How to make a solar battery with your own hands: instructions for self-assembly

Solar panels are a source of energy that can be used to generate electricity or heat for a low-rise building. But solar panels are expensive and are inaccessible to most residents of our country. Do you agree?

It’s another matter when you make a solar battery yourself - costs are significantly reduced, and this design works no worse than an industrially produced panel. Therefore, if you are seriously thinking about purchasing an alternative source of electricity, try to make it yourself - it is not very difficult.

This article will discuss the manufacture of solar panels. We will tell you what materials and tools you will need for this. And a little lower you will find step-by-step instructions with illustrations that clearly demonstrate the progress of the work.

The content of the article:

Briefly about the device and operation

Solar energy can be converted into heat, when the energy carrier is a coolant fluid, or into electricity, collected in batteries. The battery is a generator operating on the principle of the photoelectric effect.

The conversion of solar energy into electricity occurs after the sun's rays hit the photocell plates, which are the main part of the battery.

In this case, light quanta “release” their electrons from extreme orbits. These free electrons produce an electric current that passes through the controller and accumulates in the battery, and from there it goes to energy consumers.

Silicon elements act as photocell plates. A silicon wafer is coated on one side with a thin layer of phosphorus or boron, a passive chemical element.

In this place, under the influence of sunlight, a large number of electrons are released, which are retained by the phosphorus film and do not fly apart.

On the surface of the plate there are metal “tracks” on which free electrons line up, forming an ordered movement, i.e. electricity.

The more such silicon wafers-photocells, the more electric current can be obtained. Read more about the principle of operation of a solar battery Further.

Materials for creating a solar plate

When starting to build a solar battery, you need to stock up on the following materials:

- silicate plates-photocells;

- chipboard sheets, aluminum corners and slats;

- hard foam rubber 1.5-2.5 cm thick;

- a transparent element that acts as a base for silicon wafers;

- screws, self-tapping screws;

- silicone sealant for exterior use;

- electrical wires, diodes, terminals.

The amount of materials required depends on the size of your battery, which is most often limited by the number of solar cells available. The tools you will need are: a screwdriver or a set of screwdrivers, a hacksaw for metal and wood, a soldering iron. To test the finished battery, you will need an ammeter tester.

Now let's look at the most important materials in more detail.

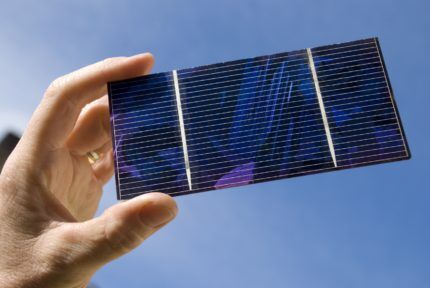

Silicon wafers or solar cells

Photocells for batteries come in three types:

- polycrystalline;

- monocrystalline;

- amorphous.

Polycrystalline wafers are characterized by low efficiency. The size of the beneficial effect is about 10 - 12%, but this figure does not decrease over time. The service life of polycrystals is 10 years.

Monocrystalline solar cells boast a higher efficiency - 13-25% and a long service life - over 25 years. However, over time, the efficiency of single crystals decreases.

Monocrystalline converters are produced by sawing artificially grown crystals, which explains the highest photoconductivity and productivity.

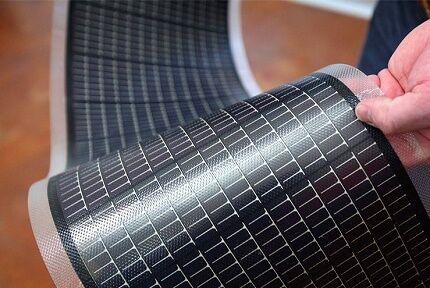

Flexible batteries with amorphous silicon are the latest. Their photoelectric converter is sprayed or fused onto a polymer base. The efficiency is around 5 - 6%, but film systems are extremely easy to install.

Film systems with amorphous photoconverters have appeared relatively recently. This is an extremely simple and extremely cheap type, but it loses consumer qualities faster than its rivals.

