Polypropylene pipe 50 mm is one of the most popular polymer products

Polymer materials quickly replaced metal products. Especially in heating, sewerage and water supply systems.Polypropylene pipe 50 mm is one of the popular polymer products, which has become widely used for the construction of highways.

The content of the article:

Where is a 50 mm polypropylene pipe used?

The purpose of the 50 mm pipe is one - installation in systems water supply (hot and cold) and heating. The temperature of the water that is driven through the pipe system determines the design features of polypropylene pipes. Namely, whether they will be reinforced or not.

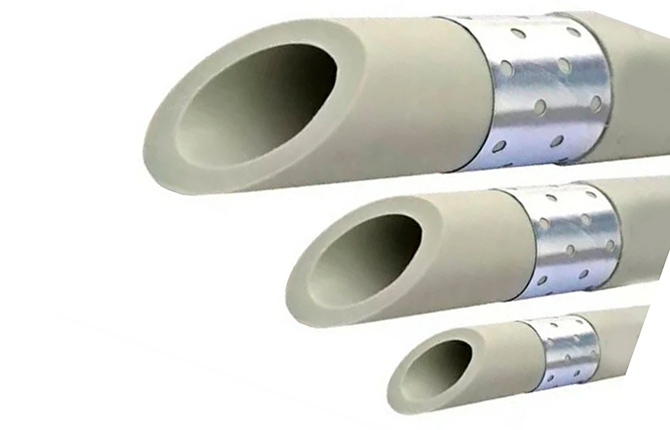

In systems where there is often a difference in pressure and temperature, reinforced models are used. Polypropylene pipes 50 mm received this name due to the reinforcing metal (usually aluminum) frame, which is placed inside the walls of the product during its manufacturing process. The frame strengthens the structure, preventing it from breaking under the influence of negative factors - high pressure and temperatures. Such models can withstand pressures of more than 2.5 MPa.

Unreinforced polypropylene a 50 mm pipe is a solid type product, that is, completely made of polymer without additional inserts.

Advantages of polypropylene pipe 50 mm

The polymer material has many advantages. The main one is long-term operation with proper installation and maintenance. For example, in a cold water supply system such a pipe will last at least 100 years. In hot water supply – at least 50 years.

Other advantages:

- Resistance to chemicals and aggressive environments.That is, water or other liquid moving inside does not change its characteristics over time. That is why a 50 mm polypropylene pipe is used today for pumping drinking water.

- The product easily tolerates changes in pressure and temperature.

- Thermal conductivity is low. This quality is very valuable, especially in cold water supply systems. A pipe laid in warm rooms is not covered with condensation, which means that humidity does not increase, which has a negative effect on many building materials, especially finishing materials - wallpaper, paint, etc.

- Sound absorption is high. The noise from the water moving inside is not heard. Vibration, which often appears in plumbing and heating systems from the operation of pumping equipment, is well damped.

- Easy to install. Connections of 50 mm polypropylene pipes to each other are made through the use of fittings and a special device - an electric soldering iron. The technology is called coupling, bell-shaped or diffuse. The process itself is so simple that a person ignorant of this matter can handle it. In addition, the operation is carried out in just a few seconds, which increases the speed of assembly and installation of the system.

- There is no need to maintain the polymer material. It does not need to be painted or covered with any protective layer or fixtures. Over the years, plastic does not change its color. Humidity and temperature changes are not scary for him.

- Low specific gravity, which simplifies work with 50 mm polypropylene pipes. This applies to transportation, loading and unloading, and installation.

- High quality at a low price. This ratio cannot be compared with steel products.

- Complete absence of corrosion processes. This is especially important when transporting hard and not entirely pure water.Salt and dirt do not settle on the internal surfaces of the pipes in the form of salt deposits. The products can be installed in any environment without prior waterproofing.

- At sub-zero temperatures it does not burst; when thawed, it returns to its original state - the characteristics do not change.

If we talk about the disadvantages of a 50 mm polypropylene pipe, then we can note one - high linear expansion at elevated temperatures of the liquid moving through it. But this problem can be solved simply - you need to install compensators into the pipe system or accurately select products based on temperature indicators.

Polypropylene pipes for water supply and heating systems. About the species and their advantages over others in the video.

