Filters for coarse and fine water purification: overview of types + installation and connection rules

We have a number of well-founded claims regarding the quality, chemical composition and purity of water supplied by the central water supply. They are justified by deteriorating health conditions, rapid wear of equipment and eternal problems with water pressure. Both our physical and economic condition deserve attention, don’t you agree?

To combat the listed negative circumstances, there is a proven method - you need a coarse and fine filter. Depending on the tasks being solved, both individual devices and a group of interconnected devices that perform multi-stage processing are installed.

Here you will learn what kind of work a certain type of device does, in what sequence they are placed, and how they ultimately affect the quality characteristics of water. For a complete understanding of the information, we have included visual illustrations and video tutorials.

The content of the article:

Filtration stages in the water treatment process

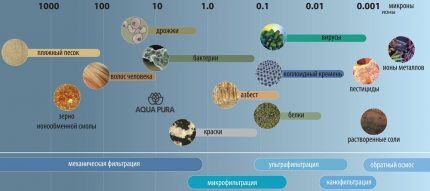

The first, most important step in water treatment is mechanical purification. Coarse cleaning devices remove particles of 1 micron and above from water. They perform an irreplaceable function in the filtration process, without which further water purification is impossible.

Rust, sand, clay particles, scale from old water pipes - everything is removed to obtain clear water at the output.

Only after the first stage of pre-filtration can you begin to remove organic impurities, heavy metal compounds, chemical elements and microorganisms. For this purpose, ultrafine filtration devices are used.

It is possible to determine more specifically the need for cleaning from certain contaminants only on the basis of analysis results.

To choose the right filter, you need to clearly define why its installation is needed:

- for filtering hot and/or cold water;

- what kind of contaminants need to be cleaned from;

- what capacity and loading volume should the filter have;

- for what purposes - to protect plumbing and equipment or for drinking water and cooking.

It is also necessary to take into account where the device will be used - in a private house, apartment, boiler room or industrial enterprise.

Design and use of coarse filters

Coarse cleaning devices may have different designs, but their operating principle is similar. Inside they have a removable element, which can be in the form of a metal mesh, disk, cartridge - it performs filtration.There is also an outlet for collecting contaminants. To remove accumulated debris, the device is periodically washed.

Additionally, the devices can be equipped with a pressure gauge to help control the pressure in the system. A drop in water pressure may indicate that it is time to change or wash the cartridge or mesh.

Filters can also be produced in pairs with a reducer, which reduces pressure and dampens water hammer. Some models have shut-off valves.

The common properties and differences between different models are the following characteristics:

- Filter element. For rough cleaning, a metal mesh, a polypropylene fiber cartridge, or a disk element are often used.

- A method for removing accumulated dirt. Devices are divided into those that are washed manually and self-washing.

- Can be used for hot, warm or cold water.

All differences affect the functionality of the devices. Therefore, below - in more detail about their capabilities.

Sediment filters for rough cleaning

Sediment filters include devices with a filtration mesh. They are made primarily of a metal body (brass or stainless steel) with a straight or oblique outlet located directly perpendicular or at an angle. Inside, along the flow of water, there is a stainless steel mesh.

There are also models of conical axial devices, in which the body is straight and the filtration mesh is shaped like a cone and is located inside. Their design ensures low hydraulic resistance.

Installed in the area of the steam heating system in front of circulation pump, in the water supply system - before water meter. When installing in front of a pump, it is necessary to study the parameters to prevent an increase in the load on the pump. In addition, some manufacturers expressly prohibit the installation of any devices in front of their equipment.

A filter in the form of a cylinder made of metal mesh is used for installation in the area where water is suctioned from a source. Used to prevent large debris from entering the water supply and preventing damage to the pump.

Self-flushing main devices

The filter structure consists of a housing, a cartridge, and a faucet for washing. The metal or plastic housing has two holes that are connected to the water main. The stainless steel filter mesh is removable and retains mechanical impurities from 100 microns.

There is a backwash tap at the bottom of the housing bowl. Some models are equipped with a pressure gauge to monitor the degree of contamination.

