How to choose a double-circuit floor-standing gas boiler: what to look for before buying?

Of all the options for home heating devices, in terms of the cost of energy resources and ease of maintenance, gas equipment can be called the optimal solution.

If you need to not only heat the room, but also provide the house with hot water, then the best choice would be a double-circuit floor-standing gas boiler, capable of serving both compact houses and spacious apartments.

The buyer faces a difficult task. Agree, it is quite difficult to navigate the variety of offers from manufacturers of heating units.

We will help you understand the design and operating specifics of different models, outline the main parameters for a smart purchase, and also provide practical recommendations for choosing a gas boiler.

The content of the article:

- Convection or condensation boiler?

- Power supply type: non-volatile or not

- Heating principle: flow or storage

- Materials for heat exchanger: which is better

- Selection of equipment by type of smoke removal

- Methods for igniting a double-circuit boiler

- Use of coolants in boilers

- How to choose the power of a double-circuit boiler

- What else should you pay attention to?

- Conclusions and useful video on the topic

Convection or condensation boiler?

Let’s try to figure out what you need to know about the characteristics of such equipment, its design and operational features.

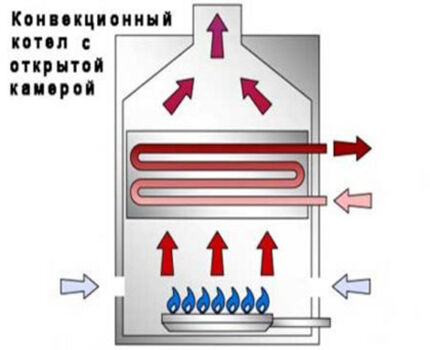

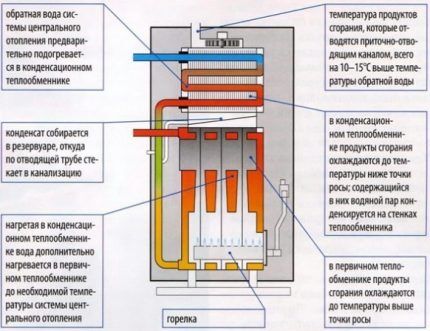

Convection gas floor boilers use heat to heat the coolant, obtained from the energy that is released during gas combustion. In this case, a large amount of heat, along with steam and flue gases, escapes into the atmosphere.

Although convection boilers are not considered the most efficient, from an economic point of view, their existence on the heating equipment market justifies a number of advantages. These include simple design, reasonable cost, compact size, easy installation and repair.

One of the disadvantages of condensing boilers is their relatively high cost. The last factor, however, quickly pays off, since there is a noticeable reduction in gas consumption. The second is the difficulty of disposing of condensate, which cannot be easily drained into a septic tank so as not to destroy the bacteria that process the wastewater.

Power supply type: non-volatile or not

The principle of operation of a volatile boiler is as follows: the installed automation detects, using sensors, the activation of DHW equipment or a decrease in temperature in the heating circuit and turns on the heating.

The coolant, passing through the heat exchanger, is heated to the required temperature and supplied to the heating or hot water circuit using circulation pump.

It is clear that a volatile device will consume electricity. To reduce its consumption, it is better to choose models with energy consumption class A++.But, in addition to energy consumption, it is also necessary to take into account the cost of repairs, replacement of spare parts, and automation.

For example, failure of electronic boards is a fairly common occurrence; repairs are expensive, and replacing a part with a new one will cost almost half the cost of the boiler itself.

But non-volatile models can be called the most adapted to conditions when the electricity is turned off, and energy fluctuations make you worry about the integrity of the automation.

Heating principle: flow or storage

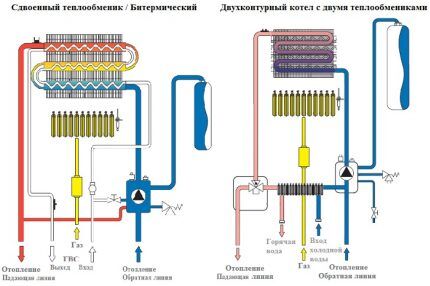

The flow principle of heating can be carried out by two types of heat exchangers:

- separate;

- bithermic.

