Repairing the Gnome pump: a review of popular breakdowns and how to fix them

With proper operation, the Gnome pump can serve its owner for decades.And even if a breakdown occurs, you should not rush to replace it with another unit or call a repair specialist.

Most malfunctions can be eliminated yourself, because repairing a Gnome pump is not difficult if you know the cause of the problem and how to eliminate the malfunction. In our material we will talk about the design features of the electric pump, the most common causes of equipment failure and ways to eliminate them.

The content of the article:

General information about Gnome pumps

Pumps "Gnome" for pumping clean and dirty water, they are very often used by summer residents and owners of country houses. These are reliable and durable electric pumps that do not require complex and expensive maintenance.

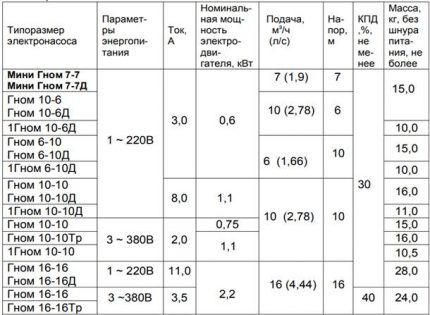

This brand produces centrifugal submersible pumps with various technical characteristics:

- productivity from 7 to 200 m3/hour;

- nominal pressure from 7 to 50 m;

- electric motor power from 0.6 to 21 kW.

In everyday life, the most commonly used models are “Mini Gnome”, “Gnome 16-16T”, “Gnome 10-10T” and “Gnome 20-25”, so further we will talk about these household electric pumps.These models are small in size and weigh from 10 to 32 kg.

Portable centrifugal pumps "Gnome" have a monoblock design and are used for pumping clean and dirty water with a density of up to 1100 kg/m3 and containing solid mechanical particles up to 5 mm in size in an amount not exceeding 10%. The maximum density of solid particles is 2500 kg/m3.

Pumps are used to supply water from open reservoirs, wells, and wells. They are used for draining pits and trenches, for watering agricultural crops, and pumping groundwater from flooded premises. The temperature of the pumped water for conventional models is up to 35 °C, for “T” models - up to 60 °C.

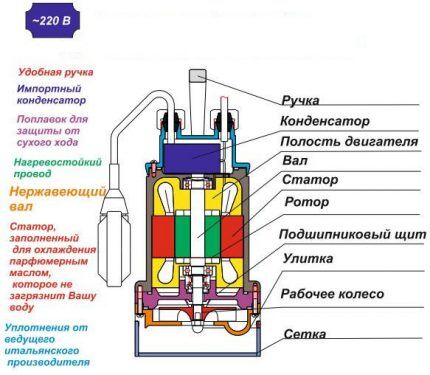

Centrifugal submersible pumps "Gnome" have a simple design and consist of the following main parts:

- An electric motor that includes a stator, a bearing shield and a rotor.

- Pump unit, with an impeller located on the rotor shaft, with an intake grid and outlet.

- Sealing system to protect against water ingress.

- Housing made of metal, cast iron or plastic.

- Power cable.

The electric motor is cooled by the external environment and oil, which is located in a special oil chamber of the electric motor. Oil also performs the function of lubricating rubbing parts. The rotation speed of the rotor and impeller is 3000 rpm.When rotating, a centrifugal force is generated, which pushes water through the pressure pipe.

Water enters the pump through a filter mesh that traps large particles. Then the water moves through the channels to the outlet, from which it enters the outlet pipe. The electric pump is started by a starting device, which is connected to the power cord. Gnome electric pumps have a capacitor and a circuit breaker that protects the electric motor from overload.

Pumps "Gnome" belong to submersible type, so they are launched only after complete immersion in water. The exception is “Gnome” electric pumps with a “cooling jacket”. Most electric pumps are equipped float switch, which is mounted on the handle of the unit and provides a minimum suction height of 15 cm.

Typical causes of failure

According to statistics, 95% of cases of breakdown of Gnome pumps are associated with improper operation and installation. The most common causes of malfunctions:

No. 1. The motor protection circuit breaker is incorrectly selected

An incorrectly selected and installed circuit breaker does not respond to critical voltages in the electrical network. To protect the electric motor, it is necessary to install a special machine, which is purchased separately.

The type of protective device is recommended by the pump manufacturer in the operating instructions. According to the manufacturer’s recommendations, for example, for an electric pump of the Gnome brand, it is necessary to use a BA 101-3 machine.You can also use ABB MS series automatic machines.

No. 2. Melting of the thermal protection winding insulation

Thermal protection is built into the winding and when the electric motor heats up, it turns off its power. If the pump often overheats for some reason, then each time the insulation melts. This is an irreversible process that can lead to a short circuit and inevitable breakdown of the electric motor.