The principle of operation of the device is that the flow passes through a filter element - a removable stainless steel cartridge. Mechanical contaminants are retained in the mesh. Some of them remain in it, and some settle at the bottom of the case.

The peculiarity of self-flushing devices is the ability to remove accumulated dirt without disassembling or unscrewing the housing. To do this, you need to open the tap located in the bottom of the housing and drain the water into a container or down the drain.

The debris is washed away by the stream and the device continues to operate as usual. To remove old deposits on the mesh, you can remove it and clean it more thoroughly.

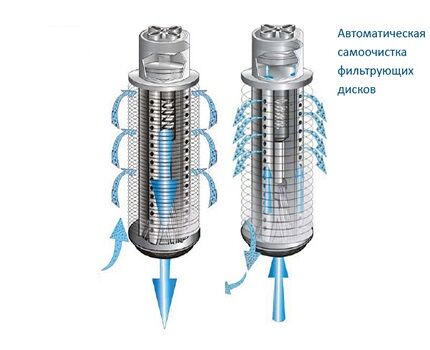

Processing with disc filters

The devices are used primarily for preliminary water treatment, preparing water for further purification, softening and iron removal. Installed in centralized and autonomous water supply systems, at heating plants, are used in irrigation systems, including drip ones.

The filter element is made of polymer disks, mounted on an axle and tightly compressed together. Their surface is covered with small grooves, the dimensions of which determine the degree of cleaning, ranging from 20 to 400 microns.

The cleaning process goes like this: a stream of water fills the body and seeps through the flow grooves in the disks, and then is discharged into the outlet. Over time, dirt settles and accumulates on the surface.

Decrease water pressure - a signal that the device requires cleaning again. You can determine the degree of blockage using a pressure gauge.

Cartridge filters for fine and coarse cleaning

Cartridge filters are very popular because they have a relatively low cost and can be used to filter industrial and drinking water. They free water from large suspensions - sand, rust, as well as small particles up to 1 micron (0.001 mm) in size.

They do a good job of removing turbidity. Devices with a throughput of 100 to 20 microns are used on main filters for coarse purification; from 10 to 1 microns are used for treating drinking water.

They are produced in the form of a flask with a cartridge made of polyester or twisted polypropylene thread. Installed on the pipeline main. After the cartridge's life has been exhausted, it is replaced. The removable element cannot be washed or reused.

Filling materials for cartridges

To make the cartridge, polypropylene fiber, woven polypropylene rope (cord), cellulose impregnated with polyester, and nylon cord are used.But it is propylene that has gained the greatest popularity due to the fact that it has a low cost, is not exposed to chemicals, and is not destroyed by biological organisms.

Polypropylene cord filters use a special winding method that allows larger particles to settle on the outside of the cartridge while smaller particles remain inside the spool. They do not clog very quickly, but the more they exhaust their resource, the more contaminants they let through.

For water supply, this is precisely a positive property, because a dirty filter does not reduce the pressure in the system. Polypropylene fiber has a foamed structure that contains small bubbles, which accumulate contaminants. The shortcomings of the material manifest themselves in cheap low-quality models.

When purifying water, the outer filtration ball becomes clogged in them, while the inner layer can remain clean, that is, not participate in the filtration process. But high-quality cartridges work across the entire surface.

The temperature for using polypropylene products is 1 - 52 °C. They can be used for cold and warm water. To treat hot water, it is necessary to use cartridges made of cotton fibers impregnated with a special substance. They withstand high temperatures (up to +93 °C), exposure to microorganisms and various substances.

Ultrafine purification for drinking water

After removing solid particles and turbidity from water during rough purification, it still contains many substances - dissolved impurities and harmful microorganisms, the presence of which makes it impossible to use it to quench thirst.

New generation fine filters are able to purify water to such an extent that there is no need to boil it to drink.

Those wishing to receive information about filtering devices from leading manufacturers in the segment have a lot of useful information will find here. We advise you to read the article dedicated to this issue.