Specifications

In the production technology of 50 mm plastic pipes, different types of plastic can be used:

- homopolymer labeled PPH;

- A block copolymer is a compound of polypropylene and ethylene. RRV marking;

- static copolymer, also known as random, labeled PPRC (abbreviated as PPR).

For the production of 50 mm polypropylene pipes, the third option is used. It produces products that are more elastic, viscous, and resistant to high temperatures - up to +90 ℃. Short-term exposure to environments up to +110 ℃ can also be withstood without problems. They can be used without insulation at -10 ℃. Therefore, PPR plastic is classified as heat-resistant.

Additional advantages:

- light weight;

- high strength;

- inertness to alkalis and acids.

Today, manufacturers offer 50 mm polypropylene pipes for heating and plumbing in various colors. They can be:

- white;

- blue;

- black;

- red;

- orange.

Color design has nothing to do with product labeling.

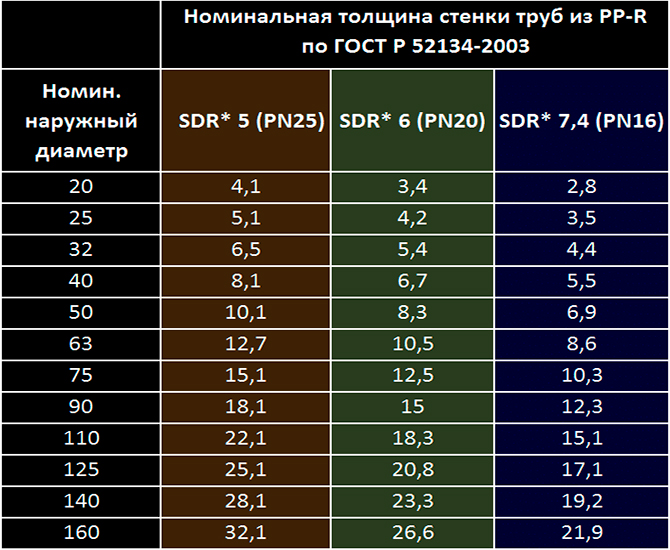

When purchasing, you need to pay attention to the labeling.It mainly concerns such characteristics as the pressure that the material must withstand. And in plumbing and heating systems, pressure often depends on temperature.

These two parameters are determined by the brand:

- PN10. The pipe can withstand pressure up to 1.0 MPa. It is used in cold water supply systems with water temperatures up to +2 ℃ or in “warm floor” heating systems with water temperatures up to +45 ℃.

- PN16. Can withstand pressure of 1.6MPa. Such a 50 mm polypropylene pipe is rarely found on the market. Can be used in systems where water is heated up to +60 ℃.

- PN20 – pressure up to 2.0 MPa. Can be installed in systems with media temperatures up to +80 ℃.

- PN25 – 2.5 MPa. Withstands temperatures up to +95 ℃. Often such polypropylene products are used in the assembly of process pipelines.

It is clear that the higher the marking, the more expensive the product. And all of them can be installed in cold-type pipelines. But the last two positions will be economically unprofitable, especially if the volume of work is large.

The price mainly depends on the wall thickness of the product, because the higher this dimensional parameter, the greater the pressure the pipe can withstand.

Soldering iron for propylene pipes 50 mm

Soldering technology is used to connect plastic pipes. For this purpose, soldering equipment is used, which is presented on the market in the form of professional and semi-professional models.

The first option is a one-piece machine, which is additionally equipped with centering of the connected pipes. This type of welding method is not simple, and the equipment costs a lot of money, so it is not used in everyday life. The technology is based on connecting pipes without intermediate elements - fittings. That is, the two ends of the pipe are connected directly.

A hand or semi-professional tool is a small device that operates from a 220-volt outlet. It is small in size and lightweight. All offered on the market soldering irons are of the same type. The only difference is the heating element. It can be either flat (often called an iron) or cylindrical.