No. 3. Operation of the electric pump without water

One of the most common causes of malfunctions. Dry operation of the Gnome submersible electric pump without a “cooling jacket” should not exceed 15 minutes. Also, you cannot use the pump to pump high-temperature water (over +35 °C for regular and +60 °C for “T” models). In both cases, the pump quickly overheats and fails.

No. 4. Using the pump outside the operating ranges

The pressure and productivity delivered by the electric pump must not exceed the parameters specified in the passport. If the equipment operates significantly beyond its technical specifications, the operating current on the motor windings increases significantly, which leads to its overheating. The pump will not be able to work with overload for a long time and will quickly fail.

No. 5. Operation of the pump on a valve or narrow pipe

Saving on pipes and purchasing them of a smaller diameter leads to a decrease in the performance of the electric pump, i.e. it begins to operate outside its operating range.

In this case, a very narrow pipe can become clogged, which will also lead to a colossal load on the pump. To avoid this, it is necessary to use pipes of the appropriate diameter.

No. 6. Pumping unsuitable liquids

Such liquids include all liquids for which the Gnome pump is not designed:

- chemically aggressive;

- highly abrasive;

- with particles larger than 5 mm and a density higher than 2.5 thousand kg/m3;

- viscous, with sediment, high temperature, etc.

Pumping such liquids leads to breakdown of many parts of the pump: from the strainer to the electric motor, therefore the use of Gnome electric pumps for fecal wastewater is strictly prohibited. If you need a unit specifically for this purpose, then you will be interested in reading this material.

No. 7. Frequent turning on/off of the pump

When starting the pump, it simultaneously consumes a larger amount of electricity than subsequently during uniform operation. This leads to melting of the windings, and then to overheating of the electric motor.

If the pump is located in a well, then with frequent changes in the water level, the pump can automatically turn off and then turn on. This significantly reduces its working life. For such wells, with changes in water level, they are more suitable surface pumps.

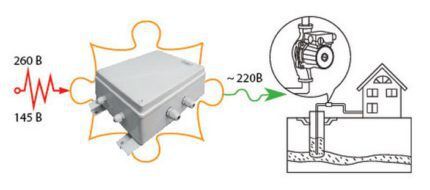

No. 8. Power surges

If the voltage deviates by more than 5-10%, the operating current in the motor windings increases significantly, which leads to overheating. This may be due to an unstable power supply or the wrong cable size being used.

In the first case, purchasing a voltage stabilizer will help, in the second, selecting the optimal cable cross-section depending on the power of the electric motor.

No. 9. Removing the pump by the power cable

Another common cause of submersible pump failure. When pulled by the electrical cable, the seal is broken in the place where the cable connects to the pump body.

This leads to water getting inside the electric motor and causing the unit to fail. The same damage occurs when the Gnome is transported by the cable or when objects fall onto the power cord.

No. 10. Incorrect direction of rotation of the impeller

When starting the pump, you must make sure that the shaft rotates in the right direction. Determining the correct rotation is very simple: when turned on, the pump will rotate in the opposite direction indicated by the arrows on the unit body (or in the picture in the passport).

If the pump rotates in the direction of the arrow, the connection is made incorrectly and the impeller will soon fail. To solve the problem, you need to open the circuit breaker and switch two of the three cable wires, and then check the direction of rotation again.

Troubleshooting and troubleshooting

Before you begin to disassemble the pump and repair it, it is necessary to correctly determine what exactly caused the breakdown. Let's look at the most common symptoms that occur when Gnome pumps malfunction.

The electric pump does not start

Possible causes and methods for eliminating them:

- The impeller is jammed.

- The capacitor in the power supply circuit is faulty.

- Broken electrical circuit, burnt contacts.

- The stator winding has burned out.

- Failure of the electric motor.

- Engine bearing jamming.

- Lack of voltage in the network or interruption in the power supply.

After making sure that there are no problems with the power supply, you need to disconnect the Gnome pump from the power supply and disassemble it to identify the reason why it does not start. Inspect the bearings, impeller, assess the condition of the electric motor windings.

The engine runs, but the pump does not pump water

The Gnome pump motor works, but it does not pump water. The sound of a running engine may be weaker and uneven.

Possible reasons:

- The filter screen or outlet pipe is clogged.

- The engine is running with insufficient power.

- Bearing wear and reduced motor speed.

- There is no pumped liquid or it has become too viscous and dense.

- Damage to the water supply line (pipes, hoses).

In this case, you need to make sure that there is no damage to pipes and hoses and that there is water in the water source. If everything is in order, then you need to disconnect the equipment from the power supply and inspect the inlet filter and outlet pipe.

If necessary, clean them and try to start the pump. If the bearings wear out, they will need to be replaced.