Sorption filters for cleaning

Sorption filters are used to remove sand, silt, rust fibers, and various impurities 20-40 microns in size, including clay and colloidal iron. They have a high resource and productivity and can accumulate a large amount of suspended matter.

Capable of neutralizing unpleasant odors and pathogenic bacteria. Some models of devices enrich water with iodine and fluorine; some use silver ions, which neutralize harmful microorganisms.

Granular activated carbon or aluminosilicates are used for absorption. Activated carbon copes with substances such as chlorine, radioactive elements, pesticides, heavy metals, petroleum products and dyes. Absorbs chlorine, calcium, phosphorus, eliminating excess hardness from the water.

Aluminosilicates neutralize heavy metals, organic impurities, and establish an optimal acid-base balance.

Sorption filters can be manufactured for domestic purposes - in the form of jugs or tanks, and for processing large volumes - as main devices. Regeneration is carried out using reverse flow of water. A significant disadvantage of such filter systems is their high cost, several times higher than the cost of other installations.

Ion exchange species for water softening

Ion exchange filters serve to soften water and remove organic impurities. They are made in the form of a plastic or metal (stainless steel) case with ion-exchange material, and a container for a regenerating (saline) solution. The operating principle is based on the passage of water through bulk filters, where it gets rid of hardness ions.

The efficiency of operation depends on the chemical parameters of the water, the filter material and the room temperature.

The main disadvantage of such installations is the complexity of maintenance, which requires the use of regenerating tanks, disposal of used components, and a small filter resource - about 200-800 liters.

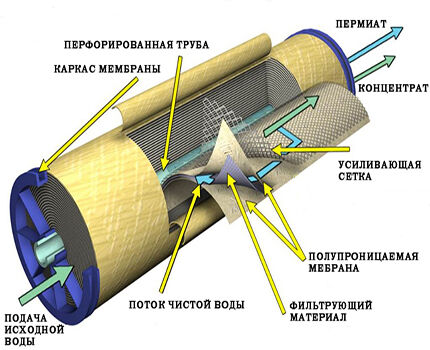

Membrane (reverse osmosis) filter

Technology cleaning using membrane filters is based on the passage of water through a large area of corrugated material with pores no larger than 3 microns. At the same time, the membrane filter retains impurities on the surface without letting them in, which significantly increases the service life of the filter material.

Water enters the membrane filter through an inlet pipe with an o-ring, using a high-pressure pump. After passing through all stages of filtration, it is divided into permeate (highly purified water) and concentrate (a solution of various impurities), which accumulates in the drainage collector.

The degree of filtration depends on the size of the pores in the membrane:

- up to 1 micron - microfiltration;

- up to 0.1 microns - ultrafiltration;

- up to 0.01 microns - nanofiltration;

- less than 0.001 microns — reverse osmosis.

Reverse osmosis units perform the highest possible filtration of water, purifying it at the molecular level, removing all microorganisms, heavy metal salts, and organic impurities.

After passing through such a filter, only 20-30% of mineral substances remain in the water, it becomes slightly mineralized, which can be interpreted as advantage and disadvantage.

Please familiarize yourself with the rating of water treatment devices installed under the kitchen sink. useful article, the contents of which we recommend that you familiarize yourself with.

Filter maintenance and cartridge replacement

Sediment filter maintenance involves periodically cleaning the filter mesh. Before starting work, you need to turn off the tap, then unscrew the inspection cover and remove the mesh. The frequency of inspections depends on the quality of the water and the degree of its contamination. After cleaning, you need to reinstall the elements and check for leaks.

To clean disk filters, you need to remove them from the line, open the housing and remove the filter element. When the filter is removed, the clamp that presses the disks against each other is loosened and they unclench. Next, all elements are washed; for more thorough cleaning, the device is disassembled and cleaned with a brush or sponge.

Cartridge filters made of polypropylene must be replaced after contamination. Manufacturers of different models indicate on the packaging the amount of water in liters that the device can clean.

