Ventilation pipes on the roof of a house: arrangement of the exhaust pipe exit through the roof

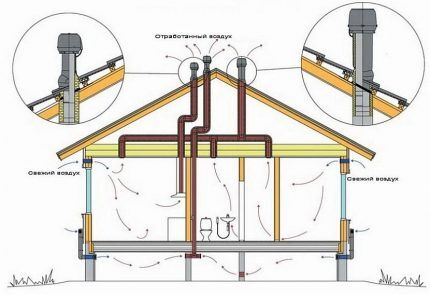

When planning the installation of ventilation, you probably thought through and decided how best to install ventilation pipes on the roof of the house. This needs to be done correctly: firstly, so as not to damage the roof and prevent leaks; secondly, so that the output provides maximum traction.

We will talk about how to properly ventilate to ensure regular air exchange. We will introduce you to modern and easy-to-install solutions offered by manufacturers to domestic consumers. We'll show you how best to do this work yourself.

The content of the article:

Options for arranging an exit through the roof

The most widespread are two options for ventilation pipes exiting to the roof:

- Use of ready-made ventilation outlets (factory-made);

- Exiting ventilation pipes directly to the roof and sealing them with a factory-made passage element.

The choice of method depends on the design features of the house and roof, appearance requirements and the available budget.

It is strongly not recommended to make a pass-through knot yourself if you do not have sufficient experience and tools. Due to the mistakes common to beginners, he will not be able to ensure the tightness of the pipe passage.The result leads to wetting and subsequent destruction of the roof, rafter frame and insulation.

Ready-made ventilation outlets

Roofing manufacturers are interested in ensuring that the roofs built from the materials they produce look beautiful and serve their owners for a long time. Therefore, along with roofing materials, they produce parts for arranging the passage of ventilation pipes through the building structure.

Such outlets are produced for a wide variety of types of flexible, metal and ceramic tiles, slate and ondulin, roll polymer and bitumen coatings for flat roofing systems.

The advantages of such outputs are:

- Excellent appearance;

- Color matching the color of the roof;

- Availability of seals and built-in thermal insulation;

- Fine vertical adjustment;

- Outlet-compatible baffle and feed-through assembly;

- Easy installation.

Installing such exits is very simple, so even an amateur in the roofing business can do it. The only thing to consider is that the work will be performed at height, so the necessary safety precautions must be observed.

If the installation is carried out on a metal tile roof, then first of all, using the template that usually comes with the kit, you need to mark and make a hole in the roofing material.Please note that in the place where the hole will be made, there should be no sheathing slats or rafters under the roofing sheets, otherwise the pipe will not be able to be placed.

Cut a hole for ventilation passage unit The easiest way is with a small grinder of 115-125 mm, although metal tile manufacturers recommend using metal scissors.

When the hole is ready, if there is a waterproofing membrane in the roof, then you also need to cut a hole in it, into which the sealant should be fixed. Then apply sealant to the passage element and screw it with self-tapping screws.

Next, you need to insert a ventilation outlet into the passage element, intended for arranging ventilation pipes on the roof. It is necessary to level it in a vertical position and secure it with self-tapping screws.

In the attic space, you need to connect the ventilation outlet with a ventilation pipe, which must be secured to the wall in the attic using clamps or a metal frame.

In a similar way, factory-made ventilation outlets are installed on roofs made of ceramic tiles, corrugated sheets, ondulin or slate.

If the ventilation outlet is planned to be installed in a roof made of soft tiles, then along with the above installation method on top of the roofing material, the ventilation outlet can also be installed during the installation of the roof under the tile sheets.

To do this, a pass-through flange and protection cut from a waterproofing carpet are attached to the base of the roof using bitumen mastic and nails. Soft tiles are subsequently mounted on top of it. This method provides excellent sealing.

As you can see, there is nothing difficult in installing a factory ventilation outlet for any type of roof, and the end result exceeds all expectations in beauty and reliability.

The only limitation in this case is the height of the standard outlet, which ranges from 300 mm to 700 mm. This makes the factory outlet only applicable if it is located close to the ridge. Only in this case will it not fall into the wind pressure zone.

