Which cable to use for wiring in an apartment: overview of wires and choosing the best option

There are a variety of wires on sale, differing in material, cross-section, marking, design and color.

When laying electrical systems, it is necessary to resolve the primary issue - which cable to use for wiring in the apartment in order to ensure the safety and reliability of the laid electrical communications.

Agree, choosing a suitable conductor is not an easy task. We will try to help you, and we suggest you familiarize yourself with the detailed classification of cables and the specifics of connecting electrical equipment.

The content of the article:

Reasons for replacing cables

Complete or partial replacement of electrical networks usually needs to be performed in two cases:

- Wiring age. Major renovations are recommended to be carried out 15-20 years after moving into a new apartment. During this time, the installed communications wear out, becoming a source of potential danger for residents.

- Redevelopment and renovation of premises (especially with the addition of powerful household appliances). Modern electric stoves, washing machines, and dishwashers place increased demands on wiring. It is not advisable to connect them to old electrical networks due to the mismatch of characteristics.When planning to purchase such units, it is better to update communications in individual rooms, for example, in the kitchen or bathroom.

Regardless of the reason for replacing electrical networks, work should begin with drawing up electrical wiring diagrams and selection of cable products.

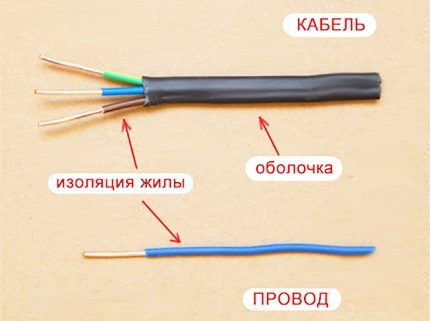

Differences between cables and wires

Novice craftsmen often ask the question of what to buy for laying electrical communications - cables or wires.

To solve this problem, you need to find out the difference between these products:

- According to GOST 15845-80 adopted in the USSR, the cable consists of one or more conductors (cores) coated with insulating material. Such elements, in turn, are enclosed in a plastic, polyethylene, metal or rubber shell, on top of which an additional protective cover, including an armored one, can be installed.

- Thanks to double insulation, the cable is reliably protected from moisture, light, exposure to aggressive substances, and mechanical damage. Increased strength and reliability characteristics allow the use of such products in the most difficult conditions, for example, under water and underground.

- The wire consists of one or more twisted strands, which can be either insulated or bare. They are usually enclosed in a non-metallic sheath (PVC, cross-linked polyethylene) or a braid/winding made of textile or wire. The security of a wire is much less than that of a cable, so its scope of use is quite limited.

According to professionals, to install a stationary electrical network in an apartment, it is necessary to use only cables. The wires can be used for portable electrical equipment, as well as in low-current systems with a voltage not exceeding 24V.

When choosing materials for laying electrical networks in residential premises, preference should be given to impeccably high-quality products. Only in this case can you install safe, fire-resistant and reliable wiring that will ensure the delivery of electric current to every corner of the apartment.

The most important characteristics of cable products

When purchasing products used for laying electrical communications, it is important to consider the features listed below.

Cable material and design

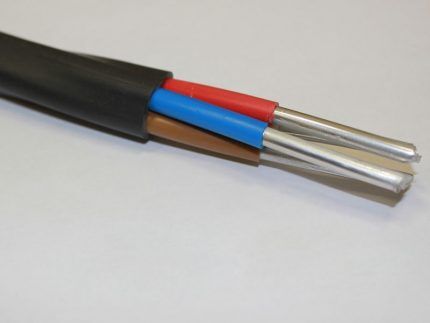

The assortment includes wiring elements using copper and aluminum conductors. Although the latter are cheaper, copper products are more reliable: they have higher current conductivity and lower resistance, and, moreover, conductors made of this metal heat up more slowly.

Copper is also more ductile and not subject to rapid oxidation, so wires made from it last a long time.

Based on these characteristics, current documents (PUE 7.1.34 And SP 31-110-2003, clause 14.3) prescribe the use of exclusively copper cables and wires for wiring in apartments.

