Kiturami gas boiler errors: fault codes and troubleshooting methods

We're sure you're not a fan of unexpected expenses. And you probably don’t want to replace a completely new boiler because of a problem that was not resolved in time.Meanwhile, problems appear even in devices that work for the first day. In the article we wrote about errors in Kiturami gas boilers and their codes. Read it. Even if you do not have heating equipment of this brand, it is better to learn more about it - you will understand whether it is worth buying it in the future.

You will learn to recognize errors in Kiturami boilers. Find out what causes them, in addition to the main reasons. For convenience, we have presented their codes in ascending order. Immediately after them, other failures and problems that do not have codes were indicated. Read the article and you will know what to do if a malfunction occurs.

Boiler errors are determined through codes. They differ among manufacturers. On Kiturami devices, combinations of numbers from 01 to 98 pop up. The decodings are the same for all boilers of this brand that run on gas. They can differ only because of the names of individual modules.

The content of the article:

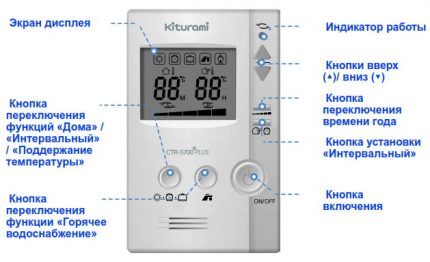

Gas boilers Kiturami

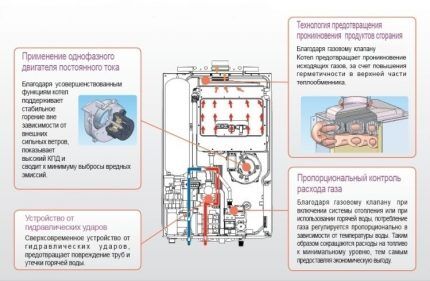

Kiturami has been making boilers since 1962 and produces up to 9,000 units daily. Kiturami produces devices that run on gas, diesel fuel, and solid pellets. Gas boilers are manufactured for fuel according to GOST 5542-2014.

Most products from the South Korean manufacturer have a dual-circuit structure, a closed combustion chamber and are fully automated. The efficiency of the devices reaches 94%.

Popular models of Kiturami gas boilers:

- World Plus;

- Eco Condensing;

- TGB;

- KSG;

- World Alpha;

- Twin Alpha;

- World 3000;

- World 5000.

The power of Kiturami boilers reaches 465 kW, and for wall-mounted models it ranges from 13-35 kW. Their turbocyclone burners operate at low pressure - about 30 mm of air column. Each type of fuel has its own burner models that can operate on the same boiler.

Kiturami appliances have protection against freezing and blowing out the chimney. Heat exchangers in World Plus devices maintain their quality even after long-term use of “hard” water.

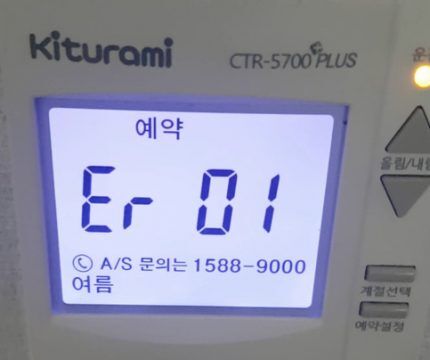

Kiturami gas boilers last up to 15 years or more, much depends on the conditions of use. Devices display errors with simple numbering - from 01 or from Er 01. Read about them to quickly fix problems and keep the device in working order.

Error codes 01 - 08

Errors from 01 to 03 indicate that the control system does not see the flame or has blocked ignition - before or after starting.

Code 01 - no flame. Perform the actions from the list, and if nothing changes, move on to the following points:

- Open the gas supply valve to maximum.

- Bleed air from the heating system.

- Inspect the grounding. The wire may have lost its integrity, or it may have been routed incorrectly. Re-ground to a depth of 30 cm or more.

