How to choose a good pump for watering your garden with water from a pond, barrel or reservoir

Consistent watering is the key to obtaining a bountiful harvest from garden beds.If on rainy days the weather takes care of the plants, then in the hot months the gardeners themselves have to deal with it, using buckets and watering cans. The use of pumping equipment helps to facilitate the work.

The market offers various pumps for watering the garden and it is difficult to purchase a suitable model, isn’t it? We will help you navigate the range of equipment, tell you about the features of different modifications and provide a step-by-step selection algorithm based on an analysis of the characteristics of the units.

In addition, we will identify trademarks and brands whose products are in demand and trusted among summer residents.

The content of the article:

Selecting a source for water intake

The choice and purchase of a suitable model of garden pump for irrigation largely depends on what kind of water is intended to be pumped and where it is planned to be taken from.

Plants cannot develop normally without a sufficient amount of life-giving moisture. But only well-settled warm water is suitable for watering green spaces.

Careful owners collect rainwater in barrels and large containers placed on the site under the gutters. If necessary, all that remains is to get it out by scooping it up with a bucket or pumping it out of the barrel with a pump for watering.

Quite often, if there is a presence on the site well or well, then water for irrigation is taken from them. But a “cold shower” can cause irreparable damage to the delicate roots of plants: they can begin to rot.

For this reason, water pumped out from a hydraulic structure is first poured into containers, allowing it to heat up under the sun's rays, and only then is it used for irrigation.

The third, and perhaps the most successful source option, where it is convenient to get water for irrigation, is a nearby natural reservoir or an artificial pond constructed on your own.

In all the water sources listed above, the degree of contamination of the water varies greatly. Therefore, separate types of pumping equipment have been developed for each of them.

Types of water pumps

Two types of pumps are used to irrigate garden crops. Depending on the method of water intake and the placement of the unit body relative to the source, they can be surface or submersible.

Option #1 - barrel for pumping out tanks

Such devices are designed specifically for pumping water from small-volume tanks, the depth of which does not exceed 1.2 m.

Among the pumping equipment on the market, such units are considered the easiest to use and maintain.

The main advantage of pumps for irrigation from a barrel is their compactness and mobility. The average weight of the unit is 3-4 kg.

Taking it by the handle, it is convenient to carry it around the site and install it one by one on containers placed under the catchment areas. In addition, barrel pumps are famous for their low noise level.

The use of barrel units is also convenient because the water used for irrigation can be pre-diluted with fertilizers for feeding cultivated plants.

Most models are equipped with a pressure regulator. With its help, it is convenient to set the pressure required for work. Tank pumps have built-in filters that trap large particles.

But as owners who have already tried household models of this type note, built-in filters do not always cope with the task. As a result, even expensive systems quickly become clogged and fail.

The easiest way to solve this problem is by arranging an additional homemade filter in the form of a piece of gauze or mesh tulle folded in 2-3 layers.

The pump is simply placed on a canvas suspended in the form of a hammock so that the mesh layer between the suction device and the water does not allow debris to seep through.

You can prevent rust and sludge from entering the system by placing the pump inside the tank so that it does not reach 5 cm from the bottom of the tank.

Option #2 - surface for shallow reservoirs

When planning to use an artificial reservoir or well as the main source of water intake, it is worth considering models surface pumps.

They are placed in close proximity to the source, and water is collected by immersing a suction hose into the structure.

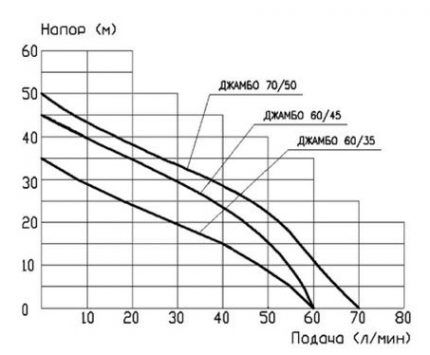

External devices are capable of pumping water from a depth of 8 m and delivering a stream to a level of about 30-50 m. Thanks to this pressure, several rows of beds can be watered from one point.

Most surface models use a metal pipe as the outlet pipe. A rubber hose is not suitable for this purpose because at the moment of pumping liquid, rarefied air is created inside it.

As a result: the elastic walls begin to shrink, preventing the water flow from moving normally towards the outlet.

The only drawback of pumps for irrigation from shallow reservoirs is vibration and noise generation during operation.

You can get rid of the loud “growling” by placing the unit in an outbuilding, or by placing the unit body on a rubberized mat or stand.

Option #3 - submersible for contaminated ponds

Submersible pumps are rarely used for gardening purposes. The working part of this type of device is immersed directly into the source, buried below the water level. The pumped-out liquid is brought to the surface under pressure through rubber pipes.

Depending on the type of model, submersible pumps are capable of pumping water from a depth of up to 80 m. This parameter is relevant when used as a source of water intake for irrigation of a drilled well.