The pump starts and immediately stops

When started, the Gnome pump runs for a few seconds and then turns off spontaneously.

This may be a symptom of the following problems:

- Float switch failure.

- Short circuit in the electric motor circuit.

- The pump overheated and the thermal fuse tripped.

- Extremely low voltage in the electrical network.

- Impeller lock.

- The liquid in which the pump is immersed does not correspond to its operating range (too hot, viscous, high density, etc.).

In this case, it is necessary to disconnect the Gnome electric pump from the network and try to turn it on again after 30-90 minutes, having first made sure that the required voltage is available in the electrical network. This time is enough for the overheated pump to cool down. If the pump stops repeatedly, it must be removed and disassembled to identify and eliminate the malfunction.

The pump works, but the pressure is low

The Gnome pump pumps water, but the water pressure is much lower than it was before.

Possible reasons:

- Leak in the water supply line (hoses, pipes).

- Low voltage in the electrical network.

- Impeller contamination and insufficient rotation speed.

- Incorrect direction of impeller rotation.

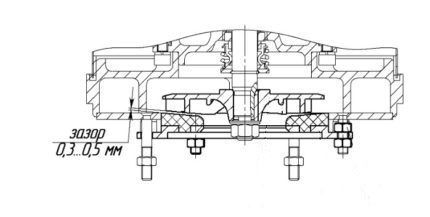

- Large gap between the wheel and the moving disk.

- Impeller wear.

If low pressure is not a consequence of low voltage in the network or a leak in the line, then the pump should be disconnected from the power supply, removed from the pumped liquid and disassembled for inspection and repair work.

When the impeller wears out, it is replaced. If clogged or incorrectly installed after self-assembly, you should disassemble the unit, clean it and install the wheel in the correct position.

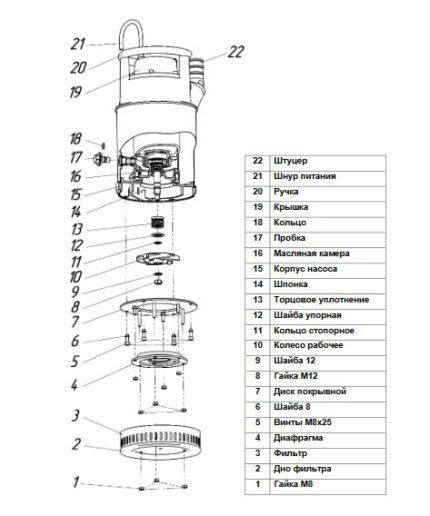

Rules for disassembling the unit

The design of the Gnome pump is very simple, and the housing is quick-release, which allows it to be disassembled without any problems. This does not require special tools. Disassembly begins by unfastening the three nuts of the receiving filter mesh and removing the mesh itself.

Then the nuts securing the cover are unscrewed, and it is removed along with the mounting-moving disk. The impeller nut is unscrewed, after which the wheel is freely removed.

All parts should be removed carefully, without using excessive force. Symmetrical parts must be numbered and marked (left/right, top/bottom) to avoid incorrect reinstallation during assembly. It is recommended to replace the rubber parts with new ones during the assembly process, using repair kits designed for this model.

When using the Gnome pump for a long time, problems may arise with unscrewing the nuts on the body, because they have rusted or become covered with a layer of limescale. In this case, the nuts can be cut off with a grinder, and when assembling, use new ones that are suitable in shape and size.

Repair of pump parts "Gnome"

Having examined the causes of malfunctions in Gnome brand pumps, you can see that almost all problems are solved by replacing the following parts: bearings, impeller, impeller shaft. Also, some malfunctions can be eliminated after adjusting the gap between the impeller and the diaphragm.

Bearing replacement sequence

When the bearings wear out, the pump may pump water but make unusual noises due to the friction and rocking of the worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit. You should not use homemade bearings or analogues from repair kits of other modifications, because this may cause the equipment to fail again in the very near future.

Replacing the impeller

To replace the impeller, it is necessary to disassemble the Gnome electric pump and remove the impeller. Then install a new impeller and reassemble the pump in reverse order. When installing a cover with an adjusting-moving disk, it is necessary to screw the fasteners onto the studs and tighten them simultaneously until the minimum gap between the impeller blades and the cover with the disk is achieved.

After assembly, it is necessary to check for leaks and, if it is broken, then refuse to use the completely damaged electric pump.

In some cases, if you have experience and the appropriate equipment, you can not replace the impeller with a new one, but try to correct the existing ring grooves using surfacing and then processing it on a lathe.

Repair of impeller shaft and housing

If there is damage to the working shaft (bending, crack), it is best to completely replace it. The hull of the "Dwarves" is theoretically subject to repair, but in practice it is almost impossible to do it correctly.

