Production of ball valves in Russia - types and manufacturing process

Relatively recently, on the water supply fittings market, the main shut-off device was a traditional valve - not very reliable, with a lot of operational problems. More successful was the replacement of valve options with full bore valves with a ball element. Not all of them are equal in quality.

Production ball valves requires a new approach to the technical process, at least the use of modern technologies. Such shut-off valves cannot be made using semi-handicraft methods.

The content of the article:

Why is it profitable to produce ball valves?

The demand for shut-off and control valves is only increasing. As old steel pipes and valves are scrapped, the idea of using a ball valve on new plastic pipes is growing in popularity.

Production with the correct organization of the technological process cannot be unprofitable for two reasons:

- In a home plumbing or heating circuit, ball valves account for at least 90% of all valves. The remaining 10% refers to the traditional valve at the entrance of the water pipe into the house or apartment;

- manufacturing a ball valve is more technologically advanced. There is no need for a large machine park and costly operations of casting steel blanks.

But in this case we are talking about the production of brass ball valves.Models made of stainless steel or PPR propylene are not considered. Stainless steel valves are used mainly for industrial pipelines and food production.

They cost more than traditional valves. Ball valves made of polypropylene are cast by enterprises that produce PPR pipes. It is inexpensive, but is used exclusively on polypropylene water pipes.

The production of a ball valve from brass is considered more profitable, since it is a universal product.

With a slight modification of the mounting method it can be used on:

- polypropylene;

- steel;

- polyethylene PEX pipes;

- metal-plastic water pipes.

The ball valve has several design features that have a positive effect on demand and production profitability:

- simple locking scheme. A metal ball with a hole rotating around a vertical axis creates virtually no turbulence in the fluid flow, which means less fluid loss. You can install a cheaper model with a ball element with a smaller flow area than a traditional valve;

- The small housing fits well into a line of water pipes or a heating system circuit. There are no long stems protruding like a valve with massive handles;

- easy installation method. Installation of the ball valve takes minutes. In order to install the simplest valve in a cast iron or bronze body, you will need couplings with bends or an adapter with a set of gaskets for a flange connection.

Another plus is that a ball valve is easier to maintain. If high-quality materials are used in production, it will remain operational for ten years.Maintenance of the valve requires periodic running and turning of the stem along the thread, opening and closing the damper. Otherwise, the disc valve and the threaded section of the axle will stick. It is difficult to open such a valve.

Types of ball valves

Any production cannot be based on the production of one model that replaces or duplicates an old cast iron valve. Today, there are at least several versions of the brass valve with a ball element; there is a demand for them, and therefore they are also included in the production plan.

