Do-it-yourself frame bathhouse: step-by-step instructions for arrangement + tips for choosing materials

Many owners of country houses or summer cottages have probably thought about building a bathhouse on their property.After all, a bathhouse is a place where you can relax not only with your body, but also with your soul. Do you agree? Next, we will tell you how to build a frame bathhouse with your own hands, and step-by-step instructions will help you cope with this task.

In addition, from the article you will learn what tools and materials will be needed for construction, we will outline the advantages and disadvantages of frame buildings and we will deal with the issue of insulating the structure.

The content of the article:

- Advantages and disadvantages of a frame bath

- Construction plan development

- Materials for the construction of a frame bath

- Foundation construction technology

- Internal and external finishing of a frame bath

- Arrangement of the roof of the building

- Floor design in a frame bath

- Warmth and waterproofing of buildings

- Conclusions and useful video on the topic

Advantages and disadvantages of a frame bath

Among the advantages of the frame structure of a bathhouse are: the relative cheapness of building and finishing materials, good thermal insulation properties, ease of construction, and environmentally friendly design.

In addition, frame structures do not require a powerful monolithic foundation, and they can be erected at any time of the year.

Along with the listed advantages, a frame bath also has several disadvantages. First of all, highly flammable materials are used for its construction, so there is a high probability of a fire if fire safety rules are not followed.

Secondly, insulating a frame bath will require much more time and effort.In addition, this will entail more financial costs than insulating a conventional bathhouse made of timber.

Another drawback is long shrinkage, which can last up to two years. When shrinking, the cladding may be deformed.

Construction plan development

Before starting construction work, you need to carefully work out the construction plan and project. Only by drawing up a project can you correctly calculate the amount of building materials.

It is necessary to determine the place where the building will be erected. The choice of bathhouse foundation directly depends on the quality of the soil. And after this, they decide on the choice of the most suitable bath design.

The standard bathhouse project includes a dressing room, a vestibule, a steam room and a shower room. The location of the furnace must be indicated on the diagram.

At the project development stage, you need to take into account all possible little things: type ventilation, chimney, interior finishing materials, exterior decoration and even roof type.

The project must indicate the dimensions of the premises. It is difficult to heat a large bathhouse, but in a small one you need to think about the maximum permissible number of people so that it does not become crowded. The most suitable size for a steam room is 2.4x2 m with a ceiling height of 2.2 m.

Additional rooms in the bathhouse will make your stay more comfortable and interesting. Therefore, if the budget allows, it is better to immediately include in the project: a swimming pool, a relaxation room, a bathroom, and a billiard room.

A well-designed project will greatly facilitate the construction process of the premises.

Materials for the construction of a frame bath

When the project is ready, you need to make a list of materials necessary for construction, after purchasing which you can begin construction.

Below we have provided an approximate list of materials that will be needed for the construction of a frame bath. The list may vary depending on the selected technology. And the required amount of materials is calculated based on the size of the bath.

| Purpose | Material |

| Foundation, subfloor | cement (M400) and coarse sifted sand |

| Bottom harness | timber 100*100 mm |

| Frame | timber 50*100 mm |

| Rack braces | timber 40*50 mm |

| Insulation of ceilings and walls | glass wool, thickness 50 mm |

| Vapor barrier | foil vapor barrier film |

| Waterproofing walls and roof | waterproofing film made of polyethylene |

| Roof | profiled sheet 0.5 mm |

| External cladding | block house |

| Interior decoration of walls and ceilings | lining, board |

| Drain system | plastic pipes, from 50 mm |

In addition, you will need tools for work, screws, nails, plumbing fixtures, etc.

For interior decoration of the walls of a frame bath, you can use lining. This is an environmentally friendly material that is made by processing wood.

Foundation construction technology

A frame bath is a lightweight structure, the foundation of which can be of any type. The first option for constructing a foundation - pile - is used on unstable soil, deep freezing of the soil, or when it is not possible to lay a trench on the site.

The most common and lightest is tape. This type of foundation is suitable for non-flowing soil, with deep underground waters. If the soil does not freeze, then the foundation does not need to be deepened too much.Consider in advance whether you need to build a separate foundation for ovens.

