: dismantle the old coating to the concrete base, and also clean the floor from dust and debris.

When installing waterproofing in the bathroom and toilet, you will need to remove all plumbing equipment.

Of all the presented types of roll insulation for an apartment, it is advisable to choose the glued type of waterproofing.

After cleaning, the floor must be primed. The material is cut to the size of the room, leaving an overlap for the overlap on the walls - approximately 10 cm. The cut strips should be left on the floor for a day so that it is leveled.

The perimeter of the room is covered with special construction tape or waterproofing tape. The material is glued using glue or mastic on a polymer-bitumen basis. The prepared strips are overlapped on each other, at least 15 cm, while the joints of the strips are additionally glued with mastic.

There are also self-adhesive materials, which are easier to install because they do not require applying glue to the subfloor. You can install roll waterproofing using a roller or pressure roller.

Experts advise doing such waterproofing in two layers, one layer perpendicular to the other, after the previous one has dried.

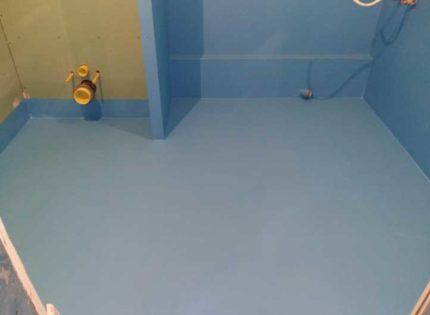

Installation of coating waterproofing

Coating type waterproofing is considered the simplest insulation method.

As in the previous method, the base is prepared first. If a dry mixture is selected for work, then you need to prepare the solution according to the instructions indicated on the package.

It is convenient to apply the mastic with a roller, after pouring it into the tray. All corners are worked with a brush.

The waterproofing material is applied in two layers. Interlayer drying between the first and second application is 2-4 hours. Repair work can be continued after the mastic has completely dried, approximately 10-15 hours.

Penetrating waterproofing technique

This method is considered the most effective, as it can withstand the results of even a serious pipeline break. Penetrating waterproofing also prevents corrosion of the reinforcement.

The execution method is similar to the previous method.

The drying time of the solution usually does not exceed one and a half hours, after which you can begin pouring the floor screed.

Conclusions and useful video on the topic

Method of waterproofing a floor using self-adhesive roll waterproofing:

Technology for coating floor waterproofing:

You can waterproof the floor yourself, but the use of any material for waterproofing the floor has a number of its own characteristics and you must strictly adhere to the manufacturer’s instructions.

During renovations, be sure to take care of waterproofing, which will protect your apartment from the negative effects of water. And, by the way, it will help you save money, because the cost of waterproofing is relatively small compared to repairing floor coverings or your neighbors’ apartment in case of flooding.

What material did you choose for waterproofing the floor in your own apartment and why did you choose it? Tell other visitors to our site about this.