Review of the Agidel water pump: device, characteristics + installation specifics

Are you looking for an unpretentious and easy-to-use electric pump for irrigation and water supply of a country house? Agree, it would be good to buy an inexpensive unit that can perform its functions without interruption for many years.

Perhaps you are interested in the Agidel water pump, about which the neighbors in the area spoke flatteringly? But do you doubt its performance and the feasibility of such an acquisition? We will help you get acquainted with this pump in detail - the article describes its characteristics, pros and cons, as well as features of installation and connection to the system.

Operating rules are also given, the implementation of which allows you to repeatedly increase the service life declared by the manufacturer; photographic materials, current diagrams and thematic videos have been selected that reveal the nuances of preparation for launch and the subtleties of regular use.

The content of the article:

Model range and manufacturers

As evidenced by reviews from consumers and specialists, Agidel is truly reliable and durable equipment. Moreover, these electric pumps have long been known to summer residents and gardeners throughout the CIS.

Electric pumps "Agidel" are of the type surface centrifugal pumps and are produced by PromGroup LLC, the successor to the Ufa Aggregate Production Association, which has been producing electric pumps under the Agidel brand for more than 50 years.

Over the years, the design of the pump has not changed fundamentally, except that high-strength polymers instead of alloys began to be used for the manufacture of some parts.

It is worth noting that the Ufa company produces all the components for Agidel electric pumps independently, and the quality of the assembly is highly appreciated by specialists.

The cost of these electric pumps in comparison with imported analogues is 2-5 times lower, and in terms of performance, reliability and durability they are almost inferior to global brands.

The model range of Agidel pumps cannot be called diverse; it contains only two models:

- "Agidel-M" - a small-sized electric pump used to supply water from a shallow depth of up to 8 m and over short distances. Available in vertical, horizontal and universal formats.

- "Agidel-10" - a medium-power, self-priming pump capable of lifting water from a well or borehole up to 7 m deep. Available only in a horizontal version.

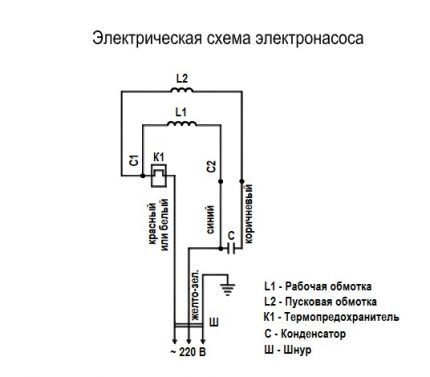

Both options are equipped with a centrifugal-type pumping mechanism, which is driven by a single-phase motor powered by a 220 V power supply.

If we compare both pumps, the “ten” looks more preferable: this unit has 33% more pressure and 14% more productivity, however, energy consumption is 2 times higher than that of the “M” modification.

Perhaps you will find information about the best ten centrifugal pumpspresented on the market.

Technical characteristics of Agidel pumps

Agidel electric pumps can be used for pumping water from open reservoirs, shallow water wells, and wells. The pumps are able to operate for a long time, thanks to the presence of special protection against overheating.

Agidel-M series

The Agidel-M electric pump belongs to the class of small-sized pumps, its weight is 6 kg, and its dimensions are 24x25 cm. The unit is used for pumping water with a temperature of no more than 35º C.

The suction height, characteristic of most modifications of M, does not exceed 8 m. However, if equip the unit with an ejector, then this figure will increase to 15 m.

There must be more than 0.3 m between the bottom of the suction valve and the bottom of the water intake source. Before starting, the pump requires filling with water.

The maximum water pressure created by a pump of this brand is 20 m, productivity is 2.9 m3/hour. Model “M” belongs to the class of economical equipment for pumping water, its power consumption is 370 W. Electrical voltage is 220 V.

Electric pumps of the Agidel brand are not designed to operate at sub-zero temperatures, so insulation is required for operation in winter.

For example, when using well pump arrange an insulated caisson buried below the freezing level of the soil.

Agidel-10 series

Unlike the “M” model, the “Agidel-10” electric pump is a more powerful and large-sized device. Its weight is 9 kg, and its dimensions are 33x19x17 cm. Operation of the unit without filling it with water is prohibited, otherwise the mechanical lip seal will fail.

The suction height of this modification is 7m. The pump provides a maximum design head of 20 m, which is the sum of suction, discharge and pipeline losses.

Productivity is 3.6 m3/hour. Installation method: horizontal. “Ten” consumes exactly twice as much electricity - about 700 W. Operates from a single-phase power supply with a voltage of 220V.