Objectively, the life of the filter depends on the condition of the water in the centralized water supply or an autonomous source. Therefore, it can serve for up to six months. But if the water supply breaks or for other reasons, it can become clogged even in one day.

In fine reverse osmosis filters, the replacement period for replaceable elements depends on the type of filler. For prefilters it is six months, for a carbon postfilter - a year, for a membrane - 2 - 2.5 years.

To correctly place replacement elements, you need to remember their original location. Before you start drinking water from a new filter or cartridge, you need to rinse the system - drain the water after filling the tank for the first time.

After a long period of inactivity of the system, more than 3 months, and even after replacing replaceable elements, it is disinfected. If rapid development of microorganisms and fouling of prefilters is observed in the filter, it is recommended to additionally install an ultraviolet lamp complete with the main prefilter.

Rules for installing filtration devices

When using a multi-stage cleaning device, the first stage is always a filter that performs rough cleaning. When using several types of systems, first install a device with high micropressure.

If you install filters of different cleaning methods in the wrong sequence, they will not be able to fully perform the task.

It is not recommended to install filter devices in front of pumping equipment. The exception is strainers with approximately zero resistance, which protect the pump from large debris.

The use of any other filters - iron removers, softeners, etc. - will increase the load on the pumping station and cause its premature wear. Installation, adjustment and repair are carried out in the absence of pressure in the water supply.

Installation of sediment filters (mud filters)

Oblique and straight coupling filters are installed on horizontal sections of the water pipe exclusively in the direction of flow. Oblique filters can also be mounted on a vertical pipeline if the flow moves from top to bottom.

The filter should not be subject to stress from vibration, bending, compression and tension of the pipeline. When installing it, ensure uniform tightening of the fasteners; if necessary, install compensators and supports that reduce the load.

The correct location of the filter is with the inspection cover facing down. For preventive maintenance, free space is provided under the device.

According to the insertion method, mesh filters are divided into coupling and flange filters. The first type is installed on pipes of small diameters, the second type is used for main water pipelines and junctions in the water supply system of apartment buildings.On pipes with a diameter of up to two inches, threaded filters, the so-called American ones, are used.

How to install a reverse osmosis system?

The filter is installed in an easily accessible place on a horizontal section of the water pipe with the flask pointing downwards. When installing a water meter, the filter must be placed in front of it.

Installation is carried out in the following sequence:

- Apply anaerobic sealant to the connecting threads, filling all grooves with an even layer and leaving for 15 minutes to harden.

- Next, attach the fasteners to the filter, paying attention to the direction of water flow in the water supply.

- By placing the filter fasteners against the wall and making sure that the device's outlets coincide with the position of the pipe, mark the locations for the holes.

- Drill holes and insert dowels, then, using self-tapping screws, screw the filter holder to the wall.

- To connect the filter outlets to the main line, cut the pipe and bend it to align its axis with the axis of the filter. To prevent the pipe from breaking when it is bent, a special conductor is inserted into the middle.

- Then put a ferrule and nut on the pipe, and insert the fitting (all the way). The ferrule is pulled tightly against the fitting and the nut is tightened.

- Connect the fitting to the filter and screw on the union nut, tightening it tightly with a wrench.

After installation, turn on the water and check for leaks. For ease of repair and maintenance, shut-off valves are provided on both sides of the device.

Connecting a reverse osmosis filter

Installation of the treatment system involves assembling individual elements and does not require special tools. Therefore, carry out reverse osmosis installation Even a person who has never done this can do it.

The manufacturer recommends placing the filter under the kitchen sink. To make it convenient to draw filtered water, a separate tap is installed. To install it, you will have to drill a hole in the corner of the sink or on the countertop area near the sink.

The reverse osmosis filter is assembled as a construction kit. Installation consists of the following steps:

- installation of a drinking tap and connecting it to the filter;

- connection to the cold water pipeline;

- installation of the tank ball valve and drain clamp;

- commissioning and flushing of the system.

For good operation and performance of the reverse osmosis filter, it is necessary to ensure normal pressure in the system. If the water pressure in the supply pipe does not exceed 2.8 bar, it is recommended to install a pressure booster pump.

