Do-it-yourself hydroelectric power station: how to build an autonomous mini-hydroelectric power station

The power of water flow is a renewable natural resource that allows you to obtain virtually free electricity.The energy donated by nature will provide an opportunity to save on utilities and solve the problem of recharging equipment.

If there is a stream or river running near your home, it is worth taking advantage of it. They will be able to provide electricity to the site and the house. And if you build a hydroelectric power station with your own hands, the economic effect increases significantly.

The presented article describes in detail the manufacturing technologies of private hydraulic structures. We talked about what is required to set up the system and connect it to consumers. Here you will learn about all the options for miniature energy suppliers assembled from scrap materials.

The content of the article:

Hydroelectric power plants for non-industrial purposes

Hydroelectric power plants are structures that can convert the energy of water movement into electricity. Alternative Green Energy Suppliers so far they are actively exploited only in the West. In our country, this promising industry is only taking its first timid steps.

Small private hydroelectric power plants can be dams on large rivers, generating from ten to several hundred megawatts or mini-hydroelectric power plants with a maximum power of 100 kW, which is quite enough for the needs of a private home. Let’s find out more about the latter.

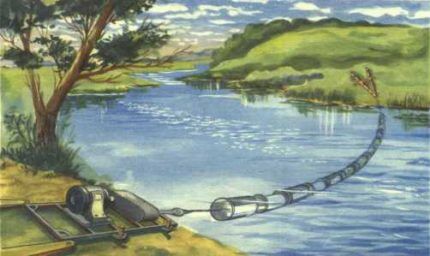

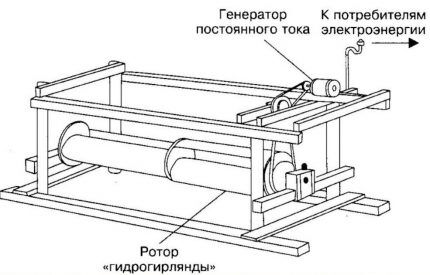

Garland station with hydraulic screws

The structure consists of a chain of rotors attached to a flexible steel cable stretched across the river. The cable itself plays the role of a rotation shaft, one end of which is fixed on the support bearing, and the other activates the generator shaft.

Each hydraulic rotor of the “garland” is capable of generating about 2 kW of energy, however, the water flow speed for this must be at least 2.5 meters per second, and the depth of the reservoir should not exceed 1.5 m.

Garland stations were successfully used back in the middle of the last century, but the role of propellers was then played by homemade propellers and even tin cans. Today, manufacturers offer several types of rotors for various operating conditions.

They are equipped with blades of different sizes, made of sheet metal, and allow you to obtain maximum efficiency from the operation of the station.

But although this hydrogenerator is quite simple to manufacture, its operation requires a number of special conditions that are not always feasible in real life. Such structures block the river bed, and it is unlikely that your neighbors along the bank, not to mention representatives of environmental services, will allow you to use the energy of the stream for your purposes.

In addition, in winter, the installation can only be used on non-freezing reservoirs, and in harsh climates it can be preserved or dismantled. Therefore, garland stations are erected temporarily and mainly in deserted areas (for example, near summer pastures).

A modern analogue of a garland installation is submersible or floating frame stations with transverse rotors. Unlike their garland predecessor, these structures do not block the entire river, but use only part of the riverbed, and they can be installed on a pontoon/raft or even lowered to the bottom of the reservoir.

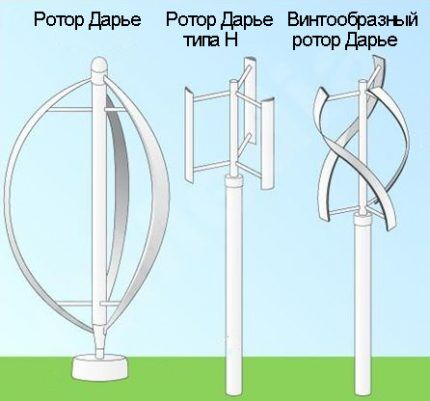

Vertical Daria rotor

The Darrieus rotor is a turbine device that was named after its inventor in 1931. The system consists of several aerodynamic blades fixed on radial beams and operates by differential pressure using the “lifting wing” principle, which is widely used in shipbuilding and aviation.

Although such installations are mostly used to create wind generators, they can also work with water. But in this case, precise calculations are needed to select the thickness and width of the blades in accordance with the strength of the water flow.

Vertical rotors are rarely used to create local hydroelectric power stations. Despite the good efficiency indicators and the apparent simplicity of the design, the equipment is quite complex to operate.

