DIY LG washing machine repair: frequent breakdowns and instructions for fixing them

South Korean washing equipment from the LG brand is very popular due to its reliability and functionality.It contains complex technical components and simple parts that you can replace yourself. It is not necessary to immediately run to the service center after detecting irregularities in operation. After all, saving where you don’t have to spend is always useful, right?

Those who want to repair an LG washing machine with their own hands will learn from us all about common types of breakdowns and methods of dealing with problems in the operation of the washing machine. With our help, independent repairmen will solve any technical problem without any problems or difficulties.

The article presented to your attention thoroughly examines the types of problems that occur when using LG machines. Options for eliminating them are described, taking into account the manufacturer’s recommendations and design features. Visual videos and photo applications will assist in mastering a difficult topic.

The content of the article:

Operating principle of the washing machine

What does a washing machine do? In fact, it pours water into the body, heats it and spins a drum filled with dirty laundry. This happens in a certain way, which ultimately leads to cleaning the laundry from dirt.

Now a little more detail. As soon as the washing program is started, the first thing to do is open the water supply valve. Water flows through the dispenser into the tank.

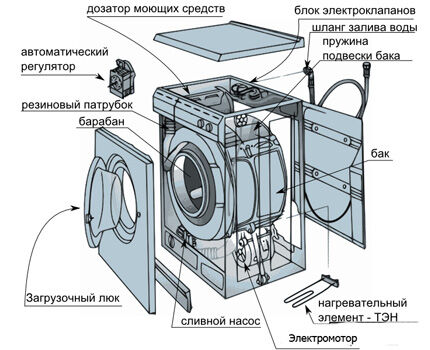

Important parts of the machine you need to know:

- Dispenser - drawer for detergents.

- Tank — a plastic container in which there is a drum and a heating element (heating element). Water is poured into it.

- Pressostat - aka pressure switch. Monitors the water level in washing machines.

- heating element — tubular electric heater. Heats the water.

The pressure switch gives the signal to stop the water supply as soon as the required volume is reached. Then the heating element is turned on. There is always a water temperature sensor next to the heating element (thermostat). As soon as he reports that the water has heated up strictly to the required temperature, the motor comes into play and rotates the drum.

Towards the end of the wash it starts working water pump - this is what is most often called the water drain pump. This is where the “production cycle” of the washing machine ends and the analysis of typical faults of LG brand machines begins with it.

Common types of breakdowns

The components of a washing machine are electromechanical devices that move under the influence of current. They work under load and are exposed to tap water and temperature changes.

Here is a list of what can break:

- electric door lock;

- fill valve;

- pressure switch;

- heating element;

- temperature sensor;

- electric motor;

- speed sensor (“Hall sensor”);

- drum bearings;

- water pump;

- electrician (wire connections);

- seals and hoses.

If the machine has drying and steam processing functions, then several more items are added: a steam generator, an air heater, a fan, an air temperature sensor.

But the most popular reasons for calling service centers are the failure of the pump, heating element, fill valve, pressure switch, electrics and bearings.

Generally LG washing machines They are very reliable and, compared to other brands common in Russia, they break down much less often.

Diagnostics and repair of main machine components

Washing machines are not fundamentally different from each other. The descriptions given here will help you navigate their design (even if your machine is not LG).

The first stage of repair work is diagnostics. You should not start replacing parts without being completely sure of the cause of the breakdown. The failure of one or another element is signaled by special signs. New generation machines have a system hint codes, which help determine the location and cause of the failure.

For most operations, a Phillips screwdriver will suffice. In some cases, pliers and wire cutters will help, but in others you will have to use wrenches and sockets 10 and 14. For more complex repairs (for example, replacing bearings), you will need more cunning devices.

To make the task easier, it is recommended to take paper tape and markers. Before disconnecting the wires, mark them with tape labels with different colored numbers. Take a photo so you can be sure to assemble it correctly later.

Most components and individual devices of the washing machine cannot be repaired. For example, when it burns out heating element, it needs to be changed entirely. To find a suitable model for sale, find out the model number of your car (“Model No") and its serial number ("S/No" or "Serial No"). They are written on a sticker or plate. Look for it on the body: under the drum door, behind, on the side.

