Frenetta heat pump: design and principle of operation + can you assemble it yourself?

Those who love to tinker will always find use for their own strength, patience and waste materials.From practically free components, they can easily build an extremely useful thing in everyday life.

For example, they can make an efficient Frenette heat pump with their own hands without spending anything. But they will replenish their knowledge and skills, and this is priceless, right?

The information presented will help you understand the principle of operation of the unit. With our help, you can decide on the design and learn how the model is made. Clear instructions for the production of this type of heat pump will provide effective assistance to independent home craftsmen.

We provide practical recommendations for producing productive homemade products and tips for operating such equipment.

The content of the article:

How the device works

Those who have come into contact with issues of cost-effective heating are familiar with the name “heat pump”. Especially in combination with terms like “land-water”, “water-water”, or “air-water” and so on.

Such a heat pump has practically nothing in common with the Frenette device. Apart from the name and the end result in the form of thermal energy, which is ultimately used for heating.

Heat pumps operating on the Carnot principle are very popular both as a cost-effective way to organize heating and as an environmentally friendly system.

The operation of such a complex of devices is associated with the accumulation of low-potential energy contained in natural resources (earth, water, air) and its conversion into thermal energy with high potential.

Eugene Frenette's invention is designed and works completely differently.

The operating principle of this device is based on the use of thermal energy, which is released during friction. The design is based on metal surfaces located not close to each other, but at some distance. The space between them is filled with liquid.

Parts of the device rotate relative to each other using an electric motor, the liquid located inside the housing and in contact with the rotating elements heats up.

The resulting heat can be used to heat the coolant. Some sources recommend using this liquid directly for the heating system. Most often, a regular radiator is attached to a homemade Frenette pump.

As heating system coolant Experts strongly recommend using oil rather than water.

During operation of the pump, this liquid tends to heat up very strongly. Water in such conditions can simply boil. Hot steam in a confined space creates excess pressure, and this usually leads to rupture of pipes or housing. It is much safer to use oil in this situation, since its boiling point is much higher.

There is an opinion that the efficiency of such a heat generator exceeds 100% and can even be 1000%. From the point of view of physics and mathematics, this is not an entirely correct statement.

Efficiency reflects the energy loss spent not on heating, but on the actual operation of the device. Rather, the phenomenal claims of the incredibly high efficiency of the Frenette pump reflect its efficiency, which is truly impressive. The energy consumption for operating the device is negligible, but the amount of heat generated as a result is very noticeable.

Heating the coolant to the same temperatures using a heating element for heating, for example, would require significantly more electricity, perhaps tens of times more. A household heater wouldn’t even heat up at this level of electricity consumption.

Why aren’t all residential and industrial premises equipped with such devices? The reasons may vary.

Firstly, water is a simpler and more convenient coolant than oil.It does not heat up to such high temperatures, and eliminating the consequences of water leaks is easier than cleaning up spilled oil.

Secondly, by the time the Frenette pump was invented, a centralized heating system already existed and was functioning successfully. Dismantling it to replace it with heat generators would have been too expensive and would have caused a lot of inconvenience, so no one seriously considered this option. As they say, the best is the enemy of the good.

Recommendations for using the device

It is worth noting that variations of the Eugene Frenette pump using water as a coolant still exist. But usually these are large industrial models that are used in specialized enterprises.

The operation of such devices is strictly controlled using special instruments. It is almost impossible to provide a similar level of security at home.

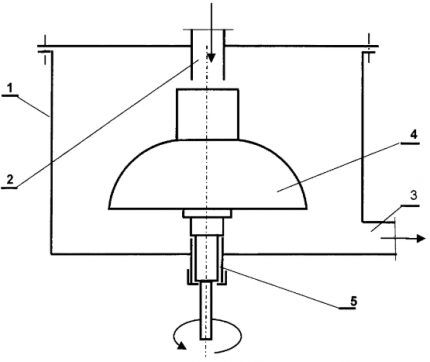

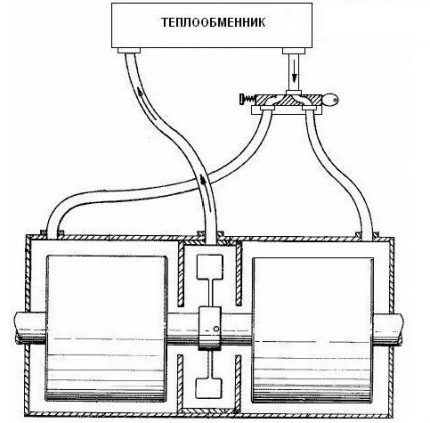

The most popular version of the Frenette pump, which uses water rather than oil as a coolant, is a device developed by scientists from Khabarovsk: Natalya Ivanovna Nazyrova, Mikhail Pavlovich Leonov and Alexander Vasilyevich Syarg. In this mushroom-shaped design, water is specially brought to a boil and turns into steam.