Before starting work, the system needs to be “spinned up”, but only the freezing of the reservoir can stop the running station. Therefore, the Darrieus rotor is used mainly in industrial enterprises.

An interesting solution in the field of designing small hydroelectric power plants with a vertically operating turbine was proposed by the Austrian inventor Franz Zotleterer:

A significant advantage of whirlpool stations is quite rightly considered to be the preservation of fish resources. The operation of a vertical turbine does not harm living organisms of the river. In addition, mud does not linger on the walls of structures due to the specific movement of water flow.

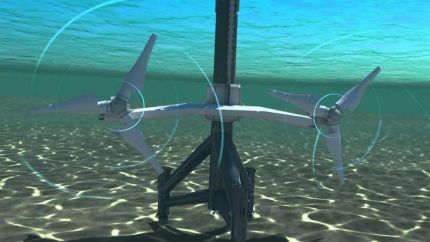

Underwater screw propeller

In fact, this is the simplest air windmill, only it is installed under water. The dimensions of the blades, in order to ensure maximum rotation speed and minimum resistance, are calculated depending on the force of the flow.For example, if the current speed does not exceed 2 m/sec, then the width of the blade should be within 2-3 cm.

Such a windmill is installed “towards” the flow, but its blades operate not due to the pressure of the water pressure, but due to the generation of lifting force (on the principle of an airplane wing or a ship’s propeller).

Water wheel with blades

A water wheel is one of the simplest versions of a hydraulic engine, known since the times of the Roman Empire. The efficiency of its operation largely depends on the type of source on which it is installed.

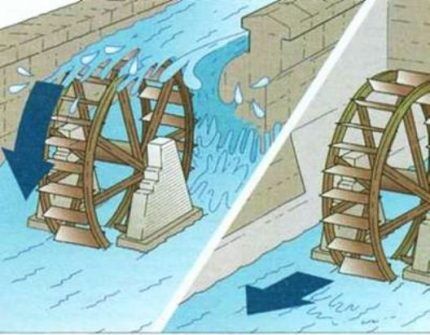

Depending on the depth and bed of the watercourse, different types of wheels can be installed:

- Gravy (or bottom) – suitable for shallow rivers with fast currents.

- Medium-range – are located in channels with natural cascades so that the flow falls approximately in the middle of the rotating drum.

- Liquid (or overhead) – are installed under a dam, pipe or at the bottom of a natural rapid so that the falling water continues its path over the top of the wheel.

But the principle of operation for all options is the same: water falls on the blades and drives a wheel, which causes the generator for the mini-power station to rotate.

Manufacturers of hydraulic equipment offer ready-made turbines, the blades of which are specially adapted to a certain speed of water flow.But home craftsmen make drum structures the old fashioned way - from scrap materials.

The following photo selection will help you get acquainted with the steps of constructing the simplest version of a mini hydroelectric power station:

Perhaps the lack of optimization will affect efficiency indicators, but the cost of homemade equipment will be several times cheaper than a purchased analogue. Therefore, a water wheel is the most popular option for organizing your own mini-hydroelectric power station.

Conditions for installing a hydroelectric power station

Despite the tempting cheapness of the energy generated by a hydro generator, it is important to take into account the characteristics of the water source whose resources you plan to use for your own needs.

After all, not every watercourse is suitable for the operation of a mini-hydroelectric power station, especially year-round, so it does not hurt to have in reserve the possibility of connecting to a centralized main line.

A few pros and cons

The main advantages of an individual hydroelectric power station are obvious: inexpensive equipment that generates cheap electricity, and also does not harm nature (unlike dams that block the flow of a river). Although the system cannot be called absolutely safe, the rotating elements of the turbines can still cause injuries to the inhabitants of the underwater world and even people.

Advantages of mini-hydroelectric power plants:

- Unlike other “free” energy sources (solar panels, wind generators), hydraulic systems can operate regardless of the time of day and weather. The only thing that can stop them is freezing of the reservoir.

- To install a hydrogenerator, it is not necessary to have a large river - the same water wheels can be successfully used even in small (but fast!) streams.

- The units do not emit harmful substances, do not pollute water and operate almost silently.

- To install a mini-hydroelectric power station with a capacity of up to 100 kW, you do not need to obtain permits (although everything depends on the local authorities and the type of installation).

- Excess electricity can be sold to neighboring houses.

As for the disadvantages, insufficient current strength can become a serious obstacle to the productive operation of the equipment. In this case, it will be necessary to build auxiliary structures, which entails additional costs.

If the potential energy of a nearby river, based on an approximate calculation, is not enough to generate electricity in a volume sufficient for practical use, it is worth paying attention to methods of constructing wind generators. A windmill will serve as an effective addition.