Before installing a new part, make sure to turn off the plug again. Many units operate on deadly 220 volts.

Replacing the drain pump according to the rules

The washing machine does not drain water, the display shows an error code "OE". It's simple - it's a pump, and it's not necessarily broken.

Usually, during draining, a characteristic sound is clearly heard - the pump impeller is rotating. You can see it in action without even disassembling the car. To do this, you need to open the large round plug - it is located in the lower right corner, under the hatch or plastic panel with latches. Be careful: water will flow!

Even if the impeller does not spin, it could simply be clogged. First thing drain the water. Near the large round plug you may find a thin tube closed with a small plug. Using a large flat container, carefully pull out the tube and open it. And be patient.

Another way to drain the water is to lower the drain hose to floor level. Most likely it is secured with clips on the back wall. When the tank is empty, you can safely open the pump cap and take out everything foreign that you find there.

It is possible that all the problems were associated only with a clogged drain system. It will just need to be cleaned, for which detailed video instructions will help:

If the pump does break, you will have to disassemble the car a little:

- Remove the plug from the outlet.

- Take out the dispenser. You will need to tilt the machine, and there is usually water left in the dispenser that can spill.

- Remove the bottom plastic panel. It is secured with two self-tapping screws and latches around the perimeter.

- Tilt the machine or place it on its left side (the pump is usually on the right).

Now you can test the pump multimeter and remove it. Even if it works electrical circuit, the pump could be worn out mechanically. In such cases, the machine does not always agree to drain the water, and the impeller may dangle on its axis.

So, you've diagnosed a pump problem or you're not sure it's working. You can take the device to a home appliance service to be sure to find out if it is working properly.

If you are sure that washing machine pump is faulty - change it, for this:

- Remove the dispenser - there may be water left in it.

- Remove the bottom plastic panel: unscrew the two screws and carefully pry up the edges, starting from the top. It is better to do this with a chisel than with a screwdriver - there will be less damage.

- Place the car on its left side.

Wires and hoses are connected to the pump. The wiring terminals are pulled out by hand (don't forget to mark and photograph them). To remove the hoses, you need to loosen the clamps with your fingers or pliers.When everything is turned off, unscrew the three screws around the filter plug.

You may not find the exact same part for sale. But there are very few types of drain pumps, and almost each one fits dozens of different models of washing machines. Perhaps the easiest way is to contact your nearest service center for a new spare part.

Before installing the new pump, clean off any dirt and deposits. These can greatly affect the life of the impeller.

It will be more convenient to first screw the pump with self-tapping screws, then connect the hoses and wires. Don't forget to close the cap. Place the machine in place and run the shortest cycle “idle”, for example, “Rinse and spin" After making sure that everything works, you can finally assemble the car.

Installing a new water heater

Error code - "HE". Another sign is that the door glass is cold, while according to the program the water should be 40°C.

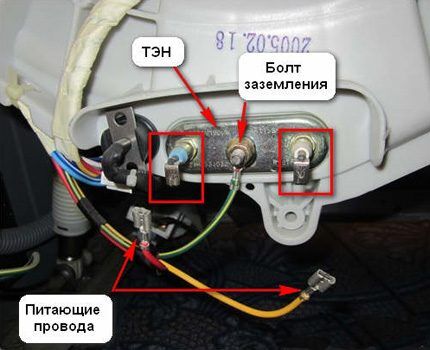

To make sure that water heating device - heating element is faulty, you need to remove the back cover, for this you will need a Phillips screwdriver. First, remove the plug from the socket, then unscrew the four screws and pull the cover up slightly.

The heating element is located at the very bottom of the tank, three wires go to it. The middle one is grounding, and the extreme ones are power, 220 volts. Disconnect these terminals and check the heater multimeter.

Disconnect the wires. To extract heating element, you need to unscrew the nut in the middle and “sink” the stud. Using a screwdriver, pull out the heater as far as possible.

