High pressure water pump: principle of operation, types, rules for selection and operation

Residents of suburban villages, whose territories are not connected to central water supply mains, solve the issue of water supply by installing autonomous systems. In achieving this task, the high pressure water pump plays a key role. Its main job is to stabilize the pressure in the system.

We will tell you what range of water pumps the market offers and what criteria to use to select equipment. Let's introduce the leading manufacturers in the segment. Here you will learn about the design features of the technology underlying the division into types.

For a clearer understanding of the information, we have supplemented the text with useful diagrams, collections of photos and video tutorials.

The content of the article:

Purpose and types of units

Regardless of where the water is taken from - from the nearest reservoir, a specially equipped well, a well, it can be automatically supplied to the site using a conventional pump.

But for normal operation of household appliances water pressure in the system should be at least 2.5 atmospheres and not exceed 6 atmospheres. And this parameter can only be achieved by installing a constant pressure maintenance system.For this purpose, various options for high-pressure water pumps are used.

When is a high pressure pump needed?

Device for enhancement and support water pressure in an autonomous system used when the pressure is so low that it is not possible to use water to operate household appliances.

Installing a pump is acceptable, but not particularly recommended for stabilizing pressure parameters in an apartment circuit if residents experience a real water shortage.

Using the device will be relevant if system pressure is no higher than 1 - 1.5 atmospheres. The small-sized device can be installed either on a common pipeline or at the outlet to a separate household unit.For example, by connecting to a pipe supplying water to a boiler or washing machine.

In the first case, you will have to purchase a powerful device with good performance characteristics; in the second, you can get by with installing a small, low-power automatic pump.

The operation of the unit can be carried out by:

- Manual control – assumes continuous operation of the device, regardless of whether water is currently being supplied, but provided that the device is turned off manually. They are used in the installation of “warm floors”, where maintaining the pressure in the heating circuits at the required level is constantly required.

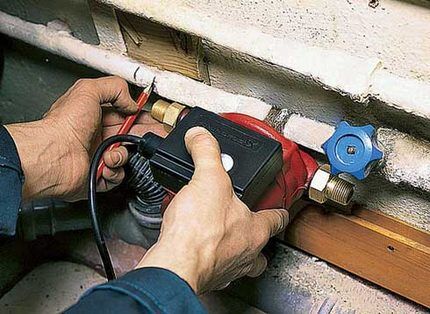

- Automatic mode – the device is turned on by an automation system, for example, when a tap is opened. The operation is regulated by a special flow sensor: the moment the tap is turned off, the pump stops functioning.

The main function of the regulation system is to turn on the unit when the pressure drops and turn it off when it reaches the specified parameter. After all, a decrease in pressure in the line and an excessive increase in it destroys pipe joints and has a detrimental effect on the operation of household appliances.

Alternative measures to increase blood pressure

However, installing a pump designed to stimulate pressure will be completely useless if the source has a low flow rate. It will not help if the system is shut down from time to time. The optimal solution in such a situation would be to use a self-priming pumping station.

The pumping station is equipped on the basis of the same category of pumps, equipped with or without injectors. Besides complemented by a hydraulic accumulatordesigned for storing water.It looks like a regular tank, only there is a rubber membrane with air inside. Controls a set of water pressure switch equipment and accessories.

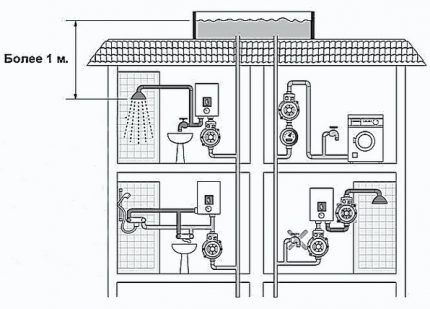

The installation of a self-priming pumping station is also effective in the case when there is normal pressure in the basement of the house, but there is no pressure at all on those located above.

The accumulated water can then be used regardless of whether there is water in the system, which is especially important if there are frequent interruptions in its supply. A significant disadvantage of such installations is the bulkiness of the design due to the presence of a hydraulic tank and the noise of the equipment during operation.

