Roof ventilation pipes: tips for choosing a pipeline + installation instructions

Every owner of a private house has at least once encountered troubles caused by an imperfect ventilation system. Agree, living in a house with a musty smell from walls covered with mold, or streams of condensation on pipes and glass is not very comfortable.

To avoid problems with the ventilation system, it is necessary to think through every stage of its construction, from the basement to the highest point above the roof, even before building a house. Some of the shortcomings can be eliminated in an already constructed building - for example, you can replace the air duct or install a deflector.

In this article we will look at how to choose roof ventilation pipes and install them correctly, and also give some tips on improving protective functions and draft. We hope that our recommendations will be useful in solving ventilation problems on your own.

The content of the article:

General requirements for ventilation pipes

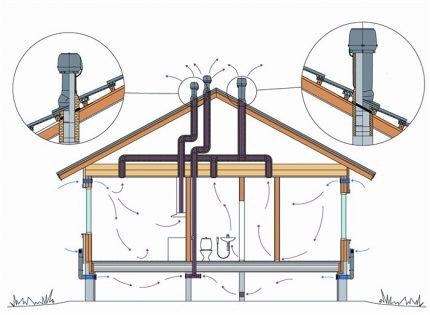

Air ducts occupy a significant part of the ventilation system. Through these communications, used air is removed to the outside or, conversely, supplied to the premises.

The ventilation system is installed for years, so special requirements are placed on pipes and other elements, and the installation process is subject to rules.

Let's look at a few important points regarding air ducts in the photo gallery:

If you decide to design the ventilation pipe outlet on the roof yourself, we recommend two options: galvanized steel or plastic. Both options are presented on the ventilation equipment market in large quantities, from standard half-meter products to extended length pipes.

For self-production, they usually use sheets of thin galvanized steel, which can be easily processed with available tools. It is suitable for installation on the roof due to its characteristics, while the creation of a pipe, adapter and “mushroom” is inexpensive.

Installation instructions for roof ventilation

From how you do ventilation pipe outlet on the roof, both the functionality of the hood itself and the condition of the attic space depend.We recommend purchasing in advance passage elements designed for a specific material - flexible or metal tiles, corrugated sheets, slate.

Let's consider how best to install ventilation pipes on the roof so that the system operates at maximum performance.

Stage #1 – preparation of materials and tools

If you are going to work on the roof yourself, be sure to take care of comfortable clothing, gloves and shoes, select ladders for climbing and moving on the roof, and also prepare a safety rope for your own safety.

You will need:

- ventilation tube;

- factory or homemade passage node;

- thermal insulation material;

- sealants and sealant;

- hammer drill or drill;

- jigsaw;

- Screwdriver Set;

- metal scissors;

- marker for marking;

- self-tapping screws or anchors.

The passage node is selected taking into account the type and slope of the roof.

There is a large selection of ready-made units available for sale, designed for pipes of standard diameter - we recommend using them.

For a more durable fixation of metal products, anchor fasteners are used, but plastic ones can be mounted on self-tapping screws.

Stage #2 - choosing a ventilation outlet location

The place where the pipes exit to the outside is thought out when drawing up the house design.But sometimes you have to lay additional channels and act when the roofing is completed.

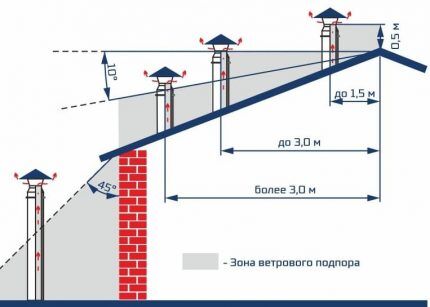

When choosing an exit point, they are guided by the documentation SNiP 41-01-2003, SP 7.13130.2009, and when choosing the height of pipes for sewerage, they are guided by recommendations SNiP No. 2.04.01.

It is believed that on a flat roof the height of the pipe should be at least 0.5 m, and on a pitched roof it should be placed at a distance of up to 1.5 from the ridge, and it should also protrude above the ridge by about 0.5 m.

If located nearby chimneys, then the hood is placed at the same level relative to the ridge, but it should be just below the chimney.

If the location is chosen incorrectly, noise or humming may appear in the air duct from air moving in jerks. You will have to install resonators or additional risers.