Let's look at how to properly build a strip foundation. The first thing that needs to be done is to clear the site for the construction of a bathhouse and the surrounding area, and also level the foundation for the building.

Next, mark the contour of the foundation. To do this, two pegs are driven into the ground, and a rope is stretched between them. Using a construction square at an angle of 90 degrees from the installed stakes, the distance to the next ones is measured and a rope is pulled between them.

Then, using the same principle, the outer contour of the foundation is marked. A distance of at least 100 mm must be maintained between the inner and outer rope. This will be the width of the wall of the structure.

Using the resulting markings, you need to dig a trench with a compacted bottom. The depth of the trench should be 20 cm below the soil freezing level.

The bathhouse must have a drainage system. Before pouring the foundation, you need to dig a hole for the pipe and drain well. The floor in the bathhouse is poured with a slight slope towards the exit point of the pipe.

The next step is the arrangement of a sand and crushed stone cushion. Its thickness is from 10 to 20 cm. Sand is poured onto the bottom, moistened with water and compacted. You need to pour crushed stone on top of the sand, compact it and level it.

After this, you need to build a formwork from the edged board, which will rise above the ground by at least 30 cm.

[adinserter name=”desktop: insert in text -3″]To prevent the concrete solution from leaking, the formwork is wrapped in polyethylene and secured with staples. Then, to ensure the rigidity and strength of the future foundation, a reinforced mesh is laid out.

After this, you can pour the concrete solution. To prevent concrete delamination, the mixture must be poured from a height of 50 cm or less.

All that remains is to insert the pins into the uncured mixture, onto which the base of the bathhouse frame will be placed.

Installation of foundation piping

After pouring the foundation and drying it, you can begin tying the structure. For the bottom trim you need a strong beam with a section of 100x100 mm.

Start tying from the corner. To do this, you need to connect the beam very tightly with nails, and the pins pre-installed in the foundation will not allow the strapping to move.

Before laying out the trim, lay a waterproofing material between the concrete and the wood, for example, roofing felt.

The procedure for constructing walls

It is most convenient to assemble the bathhouse frame in an open area in the yard. The distance between the racks must be calculated based on the size of the sheathing boards, so as not to do additional work on fitting and as a result get a dense, even wall.

Typically, the pitch of the racks is 60 cm. This distance corresponds to the standard width insulation. During installation, it will be positioned by surprise and will not fall out.

In a wall with an opening, according to the project, the pitch of the racks needs to be increased by 40 cm. Additional racks are installed in the places where the frame adjoins the lintels. Simultaneously with the installation of the wall frame, you can carry out installation of logs for the floor. Material – board 150x50 mm.

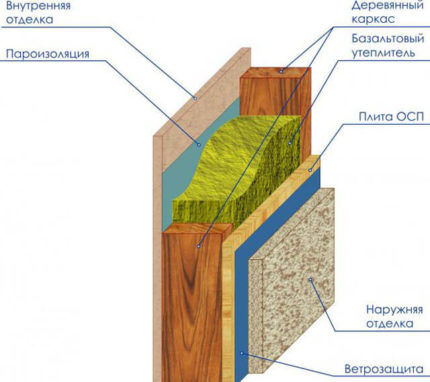

All parts of the frame need to be assembled, leveled and connected. Insulation and waterproofing are laid between the racks.

For reliable insulation, there are recommendations to use two layers of material. The first layer is tile insulation, the second is roll insulation. In this case, there will be no gaps that allow heat to pass through.

When performing external finishing work, it is imperative to leave a ventilation gap, which will ensure drying of the wall frame from accumulating condensate.

Internal and external finishing of a frame bath

For the exterior decoration of the bathhouse, it is better to use hardwood. Be sure to lay a layer of waterproofing material under the facing board.

The material for interior wall decoration must respond well to humidity and high temperature. For the steam room, hardwood lining is used so that it does not release resin. In other rooms of the bathhouse, you can use lining made from coniferous trees.

The best option for decorating sun loungers, shelves and the ceiling will use linden.