Measuring the strength of water flow

The first thing you need to do to think about the type and method of installation of the station is to measure the speed of water flow at your favorite source.

The easiest way is to lower any light object (for example, a tennis ball, a piece of foam plastic, or a fishing float) onto the rapids and use a stopwatch to measure the time it takes for it to swim the distance to some landmark. The standard distance for the “swim” is 10 meters.

Now you need to divide the distance traveled in meters by the number of seconds - this will be the speed of the current.But if the resulting value is less than 1 m/sec, it will be necessary to erect artificial structures to speed up the flow due to elevation changes.

This can be done with the help of a collapsible dam or a narrow drain pipe. But without a good flow, the idea of a hydroelectric station will have to be abandoned.

Production of hydroelectric power station based on a water wheel

Of course, assembling and erecting a colossus designed to serve an enterprise or settlement of even a dozen houses is an idea from the realm of science fiction. But building a mini-hydroelectric power station with your own hands to save electricity is quite possible. Moreover, you can use both ready-made components and improvised materials.

Therefore, we will consider step by step the manufacture of the simplest structure - a water wheel.

Required materials and tools

To make a mini-hydroelectric power station with your own hands, you need to prepare a welding machine, an angle grinder, a drill and a set of auxiliary tools - a hammer, a screwdriver, a ruler.

Materials you will need:

- Corners and sheet metal with a thickness of at least 5 mm.

- PVC or galvanized steel pipes for making blades.

- Generator (you can use a ready-made one or make it yourself, as in this example).

- Brake discs.

- Shaft and bearings.

- Plywood.

- Polystyrene resin for casting the rotor and stator.

- 15 mm copper wire for a homemade generator.

- Neodymium magnets.

Please note that the wheel structure will constantly be in contact with water, so metal and wooden elements must be selected with protection from moisture (or take care of impregnation and painting them yourself). Ideally, plywood can be replaced with plastic, but wooden parts are easier to obtain and shape into the desired shape.

Wheel assembly and nozzle manufacturing

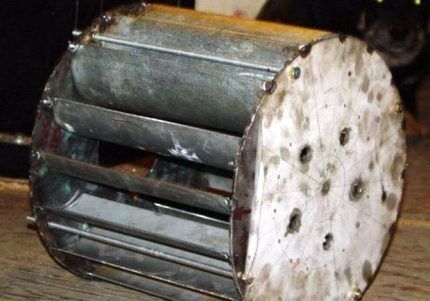

The basis for the wheel itself can be two steel disks of the same diameter (if it is possible to get the steel drum from the cable - great, this will greatly speed up the assembly process).

But if metal is not found in the materials at hand, you can cut circles from waterproof plywood, although the strength and service life of even treated wood cannot be compared with steel. Then you need to cut a round hole on one of the disks for installing the generator.

After this, the blades are made, and at least 16 pieces will be needed. To do this, galvanized pipes are cut lengthwise into two or four parts (depending on the diameter). Then the cutting areas and the surface of the blades themselves must be polished to reduce energy loss due to friction.

The distance between the two side discs should be as close as possible to the length of the blades. To mark the location for future hubs, it is recommended to make a template from plywood, which will mark the location for each part and the hole for fixing the wheel to the generator. The finished markings can be attached to the outside of one of the disks.

The circles are then installed parallel to each other using solid threaded rods, and the blades are welded or bolted in the desired positions. The drum will rotate on bearings, and a frame made of angles or small diameter pipes is used as a support.

The nozzle is designed for cascade-type water sources - such an installation will allow you to use the flow energy to the maximum. This auxiliary element is made by bending sheet metal, followed by welding the seams, and then mounted on a pipe.

However, if your area has a flat river without rapids or other high-altitude obstacles, this detail is not necessary.

Now the wheel needs to be mounted on the axle and mounted on a support made of welded or bolted corners. All that remains is to make a generator (or install a ready-made one) and you can go to the river.

DIY generator

To make a homemade generator, you need to winding and filling the stator, for which you will need coils with 125 turns of copper wire on each. After connecting them, the entire structure is filled with polyester resin.

Now you need to prepare a plywood template that matches the size of the brake disc.

Markings are made on the wooden ring and slots are made for installing magnets (in this case, neodymium magnets 1.3 cm thick, 2.5 cm wide and 5 cm long were used). Then the resulting rotor is also filled with resin, and after drying, it is attached to the wheel drum.

The last thing to install is an aluminum casing with an ammeter covering the rectifiers. The task of these elements is to convert three-phase current into direct current.

To prevent leaves, sand and other debris brought with the flow from getting into the wheel, it is advisable to place a protective net in front of the device.