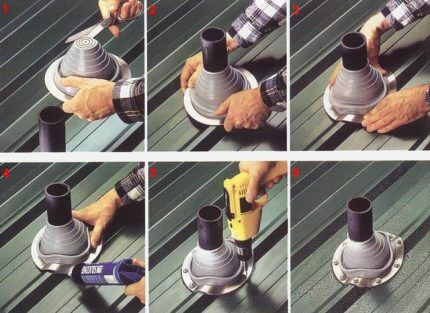

Stage #3 - making a hole in the roof

Having chosen the installation location for the pipe, you need to make a hole for the passage element. If the product is factory-made, then it is equipped with a special template: it should be attached to the roofing and circled with a marker. When attaching a homemade product, you need to focus on the dimensions of the lower part of the assembly.

Then the layers of the roofing “pie” are removed, starting from the top. The most difficult thing to work with is metal coating.

A sloppy cut must be straightened with pliers - the edge should be smooth, without bends or deformations.

Under the roofing there is a sheathing. If the boards are 100mm, then there is a chance that the pipe will fit between them. But if the boards are wider, for example, 150-200 mm, or installed at narrow intervals, then fragments will have to be cut out to install the pipe. The unnecessary section of the board is cut off with a jigsaw or gradually drilled out with a screwdriver.

Under the sheathing there is a waterproofing layer. Along with the factory transition units, the kit includes water seals designed specifically for installation on the membrane. They protect both waterproofing and insulation from water leakage from the roof.

We proceed in order:

- Place the water seal on the membrane.

- We use a marker to trace it along the inner contour.

- Cut a hole in the membrane along the contour.

- Apply sealant to the water seal.

- We install the water seal into the hole, piercing the surrounding membrane with the holder pins.

- We fasten the device with self-tapping screws to the sheathing boards. For this purpose, it is equipped with special “ears”.

The transition units may include seals and other elements - they must be installed according to the manufacturer's instructions.

Stage #4 - installation of the transition unit and pipe

First we install the passage element. To do this, apply it to the hole, find the correct position and mark the boundaries with a marker.

Then we apply sealant along the edge of the hole and on the grooves of the flange, press the pass-through assembly to the roofing and fix it with self-tapping screws. We recommend that you first fasten the two side screws - at the extreme points, and then all the rest. Try to ensure that some of the screws fit not only into the tiles, but also into the sheathing - this way the fastening will be much stronger.

If, after fixing it to the screws, sealant appears along the edges of the flange, this is not a problem - this way the connection will be even more airtight.

Once the sealant has hardened, you can install the pipe. Factory products have a pipe inside that matches the diameter of the air duct. It is simply inserted inside the passage unit, while the expanded sealed part remains outside.

From the inside, from the attic or attic, they bring air duct. It is either connected directly to the roof pipe, or connected via a flexible transition element if the pipes are not located along the same axis.

How to protect the ventilation duct?

It is easy to notice that the ventilation pipes rising above the roof differ in their design. The fact is that some of them are not equipped with either a “fungus” or a deflector.These are pipes for sewer service.

The air in sewer pipes is always warm, so any elements installed on top will become covered with ice in winter, as a result of which the pipe will simply stop working

But other ventilation ducts require protection. To do this, a device is attached to the upper part that prevents street debris from entering the channel: dry leaves, branches, dust, sand. The protective element goes by different names - “mushroom”, cap, weather vane, cover, “umbrella”.

If you want to make a “mushroom” yourself, it’s not difficult. Video assembly instructions can be found at the end of the article.

How to increase draft in an air duct?

Duct performance can be improved by using deflector, which is also installed on the pipe and is at the same time a protective element.

The operating principle of the deflector is based on the wind force. The built-in diffuser dilutes the air flow and creates a low-pressure area, thereby increasing draft inside the duct. It is estimated that installing a deflector increases ventilation efficiency by 30%.

Modern devices have a decorative appearance and do not spoil the overall appearance of the roof after installation.You can install the deflector yourself.

Conclusions and useful video on the topic

Installation of pipes on corrugated sheets:

Detailed video instructions for making an “umbrella”:

Practical experience in installing a ventilation pipe on a roof made of Ondulin:

A ventilation pipe on the roof is as necessary an element of home improvement as a chimney. Its functionality depends entirely on proper installation. When installing, try to adhere to the requirements of SNiP, manufacturer’s instructions and safety rules.

If you correctly secure the transition unit and install the pipe, the roof's tightness will not be affected, and the ventilation system will work properly and create a favorable microclimate in the house.

Have questions, found shortcomings, or want to supplement the material with valuable information on the topic of the article? Leave your comments, share your experience, ask questions - the contact form is located below.