It is impossible not to mention the ventilation outlets equipped with an exhaust fan.

Such an exit to the roof ventilation pipes allows you to provide confident traction, independent of wind and temperature. It can be installed even in an area where there is wind pressure, where natural ventilation will not work. Due to the fact that the fan with an electric motor is located outside the house, it will not create extraneous noise inside the room.

Pipe exit through the passage element

If there is a need to route a long ventilation pipe through the roof, a sleeve for the passage of an antenna, or simply carry out installation at minimal cost, then a universal passage element is used, called a flash master.

This penetration is attached to the roofing material using silicone and self-tapping screws, and at the junction of the seal to the pipe it is pressed with a clamp for additional reliability.

If the hood is laid openly indoors and not in the ventilation shaft, then the ventilation pipe must be somehow secured to the wall. This can best be done using clamps with elastomer gaskets to reduce noise interference.

Suitable for pipes with diameters from 6 mm to 467 mm and can be installed on any type of roof. In addition, such a passage unit can be made of both rubber and silicone, which can withstand temperatures up to 240OWITH.

Advantages of using a universal pass-through element:

- Low price;

- Easy installation;

- Suitable for any roof;

- Suitable for any pipes with a diameter up to 467 mm;

- Made to match the color of the roof;

- Ensures tightness and reliability.

Like the factory outlet, you can install a ventilation pipe with a pass-through element yourself, observing safety rules when working at height.

When using a passage element, one should not forget about the need to insulate the ventilation pipe and install a deflector or umbrella on it.

Where to place the ventilation outlet?

When installing an exhaust outlet through the roof, it is important not only to ensure the tightness of the passage through the roofing pie, but also to choose the right location.You also need to correctly determine the height of the exit, because the draft in the ventilation duct directly depends on it.

Firstly, it is best to place the ventilation outlet through the roof as close to the ridge as possible.

This arrangement has several advantages:

- Most of the ventilation duct will pass through the attic, where there is no wind and the temperature is always slightly higher than outside. Thanks to this, the insulation layer on the pipe can be made thinner;

- The ventilation outlet, located at the ridge, has a minimum height above the roof surface, therefore it is resistant to gusts of wind and does not require additional fastenings;

- You can use a factory-made ventilation outlet, which will give the roof additional aesthetics.

Don't worry. It is better to carefully consider how to make a sealed outlet for the ventilation pipe on the roof if it is not possible to install it close to the ridge. In this case, the passage simply needs to be further insulated and secured.

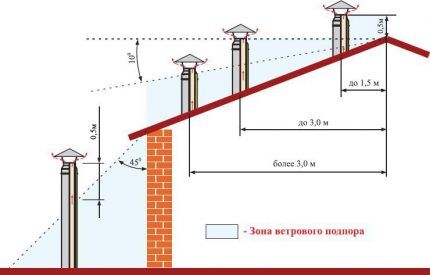

Secondly, in order to avoid getting into the wind pressure zone with the pipe, which every house with a pitched roof has, the height of the ventilation pipe deflector should be:

- 0.5 m above the roof ridge, if the exit is located no further than 1.5 m from the ridge;

- not lower than the roof ridge, if the exit is located at a distance from 1.5 m to 3 m from the ridge;

- not lower than a line drawn at an angle of 10O from the ridge to the horizon, if the ventilation outlet is located more than 3 m from the ridge;

- if the ventilation pipe is led from the extension to the house, then its deflector should be located 0.5 m above the line drawn from the roof eaves of the main building at an angle of 45O to the horizon.

Ensuring the specified height above the roof is extremely important for any ventilation, and for natural ventilation it is vital.

If you neglect this rule, the hood deflector will fall into the wind pressure zone and in windy weather, in the best case, there will be no draft, and in the worst case, reverse draft will appear and air from the street will flow into the house.

How to secure a tall pipe?

If for some reason it is not possible to bring the ventilation outlet closer to the ridge, and meeting the requirement for wind support forces you to make a very high pipe above the roof surface (more than 1.5-2 m), then the ventilation pipe must be additionally secured.

This must be done because the higher the pipe, the greater the wind loads it is exposed to due to the larger blowing area. In case of strong gusts, the pipe can simply break in a place close to the passage through the roof.