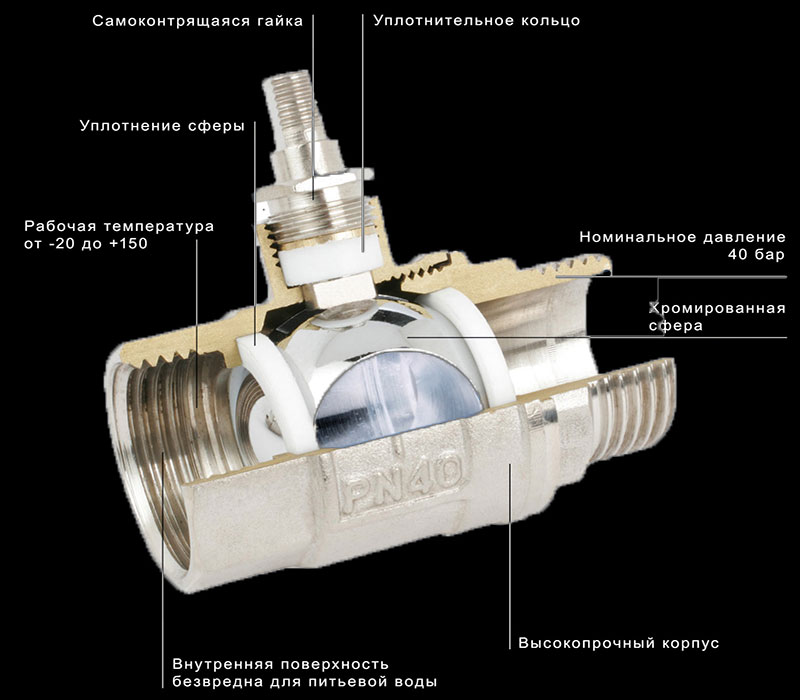

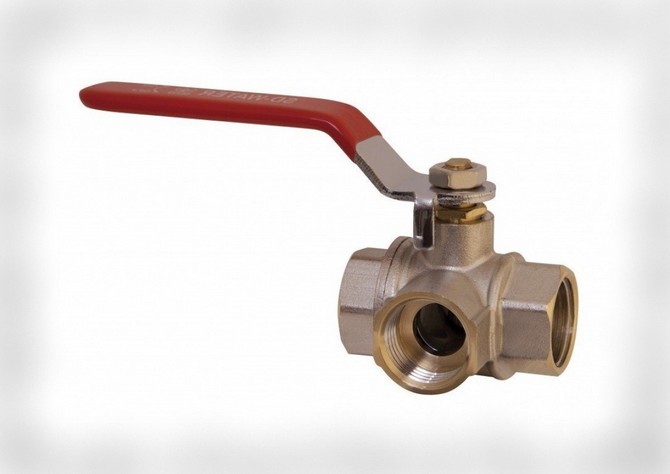

A typical structure of a classic crane is shown in the diagram.

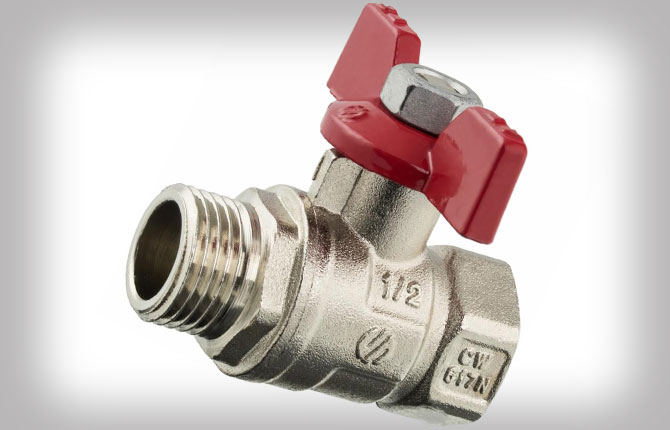

The basis of the product is a brass body with a central chamber, inside of which there is a ball element. The ball has a through hole, the diameter of which is a fraction of a millimeter smaller than the inlet hole.

The locking element can rotate on the rod around a vertical axis. The edges are sealed with fluoroplastic rings that fit tightly to the chrome surface of the ball.

There are few parts, all of them are of simple configuration, so production can be easily automated.

With different types of housing

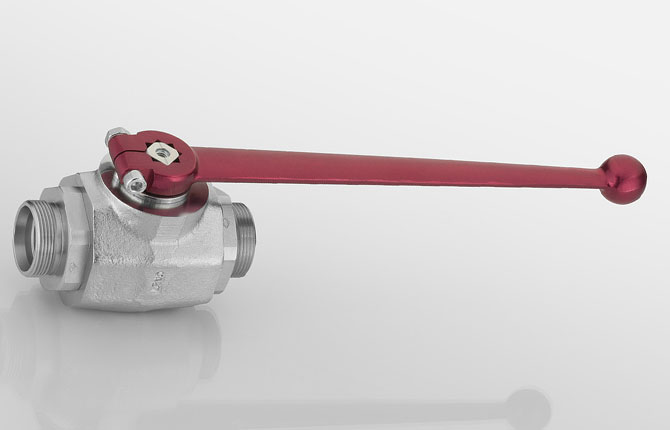

Depending on the operating conditions of the ball valve, several types of housing are put into production. The simplest option is with a collapsible body, double thread for a fitting.

The body is made in the form of two parts, connected to each other by thread. The production of such models is a little more expensive, but it is possible to change the ball element and the pressure sealing ring made of fluoroplastic.

Cheaper models are assembled by shrink fitting without threads. Manufacturing can be more cost-effective because an automated press can be used to assemble the ball valve.