Unlike the previous model "Agidel-10" cannot be equipped with an ejector. The electric pump housing is made of aluminum alloy.

Purpose and scope of application

Surface pumps "Agidel" are popular among summer residents and owners of country houses. The units are installed on a flat surface in special containers, utility rooms or under a canopy to protect them from precipitation and sunlight.

Despite its suitability for working with open reservoirs, it is desirable that the pumped water undergo pre-filtration. For example, when using a unit for pumping water from a well, it is recommended to install a bottom filter.

The scope of application of the pumps is quite limited, but it fully satisfies the needs of the owners:

- autonomous home water supply system;

- irrigation of agricultural crops;

- water supply to water-consuming household appliances;

- filling/pumping of pools and tanks;

- water supply from a well, well, open reservoir.

Agidel pumps are not recommended for pumping water from flooded basements, because... in most cases, the water will contain large suspended particles, which will quickly damage the unit.

Your pump has stopped pumping water and you don’t know what to do? You might find information about repair of the Agidel brand pump.

Design and principle of operation

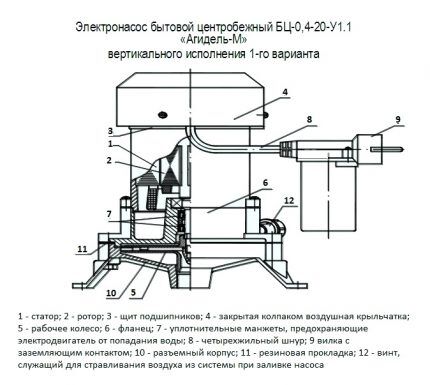

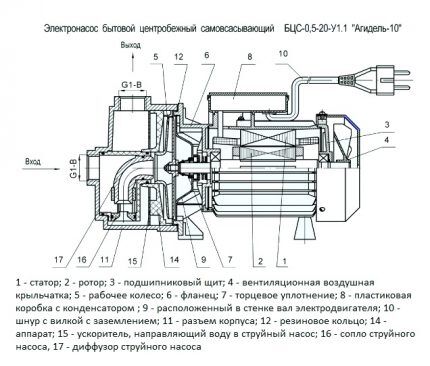

Agidel electric pumps have a simple monoblock design, characteristic of all centrifugal surface pumps.

Since the time of the first version of Agidel-BC, the design of the unit has remained the same, only special protection against overheating has appeared, allowing the pump to be operated without interruption for a long time.

An electric pump marked M consists of two main parts: an electric motor and a centrifugal pump. In the “Ten”, the set of an engine and a centrifugal pump is also supplemented with a jet pump.

It is responsible for ensuring the “self-priming” of water supplied to the system by its centrifugal counterpart.

The electric motor that drives the pump includes a stator with a built-in thermal fuse that protects the winding of the mechanism from overheating.

The electric motor also includes a rotor, bearing shield, and flange. Cooling during operation is carried out by a vane fan, which is closed with a cap.

The operating principle of the pump is based on the action of centrifugal forces, thanks to which the unit provides water supply. The source of centrifugal force is the impeller located on the rotor shaft.

The flange contains cuffs that protect the electric motor from water entering it.

Water enters the pump through the inlet valve, which also serves as a filter that prevents foreign objects (large particles, debris, rock debris, etc.) from entering the pump.

In the Agidel-M model, this valve plays the role of a shut-off valve when priming the pump before starting.

The housing connector and flange are sealed with a rubber gasket. Model “M” is additionally equipped with an air bleed screw. To install the pump in a vertical position, the housing has mounting holes. Holes in the rack are used for horizontal placement.

Operation of Agidel pumps

When installing pumps, three conditions must be met:

- Installation and operation must be carried out at positive ambient temperatures.

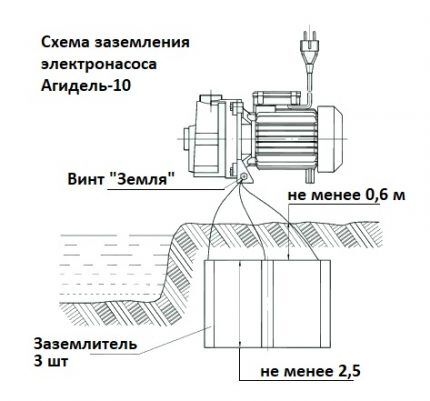

- It is prohibited to operate Agidel units without a grounding device.

- The pump must be installed on a flat surface.