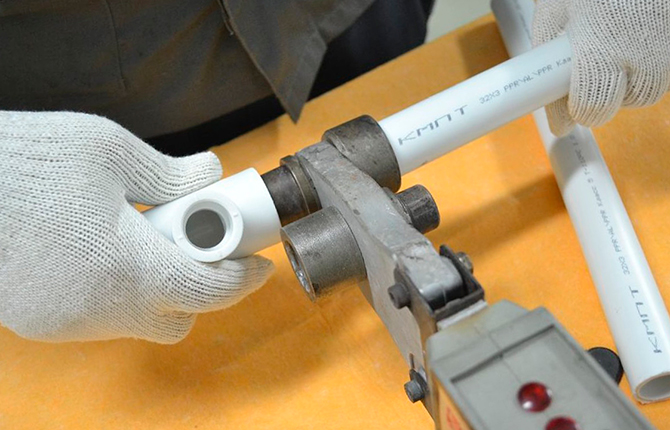

A flat soldering iron can be used to connect polypropylene pipes with a diameter of up to 63 mm. It comes with several attachments for each diameter – including 50 mm. They are installed on the heater and bolted to it.

The cylindrical apparatus is slightly smaller in size and, accordingly, lighter. It is often used when it is necessary to connect pipes in hard-to-reach places. The attachments are fixed on it with a clamp, which is clamped with a screw. It comes with two types of attachments – a mandrel and a sleeve. The first is used to heat the inner surface of the fittings. The second is for the outer plane of polypropylene pipes.

The design of the soldering iron is simple; it has few parts and components, which makes it low in cost. The price still depends on the configuration and power of the device.

How to solder 50 mm polypropylene pipes

The essence soldering of polypropylene pipes with fittings - heating the material from which they are made to a certain softness. After which the ends of the joint are connected, the polypropylene cools and acquires its original strength. But it is at this stage that the sections of the two pipes merge. The most important thing is to press the ends tightly together.

Before you start work, you need to prepare everything. Purchase the required number of 50 mm polypropylene pipes and fittings for them.

Additional tools to work with:

- pipe cutter;

- roulette;

- pencil or marker;

- a means by which pipe ends are degreased;

- hand mittens.

You can move on to the process itself:

- The soldering iron is plugged into the outlet. There is a temperature regulator on its body, which must be set to 260-270 ℃.

- After a few minutes, the device will heat up, the glowing eye on it will turn off, indicating that you can start soldering.

- A fitting for 50 mm polypropylene pipes is inserted into the mandrel, and the end of the pipe itself is inserted into the sleeve. It takes a certain amount of time for the polymer to melt. The soldering iron manufacturer indicates it in the instructions. You need to get acquainted with it.

- The heated parts of the future joint are removed from the nozzles and inserted into each other until they stop. The parts should remain in this position for 15-20 seconds.

- It is recommended to leave the joint without movement so that it cools down completely and regains its strength.

Attention! Elements inserted into each other cannot be rotated about the axis of the connection. This is a big mistake, which leads to incomplete sealing of the joint. When rotated, the molten material begins to curl, leaving grooves. Because of them, water will begin to flow out of the system.

An important point in the technology is the precise maintenance of the heating time of the two parts being connected. If they couldn’t stand it, they ended up with polypropylene that was not completely softened. Overexposed - the material will become too soft, which will lead to deformation of the elements themselves.

One more recommendation. If, for example, welding of 50 mm polypropylene pipes is carried out at low temperatures (outside in winter), then the heating time can be increased to 50%.

There is another technology for soldering 50 mm polypropylene pipes, which is called cold. A special solvent is used to join the parts.It is applied to the ends of polymer pipes, which soften under its action. After this they are connected to each other. The method turned out to be unpopular.

In fact, the soldering technology is simple. At the same time, propylene pipes themselves have excellent technical and operational characteristics. Let's add here the relatively low price - hence the popularity of the material.

How have you already equipped your home’s water supply or heating system? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose useful information.

How to solder polypropylene pipes, see the video.

Sources:

- https://engineering-en.techinfus.com/santeh/trubodel/texnologiya-svarki-polipropilenovyx-trub-svoimi-rukami.html

- https://santehstandart.com/poleznye-materialy/polipropilenovaya-truba-50-mm/

- http://semidelov.ru/mar/polipropilenovye-truby-vidy-oblast-primeneniya-i-montazh/#section-2

The most important thing is that such pipes do not burst if the water in them freezes.

That's for sure. My garden tap froze outside. In the spring it thawed and water flowed without problems, everything was intact.

Still, it’s better to insulate it for the winter. It will freeze and unfreeze several times, then no one will guarantee that it will not burst in a couple of years.