Electromagnetic starter 380V: device, connection rules and recommendations for selection

An electromagnetic starter is a device that is very often a component of electrical circuits.As a rule, a 380V three-phase electromagnetic starter is used in electric motor control circuits. However, in addition to switching electric motor circuits, the same element can be successfully used for other purposes.

Let's consider a typical device and operating principle of an electrical appliance. In addition, we will outline the criteria for choosing a starter, decipher its markings and describe the nuances of connecting an EMF to an electrical circuit.

The content of the article:

EMF design features

The design of an electromagnetic starter (EMF) is not highly complex. But this factor does not in any way reduce the reliability of the device.

How does this device work?

The reliability criterion is, for the most part, established by the correct connection of the circuits and the precise selection of the load.

If these criteria are met, the device will operate flawlessly for a long time in most cases.

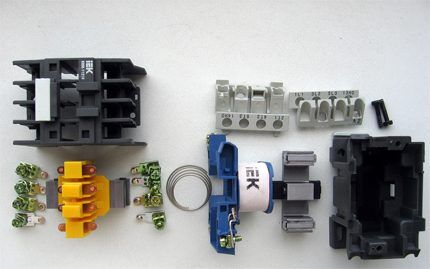

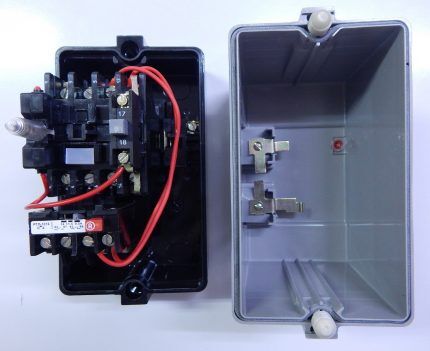

The classic version includes the following elements:

- The body is dismountable in two halves.

- Inductor.

- Magnetic core.

- Switching mobile chassis.

- Group of main contacts.

- Group of auxiliary contacts.

The element of the magnetic starter, responsible for organizing the switching of the power circuit, is a movable chassis combined with one part (moving) of the magnetic circuit.

The chassis itself is made of dielectric material, and metal (brass) plates are used as closing contacts. At the ends of the plates there are contact patches made of refractory metals, usually a silver alloy.

The fixed part of the magnetic circuit is rigidly mounted inside the second half of the electromagnetic starter housing. An inductance coil is placed on this part of the magnetic circuit and a return spring is installed.

The second part of the device body is also equipped with contacts for power and auxiliary groups. These contacts are rigidly fixed to the housing using screws.

The design of a standard magnetic starter involves combining two halves of the housing, as a result of which the two halves of the W-shaped magnetic circuit are also combined into a single structure.

At the same time, due to the return spring, a small gap remains between the halves of the magnetic circuit; the main contact groups in this position remain broken.

Operating principle of EMF

The operating principle of the device is based on the effect of electromagnetic induction. If there is no voltage on the coil located inside the starter, the magnetic circuit remains in the “with gap” position, the main contacts are broken.

When an electric current is passed through the coil, under the influence of a magnetic field, the second (moving) part of the magnetic circuit overcomes the force of the spring and is attracted to the first (fixed) part.

Accordingly, the main contact groups of the starter are closed by the plates of the movable chassis.

The reverse process is obvious - when the voltage is removed from the terminals of the inductor, the magnetic field ceases to operate, and under the force of the return spring, the movable chassis and the second part of the magnetic circuit are repelled. Accordingly, the magnetic starter returns to the contact-break state.

It should be noted that based on the configuration of the electrical device, the circuit of contact groups can have a very different structure. Especially regarding auxiliary contacts, which may be in a closed or open state in contrast to the state of the main contacts of the device.

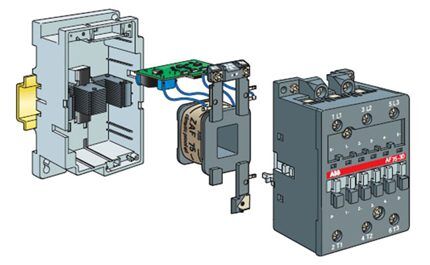

A feature of modern designs of magnetic starters is the modernization of the inductor control circuit.

If the design of previous “outdated” devices involved direct supply of voltage to a coil taken from one of the phases, electronic circuits are now increasingly used.

For example, products from a well-known company "ABB" are equipped with an electronic circuit for stabilizing the voltage supplied to the inductor terminal of the magnetic starter.

Controlling the coil through an electronic circuit is characterized by the fact that the alternating voltage is first rectified and then a pulse signal is generated. This approach provides increased service life and improved stability of operation.

How to choose the right electromagnetic starter

Considering the somewhat wide range of products of this kind that are present on the commercial market, selection rules become more than relevant for the end user.

Technical parameters of the device

Accurate and correct selection of a 380-volt magnetic starter, for example, for an electric motor, will ensure uninterrupted operation of the motor, and most importantly, the safety of the electrical system.

A specific device is selected, of course, based on the technical and operational parameters of the load expected to be connected. The product’s belonging to a particular brand also has a significant impact on the right choice.