Now remove the rubber seal by prying up its edges with a flat-head screwdriver. Do not touch the edges of the hole with it! The slightest notches will break the seal.

The new heating element is sold complete with a seal. When buying it, you will probably notice the absence of an internal elastic band: do not let this bother you. It formed over time as the seal was sandwiched between the heater and the inner plate.

Your heater may have a built-in temperature sensor. If it is working properly, then it is not necessary to change it. There is a bracket inside the tank - the heater must fit into it. After inserting it all the way, rotate the drum by hand. If a scraping sound is heard, the heating element has passed above the bracket.

There is also a danger of missing lower, and then the tank will suffer from the high temperature. Now tighten the nut, but without much effort. Pour water into the tank. You can directly through the drum, for example, from the shower. Make sure that the seal does not leak, if necessary, tighten the nut slightly.

Professional guidance on replacing the heating element is presented in the video:

Fill Valve Repair Options

Intake valve problems can manifest themselves in a variety of ways.

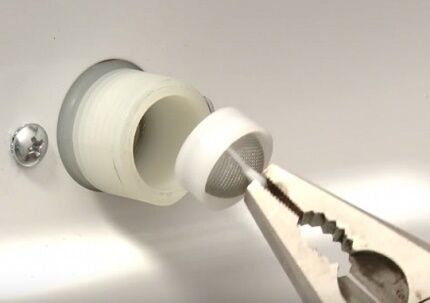

Problem #1. The water is drawn slowly, the powder in the dispenser is not completely washed off. Maybe the weak water pressure is to blame. If not, it means the filter is clogged.

- Turn off the water supply to the washing machine.

- Unscrew the inlet hose directly at the entrance to the machine.

- Use pliers to remove the filter.

Most likely, the plastic mesh is clogged. It can be cleaned with a toothpick under running water.

Problem #2. Water is not being collected. An error code may appear "IE".

First check the filter as described in the previous paragraph. If cleaning doesn't help, you need to get to the valve and check it with a multimeter. To do this, unplug the plug from the socket and remove the top cover - it is secured with two screws at the back. After unscrewing them, move the cover back a little, and then it will come off without effort.

Double check that the power cord is not plugged in. Now disconnect the terminals from the valves. Use a multimeter to check the resistance: it should be between 2.5 - 4 kOhm.

Problem #3. The machine does not wash, but water is bubbling inside. There is no point in checking the electrical part of the valves - this is mechanical wear. The valve is not a very expensive part and is not usually repaired. Just in case, mark the wires and take pictures of how they were. Replacement procedure:

- Remove the plug from the socket (most often 220 volts are supplied to the valves).

- Turn off the water.

- Remove the top cover by unscrewing the two screws on the back and sliding it back a little.

- Disconnect wires and hoses from valves.

The valve is secured with self-tapping screws or special latches. In the second case, you need to turn it while simultaneously pressing on the plastic protrusions from the outside. There shouldn't be any difficulties installing a new spare part.

Replacing the pressure switch yourself

When it fails pressure switch, the machine takes in too much water. It happens that water is constantly being collected and drained at the same time. Sometimes a breakdown of this sensor manifests itself in poorly wrung out laundry. The display may show an error code "PE".

Removing this sensor is easy. Unplug the plug from the socket, remove the top cover by unscrewing the two screws on the back and sliding it back a little.

It is attached with one self-tapping screw. First disconnect the terminal, then remove the sensor, and finally disconnect the hose from it. To check pressure switch, you need to blow into it. In good condition pressure switch you will hear a click. Install new pressure switch in reverse order.

Recommendations for electrical repairs

The hardest thing to diagnose is wiring problems. The washing machine's electrician is responsible for the operation of all systems, and contact failures lead to a variety of consequences.

If you're not sure what's wrong, check the electrical system. Remove the plug from the outlet and open the back and top covers. You can remove the bottom plastic panel if there are problems with the drain.

Systematically inspect all wires and their connections:

- The terminals must be clean and shiny.

- The color of the wire insulation should be bright and uniform.