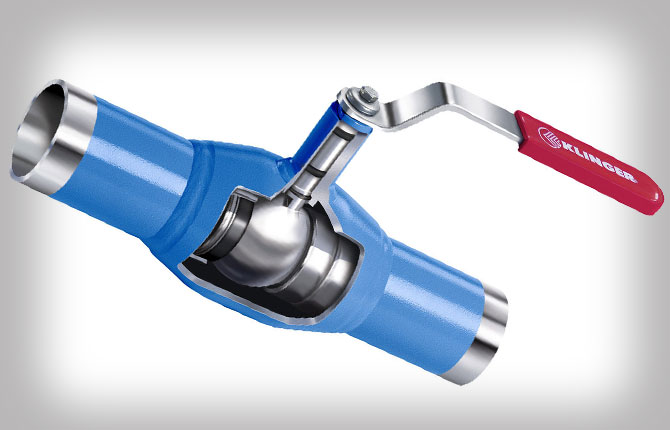

For underground communications, a non-separable ball valve with a steel body with a protective coating is used. A special feature of production is the use of welding for assembly work.

High-pressure pipelines are equipped with shut-off equipment made of steel with a cast body.

The manufacturing process of steel ball fittings differs from brass models only in the materials used and the method of installing the sphere. The ball is placed inside through the hole for the rod, and instead of the latter, a conical bushing is used. The ball seal is made of polyoxymethylene, and a ring made of nitrile rubber is placed on the sleeve.

A ball valve made of special steel grades is used as a shut-off valve on lines for transporting liquid food products and corrosive liquids.

Production using classical methods is hampered by the poor machinability of stainless steel. Therefore, the body is assembled, which allows you to repair and maintain the internal cavity of the faucet, and even change the ball element.

By type of media flow control

In conventional locking equipment, the ball element can take two positions - “open” and “closed”. Intermediate options, when the tap is not opened completely, are considered off-design and are not recommended for use for conventional models.

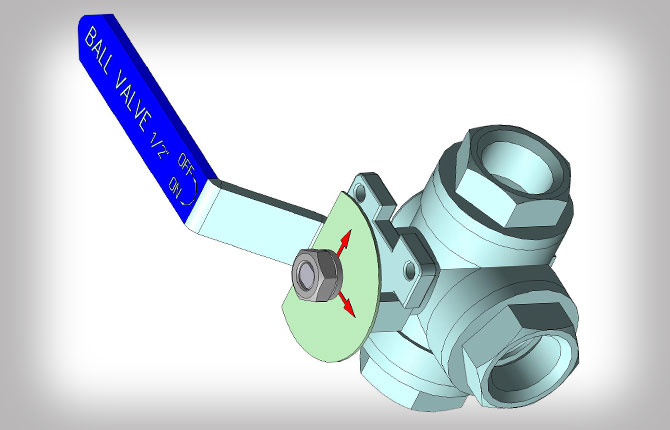

The ability to open the ball element not completely, but to a certain angle, is used to control the flow of liquid in three-way valves.

The production of simple brass models does not require additional equipment. To produce products from corrosion-resistant steel, specialized metalworking machines will be needed.

Using a tap, you can switch the incoming fluid flow to one of two outputs.Moreover, in some models it is possible to rotate the ball element not completely, but at a certain angle.

You can regulate the flow through the tap manually or using a pair of electric motor and gearbox.

Due to the increased popularity of heating systems of the “warm floor” type, the production of semi-automatic valves for regulating the temperature of the coolant in the heating circuit is actively expanding.