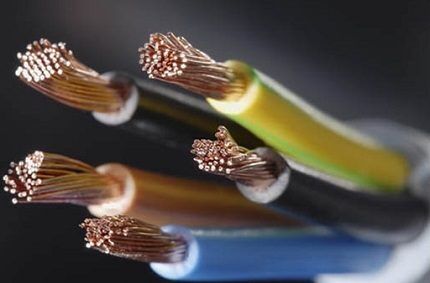

By design, wires can have one or more cores. A single-wire element is a monolithic conductor surrounded by an insulating sheath. This product is convenient and easy to install, and it costs less than multi-wire ones.

At the same time, cables of this design, especially those with a large cross-section, are more rigid and often break when bent. Because of these features, experts give preference to plastic multi-core products.

Such models tolerate twisting, bending, and turning well, making them suitable for laying any electrical networks.

However, if there is an urgent need for wiring under plaster, the use of a single-core copper product is allowed, since the finishing material provides additional protection.

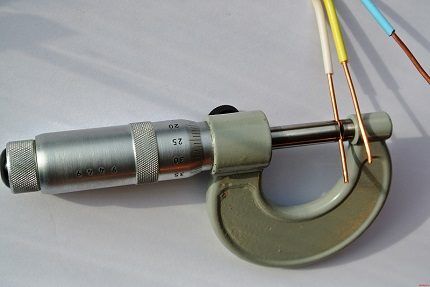

More information about cable cross-section

This indicator, measured in square millimeters, reflects the current carrying capacity. A copper cable product has one mm2 capable of passing a current of 8-10 amperes, while aluminum has a maximum rating of only 8A.

To ensure safe operation of the electrical network, it is better to select conductors with higher throughput.

Thanks to this, the core does not heat up above the permissible norm, which protects the insulation from melting. The cross-sectional reserve is also important, since the wiring hidden under the plaster is poorly cooled.

At the same time, it is not recommended to take a cable whose rating is much higher than the calculated one (for example, 4 instead of 2.5 mm2).In this case, it is necessary to apply wiring protection calculated on the basis of this indicator, that is, automatic circuit breakers and RCDs of higher power are required.

Ideally, the cross-section should correspond to the marking indicated on the cable product tag, but the actual indicator is often smaller.

Small discrepancies are acceptable since certification focuses on resistance and not cross-section. Significant discrepancies in the numbers indicate a marriage.

When choosing and calculating the cross-section of electrical cables need to be guided PUE 7.1.34, and each wiring line must be calculated separately, taking into account the expected load.

However, in most cases it is acceptable to be guided by practical experience in electrical wiring. Based on numerous observations and calculations, electrical wiring devices often use cables with the following cross-section:

Core insulation thickness

Any conductor used in a multi-core or single-core cable is surrounded by insulation, for which PVC or other types of plastic are used (they can be ordinary or have reduced flammability and smoke production).

The thickness of the insulation is regulated by the relevant GOSTs: for household cables designed for voltages up to 660 V, with a cross-section of 1.5 and 2.5 square millimeters, the standard requires the use of an insulating layer of 0.6 mm.

To avoid mistakes, it is better to buy cables of well-known brands, offered in reputable specialized stores.

Cable sheath thickness

The outer sheath forms an integral cable, fixing and protecting the insulated conductors inside.

Like core insulation, it is usually made from various types of plastic (PVC, cross-linked polyethylene, low-flammability polymer), but is thicker.

According to accepted rules, the protective sheath layer of single-core cables is 1.4 mm, and multi-core cables are 1.8 mm; in practice, the thickness of such products may vary slightly downward.

All residential wiring components, even if they are intended to be used for areas with minimal power, must be made of cables that have protected wires and an integral sheath.

Double insulation allows maximum protection of the electrical network from damage and ensures the safety of people, helping to avoid electric shock.

Rules for reading cable markings

The sheath of the cable used for electrical installation in a residential area contains all the information necessary for choosing a product. The inscription, which must be clear and easily readable, is printed or embossed during the manufacturing process of the product.

