Review of the Gnome water pump: design, characteristics and operating features

Are you looking at a domestic pump, choosing a unit for pumping dirty water? Pumping equipment should be functional, reliable and easy to use, right?

Do you doubt the real capabilities and technical characteristics of an inexpensive device? We will help you find out all your questions - the article discusses in detail the Gnome water pump, designed for pumping contaminated and clean water.

The operating characteristics, markings, pros and cons of the equipment, as well as operating features are given. The article material is supplemented with visual photos and a video review of the Gnome brand pump.

The content of the article:

Technical characteristics and markings

Electric pumps under the Gnome brand are produced by Russian and Belarusian manufacturers. Pumps in the “Gnome” line belong to the class of single-stage vertical submersible pumps of a monoblock design.

They are designed for pumping drainage and groundwater containing no more than 10% solid mechanical particles by weight, the density of which does not exceed 2.5 thousand kg/m3.

Pumping fractions of no more than 5 mm is allowed. The temperature of the pumped liquid is up to +35 ºС, and for models marked “Tr” – up to +60 ºС. The unit is used in everyday life, industry, housing and communal services, and agriculture.

More details about the device and features of drainage pumps discussed in our other article.

The body of the submersible electric pump is made of plastic, cast iron or steel. The impellers and motor casing are made of cast iron.

The equipment is produced with different types of motor, depending on which the ability to be powered from a household power supply with a voltage of 220 V or from a three-phase industrial power supply with a voltage of 380 V and a frequency of 50 Hz is determined.

The electric pump package includes: a 10 m long power cord for a three-phase power supply or a cord and a starter for a single-phase power supply. Most manufacturers, for an additional fee and at the request of the buyer, include in the kit a circuit breaker to protect a motor operating from a 380 V network.

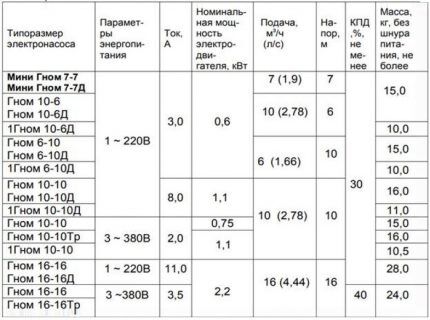

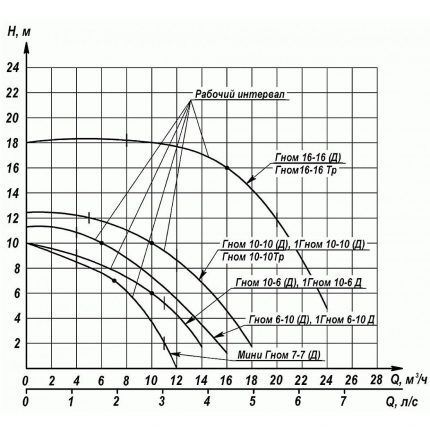

Technical characteristics such as power, power supply parameters, performance (pumping speed), maximum pressure, as well as the size and weight of the equipment depend on the specific model.

You can compare the technical characteristics of Gnome pump models using the table:

All pumps produced under the Gnome brand are marked. Knowing what is hidden behind the numbers and symbols, you can easily understand what characteristics and features the pump has.

The word “Gnome” itself is an abbreviation and stands for:

- G - dirty water;

- N - pump;

- ABOUT — single-stage;

- M — monoblock.

The first digit in the marking indicates productivity in m3/hour, the second is the pressure in meters. For example, “Gnome 10-10 Tr” is a pump with a capacity of 10 m3/hour and a head of 10 m.

The designation “Tr” indicates that this equipment can pump water with temperatures up to +60 C. The letter “D” means that the equipment is equipped with a float switch (level sensor).

Pumps marked with the abbreviation “Ex” belong to the explosion-proof group. Such units are capable of pumping water with impurities of petroleum products, which contain no more than 3% sulfur.

In emergency situations, the pump can be used to operate in environments containing up to 100% crude oil products.

Review of manufacturers and model range

Today, three Russian factories are engaged in the production of Gnome submersible pumps - Odintsovo Pump Plant, MNZ No. 1 and Livgidromash, and one Belarusian - Polesyeelectromash.

The equipment of the Odintsovo Pump Plant is considered to be of the highest quality. The units of this release are distinguished by high build quality and a low defect rate. The disadvantages of these products include the high cost of pumps in comparison with analogues and expensive repairs.

You may also be interested in information about pump repair, discussed in detail in our other article.