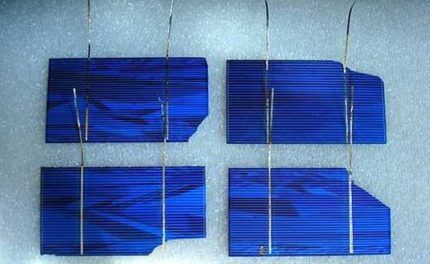

It is not practical to use photocells of different sizes. In this case, the maximum current produced by the batteries will be limited by the current of the smallest element. This means that larger plates will not work at full capacity.

Most often, for homemade batteries, mono- and polycrystalline photocells measuring 3x6 inches are used, which can be ordered in online stores such as E-bye.

The cost of photocells is quite high, but many stores sell so-called elements of group B. Products classified in this group are defective, but suitable for use, and their cost is 40-60% lower than that of standard plates.

Most online stores sell photovoltaic cells in sets of 36 or 72 photovoltaic conversion plates. To connect individual modules into a battery, buses will be required, and terminals will be needed to connect to the system.

Frame and transparent element

The frame for the future panel can be made from wooden slats or aluminum corners.

The second option is more preferable for a number of reasons:

- Aluminum is a lightweight metal that does not place a significant load on the supporting structure on which the battery is planned to be installed.

- When anti-corrosion treatment is carried out, aluminum is not susceptible to rust.

- Does not absorb moisture from the environment and does not rot.

When choosing a transparent element, you need to pay attention to parameters such as the refractive index of sunlight and the ability to absorb infrared radiation.

The efficiency of photocells will directly depend on the first indicator: the lower the refractive index, the higher the efficiency of silicon wafers.

The minimum reflectance coefficient is for plexiglass or its cheaper version - plexiglass. The refractive index of polycarbonate is slightly lower.

The value of the second indicator determines whether the silicon solar cells themselves will heat up or not. The less the plates are exposed to heat, the longer they will last. IR radiation is best absorbed by special heat-absorbing plexiglass and glass with IR absorption. A little worse is ordinary glass.

If possible, the best option would be to use anti-reflective transparent glass as a transparent element.

System design and site selection

The solar system project includes calculations of the required size of the solar plate. As mentioned above, battery size is usually limited by expensive solar cells.

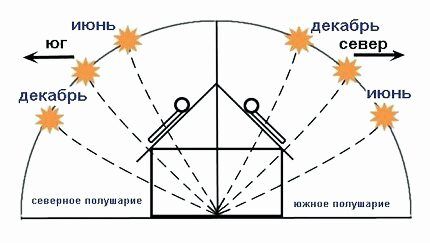

The solar battery must be installed at a certain angle, which would ensure maximum exposure of the silicon wafers to sunlight. The best option is batteries that can change the angle of inclination.

The installation location for solar plates can be very diverse: on the ground, on a pitched or flat roof of a house, on the roofs of utility rooms.

The only condition is that the battery must be placed on the sunny side of the site or house, not shaded by the high crown of trees. In this case, the optimal angle of inclination must be calculated using a formula or using a specialized calculator.

The angle of inclination will depend on the location of the house, time of year and climate. It is desirable that the battery has the ability to change the angle of inclination following seasonal changes in the height of the sun, because They work most effectively when the sun's rays fall strictly perpendicular to the surface.

Calculations show that 1 square meter of solar system makes it possible to obtain 120 W. Therefore, through calculations it can be established that to provide the average family with electricity in the amount of 300 kW per month, a solar system of at least 20 square meters is required.

It will be problematic to immediately install such a solar system. But even installing a 5-meter battery will help save energy and make a modest contribution to the ecology of our planet. We also advise you to familiarize yourself with the principle of calculating the required quantity solar panels.

A solar battery can be used as a backup energy source during frequent outages of the centralized power supply. For automatic switching it is necessary to provide an uninterruptible power supply system.

Such a system is convenient in that when using a traditional source of electricity, charging is carried out at the same time solar system battery. The equipment servicing the solar battery is located inside the house, so it is necessary to provide a special room for it.

