How to choose shut-off valves for polypropylene pipes - the advantages of plastic products

When constructing a pipeline, fittings are used to regulate, discharge, distribute, mix and turn off the flow in the circuit. Such products are divided into several types. Each has its own purpose and certain technical characteristics. Shut-off valves for propylene pipes are in particular demand, as they are an important element of utility pipelines.

The content of the article:

Advantages of polypropylene products

Polypropylene pipes are widely used for the construction of various engineering communications in industry and everyday life. This is due to the presence of many advantages. Systems for water supply and heating of the house are laid from polypropylene pipes and components (including shut-off valves).

The main advantages of plastic products:

- Durability. Polypropylene pipes and shut-off valves are made of durable material that resists various negative influences (pressure, high temperatures, etc.). This ensures their durability. Thus, a cold water supply system made of polypropylene pipes can last up to 50 years. At hot water pipes and heating service life is shorter - about 25 years.

- Smoothness of the inner walls. The inside of the polypropylene pipes is smooth. This prevents the formation of plaque and deposits, which over time lead to a narrowing of the internal diameter of the pipeline. Lime deposits often cause a drop in pressure in the network. Polypropylene units and polypropylene pipes do not have this drawback, which cannot be said about their metal counterparts.

- Easy installation.Laying a water supply or heating system in a house using polypropylene pipes and shut-off valves is not a complicated procedure. All work can be done independently. An important point - when laying communications, it is important to firmly connect the polypropylene elements.

- Price. Products made from polypropylene are cheaper than their metal counterparts. This is one of the factors that ensured the growth in popularity of the material.

- Polypropylene components are resistant to corrosion and the formation of limescale. This ensures the tightness of the network throughout its entire service life. There is no need to carry out periodic maintenance of the system.

Types of fittings

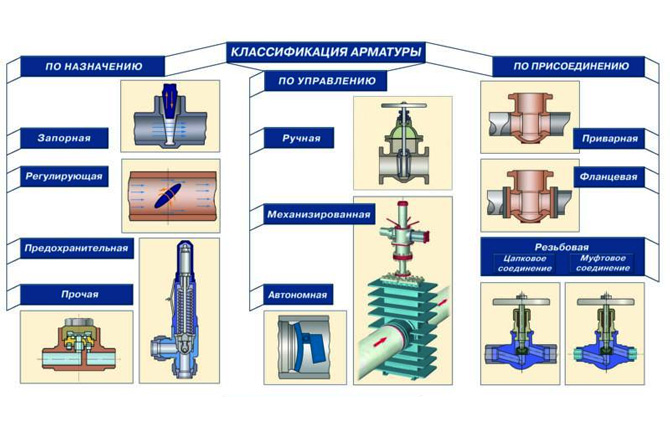

According to design and functional load, fittings are divided into several types:

- Regulatory. Serves to change the flow strength in the network. There are throttle (reducing) and shut-off and control valves. The first type is used to quickly change the load on the network. The shut-off and control valve is used to regulate and shut off the flow.

- Locking (rib). It is often used when installing water supply and heating systems in private houses and city apartments. The main task of the fittings is to block the flow. Sometimes used with instrumentation devices. Such fittings are also called control fittings.

- Mixing and distribution. The fittings make it possible to mix several flows and distribute them in the desired direction.

- Protective. The main task of the device is to prevent negative consequences that arise when the properties of the working fluid change (emergency situations). The fittings protect against changes in flow direction and other phenomena that can lead to disruption of the system.

- Phase separation. Divides a stream depending on its state.Used to collect condensate or separate liquid from steam.

- Safety. The devices serve to protect the pipeline from sudden increases in pressure. The absence of such fittings may result in the destruction of communications.

Each type of fittings performs specific functions. This is due to the design of the products. When constructing a pipeline, it is important to correctly mark their installation locations.

Shut-off valve type

Shut-off valves are a common type of structure that is used when laying water supply and heating pipelines. Serves to stop and regulate the flow of media.

Types of shut-off valves for polypropylene pipes:

- Ball valve. Opens or closes the flow. It has, respectively, two modes “Open/Closed”. Often installed when installing pipelines, regardless of their purpose.

- Valve. The device has several modes. Depending on the position, it opens or closes the pipeline. Used to regulate the fluid that passes through the system.

- Valve. The unit performs a locking function. Seals the passage using a butterfly valve.

When choosing reinforcement, its functional load is taken into account. Particular attention is paid to the installation location. The efficiency of the device will depend on this.

Characteristics of shutter devices

Shut-off valves must meet the following characteristics:

- operating temperature – 95 °C (modified plastics can withstand heating up to 110 °C);

- maximum pressure in the system – 20 bar;

- service life - 50 years when using units in a cold water supply system, 25 years - in a hot water supply and heating circuit.