The reactive force of steam is then used to increase the speed of movement of the coolant liquid through the pump channels to 135 m/min. As a result, energy costs for moving the coolant are minimal, and the return in the form of thermal energy is very high.

However, such a unit must be extremely durable, and its operation must be constantly monitored to avoid accidents.

What should you do if you plan to use a Frenette pump to heat a large room or an entire house? Water is a traditional coolant; most heating systems are designed specifically for it. And filling an entire heating system with the right liquid oil can be costly.

This issue can be resolved very simply. It is additionally necessary to build a conventional heat exchanger in which the heated oil will heat the water circulating through the heating system. Some heat will be lost, but the overall effect will remain quite noticeable.

An interesting idea might be to use a Frenette pump in combination with underfloor heating system. In this case, the coolant is released through narrow plastic pipes laid in a concrete screed.

This heating system functions in the same way as a conventional water heated floor. Of course, a project of this type can only be implemented in a private house, since high-rise apartment buildings are only allowed to use electric heated floor.

A practical and convenient way to use such a device is to heat a small room: garage, barn, workshop, etc. The Frenetta pump allows you to effectively and quickly solve the problem of autonomous heating in such places.

The energy consumption for its operation is small compared to the resulting thermal effect, and it is not difficult to build such a unit from the simplest materials.

Frenette pump design options

Eugene Frenette not only invented the device named after him, but also repeatedly improved it, coming up with new, more effective versions of the device.

The very first pump, which the inventor patented in 1977, used only two cylinders:

- outer - the hollow cylinder has a larger diameter and is in a static state

- interior — the diameter of the container is slightly smaller than the dimensions of the cavity of the outer cylinder.

The inventor poured liquid oil into the resulting narrow space between the walls of the two cylinders. Of course, the part of the structure in which this coolant liquid was located was carefully sealed to prevent oil leaks.

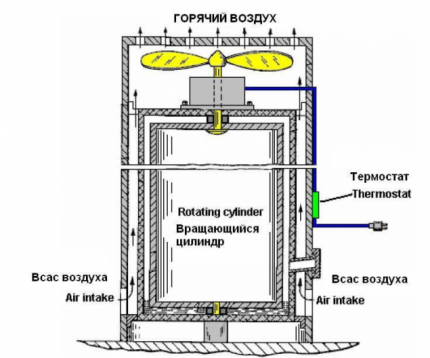

The inner cylinder is connected to the electric motor shaft in such a way as to ensure its rapid rotation relative to the stationary large cylinder. A fan with an impeller was placed at the opposite end of the structure.

During operation, the oil heated up and transferred heat to the air surrounding the device. The fan made it possible to quickly distribute warm air throughout the entire room.

Since this design heated up quite strongly, for the sake of convenient and safe use, the structure was hidden in a protective case. Of course, holes were made in the case for air circulation.

A useful addition to the design was a thermostat, with which the operation of the Frenette pump could be automated to some extent.

The central axis in this heat pump model is located vertically. The engine is at the bottom, then there are nested cylinders, and there is a fan on top. Later, a model with a horizontal central axis appeared.

It was this device that was first used in combination not with a fan, but with a heating radiator. The motor is placed on the side, and the rotor shaft passes through the rotating drum and comes out.

This type of device does not have a fan. The coolant from the pump moves through pipes to the radiator. In a similar way, the heated oil can be transferred to another heat exchanger or directly into the heating pipes.

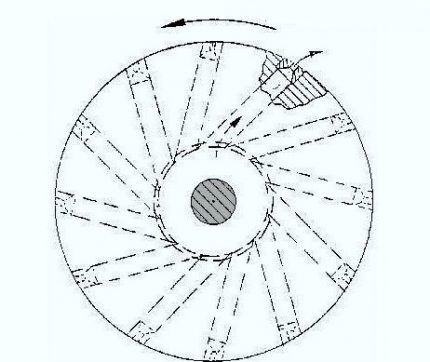

Later, the design of the frenette heat pump was significantly changed. The rotor shaft still remained in a horizontal position, but the inner part was made of two rotating drums and an impeller placed between them. Liquid oil is again used as a coolant here.

When this structure rotates, the oil heats up additionally as it passes through special holes made in the impeller and then penetrates into the narrow cavity between the walls of the pump housing and its rotor.Thus, the efficiency of the Frenette pump was significantly increased.