Installing a solar panel step by step

Having chosen a place to place the solar panel and equipment for servicing the solar system, as well as having all the required materials and tools available, you can begin installing the battery.

During installation, it is necessary to observe safety precautions, especially when carrying out installation of a finished panel on the roof of the house. Let's look at a step-by-step algorithm on how to make a solar battery.

Step #1 - soldering contacts of silicon wafers

Installation of a homemade solar battery often begins with soldering the conductors of photocells. Of course, if you have the opportunity, it is best to buy photocells with conductors right away, because Soldering is a very difficult and painstaking job that takes a lot of time.

Soldering is carried out as follows:

- A silicon photocell without conductors and a metal conductor strip are taken.

- The conductors are cut using a cardboard blank, their length is 2 times greater than the size of the silicon wafer.

- The conductor is carefully laid out on the plate. There are two conductors per element.

- It is necessary to apply acid to the place where soldering will be done to work with a soldering iron.

- Solder using a soldering iron, carefully attaching the conductor to the plate.

During the soldering process, you cannot put pressure on the silicate element, because it is very fragile and can break! If you are lucky enough to have purchased photocells with ready-made contacts, then you will save yourself from long and complex work by moving straight to making the frame for the future battery.

Step #2 - making a frame for a solar battery

The frame is the place where the photocells will be installed. To make the frame, aluminum corners and slats are taken, from which the frames are made. The recommended corner size is 70-90 mm.

Silicone sealant is applied to the inside of the metal corners. The corners must be sealed carefully; the durability of the entire structure depends on this.

After the aluminum frame is ready, we proceed to manufacturing the rear housing. The rear case is a wooden box made of chipboard with low sides.

High sides will create a shadow on the photocells, so their height should not exceed 2 cm. The sides are screwed using self-tapping screws and a screwdriver.

Ventilation holes are made from chipboard at the bottom of the box-casing. The distance between the holes is approximately 10 cm.A transparent element (plexiglass, anti-reflective glass, plexiglass) is installed in the aluminum frame.

The transparent element is pressed and fixed, its fastening is carried out using hardware: 4 in the corners, as well as 2 on the long and 1 on the short side of the frame. Hardware is attached with screws.

The frame for the solar battery is ready and you can proceed to the most important part - the installation of photocells. Before installation, it is necessary to clean the plexiglass from dust and degrease it with an alcohol-containing liquid.

Step #3 - installation of silicon wafers-photocells

Mounting and soldering silicon wafers is the most time-consuming part of creating a DIY solar panel. First, we place the photocells on the plexiglass with the blue plates facing down.

If this is your first time assembling a battery, you can use a marking pad to position the plates exactly at a small (3-5 mm) distance from each other.

- We solder the photocells according to the following electrical diagram: “+” tracks are located on the front side of the plate, “-” - on the back. Before soldering, carefully apply flux and solder to connect the contacts.

- We solder all photocells sequentially in rows from top to bottom. The rows must then also be connected to each other.

- Let's start gluing the photocells. To do this, apply a small amount of sealant to the center of each silicon wafer.

- We turn the resulting chains with photocells upside down (where the blue plates are) and place the plates according to the markings that we made earlier. Gently press each plate to secure it in place.

- We connect the contacts of the outer photocells to the bus, respectively “+” and “-“.It is recommended to use a wider silver conductor for the bus.

- The solar battery must be equipped with a blocking diode, which is connected to the contacts and prevents the batteries from discharging through the structure at night.

- We drill holes in the bottom of the frame to bring the wires out.

The wires must be attached to the frame so that they do not dangle; this can be done using silicone sealant.

Step #4 - Test the Battery Before Sealing

Testing of the solar panel must be carried out before sealing it, in order to be able to eliminate faults that often arise during soldering. It is best to test after soldering each row of elements - this makes it much easier to detect where the contacts are poorly connected.

For testing you will need a regular household ammeter. Measurements must be taken on a sunny day at 13-14 hours, the sun should not be hidden by clouds.

We take the battery outside and install it in accordance with the previously calculated angle of inclination. We connect the ammeter to the battery contacts and measure the short circuit current.