According to the method of water supply submersible pumps for irrigation are presented in two versions:

- Vibrating. They work due to the movement of a membrane located inside. It causes pressure differences, under the influence of which water is first sucked in and then pushed out. Vibrating devices have a low price, but are afraid of clogging with silt.

- Centrifugal. They raise water to the surface by rotating the blades and wheels. They “grind” water with such force that they are not afraid of minor pollution. But such units cost an order of magnitude higher than vibration units.

The outer shell of submersible pumps can be made of stainless metal or plastic. Each of these materials is designed for constant contact with the working environment.

If it is necessary to use a pond as a source of water intake, the water in which is not particularly clean, preference should be given to drainage models.

Such units are a way to “recycle” lightly and heavily polluted water, which contains various kinds of impurities with a diameter of 5-10 mm.

The shredder, located just above the suction device, during the pumping process will crush the leaves, silt and other debris that have entered the device along with the water into tiny particles.

Thanks to this, irrigation water will be additionally enriched with organic fertilizers, which will only have a positive effect on the yield of cultivated crops.

A significant drawback of drainage units used as pumps for irrigation from a pond is low pressure in the system. So you can water the garden with their help only by gravity.

If you plan to use a nozzle or a divider, then the water may not come out at all. You can get out of this situation by doing the work step by step.

First, using a drainer, liquid is pumped into the storage tank. And then, after it settles and the heavy suspensions settle, the garden is watered using a surface and submersible garden pump.

Option #4 - automatic for drip irrigation

Automatic pumps equipped with timers are especially popular. They greatly facilitate the task for owners who do not have the opportunity to waste precious time and excess moisture on watering for many hours.

Pumps for drip irrigation are equipped with pressure switches and hydraulic accumulators.Control in such systems can be either manual or automatic.

Although such equipment is not cheap, the costs fully pay for themselves over time, allowing for more efficient use of hundreds of cubic meters of moisture supplied during the season. And the owner frees up a lot of time that would previously have been spent on watering.

Criteria for selecting units

When choosing pumping equipment, you need to determine the following factors:

- Distance from the water intake source to the garden beds.

- Height difference from the installation site of the pumping equipment to the extreme point of the garden.

- Plot dimensionsallocated for crops that require frequent watering.

- Irrigation type (root, drip, sprinkling).

- Frequency of use pumping equipment.

For drip irrigation, it is enough to install low-power equipment. When planning to irrigate crops through sprinkling, you should give preference to systems that can easily withstand high pressure.

The most reliable are units with two-stage mechanisms. Such powerful units are chosen by owners of large plots, who have a large area allocated for vegetable beds, flower gardens and gardens that need watering.

No. 1 - calculation of device performance

To calculate the required performance of purchased pumping equipment, average indicators are usually taken.

Depending on climatic conditions and soil conditions in accordance with the current SNiP for watering beds with an area of 1 sq. m. m requires from 3 to 6 liters per day.

Therefore, for a vegetable garden with an area of 200 square meters. m the daily norm will be: 200x6=1200 l.

The maximum productivity of barrel units is 4000 l/hour. When choosing among low-power devices designed for pumping liquid from storage tanks, you should take a closer look at models with a capacity of 2000 l/hour.

The price for such devices starts from 2.5 thousand rubles.

When arranging drip irrigation, the most reliable type of pump is a centrifugal one. After all, only he is capable of pumping large portions of water under high pressure for a whole day without damaging the motor overheating.

When choosing among drainage models, keep in mind that such units have a capacity of 83 to 250 l/min with a water supply of 5 m to 12 m.

When using water for irrigation from particularly polluted water bodies, the impurity diameter of which is 15-55 mm, you should choose units with a capacity of 37 to 450 l/min. They are capable of delivering to a height of 5-22 m.

No. 2 - recommended jet pressure

Pump pressure refers to the mechanical operation of the unit, as a result of which the pressure of the liquid increases and it is pumped. In this case, part of the drive energy during the pumping process is converted into kinetic energy of the liquid.

The higher the pressure generated, the greater the distance that can be maintained between the pump and the water intake source. When calculating power, also take into account that the ratio of vertical and horizontal lengths is 1:4.

At the same time, when it comes to watering, too much pressure is more of a hassle than a benefit. After all, the exhaling pressure can not only damage the dividers, tearing them off the hose, but also cause harm to green spaces.

No. 3 - presence of an automation system

Automation significantly increases the cost of pumping equipment. But it plays a significant role, preventing overheating of the “heart” of the unit - the motor.

A float switch protects the device's motor when a predetermined minimum water level is reached. This prevents the unit from running dry, thereby minimizing the risk of breakdowns.

By choosing a unit equipped float switch, during operation you will not need to control how empty the barrel is.

You only need to wash the float switch under water pressure once a season to prevent the box body from sticking to the outlet pipe.