- Compare the gas pressure in the boiler with the indicator in the instructions. If there is a discrepancy, call the gas workers.

- Check the integrity of the ignition wire and its power source.

- Remove soot and dirt from the boiler burner.

- Also clean the ignition and control electrodes. Soot and deposits collect on them.Reposition the electrodes according to the instructions if the inclination has changed. Check if they work at all.

- Check that the gas valve and photocell of the flame detection system are working properly. Replace elements with new ones if necessary.

- Check the circuit board, connections and wires that go to it. Replace if necessary.

Code 02 - false flame or its defect. Check and, if necessary, replace the photocell of the flame control system. Replace the board if it is broken beyond repair.

Check it for oxidation, open circuit, short circuit. The burner nozzles could cause the electrodes to become dirty. Clean them and put them in the correct position.

Code 03 — the flame appears and disappears for a short time. Check the flame sensor and replace the faulty device. Check the pressure on the pressure gauge. Contact your gas service if the reading is outside the normal range.

The problem may be ventilation. Open windows and doors, inspect the built-in ventilation ducts of the room. The error remains - check the external condition of the boiler fan and determine the resistance with a multimeter. The device could break. Also look into the chimney and remove all the dirt.

Code 04 — the temperature sensor of the heating element is not working correctly. Inspect the wires that go to the sensor. Connect the broken wires and clean the oxidized contacts. Check the sensor for an open or short circuit. Inspect the control board.If something happens, contact a service that professionally repairs Kiturami brand gas boilers - they are repaired in many service centers in Russian cities. Replace these components if necessary.

Code 05 — failure of the overheating sensor. Ring the seismic sensor if your boiler has one. Replace if necessary, but do not remove. Also inspect the overheat indicator itself. Determine the pressure in the system and add water if the reading drops. Take a look at the heat exchanger. If there is excess scale, clean the unit.

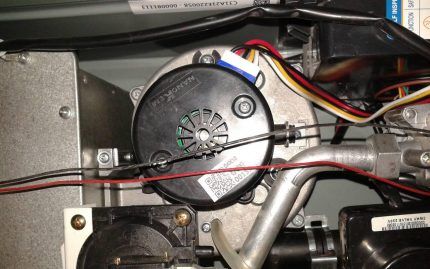

Code 06 — fan failure—fan speed cannot be determined.

To fix the error you will need to take seven steps:

- Inspect the wires that go to the fan. Clean if oxidized. Restore broken contacts.

- Assess the condition of the fan blades. If there is noticeable wear and tear, purchase a new device.

- If the differential relay connections are stuck (including after they have come loose), replace the unit.

- Make sure that the mains voltage matches the required value. If not, install a transformer and uninterruptible power supply.

- Clear the chimney of anything foreign.

- Inspect the fan rotating mechanism.

- Check the Hall sensor.

Replace any unusable parts.

Code 07 - problems with the chimney. The likely cause is the fan/blower speed being higher or lower than normal. Inspect the unit, remove foreign objects. At the same time clean the chimney from dirt and condensation.

The error appears due to gusts of wind. If the problem occurs frequently, you will have to change the pipe pattern. You need to design taking into account the wind rose.

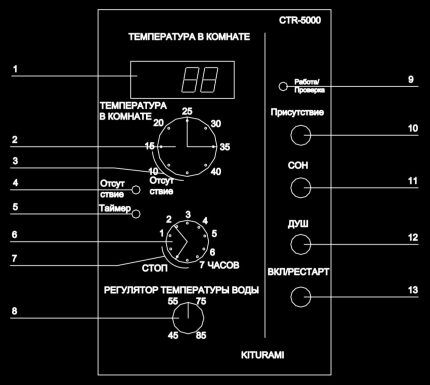

Code 08 — problem with the room temperature controller. The error appears when communication with the boiler control unit is disrupted. Code 08 will also appear if the length of the regulator wire exceeds 10 meters. Thermostat cables are sometimes exposed to telephone and high-voltage wires.