However, it is worth noting that this type of pump is not very suitable for making at home. First, you will need to find reliable drawings or calculate the design yourself, and only an experienced engineer can do this.

Then you will need to find a special impeller with holes of the appropriate size. This element of the heat pump operates under increased loads, so it must be made of very durable materials.

Self-production of the device

A review of the design options for the Frenette pump allows us to understand that the principles of its operation can be used with varying degrees of efficiency in structures of various types and types. The basic idea remains the same: a narrow space between metal elements, filled with oil, and rotated by an electric motor.

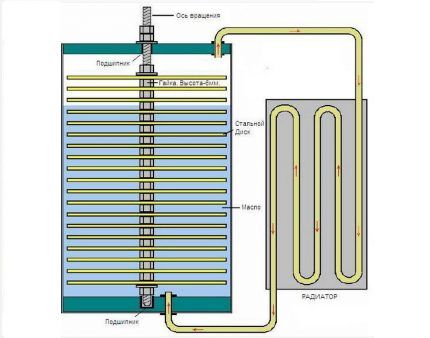

At home, the Frenette pump is most often made, consisting of a series of metal plates separated by a narrow gap.

To make such a device, you need to prepare the necessary materials:

- hollow metal cylinder;

- a set of identical steel disks with a hole in the center;

- set of nuts 6 mm high;

- threaded steel rod:

- electric motor with extended shaft;

- bearing;

- Radiator;

- connecting pipes.

Pump dimensions may be larger or smaller.But the distance between the disks must be maintained exactly - 6 mm. Standard nuts are used as spacers, and a steel rod is the center of the structure.

Its thickness should correspond to the diameter of the nut. If you don’t have a threaded rod at hand, you’ll just have to cut it.

Obviously, the hole in the disks must be such that they can be freely put on the axial rod. The outer diameter of the disks should be several millimeters smaller than the housing. If there are no ready-made elements at hand, the discs are cut out of sheet metal yourself or the work is entrusted to a turner.

The cylindrical body can be made from an old metal container of a suitable configuration or welded from metal. A piece of wide metal pipe will also work.

The walls are welded to the ends of the cylinder. The housing must be sealed so that oil does not leak. Additional holes should be made in the upper and lower ends of the housing: for the entrance and exit of heating pipes leading to the radiator.

Of course, all pipe connections should be sealed. For threaded connections, special sealants are used: FUM tape, flax, etc. If decided use polypropylene pipes, you will need special fittings and, possibly, a soldering iron to install such pipes.

A high-performance electric motor is not required to operate the Frenette pump.A device removed from an old or broken household appliance, such as a regular fan, is suitable.

The main purpose of an electric motor is to rotate the shaft. Excessively fast rotation may cause the device to malfunction. The faster the structure rotates, the more the coolant heats up.

In order for the rod to rotate freely, you need a suitable bearing of standard sizes. When all the elements are prepared, you can begin assembling the device. First, a central axis with a bearing is installed on the lower part inside the housing. Then the spacer nut is screwed onto the axle, then the disk is put on, the nut again, the disk again, etc.

Discs with nuts are alternated until the housing is filled to the top. Even at the preparation stage, you can make preliminary calculations on the number of required disks and nuts.

It is necessary to add the thickness of the disk to the thickness of the nut (6 mm). Divide the height of the body by this figure. The resulting number will give information about the required number of “nut + disk” pairs. The nut is installed last.

Once the housing is filled with these moving parts, it is filled with liquid oil. The type of oil does not matter; you can take mineral, cottonseed, rapeseed or any other oil that tolerates heat well and does not harden. After this, the structure is covered with a top lid and carefully welded.

At this point, the radiator pipes are usually already attached to the caps. For convenience during further installation and maintenance of the device, two shut-off valves can be installed on the pipes. Now you need to attach the heat pump axis to the motor shaft.

The system is connected to the network, the presence of leaks is checked, and the operating characteristics of the device are assessed.

If everything is done correctly, the axle with discs will begin to spin, heating the oil inside the device. The hot coolant will move through the upper hole through the pipe into the heating radiator. The cooled oil will return to the heat pump housing through the down pipe to be reheated.

To automate the operation of the system, you can use a special relay with a temperature sensor, which detects the heating of the heat pump housing and turns off the engine or turns it on as needed. This will prevent overheating of the system, damage to the electric motor and generally increase the service life of the device.

