How to choose cross-linked polyethylene pipes for water supply: pros and cons

Most utilities are laid using pipes.When choosing them, pay attention to the material and characteristics. The use of metal products has faded into the background. Pipes made of cross-linked polyethylene for water supply allow you to lay communications of any complexity.

The content of the article:

Areas in which pipes made from this material are used

Pipes made of cross-linked polyethylene have universal properties. They are durable and resistant to negative factors, including high temperatures. This determined their use for the construction of such communications:

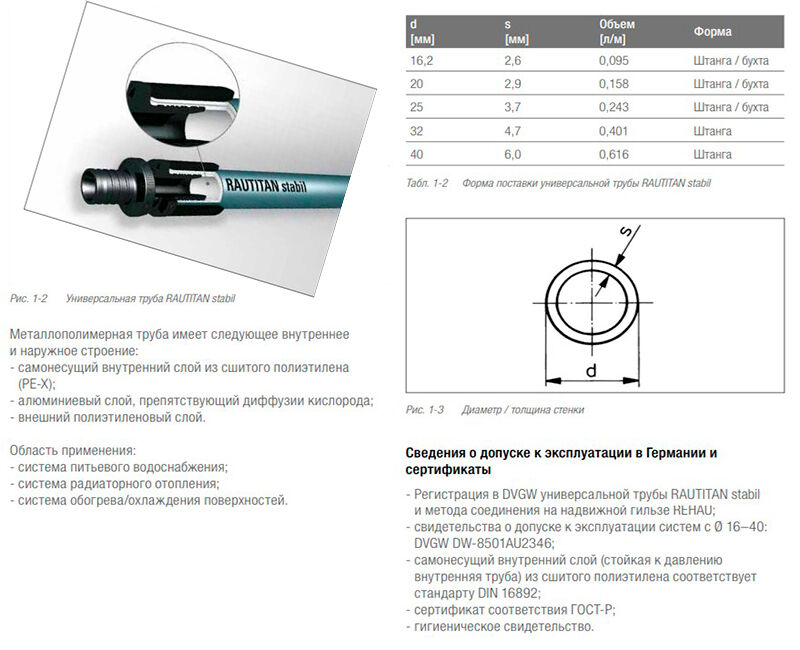

- Water supply. Cross-linked polyethylene pipes are used for laying hot and cold water supply pipelines. It is important that the material withstands heat and does not deform. Polyethylene meets these requirements. Cross-linked pipelines are not only able to withstand heat, but also high pressure, without which it is impossible to transport water through the water supply system.

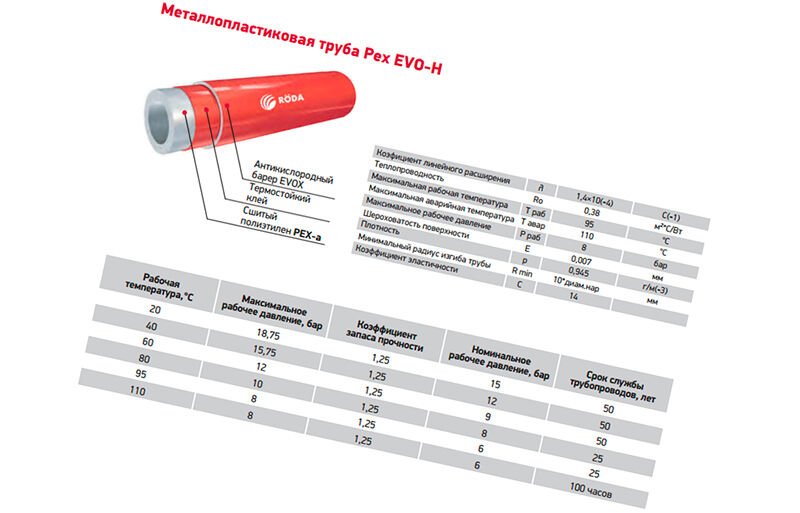

- Radiator type heating system. When choosing products for a heating system, you need to pay attention to resistance not only to high temperatures, but also to pressure. We need pipes that have a safety margin. This is especially true for pressure, which can rise sharply.

- Warm floor. Different materials are used to install the system. Temperature and pressure are irrelevant. That's why cross-linked polyethylene can be used to lay such communications.