- Water should not get on wires and contacts.

When inspecting the inside of the washer, you may find problems with the wiring.

It can be:

- oxidized contacts (white or green rough coating);

- darkened or whitened insulation;

- partially destroyed, cracked or burnt insulation;

- wet contacts.

If water gets on the contacts, they need to be wiped or dried. Be sure to fix any leaks. It is not enough to clean oxidized terminals. Perhaps they are constantly exposed to moisture, so you will have to find and eliminate the cause.

It is better to replace oxidized contacts. If possible, locate the opposite end of this wire and replace the entire wire. For such repairs, you will have to make friends with a 60-watt soldering iron. You can clean the contact as a temporary measure, but inspect again after a couple of weeks.

If the insulation is damaged, the wire definitely requires replacement. Darkened insulation is also a sign of poor contact and, as a result, overheating of the wire. Sooner or later the insulation will melt, causing a short circuit and fire.

Bearing replacement instructions

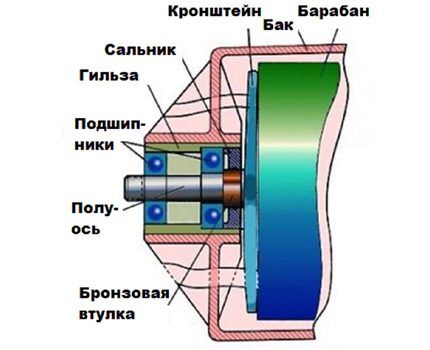

These are perhaps the biggest workers in the washing machine. They bear the entire load of rotating wet laundry and the weight of the drum. A damaged bearing can be heard immediately: an unpleasant hum appears, especially loud during spin cycles.

The bearings are protected from water by a seal, which can also wear out. In this case, water will seep into the bearings, and then they will face a slow but certain death. Humming is a completely reliable indicator. As soon as it appears, start repairing it without delay. Delay can lead to more costly consequences.

The most complex of the operations described here is bearing replacement. But by ignoring the buzz, you risk complicating things even more.

Due to damaged bearings, the drum rotates with difficulty. The bearings begin to break the tank and the power element of the drum - the cross. There is a possibility that the bearings have begun to rust due to wear of the seal. In this case, water from the tank will flow onto the engine. Imagine the consequences.

To replace the bearings you need to disassemble almost the entire machine. The idea is to remove the tank, disassemble it and remove the drum from it.

In addition to screwdrivers, you will need:

- head at 10;

- key or head 14;

- pliers;

- wire cutters;

- wiring clamps (polypropylene ties);

- simple silicone sealant (not glue!).

Gloves and a flashlight will also help a lot.

Remove the plug from the outlet. Remove the back panel and disconnect the wires going to the motor and heater. Remove all the fasteners that secure the wires to the tank, cut the clamps with wire cutters. The tank itself hangs on two springs and is supported from below by two shock absorbers.

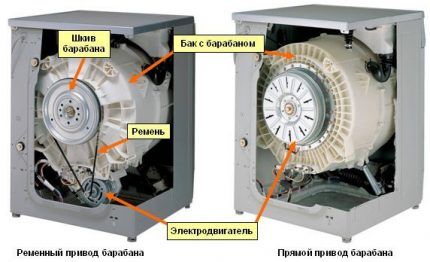

Most likely you have a direct drive machine. So, you'll have to remove it washing machine motor. Unscrew the center screw while holding the drum with your hand.

Be careful not to cut yourself on the edge of the case.Remove the rotor (the moving part of the motor), then unscrew and remove the stator (respectively, the stationary part).

There is a large elastic cuff around the hatch into which the laundry is loaded. It is wrapped around a clamp with a spring. Find this spring and, using a screwdriver, remove the clamp.

After removing the clamp, proceed as follows:

- Now you can remove the front panel. It is held in place by self-tapping screws along the top and bottom edges. Pull the panel up slightly. Disconnect the wires going to the lock.

- Remove the pipes from below (water may remain inside!) and the thin hose going up to the pressure switch.

- Remove the jumper that supported the front edge of the top cover.