Both of them have advantages and disadvantages, so the choice can only depend on the buyer of the equipment and his preferences.

Boiler with separate heat exchanger has a primary (intended for heating) and secondary (used to heat water) heat exchanger. The secondary heat exchanger has a built-in circuit that serves to heat water, which is heated by taking heat from the heating circuit coolant.

This type of boiler cannot operate in heating and water heating modes at the same time: as soon as one system comes into operation, the operation of the second is suspended.

In bithermal heat exchangers The water is heated by a burner located in a tube that runs inside the main heat exchanger. In such equipment, water heats up much faster. Such boilers are more compact and cheaper.

A significant disadvantage of bithermic boilers is the temperature difference in the hot water supply. This leads to the fact that very hot water can flow immediately after opening the tap.

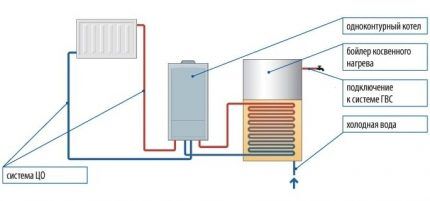

Double-circuit floor-standing gas boilers with a built-in tank, unlike flow-through models, can provide water in full. The volume of tanks varies from 25 to 60 liters. To heat large volumes, devices with high power are used. You can increase productivity even further by using boilers combined in cascades.

Materials for heat exchanger: which is better

The heat exchanger plays one of the main roles in the design of a gas heating device - the coolant circulates through it. The most common materials used in the production of heat exchangers for gas boilers are copper, cast iron, and steel.

Steel version of the heat exchanger

The cheapest, and as a result, the most popular material for a heat exchanger is steel. Therefore, it is actively used by domestic manufacturers in order to reduce the cost of the final product. Unlike cast iron, it is not brittle.

Compared to cast iron, steel is much lighter, but when compared to copper, it significantly exceeds its weight and makes the boiler structure heavier.

The steel heat exchanger heats up and cools down quickly. In addition to convenience, this leads to negative consequences - “fatigue” of the metal causes damage. The disadvantage of steel is also its susceptibility to corrosion.

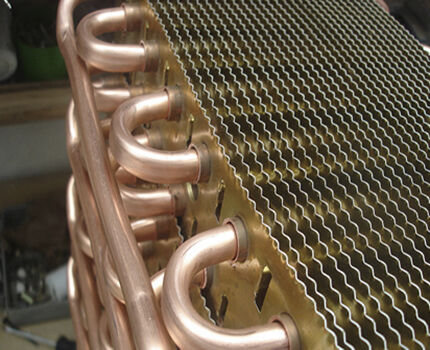

Copper type heat exchanger

The material has many positive properties - corrosion resistance, small volume, low inertia. Due to its compactness and low weight, copper is actively used for the production of lightweight wall-mounted boilers.

The opinion about the fragility of copper heat exchangers has long been refuted by manufacturers of modern heating equipment - in them, the burner power is reduced by 30%, which reduces the thermal effect on the metal and has a good effect on the duration of operation.

Boilers with cast iron heat exchanger

The main quality of cast iron that should be noted is its inertia. The material takes a long time to heat up and cools down for a long time, which increases the efficiency of heat transfer.

Such inertia can be considered both a positive quality and a negative one - in the event of sudden warming outside, the boiler will maintain a high temperature in the heating system for a long time.

Cast iron is subject to dry and wet corrosion. The latter contributes to the appearance of rust, but due to the thick walls, the corrosion process extends over a long time.

The disadvantages of cast iron boilers include the fragility of the material, which manifests itself as a result of improper operation - temperature changes, mechanical damage during transportation and installation.