Instead of a hydraulic tank, you can use a regular storage tank in which water will be accumulated during the supply period at normal pressure. You can install it on a high overpass or on the roof of a house, and use the reserve during interruptions.

Types and operation of high pressure pumps

Before deciding to install a stimulation pump device, the condition of the pipeline should be assessed. It is possible that the pressure deficiency is due to pipes clogged with sediment. If you can get out of a difficult situation only by installing the device, then you should familiarize yourself with their technical specifics in more detail.

The operating principle of high-pressure pumps, regardless of the version of the working body and the type of design, is the same.During the operation of the working unit, the device creates a vacuum space inside the cavity, due to which water is sucked in.

On sale are models of a universal type, suitable for water of any temperature, and those that can only be used in cold or only in hot environments.

Depending on the method of cooling a running motor, units are of two types: with a dry and with a wet rotor.

Dry rotor units

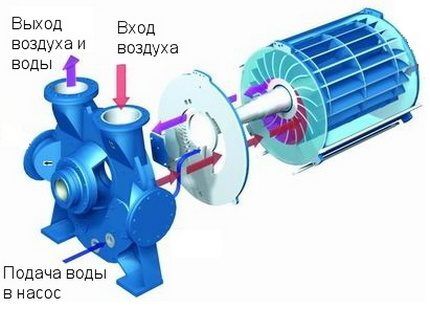

Modifications with a dry rotor are difficult to confuse with their wet counterparts. They have an asymmetrical shape with a clear advantage towards the power part of the device. The fact is that its engine is equipped with a vane cooling device, because is not washed with water during operation.

Due to the asymmetrical shape and the displacement of the axis towards the motor, “dry” models are equipped with cantilever devices for additional fixation on the wall.

Due to the fact that the engine in such models is separated from the hydraulic part at the end of the axis by an oil seal, they last much longer than “wet” ones. True, the seal, like a rolling bearing, tends to wear out and needs periodic replacement.

For this reason, units equipped with a dry rotor require more frequent maintenance and regular lubrication of rubbing parts. Another minus is that “dry” devices are noisy, so the place for their installation should be carefully considered.

Devices with wet rotor

Flow units involve cooling due to pumped water. In this case, the rotor of the device is placed in an aqueous environment and isolated from the stator by a waterproof flap.

Units with a wet rotor are characterized by a low level of noise interference. Circulation pumps with a wet rotor are designed for arranging heating systems, but are often used for water supply systems when heating residential premises.

The sliding bearings used in the assembly of the structure do not require additional maintenance. However, “wet” pumps last less and are inferior to “dry” units in terms of the pressure generated. There are restrictions on the direction of installation - only horizontally.

A significant disadvantage of pumps of this type is their vulnerability when working with dirty water, foreign inclusions of which can damage the device.

Division according to the method of creating a vacuum chamber

The mechanism of operation of this type of device is based on a displacement reaction. The pumping process is carried out under the influence of changing the dimensions of the working chamber. The amount of vacuum formed directly depends on the degree of tightness of the working chamber.

The vacuum level can be adjusted. Due to this, the pressure in certain places of the system can increase or, on the contrary, decrease.

The shaft is the leading working tool of the mechanism.An impeller equipped with blades performs rotational movements. Under the action of the blades moving in a circle, the liquid in the working chamber is captured. As it rotates, centrifugal force is generated. It also leads to the formation of a liquid ring. The unfilled space formed inside the ring is a vacuum.

Depending on the methods by which the vacuum chamber is created, high-pressure water pumps are centrifugal, vibration and vortex.

Centrifugal type devices

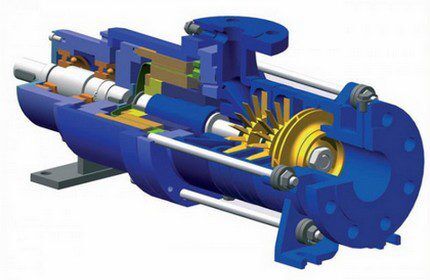

Centrifugal pump pumps - the most common type of pumping devices capable of providing high pressure in the system. They pump water by rotating an impeller fixed inside a spiral-shaped casing. The impeller consists of two fastened disks, between which blades are fixed in the direction opposite to the flow of incoming liquid.