You can also experiment with the gaps between the magnets and coils with an increased number of turns to increase the efficiency of the hydraulic station.

About all types alternative energy sources You will find out by reading the article dedicated to the introduction of “green technologies” into everyday life.

Conclusions and useful video on the topic

Video #1. An example of a working hydraulic installation with a homemade generator based on a three-phase motor:

Video #2. Mini-hydroelectric power station, designed on the principle of a water wheel:

Video #3. A station based on a bicycle wheel is an interesting option for solving the problem of energy supply on vacation far from civilization:

As you can see, building a water mini-power station with your own hands is not so difficult. But since most of the calculations and parameters for its components are determined “by eye,” you should be prepared for possible breakdowns and associated costs.

If you feel a lack of knowledge and experience in this area, you should trust specialists who will perform all the necessary calculations, recommend the optimal equipment for your case and install it efficiently.

Please write comments in the block below. Share interesting information and useful recommendations, leave thematic photos.Perhaps you want to tell us how you built a functioning hydroelectric power station on a suburban plot with your own hands? We will be glad to read your story about the device process and operation.

I saw this kind of construction in Uzbekistan when I went there on a business trip in the summer. There is a shortage of electricity there, especially in the villages. In general, there the ancient version of the charkhpalak was also turned into a mini-hydroelectric power station. That is, something like jugs is welded on these blades, they scoop up water and pour it into a tin drain. And it turns out that they water their gardens from the canal, and the mini-hydro station is right there.

Yes, otherwise we have a problem this year. In the private sector there was a centralized water supply, a river nearby, everything was well done and worked. They regularly donated money for maintenance and repairs. Now the new management has ordered to demolish everything old and build a new one using a different technology and, accordingly, payment. So now my neighbors and I are looking for cheaper ways to get water, we need to try this option. If you can also extract energy, that’s great.

I have a river, I measured the flow speed - in the spring it’s about 0.28 m/s. Should we abandon the construction of hydroelectric power stations?

The flow speed is small, but no one is stopping you from building an artificial structure (for example, a separate riverbed with a small dam) to get a flow of water at the required speed.

The article has good examples, but the Lineva damless mini-hydroelectric power station is missing; I am attaching an approximate diagram (sketched by hand, plus a diagram from the Internet).This mini-hydroelectric power station is safe for the environment! And what is most important is that the Linev mini-hydroelectric power station does not have a single blade that would not work at every single moment, plus none of them has any resistance. Plus visual video implementation of this project.

Is it possible to order such a generator?

We have a river - what we need, the current is powerful, but our hands are not very good, does anyone know a person who can accept such an order?

We tried it. Does not work. We found out that due to the large number of hinges, the efficiency is around 20%

89014547093 I will buy a mini hydroelectric power station on a mountain river

Hello Amir!

As a result of the search, we have the necessary drawings and diagrams for the manufacture of the Lineva mini-hydroelectric power station, please advise on specialists who are ready to make this unit. Territorially St. Petersburg. I’m ready to help with metal products (there are CNC and Laser machines).

Thank you.

I figured out how to make a powerful hydroelectric power station without a dam, it will only provide enormous energy from the movement of water in thousands of tons of pressure on the shaft, of course, depending on the river, on a stream you can also increase the power tens of times, I will answer everyone who is interested

Hello Igor! Tell me what a powerful hydroelectric power station looks like without a dam and what its operating principle is. Thanks in advance Zhumanali

Igor, greetings. Please write your contact details for communication on mini hydroelectric power stations, your consultation is required.

Hello Igor! I’m very interested in your project to create a hydroelectric power station! Please answer!

Yes, at least someone has expanded on this topic: how to spin up an engine, the principles are a river, but what kind of engine, gearbox, how to create speed without sticking magnets.

Good afternoon, Igor. How to look at your invention of hydroelectric power station? Do you have videos or drawings? Please answer if possible. Thank you in advance! With respect to you, Alexander.

Hello Igor, I’m interested in your project, please answer) Thank you)

Good afternoon, I would like to know about your proposal about a hydroelectric power station without a dam, do you make this structure yourself (as I understand it is a generator), which can be installed without building a dam. What is the cost of a generator up to 100 kW/hour. Thanks in advance…

please write if you are still studying 89034693529 whatsapp

Thank you for posting my video.

How to calculate the torque of the rotor. small HES.2. How many kilograms can a 100,500 kW rotor and a 5 MW hydrogen generator weigh, and what torque is needed to

Addition .To them. Crank i.e. 100,500 rotors, and 5 MW hydrogen generators, i.e. torque and how to calculate it,