There are several ways to securely secure a ventilation pipe to the roof:

- Stretch marks;

- Mowing;

- Metal stands.

Depending on the design and height of the ventilation duct and roof, these methods of reinforcement can be used together, for example, strengthening the ventilation outlet with a metal stand and then securing it with guy wires.

Providing stability with guy wires

Guys are most often made of galvanized cables, less often of thin chains.

To securely secure the ventilation outlet, the installation of at least three guy wires is required. The angles between the stretch marks should be made as equal as possible, that is, 120O, and it is better to install the extensions to the axis of the pipe at an angle of 45O.

To fasten the guy wires, a clamp with three eyes is installed on the pipe, and three anchors with rings are installed in the roof or other places. Threaded tensioners are used to tighten the cables, and screw clamps are used to make loops.

Cable braces are very easy to manufacture and install, and all the necessary materials are sold at any hardware store and are not expensive. Strengthening the ventilation pipe with guy wires with your own hands is not difficult.

Fixing the pipe position with bevels

The braces (rigid braces) are similar in appearance to cable braces, but differ from them in the principle of operation. Unlike cable braces, which work exclusively in tension and must be attached in at least three places, braces can also work in compression, so to strengthen the pipe with them, only two points of attachment to the roof are enough.

Depending on the direction of the wind, the slopes will equally well withstand the wind load, either compressing them or stretching them. Thanks to this advantage, slopes can be used in conditions of limited space, for example, if the ventilation duct exits close to the roof eaves and the installation of three braces is not possible.

The slopes are usually made from light metal profiles, painted to protect against corrosion. For fastening to the pipe, just like with guy wires, a clamp is used, and the braces are attached to the base with anchors or other fasteners.

Unlike stretch marks, braces do not require tension. They are immediately made to the required length and are rigidly fixed to the pipe and roof to eliminate any vibrations. When choosing angles between the slopes, as well as between the slopes and the pipe, it is better to adhere to the same rules as with stretch marks.

Construction of metal structures

Metal racks are used in cases where it is not possible to secure guy lines with slopes on the roof or the pipe is so high that it needs to be not only secured, but also strengthened.

The most widespread are welded volumetric racks. Externally, they look like mobile phone towers and are a welded structure that acts as a load-bearing frame for the pipe.

The use of such racks strengthens the pipe and allows it to be securely held under wind loads in all directions. Making racks yourself is problematic, since this will require metal, tools and experience in working with welded geometric structures. It is better to order their manufacture in a locksmith workshop.

If you still need or want to make your own, you will need:

- A flat surface for welding so that the stand is straight;

- Tools: welding machine, mask, electrodes, angle grinder with cutting and cleaning discs;

- Materials. For small structures, a 40 angle and a 40×4 strip are suitable. You can also use profile pipes of various sections: 40×40, 40×20, 20×20;

- High-quality primer-paint for corrosion protection.

Structurally, the rack is made of two, three or four vertical 40 angles or 40x40 profiles, which are connected to each other by short sections of a strip or profile of a smaller cross-section at a right angle or diagonally.

The greatest strength is provided by the diagonal installation of the crossbars. However, for domestic use, the strength of the crossbars installed perpendicular to the racks is quite sufficient. At the point where the vertical element is attached to the base, platforms with holes for fastening elements are welded to it.

Depending on the design of the rack, it is securely attached to the roof or wall, and a ventilation pipe is attached to it with clamps. The design is quite durable and can withstand strong gusts of wind.

However, it should be remembered that the stability of a metal stand primarily depends on the reliability of its attachment to the base: the smaller the supporting platform and the number of attachment points, the less wind the stand can withstand.

Is it necessary to insulate the ventilation outlet?

The question of the need to insulate ventilation and, in particular, its exit to the roof is often asked by independent developers.The answer to this is clear: insulation must be mandatory!

The ventilation outlet is located outside and is exposed to sub-zero temperatures, and the wind only accelerates the cooling process. Having frozen, the walls of the ventilation duct begin to cool the warm air passing through it from the room. As a result, the traction force is significantly reduced.