The point of testing is that the operating power of the electric current should be 0.5-1.0 A lower than the short circuit current. The device readings should be above 4.5 A, which indicates the functionality of the solar battery.

If the tester gives lower readings, then somewhere the sequence of connecting the photocells is probably broken.

Usually homemade solar battery, constructed from photocells of group B, produces readings of 5-10 A, which is 10-20% lower than that of industrially produced solar panels.

Step #5 - sealing the photocells placed in the housing

Sealing can only be done after making sure that the battery is working. For sealing, it is best to use an epoxy compound, but given that the material consumption will be large, and its cost is approximately 40-45 dollars. If it’s a little expensive, then you can use the same silicone sealant instead.

There are two sealing methods:

- full filling, when the panels are filled with sealant;

- applying sealant to the space between the photocells and to the outer elements.

In the first case, sealing will be more reliable. After pouring, the sealant should set. Then plexiglass is installed on top and pressed tightly against the silicone-coated plates.

To provide shock absorption and additional protection between the back surface of the photocells and the chipboard frame, many craftsmen advise installing a hard foam pad 1.5-2.5 cm wide.

This is not necessary, but it is advisable, given that silicon wafers are quite fragile and easily damaged.

After installing the plexiglass, a weight is placed on the structure, under the influence of which air bubbles are squeezed out. The solar battery is ready and after repeated testing it can be installed in a pre-selected location and connected to the solar system of your home.

Conclusions and useful video on the topic

Review of photocells ordered from a Chinese online store:

Video instructions for making a solar battery:

Making a solar battery with your own hands is not an easy task. The efficiency of most of these batteries is 10-20% lower than that of industrially produced panels. The most important thing when designing a solar battery is to choose and install the photocells correctly.

Don’t try to create a huge panel right away. Try building a small device first to understand all the nuances of this process.

Do you have practical skills in creating solar panels? Please share your experience with visitors to our site - write comments in the block below. There you can ask questions about the topic of the article.

In my humble opinion, collecting and installing solar panels is an extremely thankless task from a financial point of view. This is not about the moral side. Until there is government support in this field, as is the case in some places in the United States, there will be little point in exploiting alternative energy sources. Once upon a time, they tried to make a home server run solely on solar energy. The result is that you spent more time than you saved money. But for general development it was useful!

I don’t feel like a “Homemade Man” capable of building a solar battery. If I decide to arrange heating at my dacha this way, I will buy ready-made ones. For many reasons. Firstly, I doubt the quality of Chinese photocells. Secondly, I’m not sure that if I buy the right amount of material, I will make a working solar battery out of it and not ruin it. And thirdly, it takes time to make, and I don’t have it.

How much money will it take to “put this all in order”? Those who have money do not need this. And those who don’t have money will never allow themselves to do this.

The question here is not only and not so much about money, but about the lack of “exhaust”.

In most of our vast country there are not many sunny days. Therefore, the solar battery will be effective for three months a year. And buying a ready-made solar battery is now no more expensive than making it yourself.I saw an experiment on the Internet - a man ordered solar cells, and did the rest himself, and still the price turned out to be about the same if he had ordered a ready-made factory solar battery.

Much depends on the amount of sun per year and the angle of inclination. I have solar panels made on the basis of monolithic polycarbonate panels. My problem is that I didn’t do the drainage. Now I’ll drill holes on the back sheet to remove condensation.

The only normal use for me so far is LED lighting in the village garden.

Thank you so much for describing the method of making solar panels so clearly. I now have a complete understanding of these Banaras. Yes, creating them yourself is difficult for ignorant people.

Now I can convey to the worker what I need.

Thank you for providing the correct information)

It would be great if there was an estimate of the financial costs of manufacturing solar panels. After reading the publication, I got the feeling that buying a ready-made panel would be cheaper. However, it would still be interesting to try making it yourself at your leisure. And one more thing, I would like to read about how to store energy from panels (a note specifically to this note, it is clear that you can find this information on other sites)

There's a flexible panel in the photo. How and with what connector do I connect the wires to it? I can't find any information anywhere