With different flow section designs

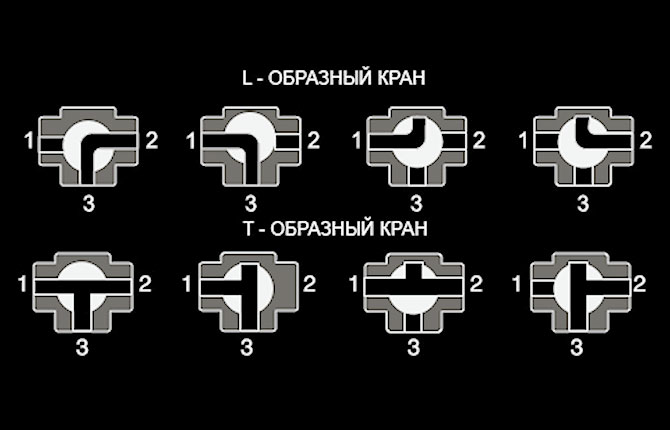

The cavity inside the ball may vary in shape and size. For the production of three-pass models, two types of flow section are used - “L” and “T” shapes.

In the first case, the L-cavity makes it possible to transfer the flow from one outlet to another. The T-cavity, in addition, makes it possible to operate in the mode of a conventional full-flow faucet.

During the manufacturing process of a ball valve for high solids liquids, the leading edge of the inlet cavity is specially rounded and polished. This is done in order to avoid the deposition of contaminants and reduce metal wear.

With different connection methods

The housings also differ in the method of attachment to pipes and pipeline fittings. The inlet-outlet can be made with internal or external pipe threads under coupling.

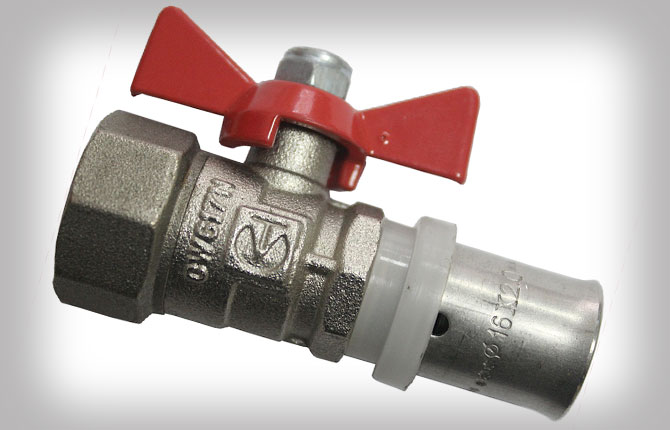

For polyethylene PEX pipes, one or both inputs are made in the form of a fitting for crimping polyethylene with a sleeve.

For the production of taps for metal-plastic pipes, the central block of the standard model body with thread is used. The inlet and outlet are screwed into the body, and they have a fitting and a threaded section for a compression nut.

This approach to organizing the production of ball valves makes it possible to make some parts universal, and ultimately reduce manufacturing costs.

Technology and equipment

In order to set up production, you will need:

- press with a set of stamps. For everyone ball valve you need at least two sets of punches and hot stamping dies;

- installation for preparing brass powder to remove contaminants from the surface of microparticles. This equipment is often abandoned, which reduces production costs, but greatly reduces the quality of the workpiece after pressing;

- CNC machine for drilling, turning and threading;

- galvanic installation for applying nickel;

- assembly press for crimping seals, rods, and fitting the ball element into the valve body.

For small-scale production you will need:

- fluoroplastic rings;

- rubber seal on the rod;

- glue;

- rotary knobs of several types;

- nuts

All of the above is cheaper to buy ready-made than to set up production on your own.

You will also have to buy stamps for hot pressing. The production of such a tool requires complex equipment and additional control means, so it is better to order them from a specialized machine-building enterprise.

If according to the business plan it is planned to produce the entire range of brass valves and fittings, then at a minimum it will be necessary to purchase compression nuts, crackers, and sleeves for all types of pipes.

Technological process of ball valve production

Manufacturing begins by heating the die and brass powder. Production by hot stamping will cost a little more than non-ferrous casting, but with a guarantee of the absence of casting defects and cavities. Stamping housings at low temperatures, as is done in the production of cheap faucets from ZAM, does not make sense due to low quality.