To construct a pipeline at home, the following types of shut-off valves are used:

- whole ball valve (cannot be disassembled or repaired);

- collapsible tap (consists of a union nut and a straight one);

- corner collapsible ball valves for radiators;

- ball valve with detachable connections (1 or 2);

- valve.

Polypropylene pipes are made in standard sizes. This makes their selection easier. When choosing, pay attention to the color of the reinforcement. It has a white or gray tint. All network elements must have the same color. This is one of the important criteria for selecting nodes.

Selection of locking products

If you have no experience in carrying out plumbing work, then it is better to use the services of a specialist. This also applies to the choice of system components.

When purchasing, pay attention to:

- Shop. When it comes to heating and water supply at home, the materials for constructing the system should be purchased in specialized stores. Consultants will help you choose a model.

- Price. This factor often becomes decisive when choosing materials and components. Many people buy cheap models. But they are short-lived and do not function fully. Therefore, you should not save, otherwise problems with the performance of polypropylene pipes and shut-off valves cannot be avoided.

- Condition of the case. Before purchasing a unit, you should carefully inspect its housing. It should not have cracks, chips or other defects. If there is damage, the service life of the product will be reduced.

- Manufacturer. It is better to purchase models from well-known companies that guarantee quality. Certificates indicate this.

- Dimensions. The diameter of the connecting pipes must correspond to the cross-section of the pipes. Otherwise, connection problems will arise when laying the pipeline.

- Installation location. The tap or valve should be installed in places where it is possible to freely control the locking mechanism.

Plastic products are cheaper, but not durable.As an alternative, choose models with a metal locking element.

Recommended reading: Polypropylene pipe 50 mm - one of the most popular polymer products.

Installation work

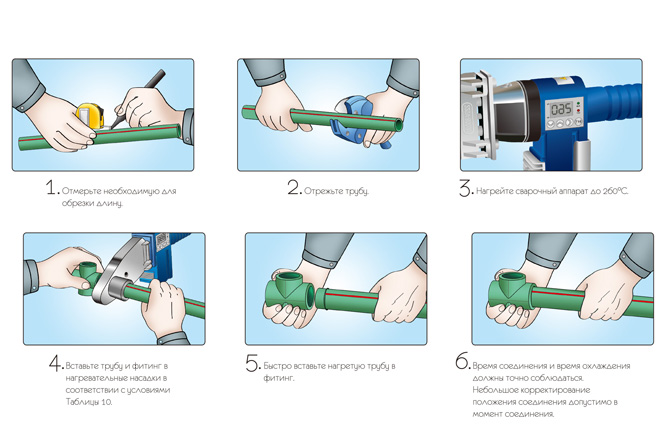

Installation of shut-off valves on polypropylene pipes is carried out in several stages. First you need to prepare a set of tools that will be needed when installing the pipeline and individual components. The connection of polypropylene pipes is carried out using a welding machine. It is installed at the workplace. To carry out this type of work, the kit includes a special clamp. After installation soldering iron set to 260 °C.

When it heats up, a polypropylene pipe and a faucet coupling are inserted into the Teflon nozzles. Wait until the material melts. When this happens, the pipeline elements are connected by insertion. Wait for the polypropylene to harden.

Installation of shut-off valves is not difficult. But for high-quality work, it is important to know the rules for using a welding machine and the features of joining polypropylene pipes. During the process of soldering the reinforcement, it is forbidden to rotate the elements, as this leads to deformation of the material. In such cases, the strength of the connection decreases.

Have you ever installed polypropylene pipes? How did everything go? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

We recommend watching a video about polypropylene pipes: types, fittings, components, master class on pipe soldering.

Sources:

- https://palitrabazar.ru/raznoe/montazh-zapornoj-armatury-dlya-polipropilenovyh-trub.html

- https://trubanet.ru/soedinenie-trub/santekhnicheskaya-armatura-dlya-polipropilenovykh-trub.html

- https://trubtraid.ru/dopolnitelnye-jelementy/armatura/armatura-dlya-polipropilenovykh-trub.html

- https://iseptick.ru/truby-i-fitingi/zapornaya-armatura-dlya-polipropilenovyx-trub-xarakteristika-vidov-osobennosti-primeneniya.html#i-5

I don’t carry out any repair work at home myself – I prefer to call in specialists. But once I had to change the shut-off valves. There was nothing complicated about it. The only thing was that I had to ask the consultant to choose the right faucet, otherwise the choice of such products is simply huge.

But after working on my own, I had a problem - I connected the fittings to the pipe myself. But I didn’t check for leaks. It didn't take long for an emergency to occur. That’s why I advise everyone to check everything more than once.