Selection of equipment by type of smoke removal

The method of removing flue gases is one of the most important factors when choosing gas equipment. It directly affects both the choice of model and the possibility of installing it in a particular room. Therefore, it is important to study possible smoke removal options and choose the best one.

Boilers with chimney type smoke removal

The combustion process in chimney-type boilers is ensured by natural draft, which uses air from the room. The required amount of air enters through the open combustion chamber.

Disadvantages of double-circuit chimney floor boilers:

- Efficiency is several percent lowerthan with turbocharged gas equipment - part of the heat flies out into the chimney along with the smoke.

- Additional costs for chimney construction. If everything is done correctly, in accordance with legal standards, then you need to additionally obtain permission, install a sensor that measures the level of carbon dioxide, and annually invite a specialist to conduct an examination.

- Active condensation formation — modern equipment has a higher efficiency and produces a low exhaust gas temperature at the outlet. As a result, especially if the chimney is not very insulated, condensation forms, which leads to rapid destruction of the chimney walls.

- The need for sufficient supply ventilation. As a result of combustion, warm air from the room is drawn into the chimney. If you have a chimney boiler, it is necessary to provide fresh ventilation.

Due to the peculiarities of the mechanism of action and operation, a separate boiler rooms.

Equipment advantages:

- relatively low cost of the device;

- simpler design, which is easier and cheaper to maintain;

- the ability to remove combustion products to a greater distance from the house.

Due to their cost, durability and ease of operation, floor-standing chimney boilers are quite popular.

In cases where the house already has a ready-made chimney that is correctly installed and working, experts advise not to spend money on more expensive models and install conventional stationary equipment connected to the chimney, with an open combustion chamber.

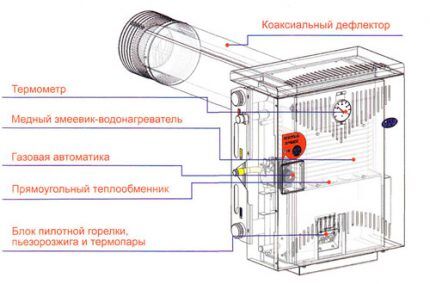

Parapet boiler: design features

Parapet boilers can be classified as a separate category of equipment based on their placement, but they also have a feature related to the removal of combustion products. They differ from stationary gas boilers in the need coaxial pipe connections to remove smoke.

Parapet boilers can be installed in premises for any purpose, even in an apartment in a multi-storey building (if there is permission) and in any place - on a windowsill or under it, instead of a radiator. The only limitation in this case is that the length of the horizontal section of the pipe should not exceed 3 m.

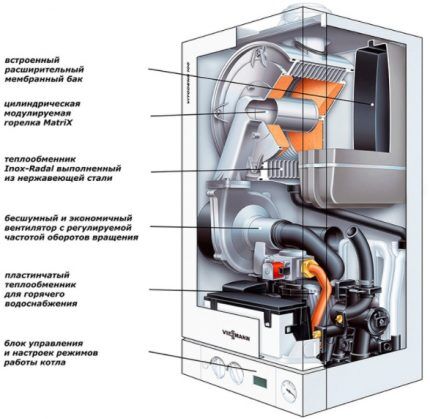

Turbocharged heating boilers

Sometimes, due to the lack of a chimney or the architectural features of the building, chimney equipment cannot be installed. Then a turbocharged boiler is used as a heating device.

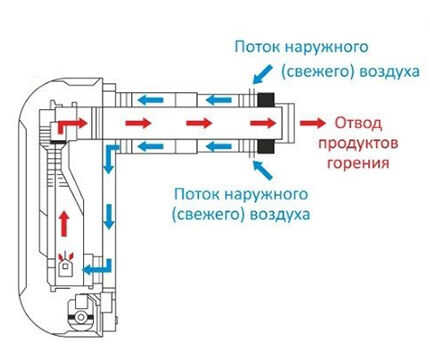

This is a device in which the fuel combustion process is carried out in a closed chamber, and the emission of flue gases occurs forcibly, through a built-in turbine, the rotation speed of which can be adjusted - set to the optimal pressure.