It is recommended to reduce the distance between the water intake source and the pump machine. The smaller it is, the more efficient the pumping is.

In addition, the unit requires reliable protection from precipitation and from direct exposure to sunlight that heats the housing.

The best option would be to install an insulated caisson or a special container for the pump. If winter operation is planned, then it is necessary to insulate the place where it will be located.

It’s good if you can install it in the basement or utility room of the house. However, it is necessary to understand that the unit will be removed from the place of water intake, which means its pressure characteristics will decrease.

Rule #1 - preparing the pump for operation

The most important thing in the preparatory work is to install the pump so that water does not get into the electric motor. Before starting the pump, it is necessary to check the foot valve by pouring 500 ml of water into it.

If the slightest leak is detected from the drainage hole in the flange of the unit, work should be stopped, the pump should be disassembled and the sealing cuffs should be replaced.

All connections of the Agidel electric pump must be sealed. The connecting points between the valve and nipple with the hoses connected to them must be tightened with clamps, or at least with wire.

For threaded connections, it is recommended to use FUM tape, flax tow, and TangitUnilok sealing thread.

It is recommended to think over an installation scheme with a minimum number of connection points. The connection should not be subjected to frequent dismantling, because in this case, its tightness is lost.

The connection of the water pipe to the inlet valve must be done using a rubber hose with a wall thickness of at least 4 mm and an internal diameter of 25-30 mm.

The socket for connecting the pump to the electrical network must be installed indoors or under a canopy. The electric pump must be grounded!

Rule #2 - fill with water before starting

The Agidel-M pump must be filled with water before each start-up. The point of priming is to squeeze air out of the pump through the shut-off valve and fill it with working fluid.

Pour 1.5 liters of clean water through the funnel provided for pouring in 4 - 5 minutes. before the start.

Filling water into the electric pump can be done using a vacuum pump or an ejector. In this case, air pumping continues until the equipment begins to pump water.

This is a rather labor-intensive method, usually used only for large pumping stations, but it can also be used for Agidel electric pumps.

When filling modifications with the letter M, it is better to give preference to schemes that exclude the possibility of air being sucked in through the funnel.

When using filling schemes with the possibility of suction, it should be taken into account that when the water level in the funnel decreases, it can cause air suction, which will cause the unit to immediately stop working.

Rule #3 - safety precautions during operation

Correct operation of Agidel electric pumps comes down to compliance with the following manufacturer’s recommendations and electrical safety standards.

Let's look at them in more detail:

- A surface centrifugal pump cannot be used at great depths.

- Dry running must not be allowed, i.e. operation without preliminary filling.

- It is necessary to carefully protect the electric motor from water getting into it, because... this will immediately lead to its failure.

- The electric pump must not be allowed to operate without grounding.

- Do not touch the body of a running unit.

- Do not use the electric pump for pumping chemical media.

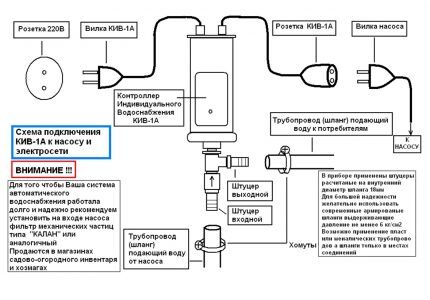

To ensure smooth start and stop, the Agidel pump can be equipped with an individual water supply controller (IW), which reduces the risk of electric motor overheating, warns water hammer in the system.

Rule #4 - Perform Maintenance

The manufacturer determines the service life of Agidel electric pumps to be 5 years. Of course, if all connection and operation rules are followed, as well as safety precautions, the pump can last much longer.

Throughout their service life, Agidel pumps do not require special maintenance.

When using the pump as a pump for summer irrigation and periodic water supply to the house, at the end of the season it is necessary to disassemble the electric pump to clean the fan and operating shaft from adhering dirt and deposits.

It is also necessary to lubricate the rubbing parts. Winter storage of the pump is carried out in a dry place at above-zero temperatures.

Failures of Agidel pumps usually occur after 5 years of operation and are associated with a ruptured hose or wear of the seal. In the first case, the hose is replaced with a new one, and in the second, the oil seal is changed using a repair kit.

Advantages and disadvantages of Agidel pumps

The Agidel centrifugal surface electric pump is a reliable unit used for irrigation or for supplying water from a source to a water consumer.

Pumps "Agidel-M" and "Agidel-10" have many advantages:

- low cost;

- ease of maintenance and operation;

- maintainability;

- low power consumption, especially the “M” model;

- electrical safety;

- reliability, durability.