- Water heating main. When constructing a pipeline, temperature conditions and pressure changes are taken into account. All this is necessary to ensure heating of a house or apartment at a sufficient level.

- Pipelines. Cross-linked polyethylene is used to construct communications for the removal of products from the food, chemical, and pharmaceutical industries. Products comply with environmental requirements. They are resistant to chemicals and do not affect the condition of the transported product.

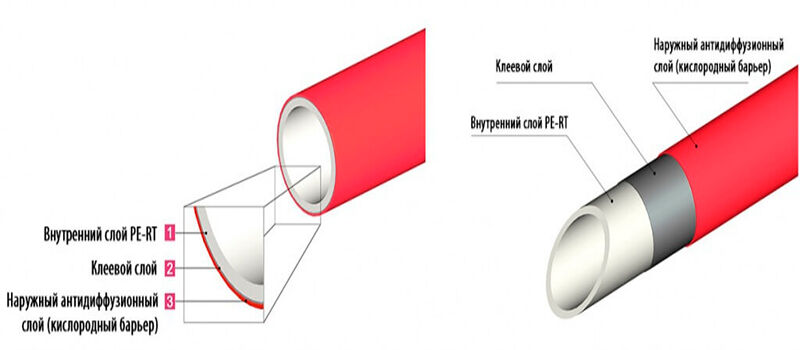

Features and production technologies

Polyethylene cross-linked at the molecular level is used in production. There are cross-links between molecules in the structure. This addition made it possible to increase the strength, rigidity and resistance of the material to extreme temperatures.

Stitching is done in several ways:

- Peroxide method. Provides high quality stitching. The main disadvantage of such pipes for water supply is their high cost. Crosslinking is performed using hydrogen peroxide. The result is a uniform seam.

- Silane method. Crosslinking is carried out using silane, water, and catalysts. The method is common, but inferior in quality to the previous one.

- Nitrogen method. Cross-linking is carried out with the participation of nitrogen radicals. Stitching quality – 70%. The method is rarely used because special conditions are required for production.

- Radiation physical method. During production, the polyethylene mass is driven through an electron accelerator. It is exposed to X-ray or gamma radiation. The method is not very popular, because the cross-linking percentage is no more than 60%.

When choosing, pay attention to the method of cross-linking polyethylene. This determines the characteristics of the products.

Pros and cons of products

Water supply pipes made of cross-linked polyethylene have the following advantages:

- resistance to aggressive substances that can be transported through the pipeline;

- environmental friendliness - cross-linked polyethylene contains no toxic substances, which allows it to be used for the construction of various communications, including water supply systems;

- resistance to ultraviolet radiation - compared to other polymers, polyethylene does not lose its properties when exposed to direct sunlight;

- elasticity – cross-linked pipes can be bent, which makes it possible to lay the pipeline according to different patterns (the number of joints is reduced);

- pipelines made of cross-linked polyethylene are lightweight and can be installed on any base;

- resistance to sudden temperature changes - the pipeline does not require insulation and can be laid in different places;

- ease of installation - to install communications, you do not need special skills, experience or special tools;

- service life 50 years;

- polyethylene is not subject to corrosion.

Correct installation work ensures reliable connection. The pipes have smooth walls, which eliminates the accumulation of deposits inside the water supply pipeline.

Flaws:

- laying features - it is undesirable to carry out open laying of pipes outside of structures;

- high price;

- Transportation and installation work are carried out carefully, since pipes are easily damaged.

Even such shortcomings do not affect the demand for material for water supply systems.

How to choose products

When choosing, pay attention to:

- stitching method;

- the presence of a protective coating;

- diameter and wall thickness;

- manufacturer.

Preference is given to well-known manufacturers, such as:

- Rehau;

- Valtec;

- Uponor;

- BIR PEX and others.

When it comes to water supply or heating, it is necessary to choose products that are durable and safe.

A cross-linked polyethylene pipe is an option for those who want to create a pipeline at home or in their country house that will last for decades. Carry out installation either yourself, following the instructions, or with the help of professionals.

If you were installing a water supply system at home, what material would you prefer? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

We also recommend watching selected videos on our topic.

Which pipe is better? Metal-plastic pipes or cross-linked polyethylene? Pipe operation classes.

Tools for installation of heating and water supply systems made of cross-linked polyethylene.