Here are some notations.

The first letter used in the marking indicates the material for the insulating sheath:

- P – wire or polyethylene insulation;

- IN – polyvinyl chloride (PVC) insulation;

- TO – control cable;

- R – rubber insulation.

The second letter indicates the material from which the core sheath is made:

- IN – PVC insulation;

- R – rubber shell;

- P – polyethylene insulation.

In addition, the marking may contain other letters that reflect other characteristics of the electrical cable:

- ng – cable insulation has reduced flammability;

- Shv — protective sealed wire; PVC hose;

- L.S. – when the wire melts, little smoke is released;

- BB – a protective shell consisting of two steel strips;

- E — shielded cable;

- B — armored wire;

- h - cable with filled spaces between conductors;

- P – flat wire;

- G - cable with increased flexibility;

- coolant - single-wire core.

The letter to indicate the material from which the cable is made is present only for aluminum products (A). For copper wires, the letter is not specified because this is the default metal.

The marking may also contain the following important information:

- manufacturer's name;

- year of issue;

- number of cores;

- section;

- voltage (nominal).

Catalogs and price tags usually do not indicate the manufacturer and date of manufacture. In this case, the marking looks like VVGng(ozh)-0.66 kV 3x1.5.

Which stands for three-core non-flammable (ng) flexible (G) copper cable with three single-wire conductors (ozh), the cross-section of which is 1.5 sq mm. The cable is designed for a rated voltage of 660 V, and has insulation and a sheath made of PVC plastic (PV).

Additional information on marking cables and wires is presented in this article.

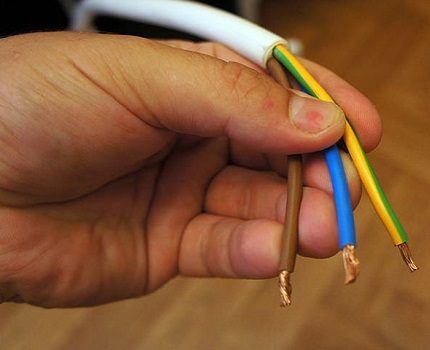

Cable colors

The wires can either be uniformly colored or have a one-millimeter stripe on the sheath along the wire.

Decoding wire colors:

- Red, brown, white wires are usually used as a phase (denoted in diagrams as L).

- Blue wires indicate zero (N).

- Green or green-yellow veins, which are marked on the plan with letters P.E., always correspond to grounding.

This color specificity greatly facilitates electrical installation work.

Packaging and certificates of conformity

There are two types of standard packaging for electrical wiring. Cables intended for retail sale in construction and other specialized stores are wound on coils.

Products offered to wholesalers, construction organizations and other large consumers are packaged in drums.

Regardless of the container, a tag with a description is attached to the product, which includes:

- plant name or brand name;

- brand of cable products;

- date of manufacture;

- GOST or TU, according to which the cable product was manufactured;

- number of segments with length designation;

- drum number;

- conductor weight;

- conformity mark;

- controller's mark.

When purchasing a cable in a whole coil measuring 100 m, a tag is given along with the product. When purchasing electrical wiring in a piece, a label is provided by the seller for viewing.

The quality of the cable is confirmed by special documents. The product must have a fire safety certificate and a certificate of conformity confirming the possibility of using this type of cable for certain electrical installation work.

The document relating to a particular type of product must indicate GOST or TU, as well as the validity period. Sellers are required to present the certificate for review upon the first request of the buyer.

External condition of cable products

When purchasing electrical wiring, you should also pay attention to the appearance of the products. It is better to avoid products that have external damage: pronounced kinks, compression, bruises.

Such faults may indicate internal problems: conductors with external defects may have breaks or be shorted to each other.In order not to make a mistake with your choice, it is advisable to carefully inspect the electrical wire in the store, and only then pay for the purchase.

Existing types of products

It is difficult to unambiguously answer the question of what wires and cables are needed for wiring in the residential premises of an apartment, since such work requires various types of similar products.