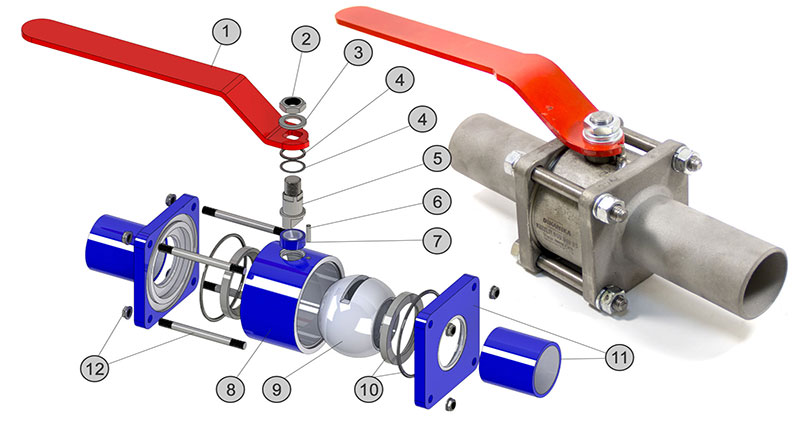

After the body comes out of the die, it is cooled and cleaned of any remaining lubricant. Next, degreasing and applying a nickel layer in a galvanic bath are performed. On a CNC machine, a hole is cut for the rod, a thread is cut, and mounting grooves are machined for the body fluoroplastic seals.

The ball is bought ready-made. Inside it, a cavity of a certain shape is bored, polished and (if necessary) chrome-plated. The rod is made in a similar manner.

Assembly is performed on a press. Apply glue and press a pressure fluoroplastic ring inside the tap from the liquid inlet side. Next, the ball is inserted, the rod is pressed in, and the body nut with a second fluoroplastic ring is screwed on.

At the end of the assembly, a rubber seal is put on the rod, the clamping nut is screwed in, and the handle is installed. The ball valve is pressure tested, and if there are no comments, the production process is considered completed.

Production in Russia and in the world

Despite the fact that the production technology has been sufficiently proven in practice, ball valves from different manufacturers differ in quality, durability, and often in appearance. Let's take a closer look at the products of different domestic manufacturers and create our own rating.

ARCO

A well-known manufacturer of pipe fittings. Products are manufactured in Spain and Tunisia. The Spanish ball valve is identical in quality to that produced by the branch.

What we pay attention to when choosing an ARCO ball valve:

- good quality brass body, degree of porosity is identical to casting. During the production process, the workpiece for the ball valve is additionally subjected to thermostatics. Brass is the same - CW617N/CW614N;

- Teflon ring inserts are very flexible, so the valve can easily withstand pressures of up to 15 bar, and in testing - all 50 bar.

The production technology includes a two-stage polishing and finishing operation of a steel ball. After drilling, the ball element is checked for runout when installed on the rod, after which the surface is chromed and polished.

Positive aspects - excellent quality of all parts, smooth opening - closing without scuffing or “sticking”.

Negative aspects - high price; a real ball valve from ARCO should cost at least 3 euros. The second disadvantage is that the product is often dismantled at retail warehouses, replacing the ball element with a Chinese steel ball.

VEXVE

The company is located in Finland and is engaged in the design and production of fully welded full bore valve fittings. This means that the ball structure is located inside the housing without detachable connections.

The valves are designed primarily for use in high-pressure product pipelines – up to 40 bar. In the production of the ball valve, alloy steel is used, the body is grade P235GH, the ball and stem are X5CrNi1810.

| Model | Options |

| Accession | Welded |

| Nominal diameters | DN10-600 |

| Flow temperature | from -30 OFrom to +200 OWITH |

| Pressure, bar | 25 |

| Knot materials | |

| Frame | Steel St.37.0/37.8 |

| Ball | AISI304 |

| Stock | AISI303 |

| Seal rings | PTFE+C |

| Pen | Galvanized steel |

| Seal under the stem bushing | Teflon |

The durability and tightness of the valve on the ball element is ensured by two disc springs that press the PTEF+C sealing rings to the surface of the ball.

Installation is carried out using welding equipment only on steel pipes. Since 2014, VEXVE OY (Finland) has been selling its own products under the VEXVE and NAVAL brands. The VEXVE ball valve is designed for use in industrial production, mainly in petrochemical product pipelines, so the cost is quite high. For example, the smallest model with a bore diameter of 15 mm costs from $50.

In general, the quality of shut-off valves is high.