During the rotation process, a centrifugal force is formed, which stimulates the displacement of water flows from the center of the chamber, throwing it to distant areas. Due to this, the pressure level in the center of the rotating impeller decreases, and water begins to flow into the inside of the housing.

Centrifugal devices in most versions are equipped with hydraulic accumulators. They are connected to pressure pipelines using pipes of different diameters.

Centrifugal type equipment is capable of providing uninterrupted water supply at high pressure. The only operating condition is that when starting the unit, the housing must be filled with water. The centrifugal version has limitations: they cannot pump water from a depth of more than 8 m, but they are quite suitable as an addition to a pressure-boosting system consisting of several pumps and storage tanks.

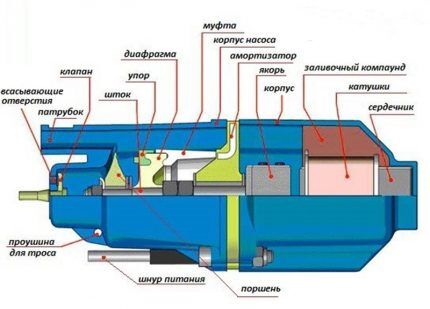

Vibrating electromagnetic pumps

The operating principle of vibration pumps is based on the ability of a magnet, due to the action of alternating current, to alternately attract and then release the armature-piston tandem. Changing the polarity, the armature makes alternating movements. Within one second, the position of the anchor can change several dozen times.

As a result of vibration vibrations, water is first sucked into the working chamber and then pushed out through the valve into the pressure pipe. The vibration unit can work in tandem with a centrifugal counterpart or pump a supply of water into a storage tank.

Vortex pump models

In the cavity of the body of such units there is a flat disk equipped with radially fixed blades. The rotation of the wheel with peripheral blades creates a vacuum.

Vortex devices are famous for their high suction power. They are not afraid of the presence of air bubbles in the water. But they are vulnerable to the presence of suspended particles in the liquid and therefore have a limited scope of application. Since vortex devices quickly break down when pumping dirty water, they are not recommended for use when constructing sand wells and wells.

Leading manufacturers and popular models

Among the proven global brands that are the most popular, it is worth highlighting:

- "Grundfos" — the Danish company relies on pumps with a circulation system, which are characterized by small volumes.

- "CatPums" — a feature of the equipment produced under this brand is low pulsation of mechanisms at the highest possible pressure.

- "Wilo" — a German concern specializes in the production of small-sized pumping stations equipped with built-in hydraulic accumulators.

- "Sprut" — a feature of pressure boosting pumps of this brand is the requirement for water purity and temperature.

The manufacturers listed above manufacture their products using proven technology that guarantees the reliability of pumping equipment. They have protection against overloads, cycling and dry running.

The price range of low-power pump models varies between 30-50 USD. More productive samples, equipped with an automation system, can be purchased for around 70-100 USD. Pumping stations will cost between 80-150 USD.

Among the models in the mid-price segment, the following have proven themselves well:

- "Sprut 15WBX-8" — a single design with a dry rotor has a capacity of 480 l/h with a power consumption of 90 W. The small-sized, lightweight device is placed directly on the pipe.

- "Euroaqua 15WB-10" — the vortex electric unit easily copes with liquids that contain air or gas.

- "Cristal 15GRS-10" — the model is famous for its low energy consumption and high efficiency, and is distinguished by its ability to heat the water flow to 65 degrees.

You shouldn't save money and buy Chinese counterfeits. The craftsmen do not undertake to repair them. Unscrupulous manufacturers assemble them in such a way that the breakdown of an individual element immediately leads to the need for a complete replacement of the unit.

Features of equipment selection

When choosing pump to provide pressure It is worth focusing on a number of parameters.