First of all, turn off the regulator and check the operation of the boiler. If everything is fine, first try to find a different location for the thermostat and turn it on again. Re-route the temperature sensor cable correctly if nothing has changed. Avoid placement in pipes under the floor.

Error codes 14 - 98

Let's start with similar errors - 14 and 34.

Code 14 — malfunction of the hot water outlet temperature meter. Look for a problem in the sensor itself and its wire.

Code 34 — an error of the same kind, regarding the hot water supply inlet temperature sensor.

Code 95 - indicates low boiler pressure / heating system, i.e. due to a lack of coolant (usually water).

Proceed like this:

- Check to see if there is water in the boiler and what pressure is in the heating circuit.

- Check and clean filters if necessary.

- Look for leaks in heating pipes and radiators. Then, eliminate leaks in the expansion tank and heat exchanger.

- Take a look at the expansion tank membrane. Replace if stretched or becomes too dirty.

- Add water to normal pressure.

- Inspect and repair the air valve on the pipe through which coolant enters the heating system.

Code 96 — the temperature indicator worked. The temperature rose above the permissible 92...97 °C. The boiler will operate in emergency mode until the temperature drops. When the error disappears, restart your device.

Eliminate the cause of the temperature jump:

- Wash the heat exchanger from scale.

- Check and replace if necessary circulation pump.

- Ring the thermostat. Buy a new one if repair is not possible.

- Do the same with the board.

Code 97 - possible gas leak. There could be a leak of natural gas near the burner. Stop the gas supply to the boiler and turn it off. Call the gas emergency service. Error 97 may also appear because air has accumulated in the system.

Code 98 pops up on liquid fuel appliances. Indicates insufficient energy level in the fuel tank.

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

The indicator does not light up "Net" — check the power in the outlet and the fuse on the ignition transformer. If there is no voltage in the electrical network, call an electrician; if there is, call the service department.

The indicator on the control unit lights up for insufficient water - there is no water in the device or the level is too low. Damage to the black wire of the boiler and the red cable of the sensor can also cause a problem.

The room temperature sensor works normally, but the radiators are cold - the circulation pump does not disperse the coolant through the pipes or does so too weakly. Inspect the locking parts on the heating pipes. Check the pump itself.

The light came on "Overheat" — the heating system is not working properly. Check her out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The strainer may need cleaning. Examine it.

- Check the circulation pump, repair or replace if necessary.

Glows "Safety" diode — gas enters the boiler burner in small quantities or does not enter at all. Inspect the valves and open them if necessary. The problem remains - call the gas workers.

The pump has been running for too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air pockets in it. Release the air.

The boiler takes longer to heat up - look for a problem with the gas pressure and the condition of the filters.

The burner vibrates when turned on - the size of the chimney is not enough for normal gas removal.

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system gets into the boiler. Chemical treatment of the circuits and heat exchanger will help.

Conclusions and useful video on the topic

Details about repairing the control unit after error 06:

Maintenance of the Kiturami boiler by gas workers:

You have read about malfunctions in the operation of Kiturami gas boilers and their symbols.Most of the errors indicate a temporary failure without risk to the entire device, but be prepared for the fact that the device may not work for several hours or days.

Fix any problem step by step. Monitor the pressure in the device and heating system, network voltage, and external conditions. Avoid gas or water leaks. Eliminate them as quickly as possible. Do not touch the gas communications inside the boiler and those leading to it.

Write comments on the topic. Tell us about the most common errors on your boiler and its brand. Write down whether it had to be repaired and how many times. Are you satisfied with your technology? The contact form is located below the article.

Tell me, on the kiturami world 5000 13R boiler, when you press the SHOWER button, the burner goes out and the boiler turns off, the boiler also does not respond to opening the hot water tap. What could be the reason ?

Hello, please tell me, the kiturami world alpfa-16 boiler has stopped heating hot water, the water flows but is cold

Hello, please tell me, the Kiturami Twin Alpha-20 boiler is switched on according to the coolant temperature, the circulation pump does not turn off, it works constantly - is this a malfunction or normal?