Conclusions and useful video on the topic

An interesting version of the Frenette pump is presented in this video:

Unfortunately, the Frenette pump has not found wide acceptance in the heating industry. Such an industrial device for household needs is difficult to find in home improvement stores. But many craftsmen successfully used the achievements of this scientist and applied them in their homes, bathhouses, garages, etc.

Perhaps you are the same DIY person who managed to realize Frenette’s idea? Please share your experience - leave comments on the article and add photos of your products. The contact form is located below.

When mechanisms operate, there is always friction, which in the vast majority of cases is undesirable.In a car engine, for example, it is about 10%. In other devices there may be a different percentage, but a priori it cannot exceed 100%, otherwise all the energy would be spent on heat. Even a schoolchild knows this. Therefore, such a pump is a common scam. It is easier and simpler to convert electricity into heat directly without stupid mechanisms.

Here we mean efficiency not in the physical sense (in which, of course, it cannot be more than 100%), but in terms of the expended energy of one type (electricity) to extract energy of another type. Well, for example, to light a match, you strike a box, create initial heat using friction, and then the match begins to burn and “gives” you much more energy than you spent. From the point of view of physics, of course, there is no efficiency greater than one, but from the point of view of the energy consumer - a person, he spent much less than he received. Especially if this match starts a fire.

It's like starting a fire with tinder instead of matches. The idea is interesting, but only in terms of use as a conversion of mechanical energy into thermal energy, for example, from a windmill or a water wheel, or slaves :)

Converting electrical energy into mechanical energy and then into thermal energy is ineffective.

By striking a match, you trigger the process of releasing chemical energy, so the example is incorrect.

In a Carnot heat pump, heat is transferred from one part of the system to another, so there you can actually get more heat in the receiver than the energy expended on its transfer.

Here there is no “transfer” of heat - a pure transformation of mechanical energy into thermal energy, so there can be no talk of any “more than 100%”.

The example with a match is not only incorrect, it is not suitable in this case at all. The friction energy of water against the walls of this structure will be proportional to the energy spent on rotating the shaft, taking into account the viscosity of the material poured into the tank. Frictional energy is not stored in the water or released from it, and will not exceed the cost of release, as in the match example.

...or the forest :))

Therefore, such a pump is a common scam. It is easier and simpler to convert electricity into heat directly without stupid mechanisms.

What about an automatic transmission in a car? There are not plates, but impellers and gears.. And everything goes through radiator cooling... Drive a couple of quarts and touch the automatic transmission pan..

Where are the stationary disks between the rotating ones? Why are there no words about them?

Because the article describes the general principle of operation of the Frenette pump, and also talks about diagrams and some homemade options. In general, with this pump there is more hassle than benefit, to be honest: the equipment is unstable, it is not recommended to put it into operation on your own, accidents are possible.

The number of stationary vortex vortices in a Frenette pump can be different, it depends on what indicators need to be achieved. I will attach part of the drawing to show in more detail the structure of such equipment. In general, all projects related to the Frenette pump are experimental. If you add water and “overdo it” with the speed, you can decompose it into hydrogen and oxygen, and that’s a completely different story.

I’m afraid that it won’t be possible to “overdo” the speed in this type of energy converter at home to decompose oxygen and hydrogen, because you will need to apply energy like in a nuclear reactor. It is easier to assemble a Meyer cell for this and decompose it directly with electricity.

There will be no more heat than the energy consumed by the engine from the network. The device, previously called a Joule stirrer, is nothing more than a mechanical heater of the coolant liquid. Instead of an electric motor, it is better to use a wind wheel. In this case, losses will disappear when converting mechanical energy into electrical energy, which is then used for heating.

All the info. the same and not one working device except *argon* on video and then without turning it on, if anyone managed to make a working device, it’s ready to purchase.

I personally dealt with this topic. Conclusion: the laws of physics in our system have not been repealed. Calculate the costs and everything becomes clear. If we use slaves as Paul suggests, then we can argue further. Drives: wind turbines, water turbines, seriously speaking, the payback period is very vague.

The device will provide slightly less heat than a heating element, since some of the energy that heated the engine (windings, bearings) will be lost. The device is a “mechanical coolant liquid heater.” It is recommended to use it for direct conversion of wind energy into heat. Efficiency is close to 100%. When using an electric generator, the efficiency will decrease to 50%.

Blah blah blah. Gentlemen of criticism. Where are your projects, assembly, dimensions, test results

information about the power of the electric motor, speed, pump capacity and storage

containers, engine operating time to heat the liquid to a given temperature, electricity consumption. Practices. Hey, answer me.

That's right, Nikolai!

Most of them are grumblers......either out of envy or something else

conceit