- Remove the dispenser and fill valve.

- Using a 10mm socket, unscrew the counterweights - one on top and two in front.

All that remains is to disconnect the shock absorbers. They are secured with plastic pins; press the spring latches on the pointed ends of the pins and remove them (you can use pliers).

Make sure you disconnect everything. Now you can lift the tank and unhook the springs. Carefully pull the tank forward. Don't forget that there is a water level control tube screwed to the bottom, which can be accidentally broken. For peace of mind, you can remove it.

Next, it will be more convenient to work on the table. At this stage, you need to disassemble the tank and remove the oil seal and bearings from it. The tank consists of two parts, twisted with self-tapping screws under the head 10. Disassemble the tank.

The drum is simply removed from the rear half of the tank without much difficulty. Next, we only need the rear half (forecastle).When working with it, remember about the heating element - do not bend or break it.

In the center of the forecastle, on the inside, you will see an oil seal. It also definitely needs to be replaced. It will not be difficult to pull it out using something as a lever (for example, a flat-head screwdriver). Place the forecastle with the outer side up and insert a punch through the outer bearing - first knock out the inner one.

Strike carefully! If the bearing becomes misaligned, it can damage the forecastle. The blows should not be strong. Alternate the places of impact according to the “criss-cross” principle: first hit the left edge, then the right, then the top, then the bottom, and so on in the same order. Make sure that the bearing comes out smoothly, without distortions.

The outer bearing is knocked out using the same principle, only the forecastle needs to be turned over and supported so that the bearing “hangs” above the table.

Installing new bearings and seals requires even more care. You can only hit the outer ring of the bearing. Using a punch, constantly check that the bearing is not warped.

A comprehensive instruction on replacing bearings with all the nuances will be presented in the video:

You should also install the new oil seal carefully - it can be easily bent. Don't try to straighten it, better buy another one.

The slightest mistakes when installing these parts will lead to leakage - water will get onto the bearings and then onto the engine.Before assembly, try to clean the drum axle. Do not scratch it or use sandpaper.

The drum should fit easily into the bearings. Before assembling the tank, apply silicone sealant to the joint. When connecting forecastles, make sure that heating element fell into the bracket intended for it. Do not overtighten the screws - this is not necessary. Thanks to the sealant, the connection will be quite reliable.

Screw the water level control tube to the tank. Next, you just have to assemble the car. There shouldn't be any difficulties. It is more convenient to work in this order:

- Hang the tank on the springs and attach the shock absorbers.

- Connect the hose pressure switch and secure it to the tank. The “extra” length of the hose should remain at the top.

- Install counterweights.

- Connect the lower pipes.

- Screw the motor stator, connect the connectors to the stator and heating element, secure the wires with clamps and brackets.

- Install the dispenser and fill valve, connect the pipes and wires.

- Screw on the top front bridge.

- Install the large front panel after connecting the lock connector.

- Pull out the edge of the cuff and place it on the edge around the hatch. Place the collar on the cuff.

- Install the motor rotor (or pulley). While tightening the center screw, hold the tank with your hand from the front.

- Connect the wires to the top panel and install it.

Check again that everything is connected and secured.

Before installing the remaining panels, you can run a short dry program to check the tightness of all connections.Once the machine is in place, level it.

Conclusions and useful video on the topic

Replacing spare parts in a washing machine is a responsible undertaking. To take into account all the nuances and perform the work perfectly, we suggest studying useful information on the nuances of assembling and disassembling an LG machine, presented in the video:

So, you have become familiar with the most common malfunctions of LG washing machines. Repairing them with your own hands is not always easy, but it is quite possible. Try it! Good luck with your renovation!

Please leave comments in the block form below, ask questions and post photos on the topic of the article. Tell us about how you repaired a washing machine with your own hands. Share useful information and technological nuances you know that will be useful to site visitors.