Disadvantages of turbocharged double-circuit floor-type boilers:

- another expense item when a turbine breaks down;

- slight but additional noise produced by the fan;

- increase in energy consumption.

Compared to chimney boilers, turbine boilers consume approximately 50 W more.

The advantages of the equipment are as follows:

- Versatility of use — the boiler can be installed in almost any room (private house, apartment).

- No access to an open fire source, the likelihood of carbon monoxide entering the house is reduced.

- No need to install a chimney. A turbine boiler is more expensive, but due to the fact that it does not require the installation of a chimney, its installation is much cheaper. The savings on the purchase of pipes and the cost of installation services significantly cover the costs of more expensive equipment.

- The boiler does not draw air from the room, which means heat loss is reduced. It takes air to support combustion from the street. Therefore, it does not require supply ventilation equipment in the room (although, in some cases, when replacing chimney boilers with turbocharged ones, the lack of additional ventilation leads to a deterioration in air exchange and an increase in humidity in the house).

There are differences between different types of boilers, but in general they are all designed for safe operation and fairly high efficiency. The choice of model depends more on financial capabilities and specific operating conditions.

Methods for igniting a double-circuit boiler

Without an automatic ignition system, few people imagine the comfortable use of gas heating equipment. There are two completely different principles that can be used for both electrically dependent and completely autonomous boilers - electric and piezo ignition.

The piezo ignition method operates on the same principle as ignition in a lighter - pressing a button causes a spark to appear, which starts the combustion process. In the future, control to ensure that the flame does not go out is carried out using a thermocouple.

The element is heated by the burner, generating a current that keeps the solenoid valve from slamming.During a temporary suspension, the wick still remains burning in the boiler.

Piezo ignition is often used in non-volatile boilers and is, in fact, a semi-automatic system. If the gas is turned off, the burner goes out and the valve closes, stopping further gas supply. You can restart the boiler by pressing the button.

Electric ignition provides complete automation - the heating device starts with the appearance of a spark, and the flame is controlled using an ionization control unit. When the power goes out, the automatic system is activated, it shuts off the gas, and when turned on, it starts the boiler.

In such devices there is no need for a constantly burning ignition filter, and this is a significant gas saving. You can eliminate the dependence of a boiler with electric ignition on the power supply using batteries.

Use of coolants in boilers

If irregular residence or frequent and long-term departures are planned at a dacha or in a private house, and draining and purging liquid from the system is not considered an acceptable option, then it is necessary to prevent it from freezing.

This can be done by adding antifreeze to the coolant - substances that do not freeze to a certain negative temperature, and in the case of even lower temperatures do not harden, but turn into a gel-like substance without increasing in volume.

In most cases, it is not recommended to use antifreeze in double-circuit floor-standing boilers running on gas (these standards are less stringent for single-circuit boilers). The instructions clearly state that coolant in the heating system there must be water.

Some manufacturers indicate a specific brand of antifreeze that can be used to fill the heating system. For example, an equipment manufacturer Viessmann recommends using brand coolant Antifrogen.

Others indicate that, as an exception, antifreeze can be used if its manufacturer guarantees that the product will not cause harm to the components and materials of the boiler, in particular the heat exchanger. It is necessary to take into account that for a certain model one coolant may be suitable and another may not be suitable at all.

Therefore, if it is important that antifreeze is used as a coolant in the heating system, you need to find out in advance, before purchasing, whether it is possible, and if so, what brand of coolant is allowed to be used for a specific brand and model of the boiler.

How to choose the power of a double-circuit boiler

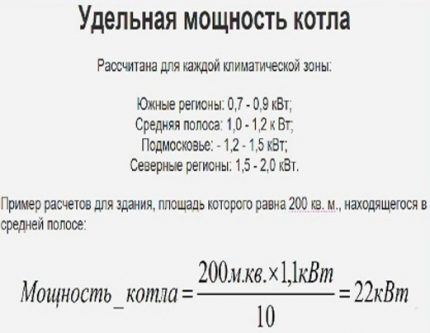

One of the most important indicators that must be taken into account when purchasing gas heating equipment is power.