Pumps produced by MNZ No. 1 are lower in cost, but have a number of disadvantages: low build quality, some leading parts are made of plastic, and high sensitivity to power supply fluctuations.

Polesyeelectromash and Livgidromash products are rarely found on the Russian market, but experts agree that this equipment meets high requirements.

The diversity of the model range of Gnome electric pumps will easily allow you to select the optimal equipment for the needs of the consumer.

All existing models can be divided into four groups:

- Household pumps. Used for pumping dirty water in private households. This group includes pumps of the Mini series - Gnome 7-7 and 7-7D, as well as models with a capacity of up to 16 m3/h. When we talk about buying a pump for household needs, we mean equipment from this particular group.

- Powerful pumps. They are used in industry, construction, and public utilities. Productivity - from 25 to 600 m3/h. These pumps can be controlled using a control station, which is purchased separately and installed by specialist installers.

- Explosion-proof pumps. Involved in the oil and gas industry, energy and chemical industries. The pumps are capable of pumping explosive liquids. The cost of such equipment is very high.

- Self-cooling pumps. Can be used for both full and partial immersion. A special feature of these pumps is the presence of a special housing design, which is called a “cooling jacket”.

The most widely used models are Gnome 10-10 and 10-10D, produced for operation from a single-phase power supply and used in private construction, in dachas and suburban areas.

Universal unit "Gnome"

Electric pumps “Gnome” are rightly called universal. Simplicity of design and operation, as well as maintainability and ease of maintenance made these pumps very popular.

They are used in a wide variety of industries to perform a wide range of tasks.

Private users usually use Gnome for:

- pumping out flood waters from basements and flooded areas;

- drainage of construction pits, trenches, pools;

- drainage of groundwater from suburban areas and agricultural lands;

- disposal of used household appliances water in the absence of a central sewer system;

- pumping liquids in autonomous pumping stations and treatment facilities;

- cleaning silted wells;

- supply of clean water from well shafts.

It should be remembered that Gnome pumps cannot be used for pumping fecal waste! For these purposes, it is better to look for specialized equipment. Our other article discusses types of fecal pumps.

Do you need a sump pump and don't know which one to choose? Then the information discussed in the article may be useful to you: Fecal pump for a cesspool: let’s figure out which unit is better and why.

In the case of pumping water contaminated with petroleum products or crude oil, the Gnome can operate for no more than 5 hours.

Device and principle of operation

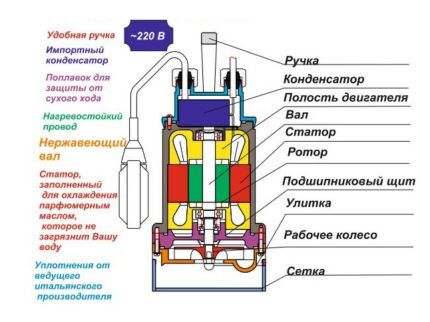

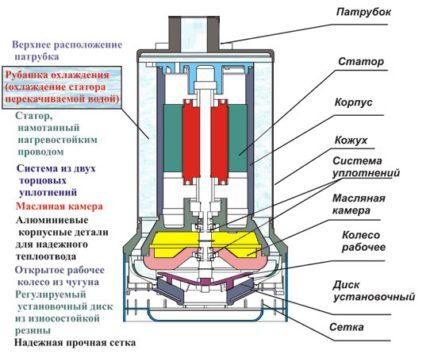

The design of the Gnome electric pumps is a monoblock, which consists of two main parts: the pump component and the electric motor.

The pump part includes:

- Working wheel;

- tap;

- pump housing.

To pump liquids with a large number of inclusions, as well as cement or clay suspension, the lower part of the housing is equipped with a filtration mesh.

The Gnome pump is equipped with an asynchronous electric motor, which consists of a stator, rotor, bearing system and cover.The function of cooling and lubricating the bearings is assigned to the oil that fills the engine cavity.

At the top of the motor there is an elastic rubber cuff that compensates for the expansion of the cooling medium in the event of heating. The electric motor itself is cooled directly by underground water during the pumping process.

The rotor speed for all Gnomes models is 3000 rpm. Thermal fuses are built into the stator, preventing the operation of the unit during periods of overheating.

If the operation of the pump was interrupted by them due to excessive temperature, the pump should be disconnected from the network and wait until it cools down.

The pump is started using a starting device located on the power cord. The equipment is equipped with a capacitor and a circuit breaker that protects the electric motor from overload.

Before starting work, the pump unit must be completely or partially (models with a “cooling jacket”) immersed in water. Dry work should not exceed 15 minutes.