It should be noted that there is a fairly high percentage of low quality products on the market. Therefore, the brand, in this case, is an important selection criterion.

Marking and type of fastening of products

Each device, at least branded, has appropriate markings directly on the body. Based on the technical information contained in the marking, it is enough to simply select a switching device in exact accordance with the required parameters.

So, switching devices from the same company "ABB" have approximately the following marking system:

A-26-30-10

The encoding string is decrypted as follows:

- «A" — the letter designation indicates the type of device;

- «26» — the second digital marker determines the rated current in amperes;

- «30» — the third designation indicates the number of power contacts;

- «10» — the last number characterizes the number of auxiliary contacts.

At the same time, the separation of numbers is characteristic of the last two positions of the list. That is, if the number “30” is indicated, this means the presence of three (3) normally open contacts and the absence (0) of normally closed contacts.

There is a similar decoding for the digital code (10), indicating additional contact groups.

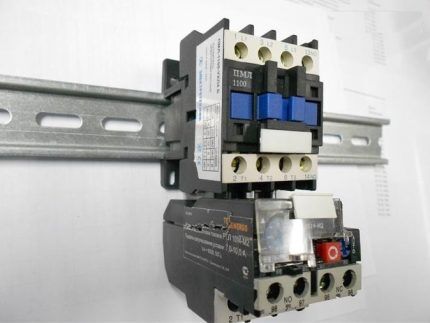

When selecting the design of a 380V magnetic starter for the appropriate purpose, you should pay attention to the technique of mounting the device.

As a rule, a significant proportion of modern devices are configured to be mounted on a DIN rail.But there are also designs of devices for fastening in the traditional way - with screws.

The nuances of connecting EMF as part of the circuit

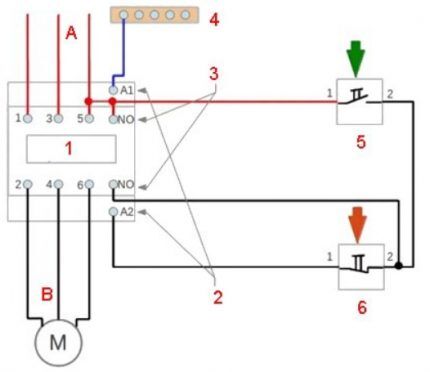

Classical EMF connection diagram does not stand out with any particular difficulties. In fact, if you do not take into account the auxiliary groups of contacts, three main lines are required to be connected - in a 380 volt circuit there are three phases.

In total there are 6 contacts - three input and three output, plus two contacts of the inductor circuit.

However, actual inclusion in an electrical circuit is often accompanied by a rather complex circuitry, where a large number of auxiliary contacts are involved.

As a rule, modern circuits for switching on the same electric motors require additional input of protection devices - thermal relay and others.

When connecting circuits to an EMF rated for 380V, you should adhere to the following rules:

- connect in complete absence of voltage;

- connect input circuits via circuit breaker;

- use a wire cross-section that is optimally suited for the contact;

- tighten the screws until they stop, but without using excessive force;

- check the integrity of the coil winding (with an ohmmeter) before connecting the power line;

- check the overall movement of the moving chassis after all connections have been made.

As a rule, switching devices of this type are installed inside a cabinet designed for the installation of electrical lines. The cabinet design has a door for ease of maintenance and restricting access by unauthorized persons.

Conclusions and useful video on the topic

A complete informative breakdown of the magnetic starter through a video recorded by a well-known trading company of electronic components.

The author of the video reveals in detail and in an accessible form the essence of the switching device:

Switching devices, similar to an electromagnetic starter for three-phase networks, are used quite often in the industrial, economic and domestic spheres. Therefore, it is useful to study information regarding such devices in a timely manner - how to work with them, how to connect them, how to determine for installation, etc.

Do you have anything to add, or do you have questions about choosing and connecting an electromagnetic starter? You can leave comments on the publication, participate in discussions and share your own experience of using such devices. The contact form is located in the lower block.

Connecting a magnetic starter is a different story. Even using a classic circuit, you can easily make a mistake, forgetting, for example, about the rating of the inductor. For some reason, everyone thinks that it is standard at 230 volts and is connected, respectively, to the neutral and to one of the phases. But we also had to deal with the 400 volt option, in which case its outputs must be connected to different phases (via a series of buttons, of course).And sometimes there are exotic coil voltage ratings, say, 110 or 36 volts. So, before connecting, do not forget to inquire about this parameter.

Good afternoon, Gleb. The likelihood of an error is reduced if the electrician uses the design switching diagram, simultaneously checking the characteristics laid down by the designers with the passport data of the actual equipment proposed by the customer.

Your statement - “Everyone...believes that it...is 230 volts” – is erroneous and characterizes the qualifications of those around you. By the way, the “exotic” voltages used to power the control coils (you mistakenly call them inductors) are much larger (attached screenshot).

Hello! Can you help with the connection!?

We also have 24V

It all depends on the installation location

Hello! Can you help with the connection!?