It should be borne in mind that an overly powerful boiler will lead to excessive consumption of gas fuel, and insufficient power of the device will not be able to provide a comfortable temperature regime, or the equipment will work at the limit of its capabilities and will quickly fail.

Power calculation formula

Achieving accuracy in calculations is hardly possible for the average user, but you can try to get approximate figures. As a basis, it is necessary to take the specific power of the heating device, calculated for a specific region, multiply by the area of the heated room and divide by 10.

The result obtained is the required boiler power under ideal conditions.

Depending on the characteristics of the room, adjustments must be made:

- for rooms with a height of more than 2.8 m, for every 10 cm of the above number it is necessary to increase the original value by 3%;

- two walls facing the street mean that it is necessary to increase power by 15%;

- an unheated room above requires an increase in the indicator by 12%, below - by 7%;

- if glazing occupies more than 8% of the total area of the room, then for each excess of 1% add 1% power;

- an external door that opens systematically increases heat loss by 15%.

When purchasing a double-circuit floor-standing gas boiler, whether floor-mounted or hanging model, you need to add another 20%. After all the calculations, it is also recommended to add a small power reserve - this way the load on the device will be less and it will last longer.

Automatic simulation function

It is better that the boiler is not only selected according to the power level, but also has the function of adjusting it. There are devices with single-stage, two-stage and simulated power. Models of the last two types are more efficient in operation because they can be adjusted.

If the boiler has automatic power control, then it does not just turn on and off the moment it reaches the set temperature, it independently reduces the power to a minimum.

If operation in the minimum temperature mode turns out to be excessive, then only then does the device switch to on-off mode.

Automatic power modeling increases energy savings, effectively affects equipment longevity and improves user comfort.

What else should you pay attention to?

In addition to power, a lot of technical characteristics of boilers affect the operation of a gas heating system.

The following parameters deserve closer attention:

- Amount of gas consumed floor-standing double-circuit gas boiler. You can choose an economical model by comparing products with the same power.

- Efficiency. One of the most important indicators affecting the economical use of energy resources. Leading manufacturers of gas equipment are working quite successfully to increase it - in modern devices it reaches about 100%.

- Hot water circuit capacity. The indicator can be from 2.5 to 30 l/min.

- Electricity consumption in volatile equipment. On average, boilers can consume about 2 kW per day. In a month we get about 60 kW

- Maximum temperatures. In the DHW system, the temperature is about 55 °C; in the heating circuit - up to 90 °C.

- Water pressure. The values in the heating circuit reach 10 bar.

Only a thorough study and comparison of characteristics, reviews from users, sellers, representatives of installation and repair services who work with gas boilers will help to identify a manufacturer of high-quality equipment among the many brands on the market.

Additional selection recommendations, assessment of the technical and operational characteristics of different models, as well as a review of the best gas boilers are given in the articles:

- Floor-standing gas heating boilers: types, how to choose, review of the best brands

- How to choose the best gas boiler: criteria for choosing the best option

- Double-circuit gas boilers: types, principle of operation, selection criteria + review of the best brands

Conclusions and useful video on the topic

Operating principle of a double-circuit gas boiler:

How to choose a gas boiler:

Choosing a device for heating a private home is a responsible and serious task. It happens that, having trusted sellers of gas equipment, you have to pay for other people’s mistakes or “help out” sellers of outdated equipment.

As a result, you get something completely different or not quite what you expected. Often, too late, the understanding comes that one would have to first understand the many characteristics of double-circuit floor-standing gas boilers, their design features and system operating parameters.

Do you have experience operating a double-circuit floor-standing gas boiler? Tell us what model you use to heat your house, what are the features of its operation. Share your impressions of using the equipment with our readers. You can ask questions and leave comments on the article in the form below.