The operating principle of Gnome pumps is based on the use of centrifugal force, which is created by the impeller. After turning on, water is sucked inside through the filter mesh, then moves to the outlet through the channels and is pushed out into the pressure pipe.

Preparing the pump for operation

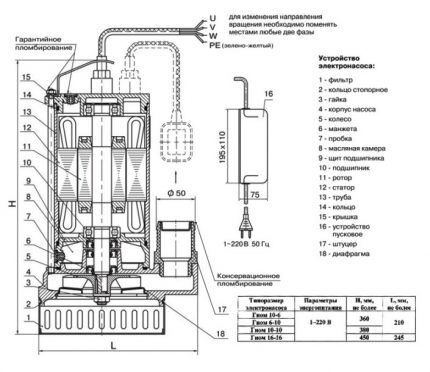

Before installing the pump, it is necessary to carry out an external inspection for mechanical damage to the housing and power cable. It is also necessary to check the presence of oil in the oil chamber.

To do this, the electric pump must be placed horizontally and, having unscrewed the top plug, carefully rotate the unit around its axis by 45 degrees. The oil should flow out through the drain hole.

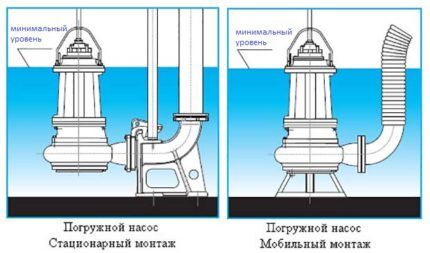

The design of the Gnome pump suggests two options for its immersion in the working environment:

- mobile, using a flexible polymer cord;

- stationary, using a rigid cable.

Please note that the electric pump must be grounded, and the power cord must be reliably protected from mechanical damage.

Electric pumps in the three-phase variation are allowed to be connected only through a circuit breaker equipped with a thermomagnetic release. This is necessary to protect the electric motor.

After checking the pump for oil, mechanical damage and grounding, it is necessary to remove the plug from the pipe. Then attach a flexible hose to the pump and secure it on both sides with clamps.

The diameter of the hose must be selected based on the size of the pressure pipe. During work, free drainage from the hose must be ensured, and its fractures and bends must be avoided.

When lowering the Gnome electric pump into a pit using a flexible or rigid cable, you need to control that the unit is located strictly in a vertical position, because This is the only way the electric motor can be fully cooled. Do not lower the pump using a rope or power cord!

When installing the “Gnome” on a sandy or muddy bottom, or in cases where the condition of the bottom surface cannot be determined visually, it is necessary to take care in advance of a substrate, which can be, for example, a thick rubberized mat.

If there is no substrate, it is recommended to hang the pump a few centimeters from the bottom. After the pump is immersed in the liquid, it starts. The electric pump must stand vertically, the deviation in one direction or another should not exceed 10 degrees.

Safety precautions for installation and operation

Operation of Gnome pumps is permitted only within the limits of the pressure characteristic, which depends on the model. Do not bend the hose or turn or lower the pump to increase the pressure.

Basic electrical safety rules that must be followed when installing, operating and maintaining the pump:

- In the event of a partial or complete interruption of power supply, the pump connection diagram must exclude the possibility of spontaneous starting of the electric motor.

- The Gnome pump must be completely immersed in the pumped liquid. Exception: partial immersion is possible for models with a “cooling jacket”.

- Do not operate the pump with a damaged housing or power cord.

These rules should not be neglected and then the pump will serve you for as long as possible.

Maintenance of Gnome pumps

Timely and correctly carried out maintenance of the electric pump will significantly extend its service life and protect it from breakdowns, and the owner from expensive repairs. You can carry out maintenance yourself only if it is not possible to do this at a service center.

Maintenance during intensive use of equipment should be carried out once a month. This is the recommendation of all Gnome pump manufacturers.

Monthly maintenance includes:

- control of oil level and quality;

- checking for kinks in the hose, breaks in the insulation on the power cord;

- inspection for mechanical damage to the body;

- measuring the insulation resistance of the cable and motor, which should be more than 0.5 Ohm.

Oil is refilled every 250 hours of operation, as well as when water and other foreign liquids and fractions are detected in the oil.

To change the oil, you need to install the unit on a flat surface and unscrew the plug in the bearing shield. Drain the unusable oil and fill with new oil. For a complete change, about 300 ml of oil is needed.

After using the pump to pump contaminated liquid with a large amount of mechanical impurities, it is necessary to run the pump for several hours to pump clean water to clean all internal elements.