Repairing a washing machine in a workshop for our friends was very expensive. Therefore, when ours broke down, my wife was in a panic, first because unforeseen expenses were planned, and then because I was going to fix it myself, even though I had never done anything like that before. But the machine is 10 years old, and I decided to practice on it, in case it was time to buy a new one. But it stopped heating the water, and I assumed that the heating element had failed. In short, nothing was complicated, I replaced the heater, and the machine is working again. And the wife was already dreaming about a new one.

And I, too, used to take broken household appliances to a repair shop, but now I “go” to the Internet for guidance on what to do. I learned how to repair our bread machine myself, which has a sore spot - the graphite bushing. Wears out quickly from constant rotation of the stirrer. By the way, I also order bushings on the Internet.The electric kettle also had to be revived.

I think if I have to repair a washing machine, I can handle it too. There would be a desire. How did we live without the Internet before? And now we constantly learn something new. Live and learn.

Thanks a lot. They helped a lot. They didn’t write a 17-socket wrench for removing the drum and how to release the latches on the electrical connectors (especially under the engine rotor).

I really liked it. Well told and shown. Thank you. I have one question for you: the drum rotates by hand easily, without any extraneous sounds, and when I turn on a quick wash or rinse and spin, water is drawn in as the tank turns. The tank first rotates, and then begins to stumble. Either one way or the other, and ultimately a failure. The 2 lights for super rinse and intensive wash light up and blink. After turning it on again, I press the spin button. I turn on the starter and the water is pumped out perfectly. I have a LG 5kg direct drive washing machine.

During washing, when switching to another mode, grinding and extraneous sounds occur

Hello. My washing machine was overheating the water, I realized that it was time for me to replace the heating element. I did everything as shown in the video, everything was fine. But I ran into a problem: it still doesn’t heat the water. Maybe you can recommend something?

It was an analogous situation! Replacing the sensor helped! Moreover, we simply removed the sensor from the old burnt out heater and installed it. Now everything works correctly!

Hello. LG 6 washing machine. After moving, it stopped turning on. When you press the START button, the indicators do not turn on, and relay clicks are periodically heard.The red indicator on the control board lights up. What could it be?

I have had. The relay clicks, but the drum does not rotate. Fault in the electronics unit. All power circuits are a complete mess! To get to the installation, I had to cut out the bottom of the plastic trough with the printed circuit board and clean off all the compound. Each pin was stripped to a shine and then tinned. Everything has been working fine for a year now. Machine LG WD-8050F

I'm looking for a service manual for the LG WD-1014C washing machine. And it would be nice to have an electrical diagram. Maybe someone can help.

Hello. It is not technically possible to check the profitability of the file now, but try this https://yadi.sk/d/j1xf7zDEfqxrLw

Also try asking a related question here https://www.lg.com/ru/support/support-product/lg-WD-1014C

There was an error se, the Hall sensor failed, the drum twitched and did not rotate. I removed the sensor, picked out the glue that had been poured in, two 680 Ohm resistors burned out, they are in parallel, resoldered them, filled them with rubber sealant, put them back, everything works like clockwork. Direct drive machine, 9 years from date of purchase.

Can you tell me where this board is located?

The pump stopped working, I could not fully determine the cause of the failure - either the wiring or the pump itself. I would like to know what voltage is supplied to the pump, constant or alternating and what voltage?

Variable, 220V.

LG WD80164 NP: turn on, select a program, start...and then the light music starts, the indicators go out cyclically and light up again, after the lock lock is triggered, the 75 Ohm resistor in the triac circuit burns out, which supplies power to the lock. I suspect the current protection is triggered.

Question:

1. What resistance should the heater have on the lock.

2. What other reasons could there be for this machine’s behavior?

where can I get an electrical diagram for it???

The LG WD-8022C washing machine has been in operation for 18 years - at the beginning of operation it was necessary to solder the busbars of the control unit board - in 2019 - repair of shock absorbers based on recommendations from the Internet. Now the initial switch-on is difficult - after 15-25 plug-ins of the power cord, the indication turns on and the entire washing cycle is successful. I suspect capacitors in the power supply circuits. I'm looking for a wiring diagram for the machine. Has anyone had a similar problem, please tell me.

I need a schematic for LG