For the lighting circuit, which receives the least load from the electrical network, a cable with a cross section of 1.5 mm is suitable2. For it, it is enough to provide a 10 A (2.3 kW) circuit breaker.

For sockets, the load in which can reach up to 3-4 kW, it is necessary to take products with a cross-section of 2.5 square meters. mm, capable of withstanding current up to 27 A and power 5.9 kW.

However, you should not load the line to such limits: for correct operation, a reserve of one third of the planned load is required. In this case, you will need a switch rated at 16 A (3.6 kW).

If planned installation of a socket for an electric stove (hob), it is necessary to lay a cable with a cross-section of 6 sq. mm for power up to 10.1 kW.

In this case it is important select the appropriate machine, designed for an electric current of 32 A (voltage 7.3 kW).

When choosing the parameters of the input cable to the apartment, it is important to take into account the power allocated to the apartment. As a rule, in this case it is necessary to use a product with a cross section of 6-10 square meters. mm.

Popular types of electrical wiring

Among the frequently used types of products for electrical installation, two common models can be distinguished: VVG and NYM.

Option #1 - VVG cable

The most popular domestically produced product, which is often used to perform electrical work in an apartment. The cable belongs to unarmored flexible power wires.

It can consist of 1-5 copper cores, the cross-sections of which vary from 1.5 to 240 square meters. mm. The conductors, which can be round, triangular or flat, are surrounded by polyvinyl chloride insulation and a common sheath.

The VVG cable has several modifications:

- VVG – the main type, the characteristics of which are given above.

- VVGng – a power cable having an outer sheath and core insulation made of non-flammable polyvinyl chloride.

- VVGng-LS – wiring, the conductors of which have non-flammable self-extinguishing insulation, and the shell has a low smoke emission rate.

- VVGng FR-LS – non-flammable cable with low smoke, having additional fire protection made of mica tape.

Although regular VVG is cheaper, its shell does not have fire-resistant properties and emits a lot of smoke when burning. These products are also not suitable for bundle laying, while non-flammable products are mounted in bundles, so that several cable lines can be laid simultaneously in corrugations, pipes or pits.

Based on the reasons listed above, for wiring electrical networks in an apartment it is better to take reliable and practical products of the PPGng-HF and VVGng-LS brands, which are the safest in domestic operating conditions:

Option #1 - NYM cable

These are copper products manufactured at Russian factories under a German license. The cable complies with both domestic GOST standards and European standards.

According to the main characteristics, the model coincides with the indicators of the VVGng cable; it is also rated for a nominal voltage of 0.66 kW.

NYM single-wire multicore cable with a cross-section of 1.5-10 mm is available for sale2 and multi-wire, the cross-section of which exceeds 16 mm2.

To ensure the non-flammability of the product, a rubber filler is placed between the polyvinyl chloride shell of the product and the cores (1-5) insulated with the same plastic.

VVGng and NYM cables have similar characteristics.

Their advantages include:

- High quality performance. All wiring components (insulation, cores, shells) comply with accepted GOST standards, making the products reliable and durable.

- High fire resistance and safety. Cables that meet all requirements work flawlessly under the prescribed load, and especially strong insulation allows bundle laying without the risk of fire when the cores interact.

- Easy cutting and convenient installation. The round cable packaging allows for comfortable installation, avoiding twists when laying networks. In this case, the wiring can be sealed at the terminal.

Another advantage is the large assortment of similar models, differing both in technical characteristics and in price.

Subtleties of connecting electrical equipment

Apartment owners often need to connect large household appliances, such as an electric stove or washing machine.

Flexible wires are intended for these purposes; it should be taken into account clause 2.1.48 PUE 7, according to which you can only take products whose purpose is indicated in the standards and technical specifications.

For example, to connect a hob, you should select a wire whose certificate contains a mention of such use of this product.

Which wires are not suitable?

There are product options that are strictly prohibited from being used for laying electrical networks, even in the most extreme cases. These include the following types of products.

Product #1 - PVS wire

Copper connection element having a PVC sheath and insulation. It has a stranded design with 2-5 conductors with a cross-section of 0.75-10 sq. mm.