If the pump has not been used for a long time, then before starting it is necessary to check whether the impeller rotates: it should rotate without applying force.

Which "Gnome" is better to choose?

A large assortment of pumps under the Gnome brand often confuses the average consumer, which pump to choose?

To choose the right electric pump, you need to consider two main factors:

- Specifications. The most important parameters are productivity and pressure.

- terms of Use. It is necessary to evaluate the liquid: the temperature background of the medium to be pumped, the percentage and size of mechanical particles, pH values and other conditions.

Today, the most popular Gnome pumps are the following models: Mini Gnome 7-7, 10-10, 16-16 and 20-25. The first pump is purchased by summer residents for watering small areas.

The second and third electric pumps have universal characteristics and can be used both for watering a plot and water supply for a small house with 1-3 water consumers, and for draining basements, pits and trenches in private construction.

The Gnome 20-25 pump is a more powerful unit, rarely used in private households, but if you decide to buy this particular pump, then pay attention to the modification in the “cooling jacket”. Most experts recommend purchasing pumps equipped with a level sensor.

If you plan to use Gnome to serve clean water from a well, before purchasing, be sure to pay attention to its overall dimensions. Remember that the pump is installed strictly vertically, so it cannot be used for wells with low flow.

You may also find our other article useful, which discusses how remove a stuck pump from a well.

Advantages in comparison with analogues

If we compare “Gnomes” with analogues presented on the Russian market, we can highlight many advantages:

- the presence of a filter that can be easily removed and cleaned;

- maintainability, availability of spare parts and their low price;

- wide model range, the ability to choose the optimal option;

- ease of operation and installation; no special skills are required to operate the electric pump;

- the ability to refuse to install shut-off and check valves;

- absence of vibration and noise;

- the presence of an automatic switch that protects against short circuits and overloads, so there is no need for constant monitoring during operation.

It is worth noting that among the pumps that can be used to pump out dirty water, “Gnome” has practically no analogues.

Information about the best models and manufacturers drainage pumps discussed in our other article.

Excellent performance, as well as high quality and affordable price are the reasons for the high popularity of these pumps in Russia and the CIS.

Conclusions and useful video on the topic

Video about the Gnome submersible pumping unit of the industrial category:

Construction and maintenance of the electric pump “Gnome 20-25”:

Technical characteristics of the modification “Gnome 10-10”:

The Gnome submersible centrifugal pump is the best option for pumping dirty water. It has many advantages, and a wide range of models allows you to choose a model for your specific needs.

The pump allows you to pump out dirty water in the shortest possible time in case of emergency situations, and it can also be used as a stationary pump in a water treatment and water supply system.

Are you using Gnome in your home water supply? Tell us how well it copes with its tasks and how often you have encountered breakdowns.

Or maybe you have experience in repairing such a pump yourself? Potential buyers may find your experience useful - leave your comments under this article.

I'm choosing between 10 and 16. Which one do you think is worth buying?

It depends on what you plan to use it for. In general, 10-10 is enough for almost all household tasks.

Hello. Kirill said correctly - depending on what for. Since you did not clarify this point, here are the characteristics of both devices:

1. Gnome 10 - flow 10 m³/h, head 10 m, power 0.75 kW, current 2 A, voltage 380 V. Without float switch

2. Gnome 16 - flow 16, pressure 16, power 2.2 kW, current 11 A, voltage 220 V. There is a float switch

In general, here is a useful sign for Gnome pumps.

There were two Mini Gnome 10-10 pumps on the farm; at the moment, one is still in good service, an excellent and unpretentious unit for pumping dirty and clean water. I also used it for watering, it gives good pressure to the entire irrigation system. Both pumps worked for 5 years, almost every day of active use. I am very pleased with pumps of this design; they are perfect for private households.

By and large, an illiterate article, or rather semi-literate. What are the 3 factories in the Russian Federation? And what about the “writer” of the Livny “Prompribor”, where did the Perm “Uralgidroprom” go? By the way, of the Russian ones the most reliable are the Livonian and Perm ones, the Moscow ones are worse. The real exception was the manufacturer "Company" CHISH ", but it seemed to collapse. The girl in the video talking about GNOM-25/20 is touching, I wonder if she will lift this 32 kg pump or if her spine will spill out into her thong - a theoretical expert. She would also tell about 40, 53 or 100 GNOM))). By the way, “100” GNOMS are also represented by Moldovan pumps - very high quality ones.

Good afternoon Please tell me what kind of oil to fill in the Gnome 16-16D pump