In nine out of ten cases, the seal of the housing will be broken, and this defect can only be corrected at the manufacturer or at a service center.

Considering that such breakdowns occur in pumps that have worked for a considerable period of time, and therefore are not subject to warranty service, it is necessary to think about the feasibility of repairs. In most cases, it is faster, cheaper and easier to purchase a new submersible pump.

Adjusting the gap between the impeller and diaphragm

The main reason for the decrease in pressure and performance of the Gnome electric pump is the increase in the gap between the impeller and the diaphragm during operation. To reduce the gap it is necessary to adjust it.

To do this, you need to remove the bottom of the filter and unscrew the top nut. Then tighten the parts of the diaphragm with nuts located on different sides until it comes into contact with the impeller.

Then unscrew the lower nuts half a turn. With this adjustment, the gap will be 0.3-0.5 mm. The adjusted position of the diaphragm relative to the impeller is secured with the upper nuts. After completing the adjustment, it is necessary to check the ease of rotation of the impeller; it should rotate without any effort.

Repair of the electric motor of the Gnome pump

Gnome brand pumps are equipped with a reliable asynchronous electric motor.Repairing an electric motor on your own is very difficult. The maximum that can be done, without having special stands, is to determine the resistance of the electric motor windings using a household multimeter.

If the resistance indicator approaches infinity, this indicates that the winding is damaged and needs to be replaced. Replacing the winding will require complex disassembly of the electric motor and the presence of a rewinding machine.

But the main difficulty lies in the assembly process - the unit must be assembled in such a way as to provide an impeccable barrier against water penetration into the electric motor. That is why it is better to entrust the repair of the Gnome pump motor to professionals.

Current and major repairs

To avoid malfunctions, it is necessary to carry out timely maintenance of the Gnome electric pump, recommended by the manufacturer.

TO includes:

- oil change every 200-250 hours of operation;

- checking the oil level and quality - 2 times a month;

- flushing the pump with clean water after pumping water with a high content of solid particles;

- adjusting the gap between the impeller and the diaphragm;

- inspection of the housing, bearings, impeller and shaft.

Current repairs of Gnome pumps are carried out when signs of malfunction appear or when the pump is not working.

Major repairs must be carried out after 25 thousand hours of operation. Overhaul begins with disassembling the unit and determining the feasibility of repair work.

Conclusions and useful video on the topic

Video on how to quickly disassemble the Gnome submersible electric pump:

Design and principle of operation of the Gnome pump:

Electric pumps “Gnome” are reliable units for pumping clean and dirty water, capable of serving their owner for more than 25 years. Correct operation and installation, as well as timely maintenance and elimination of causes leading to breakdowns, guarantee uninterrupted operation of the equipment. Most malfunctions of Gnome pumps can be eliminated on your own without the involvement of repair specialists.

If you have already encountered the repair of pumping equipment and have the necessary knowledge or skills, please share with our readers. Leave your comments and questions in the block below.

Everything is described in super detail, as if I were reading the instructions, there is probably less text there. In general, I think that to break an electric pump, you need to try very hard. Our gnome has been working since my first day in the new house: there are no malfunctions, nor any hints of them, except perhaps a little rust.

Use only for its intended purpose, periodically check the filter and do not do anything stupid - everything is as usual. And you definitely don’t need to put it in a well, I would like to see the people who thought of this.

I have been using the Gnome 10-10T submersible pump for three and a half years. During this time, the pump showed its best side.With proper operation, virtually no repairs are required. Although, if necessary, spare parts (bearings, impeller) are always available for free sale or on order from the manufacturer. The most dangerous thing for this pump is running dry. Therefore, it is imperative to include a float switch in the pump starting circuit.

Dear engineers, we need help: the impeller on the Gnome 16-16 pump was worn down, a new one was purchased and installed. Somehow the new wheel got worn down overnight. The water is clean! What could be the reasons for this problem?

Something really doesn’t fit in your story... Overnight, and in clear water... as they say about Stanislavsky’s system: I don’t believe it!

Hello. I'm guessing it's either dry running or an incorrect installation.

Guys, study the swearing part. The wheel was eaten by cavitation. The suction on the pump is clogged. The boiling of the liquid when the pressure decreases at some points of the impeller and then the collapse of these pimples and the cast iron into the hole. It's cool that plastic impellers don't eat like that.

Good afternoon I got a Gnome made in 1979, the model is not known on the nameplate, only the year of manufacture, the rest is not visible. When connected to a 380 W network. It hums but does not turn, I tried to turn the impeller and it turned with force. If you unplug it, it spins without effort. I disassembled the input for the wire, there are 3 red wires from the winding and the terminal to the body. What could be the reason?