The wire, designed for a voltage rating of 0.38 kW, can be used to connect household electrical appliances to the power grid and for making extension cords.

PVA is not suitable for laying wiring for the following reasons:

- It has a multi-wire core structure, so it requires tinning and soldering to connect the ends, which requires a lot of time and a lot of experience.

- The product creates a fire hazard: the wire strands cause the cable to heat up more, causing the insulation to wear out faster, which can lead to a short circuit.

- PVA cannot be laid in a bundle, whereas almost all cable models are suitable for this. Due to the fact that the wiring lines must be at a certain distance from each other, you will have to make grooves in the wall for each of them.

Thus, even the low price of such wires cannot compensate for the high installation costs, and the quality of the installed electrical network will not be too high.

Product #2 - SHVVP, PVVP wires

Cords or cables having single or multi-wire copper cores can be used to connect household appliances and electrical equipment.

However, they are not suitable for fixed electrical communications because these products do not have non-combustible insulation.

In addition, the service life of SHVVP and VPPV is quite short, and the multi-core design requires processing of the ends and soldering during installation.

It is also worth mentioning PUNP (universal flat wire), which was prohibited for laying electrical networks in the apartment back in 2007.

This outdated product has poor insulation and low power, making it unable to withstand modern loads

Conclusions and useful video on the topic

This video provides detailed information on the selection of products for organizing electrical wiring in residential premises:

Despite the wide variety of products, it is quite easy to select the necessary material for laying electrical communications. You need to carefully read the markings, tags and product certificates, pay attention to the technical characteristics and quality of the cable.

Share with readers your experience of wiring in an apartment, tell us what cable you used. Please leave comments on the article and ask questions that interest you. The feedback form is located below.

I came across a situation where it was necessary to replace the wiring at my dacha. The old one was already quite old and it was necessary to lay it out for a new layout. Having wondered what is better in modern realities, I went searching on the Internet. Having stumbled upon this article and having studied it, I realized that everything is simple, you just need to choose the right model according to the appropriate characteristics by reading the labeling. Now you can go shopping next weekend.

Read it. And I still didn’t understand. which wire to choose...

The choice of wires and cables for your home electrical network involves two parameters: reliability and cost. Reliability implies the length of the network and the cross-section of the wires. The thicker, the more expensive! By choosing the optimal size, we will not throw money away.

We carry out calculations based on the availability of electrical equipment, desired lighting, kitchen and bathroom equipment. It is advisable to do the wiring with cables; all wires are colored, so you don’t get confused.

Sockets and switches are also selected according to the rated power of the connected devices, with one for each, so as not to pull out or loosen the contacts.If you know what a screwdriver is, you can do it!

There is a lot of information, but there is zero concrete help for installing the wiring yourself, a lot of water!

Valery, with all due respect, this is an article about choosing a cable for wiring, and not about how to do this wiring.

I also still don’t understand what brand of cable I need to choose for wiring.

Good afternoon, Oleg.

When the text is voluminous, you need to work with its main blocks. Here I made screenshots for you of the author’s main thoughts (the material is attached at the bottom of my comment).

About choosing a cable - the text provides an example of deciphering the letter marking of a cable that is used in apartment wiring - VVGng(ozh)-0.66 kV 3x1.5. The last value, let me remind you, is determined by the network calculation. This is the type of cable you can choose.

If you find an analogue with a higher voltage, you can give it preference. By the way, the article contains a section “Popular types of electrical wiring,” which lists the main brands of cables and wires used.

And once again - all sections are determined by calculation. Next, you should be guided by the specific situation (humidity, temperature, chemical environment, other characteristics of the room), for which insulation, protective sheaths, and other cable coatings are selected.

Pay attention to the section “Which wires are not suitable”.

Thank you for the article. I found it useful.

Let me tell you briefly, the sockets are 3x2.5 cable, automatic 16A

light - 3x1.5 automatic 10A

all VVGng-ls

I came to the store and asked if I needed a cable or wires to replace the electrical wiring, the salespeople looked at me blankly, and I left with nothing.