It is installed in front of the first filter in the gap of the incoming tube. When using a pump, it is necessary to install a high pressure sensor - it automates the process of turning the equipment off and on.

Owners of their own swimming pools will receive a lot of useful information about filtration systems in the next article, which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

Video #1.How to choose a filter according to the degree and method of cleaning:

Video #2. How to insert a filter into a water supply system:

Video #3. Installing a reverse osmosis filter and changing cartridges:

When choosing a device for water purification, there is no question of which filter to install - for coarse or fine purification. It is more correct to ask the question for what purpose the water will be used and what result should be achieved.

It is necessary to use devices for water filtration starting from coarse purification and ending, if necessary, with the finest purification, which will remove foreign impurities down to the smallest particles.

Those wishing to share their experiences, express opinions, ask questions, and note shortcomings in the presented material are invited to write comments. You can leave them in the block located under the text of the article.

I also installed a filter for myself at the dacha, and installed it after they changed the pipes and saw what kind of coating there was on them, that you simply couldn’t do without a filter. I installed a fine filter for myself, it purifies the water well, before there were some small particles in the water, but after installing the filter the water became like a tear. Now I’m thinking about installing a filter in my apartment.

Sorry for such an amateurish question, but does tap water always need filtration? As for coarse filters, everything is clear - without them there is a high risk of rapid wear or damage to home appliances - washing machines, dishwashers, etc.But is a more subtle cleaning necessary? What indicators of the presence of foreign impurities can be considered critical in order to spend money on a complex and not very cheap filtration system? And at times it seems that the constant emphasis on the poor quality of tap water is being lobbied by filter manufacturers and bottled water suppliers.

Unfortunately, in most areas of our vast expanse there are problems with water almost everywhere. Somewhere they are insignificant, somewhere, without exaggeration, they are catastrophic. You can test the water yourself using several methods. For example, testing salt content is very simple - drop tap water onto a glass surface and wait for the water to evaporate. If white stains remain, you can safely think about a filter.

You can fill a glass jar with water and leave it for several days in a dark place with the lid closed. If a green coating forms, it means there are a lot of microorganisms in the water and it’s time to run for a filter. In general, take samples and go to the SES - they will tell you exactly what you are drinking.

Hello. Take a plate with normal water values, have your water analyzed, and then compare. It's not that expensive and at the same time you'll know exactly what you're drinking.

As for bottled water, Roskontrol recently tested the water of 12 major manufacturers, and it turned out that our safe water is very rare, and in terms of mineral value it is not at all.

I installed a cleaning system for my house. The water has become much tastier and softer. There is no more scale left on our dishes, well, that's what my wife tells me. Even food tastes better with purified water.Installed quickly, excellent quality. Now I recommend that all my friends and acquaintances install a water purification system for themselves.

Installed an automatic water supply station on the well. In winter, the station was dismantled because no water was used. When the station was connected in the spring, water leaked. Warranty repairs completed! After 3-4 months, everything happened again. The service station said that the ceramic oil seal was wearing out due to fine sand getting on the oil seal. What kind of budget filter should be installed in front of the station so that the oil seal wears out less.

The depth of the well is 28.5 meters. ECO station GFI-1202

Thank you for the useful article. Helped. During the construction of the house, an unpleasant fact emerged that the water from the well was so-so. We began to study the issue and learned about the BWT company, which is engaged in complex water treatment. We decided to go to the Rigamall shopping and entertainment center to get acquainted with the company, they have a company store there.

We were pleasantly surprised by the qualifications of the specialists and the list of services of the company! They offered us to do a water analysis on their own and select a water treatment system, and that’s what we did. After the results of the analysis, BVT specialists prepared for us a proposal for an individual cleaning system, which consisted of a mechanical cleaning filter, a softener, and an iron removal system and an ultraviolet lamp. We decided to install this system and in the end we are very happy with it, the water is super!

Another plus of this company is that they provide service in case of any problems, and therefore we are calm about the operation of our system.