Arrangement of the roof of the building

For such a small structure as a bathhouse, you can build a gable roof. It is safer to assemble all roof elements on an open plot of land.The rafter system is made of timber with a section of 150x50 mm. To avoid mistakes, it is better to make a preliminary layout and then repeat the assembly of the rafters.

For the roof frame, you need to nail the two rafters together at the top end. The bottom of the rafters must be placed on support points and secured. Use a crossbar (crossbar) to connect the legs of the rafters using screws.

The distance between the rafters can be selected individually; usually 1.2 m is used. Between the rafters, the location of the chimney must be taken into account. Use a plumb line to check the level of each element being installed. If there are deviations from the vertical, level the position by placing a piece of board under the rafter leg.

Now start lathing. If it is planned to use soft roofing material, for example, ondulin, for example, the lathing pitch should not exceed 10 mm.

You can insulate the roof with the same materials that were used to insulate the walls. Next, the roof is covered with roofing. The final step will be to install a galvanized corner on the roof ridge.

Floor design in a frame bath

Compliance with all recommendations and instructions for installing the floor will increase the service life of the bathhouse. A well-made floor will protect against heat loss, rotting of floor boards.

In bathhouses where there is direct contact with water, the floor is poured. The most important thing in pouring floors is to ensure rapid flow of water into the sewer.

Step-by-step instructions for installing the floor:

- Laying lags. If the distance between the supports is large—more than 3 m—additional support pillars are needed. Use roofing felt for waterproofing in several layers at the junction of the joists with the foundation and supports.

- For clay soil, a tray is made under the structure to direct water into the drainage pit.

- Installation of boards on joists. The gap for pouring flooring between the boards is about 4 mm. A gap of 2 cm should be left between the flooring and the wall of the bathhouse.

In other rooms of the bathhouse, the floor is non-leakage. To arrange it, 5x5 cm bars are mounted on the logs, and a subfloor is laid on top of them.

After the vapor barrier layer, you can begin installing the finished floor.

Warmth and waterproofing of buildings

The frame structure is lightweight, so in order not to accidentally deform the walls, appropriate thermal insulation is needed.

There are a number of criteria that a bath insulation must have: good thermal insulation, high resistance to humidity and high temperatures, and environmental friendliness.

Let's consider the most popular types of insulation for frame baths.

Mineral wool. The wool itself is light, but the facing material can make it significantly heavier. U mineral wool good insulating properties. It is resistant to temperature changes and humidity does not harm it.

Reed insulation. Natural and eco-friendly material. Has good thermal insulation. Release form: slabs 15 cm thick. Suitable size for insulating a frame bath.

Sawdust- gypsum insulation. Sawdust-gypsum composition can be made independently. A budget option that is not inferior in quality. For mixing you need a ratio of sawdust to gypsum of 10:1.

Expanded polystyrene. Insulation, which is inexpensive, easy to use and has good thermal insulation properties. Resistant to moisture, but very flammable. Therefore, it cannot be installed near a stove.

Waterproofing in a bathhouse is no less important than thermal insulation. Firstly, without protection from moisture, any insulation will deteriorate over time and lose its ability to retain heat. Secondly, without protection from moisture, the heat-insulating material will begin to rot and mold, damaging the frame of the bathhouse itself.

To protect against steam, you can use foil, glassine (inexpensive, but eco-friendly material) or polyethylene. The material must be laid overlapping, gluing the joints with construction tape.

Conclusions and useful video on the topic

The procedure for insulating and waterproofing a bath, the nuances of laying the material:

How to build a bath frame yourself:

As you can see, there is nothing complicated in the construction of a frame bathhouse. The main thing is to take all preparatory work responsibly, paying maximum attention to drafting the project and calculating the required amount of materials.

And heat and waterproofing carried out in accordance with all the rules will contribute to the long service life of the structure.

Perhaps you have had to deal with the construction of a frame bathhouse on your own site? Please share your experience with our readers. Tell us if there were any difficulties during construction and how you managed to overcome them.Leave your comments in the communication block located below the article.

Despite the simplicity of constructing a frame bath structure, you need to take all preparatory work and calculations of the necessary materials responsibly. In this case, the bath will be of high quality and will bring maximum benefit and pleasure for many years. Proper waterproofing and thermal insulation will contribute to the long life of the structure.