ADL

The Russian company ADL specializes in the production of shut-off equipment for product pipelines of all types - from household networks to industrial pipelines. The volume of production is large. The production of the main part of products is ensured by automated lines.

Brass ball valves for domestic water supply systems are known under the brands “Boston” and “Chicago”. Steel shut-off valves are sold under the brands “Bival” and “ADL”.

The cost of products is approximately half the price of Finnish and Spanish analogues, the quality corresponds to the price level. A standard ½” Boston brass faucet with American style and butterfly handle sells from $2.50.

BROEN

The company's main production is located in Denmark, there are branches in the Russian Federation, the Moscow region, and more than fifty countries. It specializes mainly in steel shut-off valves, but there are also series of regular brass full-flow models. Manufactured under the Ballomax brand.

The quality of products largely depends on the location of production. European products are subject to 100% testing and testing using a complex sampling algorithm. Therefore the quality is quite high.

"Bologovo reinforcement plant"

He produced several ball valves of the same type made of brass and steel. Until the last moment, production was stable, quality was at an average level. Bologovo brass coupling taps were distinguished by a solid body with a good margin of material thickness in the threaded section. This is where a crack appears in cheap products after a year or two of use.

Just a couple of years ago, brass fittings were in strong demand, since the price of valves and fittings was even lower than Chinese products. Recently, products have been found on the market much less frequently, there are many handicraft fakes, and the selling price for the original has more than doubled.

Bugatti

One of the most popular brands of ball fittings. Produced by the company of the same name in Italy. The main emphasis in organizing production is on the high quality of the brass body and long service life. A standard Bugatti ball valve can withstand up to 20 thousand openings and closings.

The body is always white nickel plated. Pure brass can only be used for fittings of non-standard configuration. The price of a Bugatti ball valve is 1.5-2 times higher than average, so the brand’s products are actively counterfeited.

How to distinguish an original Italian product:

- marking on the case is the letter V in a diamond, the thread size must be indicated, the inscription “Made in Italy”;

- high quality surface of the ball element. A transparent silicone grease of a grease type is placed inside the housing;

- The rod uses a clamping nut of an original shape.

A quality certificate and a product passport are always issued for a batch of cranes.But the most reliable protective element is considered to be the high quality of the surface of the case - there are no flaws, stripes, irregularities, or stains.

Aqualink

Russian-made cranes are distinguished by their relatively small size and increased weight. This suggests that the density and impermeability brass body much higher than most competitors.

The quality of the ball valve is noticeably higher than its Chinese counterparts, but “Bant” models are purchased primarily for heating and water supply systems with low internal pressure. Exceeding more than 5 bar reduces the service life of fluoroplastic liners. The ball liner wears out Teflon in a couple of months.

The advantage of the brand is the relatively low price of the product.

The production of ball valves quickly pays off, as the demand for quality products is growing. There have always been enough problems with choosing a good faucet, even if they are products from well-known manufacturers. Therefore, before purchasing, you should carefully study the models and their features.

Test of ball valves from Bugatti, Oventrop and LD: video.

Share your experience in choosing ball valves and information about the production of valve fittings in the comments. How to choose the right high-quality original production model? Save the article to your bookmarks so as not to lose useful information.

First of all, the tap is checked with a magnet. If it sticks, then it is clear that it is a fake made of transformer steel. The magnet may stick in the area of the rod, this is allowed.The next thing is to look at the quality of the inscriptions on the case. With original production, the print is always clear, embossed, and without errors. The customer is concerned about the appearance, so the stamp on the press is regularly cleaned of adhering powder.

Next, look at the wall thickness behind the thread; you can measure it with a caliper. The more massive it is, the more durable it is considered, like a Bologov crane. The handles are only metal and only butterflies, they are convenient to install and do not fall off after a couple of openings.

I don't agree. The quality of any ball valve is not the body, not the handle, but the fluoroplastic inserts. It’s very easy to check the quality; we wind the hose through a hose, connect it to an autocompressor and pump it up to 8 At. Place it in a bucket of water and see where the bubbles come from. A normal faucet siphons bubbles in the water only under the stem; it can be lubricated or tightened with a nut.