The disadvantages of Agidel electric pumps include the inability to use at a depth of more than 7 m (10 m) and the need to be located near a water source.

Please note that there are currently many counterfeits of Chinese-made Agidel pumps; the body of such units is made of plastic, and the build quality is very low.

Conclusions and useful video on the topic

Preparing for operation and starting the Agidel-M pump:

Video review of the Agidel-M pump (interview with the manufacturer):

Russian-made Agidel pumps are inexpensive and reliable units that are perfect for seasonal use. Electric pumps have both their advantages and disadvantages.

When choosing a pump, it is recommended to immediately think about its location, because... excessive distance from the water source significantly reduces productivity and pressure. If all installation and operation rules are followed, the Agidel pump can last at least 20 years.

Do you use an Agidel pumping unit at your dacha? Or are you just planning to buy this pump, but have questions? Feel free to ask your questions in the comments to this article.

The Agidel water pump is a normal pump. The advantages include good performance, long-term operation without breakdowns, and most importantly, its cost, which is significantly lower than the price range of foreign water pumps. If you do not have enough money to buy a water pump from a foreign manufacturer, then this equipment will be a good option.

I have been using the Agidel pump for 6 years. But in the information you provided there is no such model. I have a submersible model. All the pumps that were there before burned out in the second year, but this one is still in service. Its power is enough for about 40 meters with a height difference of up to 10 meters.Can pump contaminated water without losing performance. I think that other modifications should be no worse.

I’m choosing between the Agidel pump and the Chinese one, the price is about the same. If the only disadvantage it has is the inability to work below 7 meters, then I will buy it. The Chinese have less faith.

Between “Agidel” and the Chinese one, definitely choose our pump. Yes, the Chinese have learned to do some things well and “Chinese quality” no longer has a uniquely negative connotation, but this does not apply to pumps yet. No matter how many water pumps they made, I have seen them all break down quickly.

Of course, if you choose between Agidel and a Chinese manufacturer, it is better to choose our production. But you should understand that this is a budget model, which means that it will not be without some significant drawbacks.

I know what I’m talking about, because I’ve had Agidel-10 working at my dacha for quite a long time. Firstly, you need to monitor the condition of the oil seal - this is very good advice. If it cracks, water will enter the pump. But what I don’t understand is why they don’t make the shaft out of stainless steel so that it doesn’t wear out so quickly (and surprise, surprise, the seal cracks because of this).

The crimping here is standard, although in an interview with the manufacturer it is said that all connections are soldered.

Hello: “Feed – 0.4×10-3m3/s head 20-2m” how do you understand this? (Please)

Supply is the amount of water per unit of time - in your case - 0.4 liters per second, pressure - the pressure at the pump outlet - 2 atmospheres, i.e.water can be raised to a height of 20 meters if sucked from a barrel, and if from a lake and the pump is located 3 meters above its surface, then these 3 meters must be subtracted from 20 meters and water can only be supplied to a height of 17 meters from the pump level.

Yours is not true! There was an excellent Chinese pump BC-1 “Aquarius-1”. 7 years without service in the home water supply system (drowned during a sharp rise in groundwater after a rainstorm. He stood in the basement. No one thought that the water would rise so high). Now there are similar ones in appearance and they are also called BC-1. But the brand is different. I don't know anything about them. And “Aquarius-1” was the most reliable pump. At the same time, “Aquarius-2” is complete shit (analogous to Agidel). When used for irrigation, water flowed into the hut (into the cavity of the windings) within a month. Replaced under warranty - same result. As a result, the seller gave out “Aquarius-1” in return, which worked for 7 years. And if it weren’t for the flood, I would have worked for another three years. I disassembled it, looked at the condition of the mechanical seal, bearings... At least three years with my mode of use it would have been plowed...

Thank you very much, your instructions were very helpful in servicing the Soviet-made Agidel pump. It worked for about 30 seasons, and the reason why I was looking into it was because the wire through which power is supplied to the windings was cracked and oxidized.

Good afternoon. I have an Agidel-M pump. Is it possible to connect automation (pressure switch) to it? Thank you!

No

The automation can be connected to any pump.

Where are the number of revolutions? There is not

My pump from the USSR times, which still works, has 1500 rpm.

An excellent pump, repairable, lasts a long time, 2 more Soviet ones. Who can tell me what capacity is the capacitor on Agidel-M?

Hello. We have an Agidel pump in the village, installed under the house, in the underground. Tell me, please, is it possible to connect something so that there is hot water in the house?