No. 4 - location of the suction valve

The suction valve may be located above the engine compartment at the top of the device, or on the bottom of the housing.

More practical are models whose water intake is located in the upper part of the body.This design solution reduces the likelihood of silting and penetration of bottom sediment and sand particles into the chamber.

When using submersible units for irrigation, the suction valves of which are located in the bottom of the housing, use special supplies.

By placing the pump on a stand, you can partially protect the working chamber from fibrous inclusions, agitated sand suspension and large debris.

Pumps are usually supplied with adapters that allow you to connect flexible hoses and rigid pipes with a diameter of 1" and 1" 1/4ʺ. In budget models, most likely, you will have to buy an additional watering hose and spray nozzle.

Review of pumping equipment manufacturers

High demand for pumping equipment for domestic use stimulates manufacturers. Today, foreign and domestic manufacturers offer a wide range of equipment in different price categories.

Imported world brands

Among the foreign manufacturers that have proven themselves well in the pumping equipment market, it is worth highlighting:

- "HAMMER". German leader in the production of first-class pumping equipment. A wide range of models, unique technical solutions and the highest reliability - all this is united by the products manufactured under this brand.

- "PATRIOT". One of the oldest American brands. The quality of the products produced by this company has been tested for generations. Domestic buyers are more familiar with this brand for reliable and easy-to-use chainsaws. But pumping equipment is in no way inferior to them.

- "Salpeda". Recognized champion in the world market. The Italian company is famous for its good technical traditions.All equipment is manufactured using high-precision technology.

- "QUATTRO ELEMENTI". Another well-known Italian brand representing high-quality equipment. The company, founded by like-minded engineers, focuses on the reliability and maintainability of its products.

Barrel models for watering the garden of these brands can be purchased at a price of 5.5 thousand rubles. More powerful surface and submersible units will cost 6 thousand and more. A drainage installations average power - within 9 thousand rubles.

Among the companies that are still only building up their potential, but have already earned a positive reputation among a wide range of consumers, it is also worth highlighting “Makita" And "Gardena».

Domestic brands

Popular brands of pumping equipment from domestic manufacturers:

- "Vortex". Leading Russian manufacturer. The main advantage of the products is ease of use, quiet operation and minimal hydraulic losses during the pumping process.

- "Gilex". The Russian company produces reliable pumps that can be used to pump out both clean and slightly contaminated water for irrigation.

- "Gardener". The products manufactured under this brand successfully combine an affordable price with decent quality. Compact centrifugal devices easily cope with contaminated water.

The price for centrifugal submersible pumps of these brands starts at 4 thousand rubles. Drainage units of average power cost from 5 thousand and above.

Budget models of domestic production are also widely popular. "Stream" And "Baby". The price of products ranges from 1.5-2 thousand rubles.

But it is worth noting that they are very sensitive to voltage fluctuations in the electrical network. To work in our conditions, it is better to choose centrifugal models that do not have such a sin.

Conclusions and useful video on the topic

Recommendations for choosing an electric pump for irrigation:

Video review of the use of the Karcher barrel pump:

Equipment for pumping out a contaminated pond:

And finally, I would like to note that, regardless of the chosen model, equipment shortcomings most often appear due to improper handling.

If the device is designed for pumping clean water, then you should not lower it into a rainwater tank. Fallen leaves and sand will quickly clog the filters and damage the device. And it will not be the manufacturer who is to blame for this, but only the careless owner.

Do you have experience using pumping equipment to water garden beds? Please share information with our readers, tell us what pump you use. You can leave comments in the form below.

I don't have an artificial pond. At one time I installed a huge iron tank in the garden (without a top lid). I pump water into it using a centrifugal pump (a tank with a capacity of 1.5 cubic meters is filled in 20 minutes). The water warms up perfectly in hot weather. I made a hole at the bottom with a tap and attached a hose. I water without a pump, by gravity flowing through the grooves - this way the water is absorbed more evenly.

Due to constant interruptions in the water supply at the dacha, I dug a 5-meter hole in the ground and concreted it.It turned out to be an excellent container for storing water. But the consumption when watering with buckets was disproportionate to the required volume. And scooping up the remaining water 1-2 meters from the bottom of this tank caused discomfort. I bought a surface-type pump, ran a hose and installed water sprayers. Now it's absolutely beautiful. It’s a little noisy, of course, but it’s 100% automated.

Help me please. There are 5 hectares of land and a lake at the lower corner of the plot. We need a pump that can pump water a distance of 600 meters to the upper corner of the site and water it by gravity in the rows. The difference in height is about 10 meters, what do you recommend???

Help me please. There are 5 hectares of land and a lake at the lower corner of the plot, we need a pump that can pump water at a distance of 600 meters to the upper corner of the plot and water it by gravity in the rows, the difference in height is about 10 meters, what do you recommend???