Determination of unit performance

This parameter depends on the task assigned to the pump and the required water flow.When calculating the total water consumption, household and household needs are taken into account, focusing on the total indicators of the maximum water consumption of all operating points of consumption for one time unit.

The performance of mid-price segment pumps is enough to raise the pressure by at least 1-1.5 atmospheres. If this is not enough, the system is supplemented with pressure booster pumps or pressure-stabilizing reducers.

When choosing a unit, you should also take into account the fact that the productivity of the pumping device does not exceed the productivity of the well or well. Otherwise, if the source is quickly depleted and its replenishment is untimely, the equipment will simply run dry. And this can lead to its breakdown.

Recommended device pressure

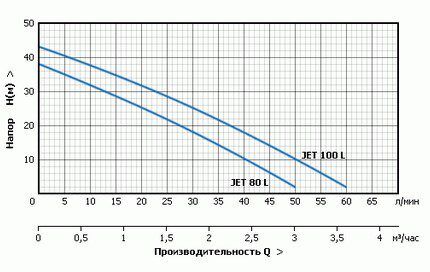

This parameter specifies the height in meters to which the unit is capable of lifting water. When determining the required pressure, the horizontal water supply distance and standard pressure losses during its transportation through the pipeline should be taken into account.

If this parameter is calculated using a simplified formula, then its value is taken equal to a tenth of the total length of the horizontal highway. For example, a tenth of the length of the hose connected to the irrigation pump green spaces.

For example, when installing a well 10 meters deep to supply water to a house located 12 meters from the water intake, provided it is installed at a height of 4 meters from the ground, the pressure of the unit is calculated by summing up the values: 10+4+(12:10) =15.2 meters.

But in order to obtain more accurate calculations, one should also take into account the diameter of the pipeline and the pressure loss when lifting water through pipes, as well as passing it through turns and nodes. Indeed, if there is insufficient pressure, the outlet pressure will be low. For this reason, when arranging water intake systems, pumps are selected that can maintain the pressure in the system within 2-6 bar.

When choosing equipment you should also consider:

- Operating temperature range;

- noise level created during operation.

Electric models and liquid fuel units are on sale. The first ones are powered only from the electrical network. They can be two- and three-phase. The second ones are equipped with an internal combustion engine. They use diesel fuel or gasoline as fuel.

The presence of an automation system significantly increases the cost of equipment. But the high price of automated mechanisms with a high level of electrical protection is completely worth it, since devices of this type respond more subtly to changing situations and consume less electricity.

Conclusions and useful video on the topic

Video review of the pressure boosting pump:

Option for arranging a system using an installation that increases water pressure:

There is a wide range of pumping equipment on the market. But experts recommend purchasing it in branded stores. They will help you choose the best option depending on the technical conditions of the facility and provide warranty service, which is especially important when purchasing expensive equipment.

Would you like to talk about how you selected a high-pressure pump, or about the use of this type of equipment in practice? Please write in the comments block below. Here you can ask questions or report interesting facts.

The construction of my new house is coming to an end. And the time has come to decide on the choice of pump. As I understand it, I need a submersible type water pump. At the moment I have settled on choosing a vibration model, I think it will suit me perfectly. More information about the installation itself would be nice. But in general, I don’t really need it, because a master will install it. And I don’t really understand this. In general, the information is very useful and interesting. Good luck.

How realistic is it to install such a pump in an apartment? Our cold water pressure is from 0.5 to 0.8, no more. First of all, I am interested in the legality of the connection.

Hello. If the pressure problem is due to narrowed pipes or clogged with rust/dirt, the pump will not help.

Art. 25-29 of Chapter 4 of the Housing Code of the Russian Federation (rearrangement and redevelopment of residential premises) - here, in my opinion, these articles regulate such actions as the reconstruction of the engineering system, which may lead to deterioration of the system of the entire house.

In general, according to the standards, your blood pressure is very low, of course - it doesn’t fit into any standard. You should write a statement to the Criminal Code and demand that everything be corrected. And so, at a house-wide meeting, it is possible to resolve the issue of installing a storage tank with a pump on the riser, if the problem is not in the pipes.