This creates two negative phenomena:

- If warm air from the room goes up, trying to go outside, then, having cooled from the walls, it begins to fall down again, creating counterdraft and turbulence, preventing the normal operation of ventilation;

- The warm air removed from the premises contains fumes from human activity. In contact with the cold walls of the ventilation duct, this moisture turns into dew and begins to flow back down the ventilation duct in drops, creating excellent conditions for the development of mold fungi.

In extreme cold, the condensed moisture does not have time to drain inside and freezes at the very exit. The ventilation outlet hole becomes smaller and may freeze completely.

To eliminate these problems, the ventilation outlet must be sufficiently insulated. The easiest way is to use factory-made ventilation outlets. The manufacturer makes the structure double-walled and puts insulation into it.

If the exit is made with ordinary ventilation plastic or metal pipes, then you can insulate them yourself. Tubular insulation made of foamed polyethylene (used for insulating sewer, water and heating pipes), rolled insulation or similar material is best suited for these purposes.

It is conveniently applied by simply wrapping it in several layers and secured with reinforced tape. Polyethylene and isolon are not afraid of water and sunlight, and birds and insects do not show interest in them.

It is not necessary to use foil insulation: it costs much more, and the effect of the metal layer is unlikely to be noticeable. The main thing is to ensure a sufficient thickness of insulation, which is recommended to be at least 30 mm.

Mineral wool is also suitable for insulating the ventilation outlet. However, you will have to make a protective cover on top of it from a durable material (fiberglass, galvanized or plastic sheet, etc.) to protect it from wind, precipitation and birds. Mineral wool in rolls is most convenient for such purposes: it is simply wrapped around the pipe.

In addition, if you are thinking about how best to fix the ventilation pipe on the roof and at the same time immediately insulate it, the elements chimney sandwich. They are easy to install and are equipped with insulation installed at the factory.

In addition, the chimneys have standard passage units that provide a tight connection, as well as standard deflectors and umbrellas for protection from precipitation and wind.

Another advantage of using chimneys for the manufacture of ventilation outlets is the possibility of connecting them with clamps for guy wires for subsequent reliable fastening.And the service life of stainless steel chimney pipes as a ventilation duct is practically unlimited.

Typical installation errors

Despite the apparent simplicity of selecting and installing a ventilation outlet, mistakes are often made in this procedure, leading to unpleasant consequences:

- Poor sealing of the passage element at the junction with the roof or an insufficient number of screws, as well as the absence of a clamp at the junction of the passage element with the pipe. The consequences are roof leaks, wetting of the rafter system and insulation, followed by destruction. Remedy: restore tightness, install a clamp;

- Lack or insufficient insulation of the exit. Consequences: decreased draft in the ventilation duct, and in cold weather freezing with complete cessation of draft. Remedy: perform additional thermal insulation;

- Installation ventilation deflector without maintaining the distance between the edge of the pipe and the umbrella of the device. Consequences: reduction of thrust, its cessation or the occurrence of reverse thrust. Remedy: make the ventilation outlet above the wind pressure zone or install a deflector with an electric fan;

- No reinforcement of the high ventilation pipe. Consequences: pipe falling during strong gusts of wind, damaging the roof or causing injury to people. Remedy: strengthen the pipe with braces, bevels or a stand.

Avoid these mistakes when installing ventilation outlets in your home. And if the work has already been completed, then make sure that it is done correctly and, if necessary, make corrections on time.

Will familiarize you with the specifics of organizing the ventilation system in a chicken coop next article, the information of which will be extremely useful to farmers and owners of small private farms.

Conclusions and useful video on the topic

This video will show you how to install a ventilation outlet on a metal roof:

Video of installing a ventilation outlet on a soft roof:

This video shows an option for installing slopes:

There is nothing complicated about installing a ventilation outlet. Thanks to a wide selection of materials, you can make and install such an outlet either independently or by using factory-made products that are undeniably attractive.

The main thing during installation is to ensure the tightness of the passage through the roof, the correct height, reliable fastening and good thermal insulation.

Tell us about how you created a passage through the roof with your own hands. It is possible that you have information on the topic that may be useful to site visitors. Please write comments in the block form below, ask questions, post photographs.

Thank you, everything is very clearly described